Powder Coating

Powder Coating: Durable & Aesthetic Finishes for Metal Parts

- Superior Durability

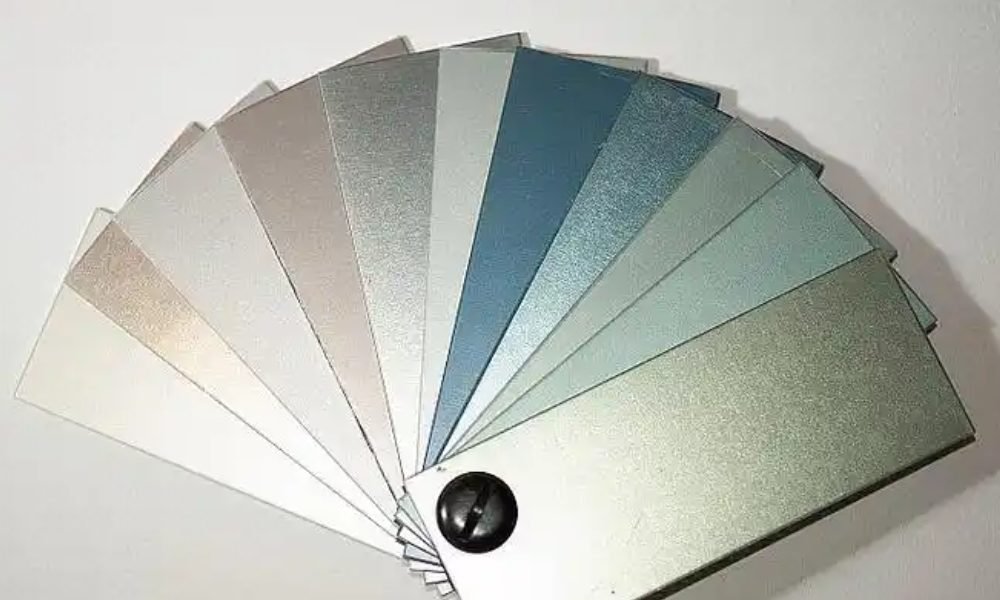

- Wide Color & Texture Range

- Corrosion Protection

- Environmentally Friendly

What Is Powder Coating?

Powder coating is a dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a grounded metal substrate. The parts are then heated in a curing oven, causing the powder to melt, flow, and chemically cross-link into a uniform, durable, and protective layer. This process is renowned for its excellent resistance to chipping, scratching, fading, and corrosion, offering a wide array of aesthetic options and being a more environmentally friendly alternative to traditional liquid paints.

| Parameter | Description |

| Color | Virtually unlimited color palette, including custom colors, metallics, and clears. |

| Applicable Materials | Most metals (steel, aluminum, stainless steel, galvanized steel, etc.). Can also be applied to some non-metallic substrates that can withstand curing temperatures. |

| Surface Roughness (Ra) | Varies significantly based on powder type and application method. Can range from very smooth (low Ra) to highly textured (e.g., sand, wrinkle, hammer tone finishes). |

| Visual Appearance | Wide range of aesthetics: matte, satin, glossy, metallic, clear, textured. Highly customizable to achieve specific visual effects. |

| Remarks | Environmentally friendly (no VOCs). Excellent durability, chip, scratch, and corrosion resistance. Requires curing at elevated temperatures (typically 160°C to 200°C / 320°C to 400°C). |

Optional Process Types

Most common, form cross-linked polymers when cured (e.g., epoxy, polyester, polyurethane, acrylic).

Offer excellent durability and chemical resistance.

Melt and flow when heated, solidify upon cooling (e.g., nylon, PVC, polyethylene).

Offer flexibility and impact resistance.

Surface Preparation

Gloss Range

Temperature Resistance

Film Thickness

Degreasing, sandblasting, or chemical pretreatment

5–95 GU @ 60°

Up to 200°C (392°F) continuous

50–150 µm (2–6 mils)

Advantages of Powder Coating

Exceptional Durability

Powder coatings create a thick, tough, and resilient finish that is highly resistant to chipping, scratching, fading, and wear, often outperforming liquid paints.

Superior Corrosion Protection

Provides excellent barrier protection against moisture, chemicals, and UV radiation, significantly extending the lifespan of metal parts.

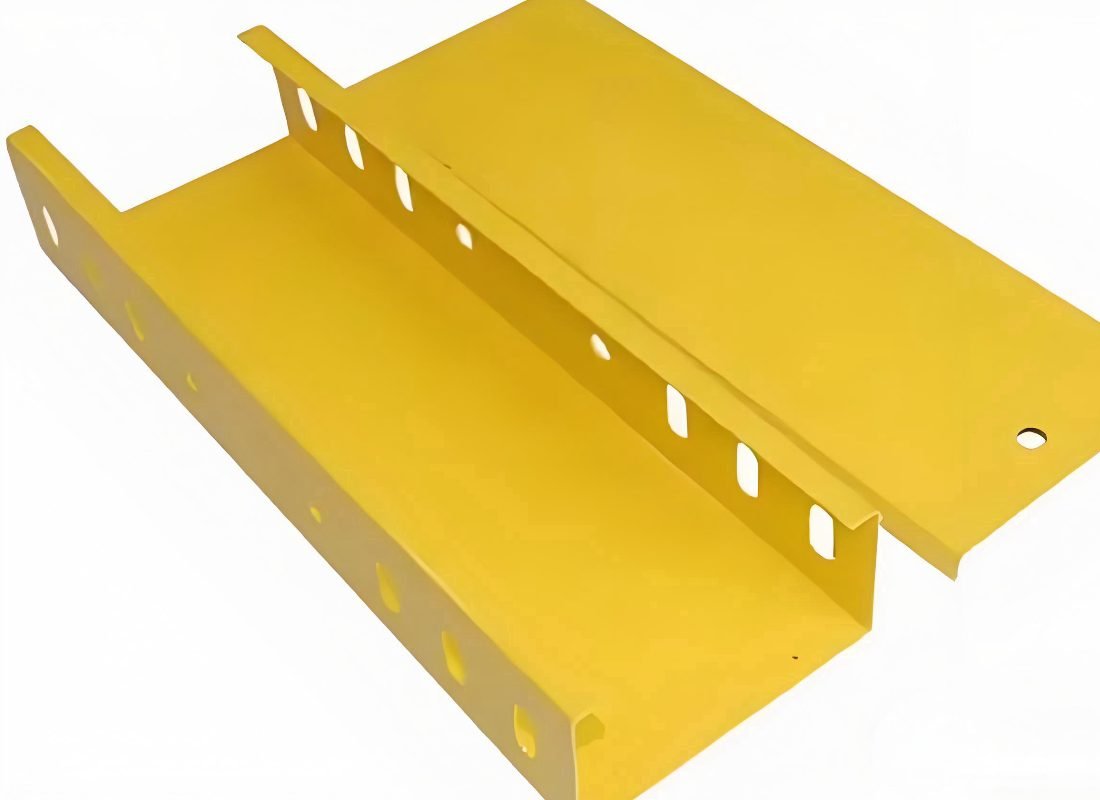

Uniform and High-Quality Finish

The electrostatic application ensures an even coating without sags, runs, or drips, even on complex geometries.

Wide Range of Aesthetics:

Available in an almost limitless array of colors, gloss levels (matte, satin, glossy), and textures (smooth, wrinkled, sand, hammer tone, metallic), offering extensive design flexibility.

Environmentally Friendly

Powder coating is a dry finishing process, meaning it contains no solvents and releases negligible volatile organic compounds (VOCs) into the atmosphere, making it a more sustainable choice.

Cost-Effective

Due to high material utilization (overspray can be reclaimed) and reduced waste disposal costs, powder coating can be more economical in the long run.

Things to Notice

Although powder coating has many advantages, it also has certain limitations. Special attention should be paid to the following points:

- Temperature Sensitivity: Requires curing at elevated temperatures (typically 160°C to 200°C), limiting its application to materials that can withstand these temperatures.

- Color Change Difficulty: Once cured, changing the color of a powder-coated part is difficult and usually requires stripping and re-coating, unlike liquid paints where a new coat can be applied over the old.

- Thickness Control: Achieving very thin film thicknesses can be challenging compared to liquid paints, which might be a concern for extremely tight tolerance applications.

- Edge Coverage: While generally good, sharp edges and corners can sometimes receive a thinner coating due to the Faraday cage effect, potentially reducing protection in these areas.

Design Considerations

Material Compatibility

Ensure the substrate material can withstand the curing temperatures required for powder coating without deforming or degrading. Most metals are suitable.

Surface Preparation

Proper surface preparation (cleaning, blasting, phosphating) is crucial for optimal adhesion and corrosion performance. Design parts to allow for thorough pre-treatment.

Part Geometry

While powder coating excels on complex shapes, avoid extremely sharp edges or deep recesses where the Faraday cage effect might lead to uneven coating thickness. Design with generous radii where possible.

Hanging/Racking Points

Plan for areas on the part where it can be hung or racked during the coating process. These points will have minimal or no coating, so they should be in non-critical or hidden areas.

Tolerances

While powder coating provides a relatively thick and consistent film, account for the added thickness (typically 1.5 to 6 mils or 38 to 150 microns) when designing parts with tight tolerances or mating surfaces.

Environmental Exposure

Consider the end-use environment and select the appropriate powder coating type (e.g., polyester for UV resistance, epoxy for chemical resistance) and AAMA specification if applicable.

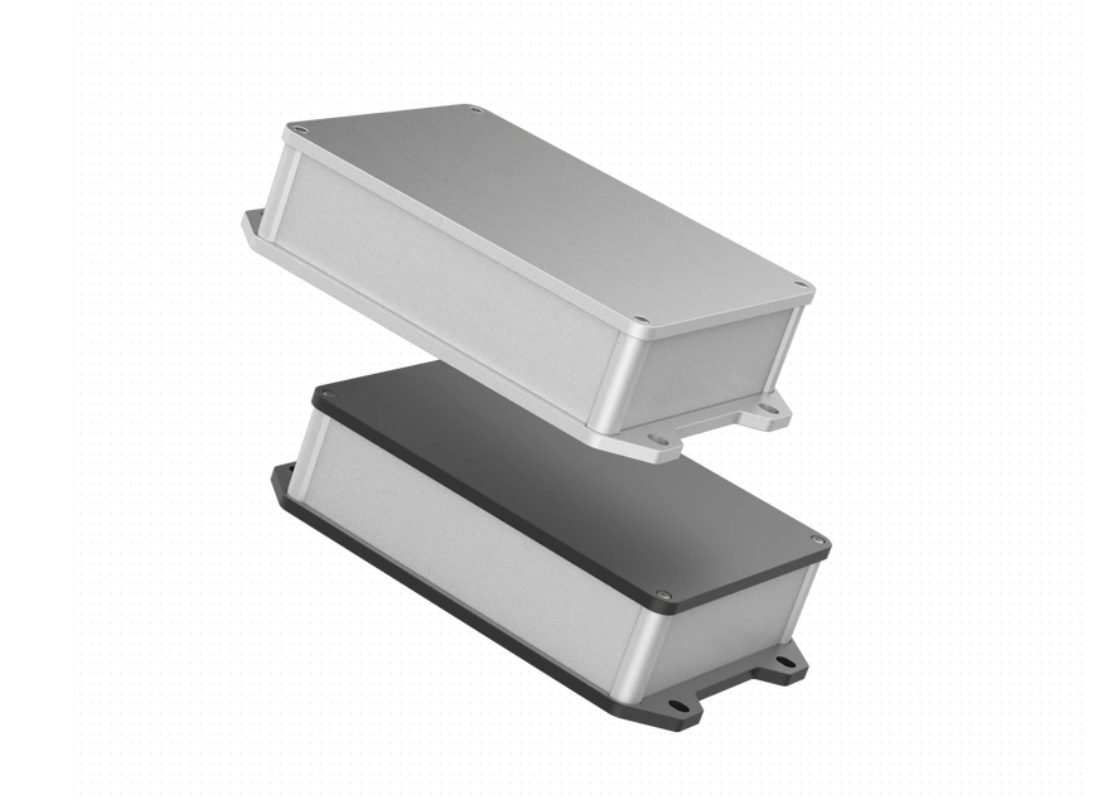

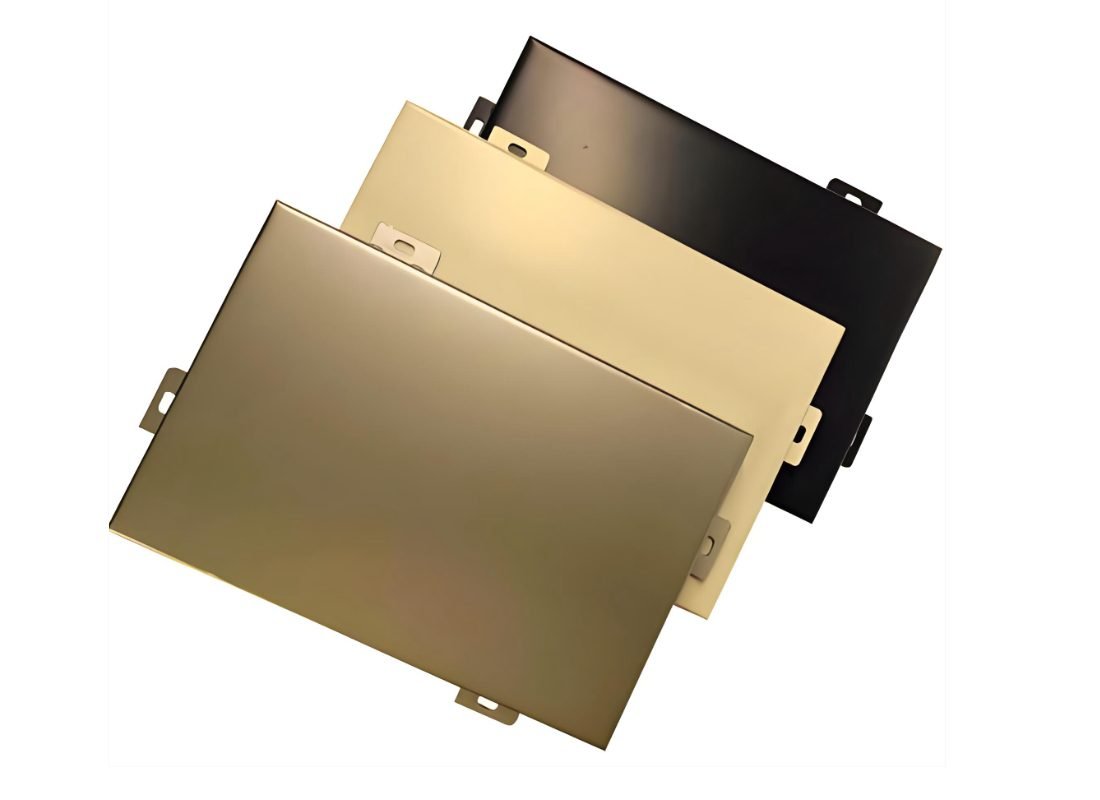

Parts with Powder Coating

FAQs

Most metals, including steel, aluminum, stainless steel, and galvanized steel, can be powder coated. Some non-metallic materials that can withstand the curing temperatures can also be coated.

Need to discuss surface finishes for your project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your Project?

Contact our team today to discuss your requirements and receive a customized quote for your needs.