Heat Treatment

- Increased Hardness

- Improved Strength

- Enhanced Durability

- Optimized Machinability

Heat Treatment Surface Finishing

| Parameter | Description |

| Applicable Materials | Primarily ferrous metals (various steels, cast iron); Some non-ferrous metals like aluminum, titanium, and magnesium alloys. |

| Temperature Range | Varies significantly by material and process, typically from 150°C to over 1000°C. |

| Effects on Properties | Increases hardness, strength, toughness, ductility, wear resistance, and machinability; Relieve internal stresses. |

| Visual Appearance | Generally does not significantly alter the surface appearance, though some processes (e.g., nitriding) can impart a slight color change. May cause minor scaling or discoloration depending on atmosphere. |

Types of Heat Treatment Surface Finishes

To reduce internal stresses, soften the material, improve ductility, and refine grain structure for better machinability or formability.

To refine grain structure, improve mechanical properties, and achieve uniform microstructure for better strength and toughness.

To increase hardness and strength by forming a hard microstructure (e.g., martensite in steels).

To reduce brittleness of hardened (quenched) materials, improve toughness, and relieve internal stresses while retaining sufficient hardness.

Surface Hardening; To harden the surface of a low-carbon steel while keeping the core tough and ductile.

To reduce residual stresses from welding, machining, or forming without significantly altering microstructure.

Benefits of Heat Treatment

Tailored Mechanical Properties

Heat treatment allows for precise control over a material's mechanical properties, enabling optimization for specific applications (e.g., high hardness for wear resistance, high toughness for impact resistance).

Improved Performance

Enhances strength, hardness, ductility, toughness, and wear resistance, leading to longer component lifespan and better performance under stress.

Stress Relief

Can relieve internal stresses induced during manufacturing processes like machining or welding, preventing premature failure or distortion.

Enhanced Machinability

Some heat treatments (e.g., annealing) can soften metals, making them easier to machine or form.

Things to Notice

Although heat treatment has many advantages, it also has certain limitations. Special attention should be paid to the following points:

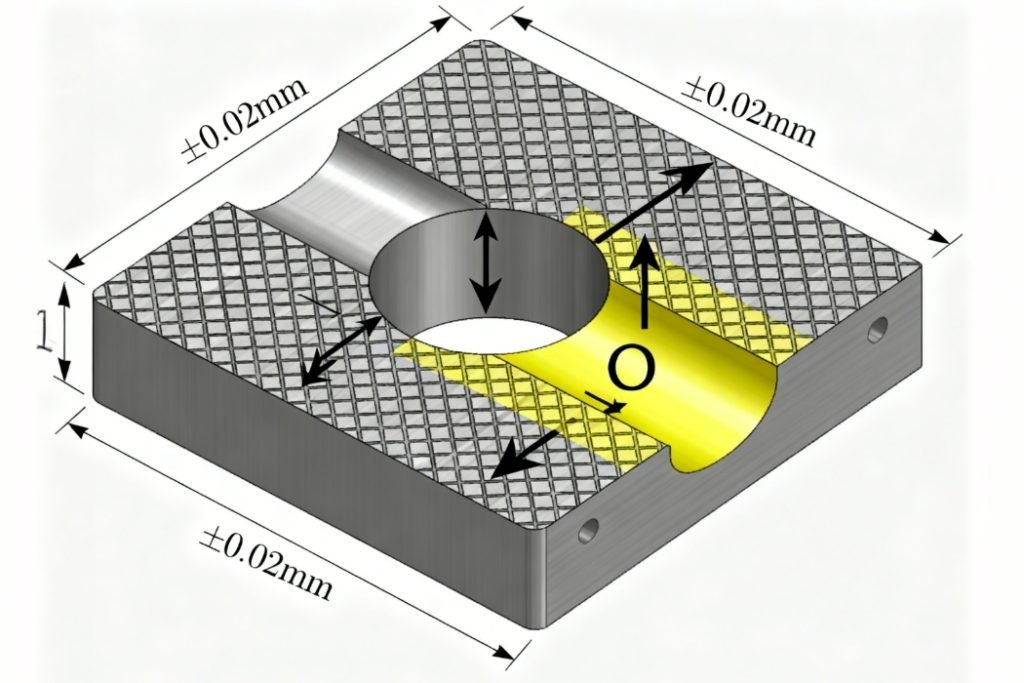

- Dimensional Changes and Distortion: The heating and cooling cycles can cause parts to distort or change dimensions, requiring careful process control and sometimes post-treatment machining.

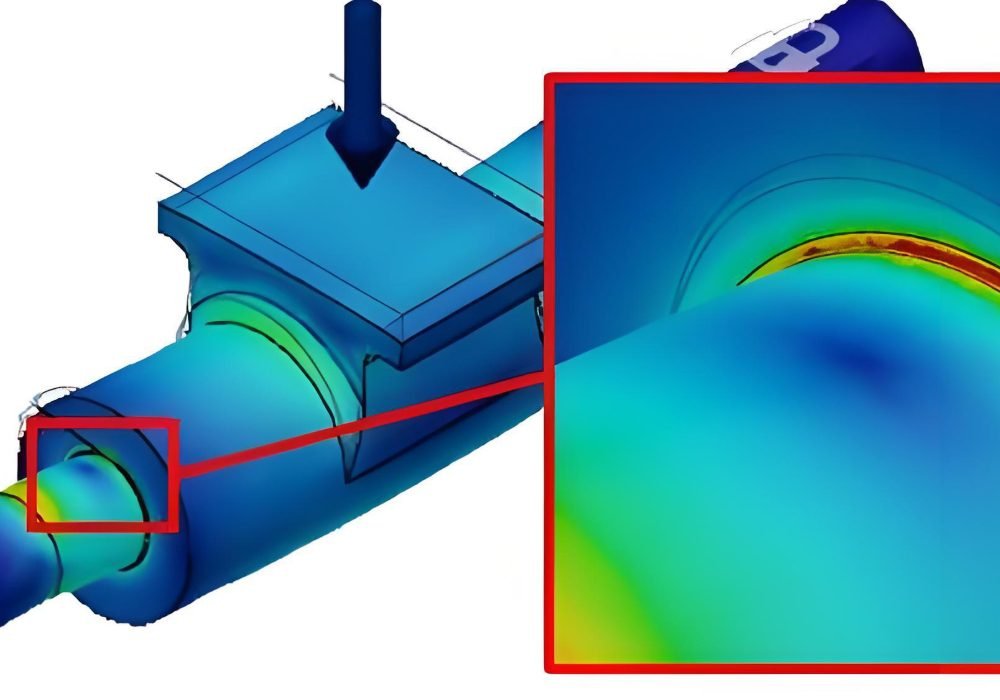

- Cracking Risk: Rapid cooling (quenching) can induce thermal stresses, potentially leading to cracking, especially in complex geometries or sensitive materials.

- Surface Degradation: Depending on the atmosphere and temperature, some heat treatments can lead to surface oxidation, decarburization, or scaling, which may require subsequent surface finishing.

Design Considerations

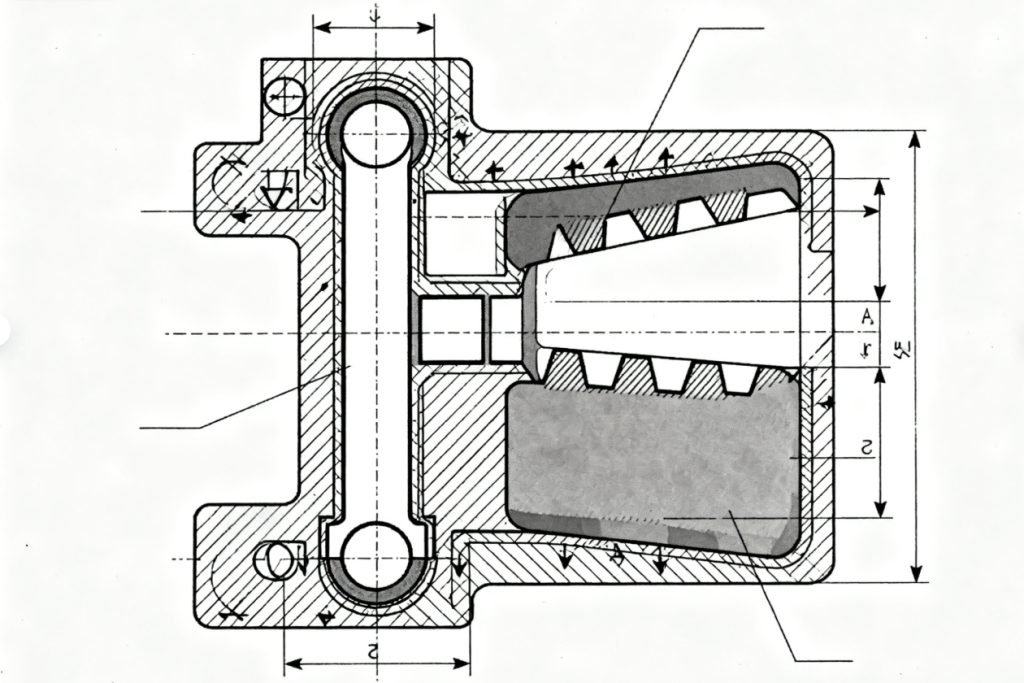

Part Geometry

Surface Finish

Tolerances

Stress Concentration

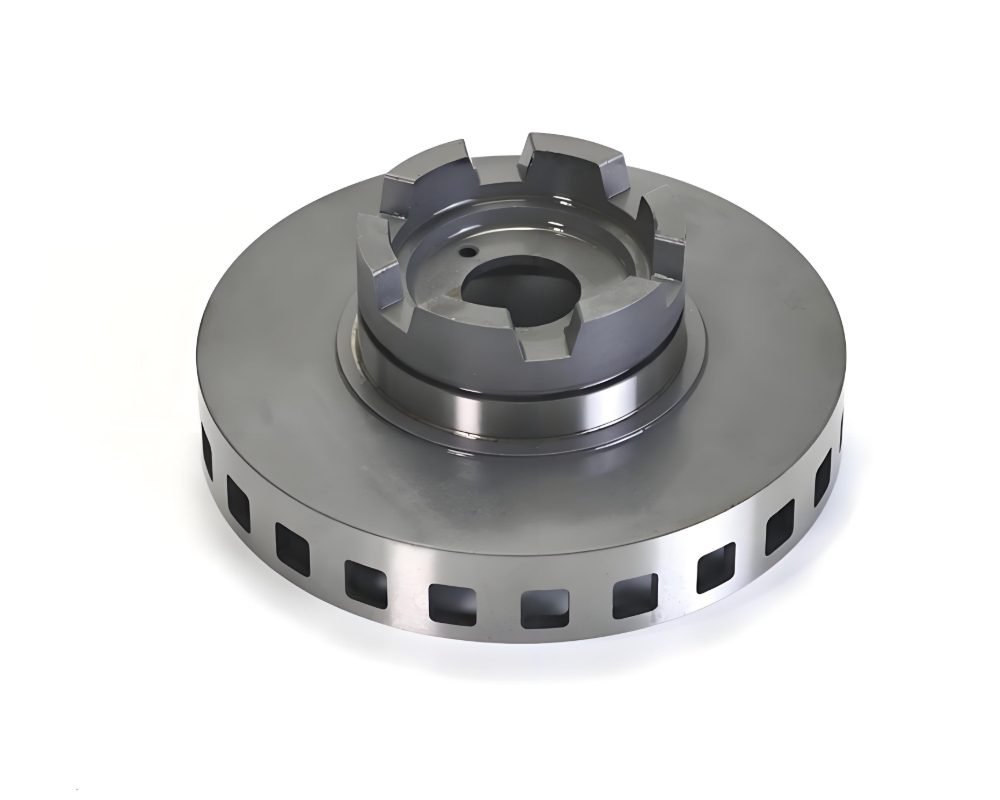

Heat Treated Parts

FAQs

Need to discuss surface finishes for your project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your Project?

Contact our team today to discuss your requirements and receive a customized quote for your needs.