Black Oxide

- Mild Corrosion Protection

- Reduced Light Reflection

- Aesthetic Black Finish

- Minimal Dimensional Change

Black Oxide Overview

| Parameter | Description |

| Applicable Materials | Primarily ferrous metals (steel, stainless steel, cast iron); Also applicable to copper, brass, zinc, and powdered metals. |

| Color | Deep black to bluish-black; appear glossy or matte depending on the pre-treatment surface finish. |

| Surface Roughness (Ra) | Not significantly change; depend on the pre-treatment finish (e.g., as-machined, polished). |

| Remarks | Mild corrosion resistance; significantly enhanced when followed by a post-treatment (e.g., oil, wax, lacquer). |

Types of Black Oxide Finishes

Below are the common types of black oxide surface finishes, their applications and specifications.

Hot Black Oxide

- Description: The most common black oxide process, involving immersion in a hot alkaline solution to form a magnetite layer.

- Applications: Firearms, automotive parts, tools, and machinery components requiring a decorative finish and moderate corrosion protection.

Temperature

Coating Thickness

Corrosion Resistance

135–145°C (275–290°F)

0.5–2 µm

24–48 hours (salt spray test)

Cold Black Oxide

- Description: A chemical process performed at room temperature using selenium-based or copper-based solutions to deposit a black coating.

- Applications: Decorative parts, low-wear components, and items where high temperatures are impractical (e.g., heat-sensitive alloys).

Temperature

Coating Thickness

Corrosion Resistance

20–30°C (68–86°F)

0.1–1 µm

12–24 hours (salt spray test)

Mid-Temperature Black Oxide

- Description: A less common process conducted at intermediate temperatures, balancing the benefits of hot and cold blackening.

- Applications: Precision components, tools, and parts where high temperatures may cause distortion.

Temperature

Coating Thickness

Corrosion Resistance

90–120°C (195–250°F)

0.5–1.5 µm

24–36 hours (salt spray test)

Benefits of Black Oxide

Aesthetic Appeal

Provides an attractive, uniform black finish that can enhance the visual appearance of parts.

Minimal Dimensional Change

Creates a very thin conversion coating (typically 0.000020 to 0.000060 inches), which adds negligible thickness to the part. Ideal for precision components with tight tolerances.

Reduced Light Reflection

The matte black finish reduces glare and light reflection. Beneficial for optical instruments, surgical tools, and military applications.

Improved Lubricity

When combined with an oil finish, black oxide can improve the lubricity of moving parts, reducing friction and wear.

No Hydrogen Embrittlement

Unlike some plating processes, black oxiding typically does not cause hydrogen embrittlement, making it safe for high-strength steels.

Speak With Our Engineering Team

Discuss your specific application challenges with our specialists.

Limitations to Notice

- Limited Corrosion Protection: By itself, black oxide offers only mild corrosion resistance. It requires a post-treatment (oil, wax) for significant protection, which may need reapplication.

- Material Specificity: Primarily effective on ferrous metals. While processes exist for other metals like copper, the most common and robust applications are for steel and iron.

- No Significant Wear Resistance: Black oxide does not significantly increase the hardness or wear resistance of the base material itself.

Design Considerations

Material Compatibility

Pre-Treatment Surface Finish

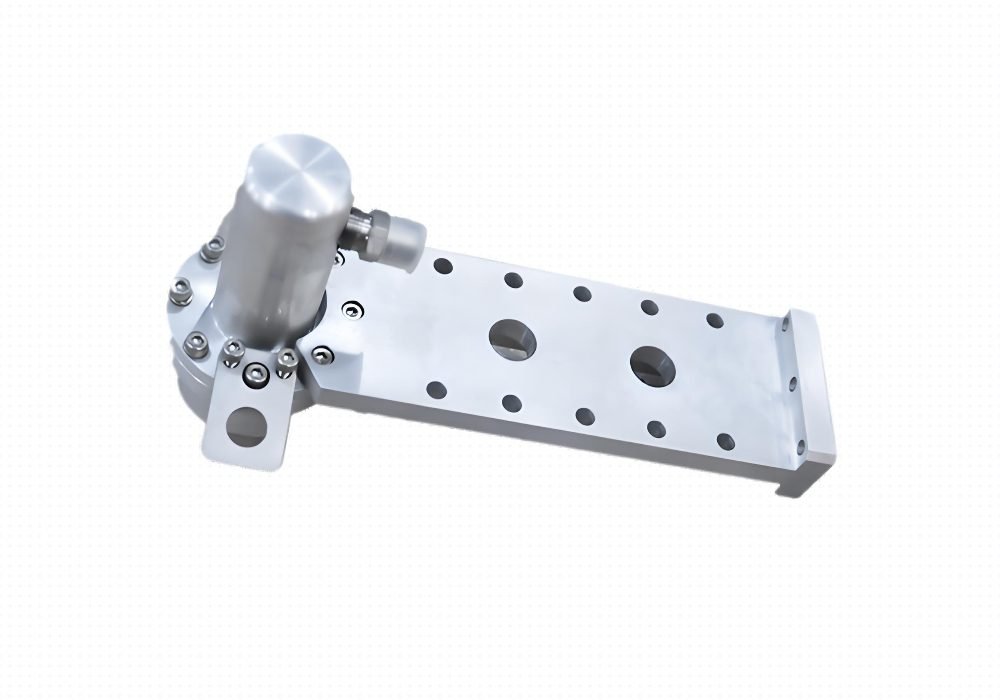

Parts with Black Oxide Coating

FAQs

Need to discuss surface finishes for your project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your Project?

Contact our team today to discuss your requirements and receive a customized quote for your needs.