As Machined

As Machined Surface Finish: Precision for Functional Parts

- Cost-Effective

- Fast Turnaround

- Functional Accuracy

As Machined Overview

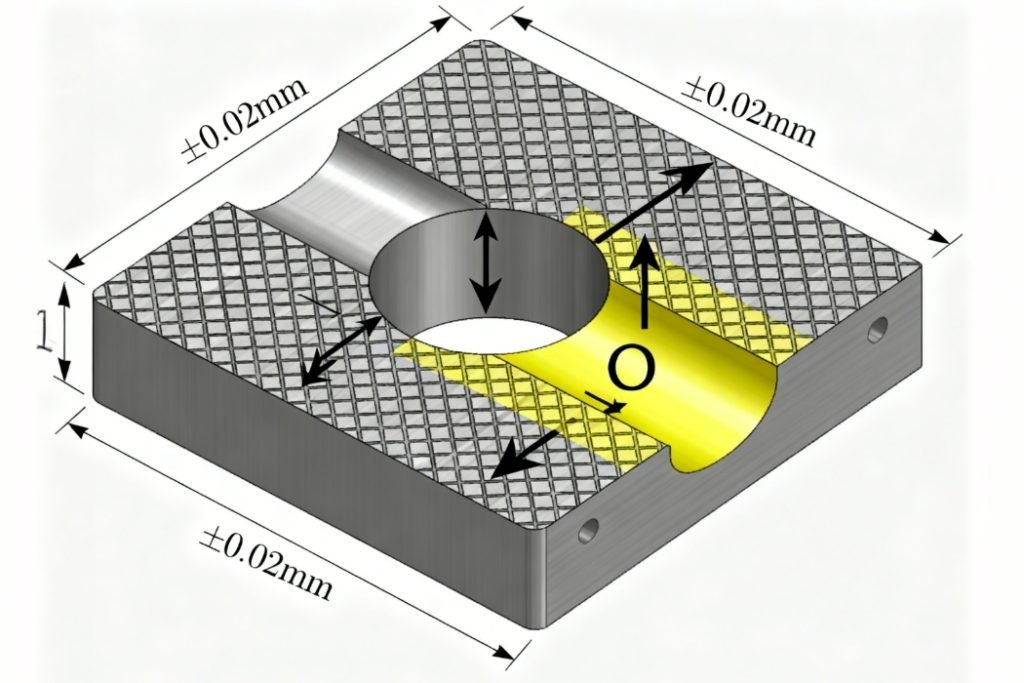

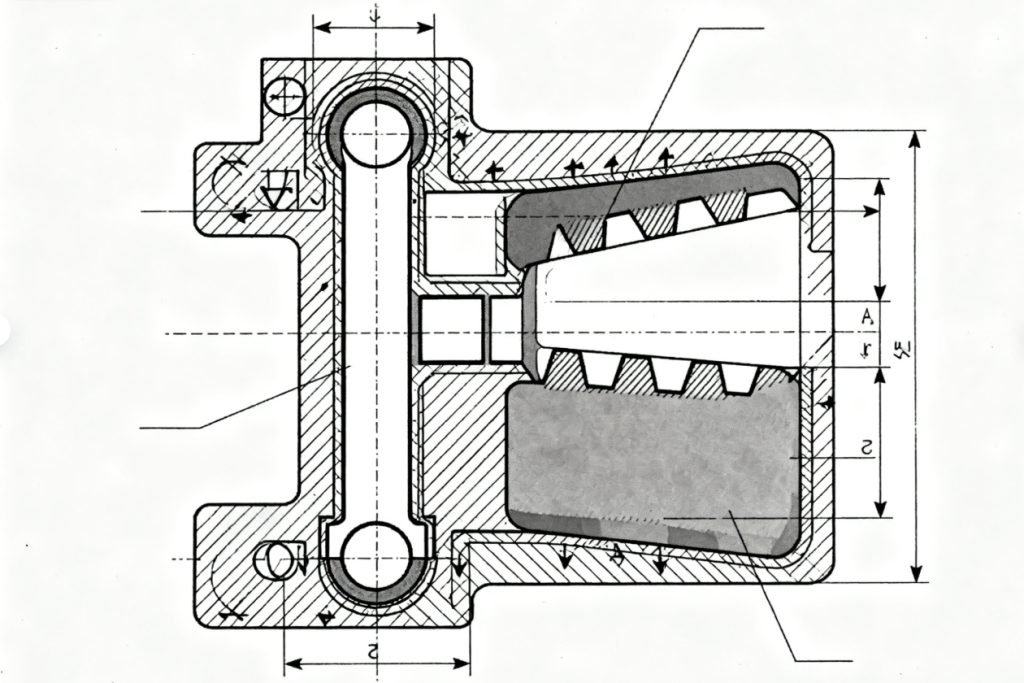

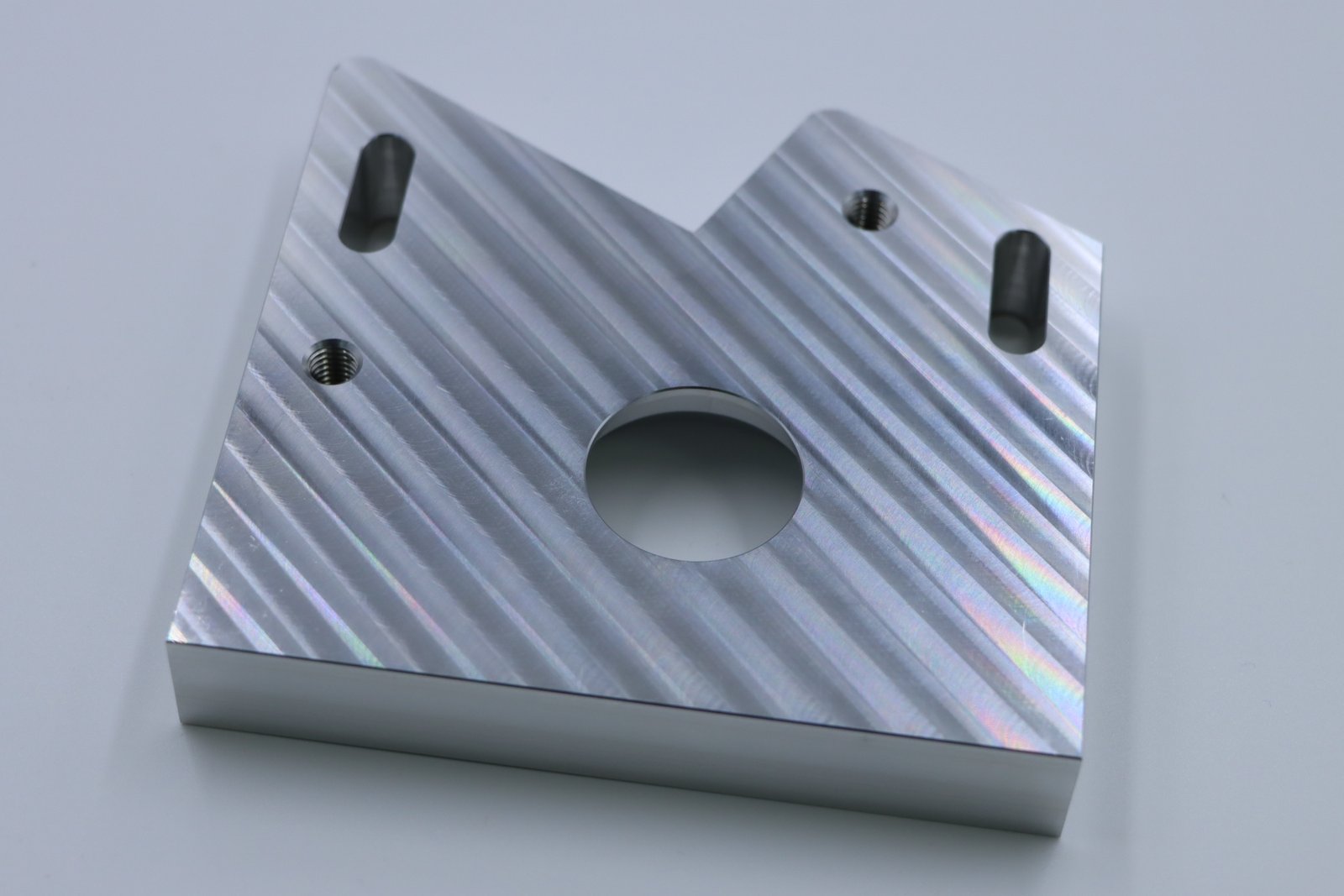

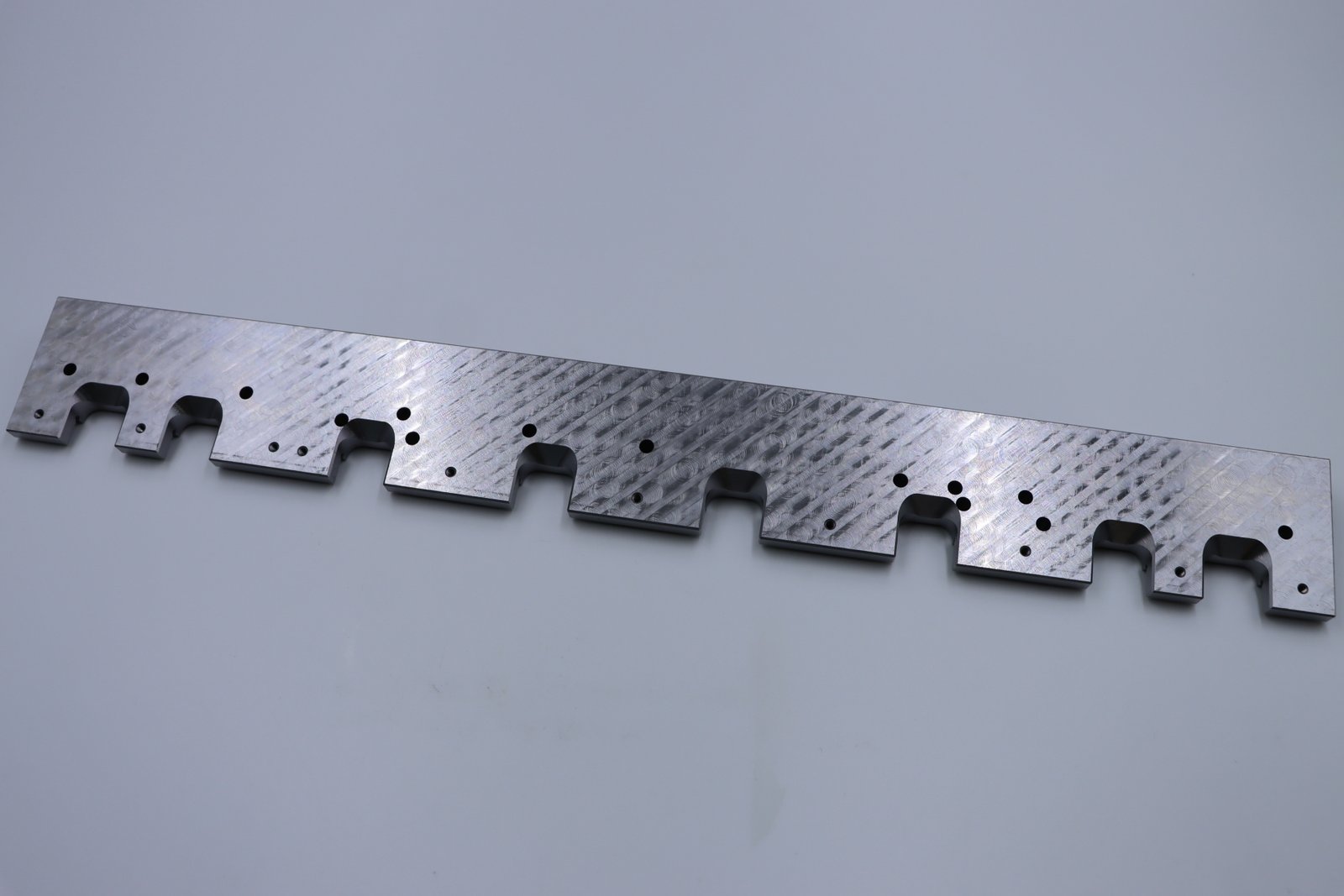

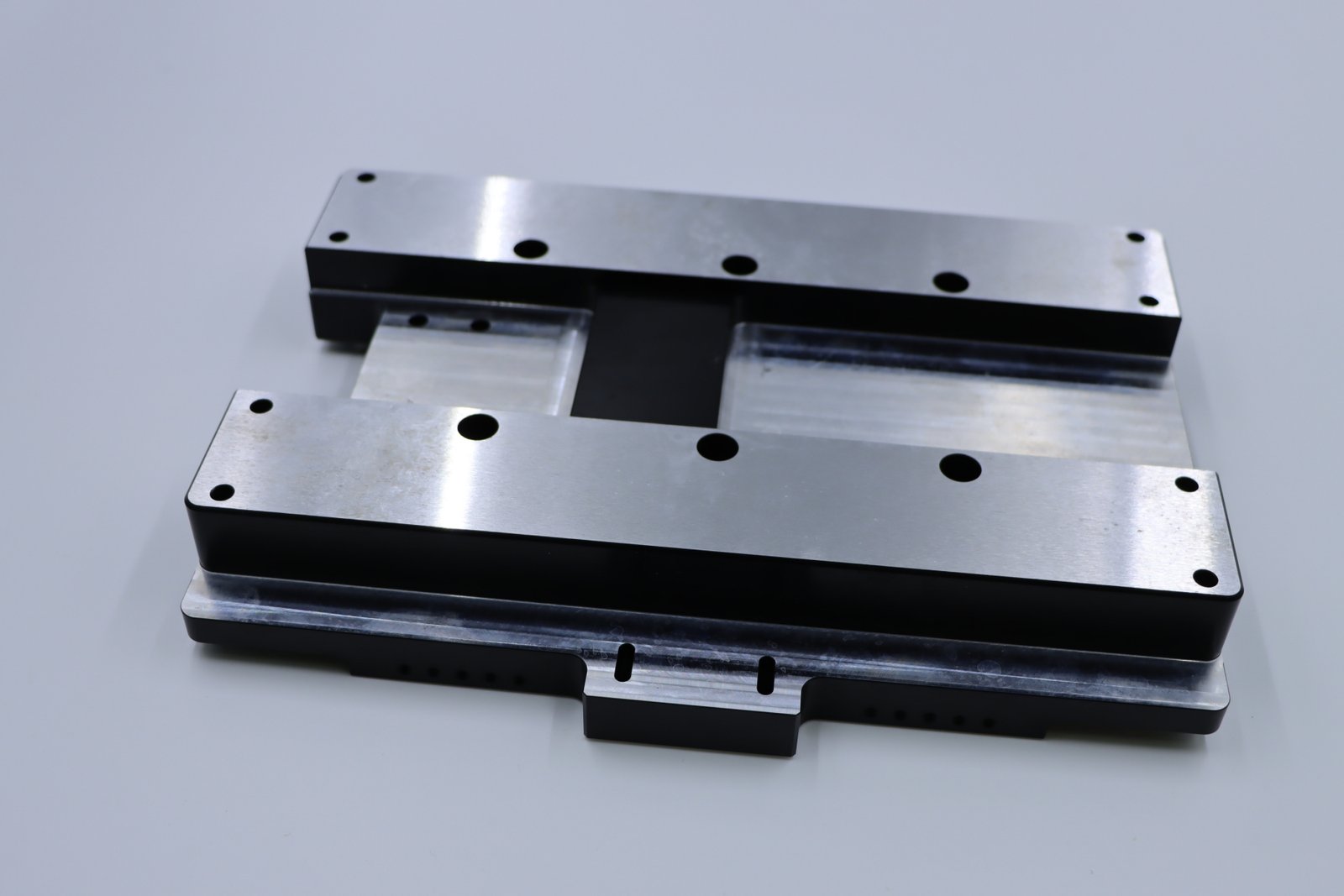

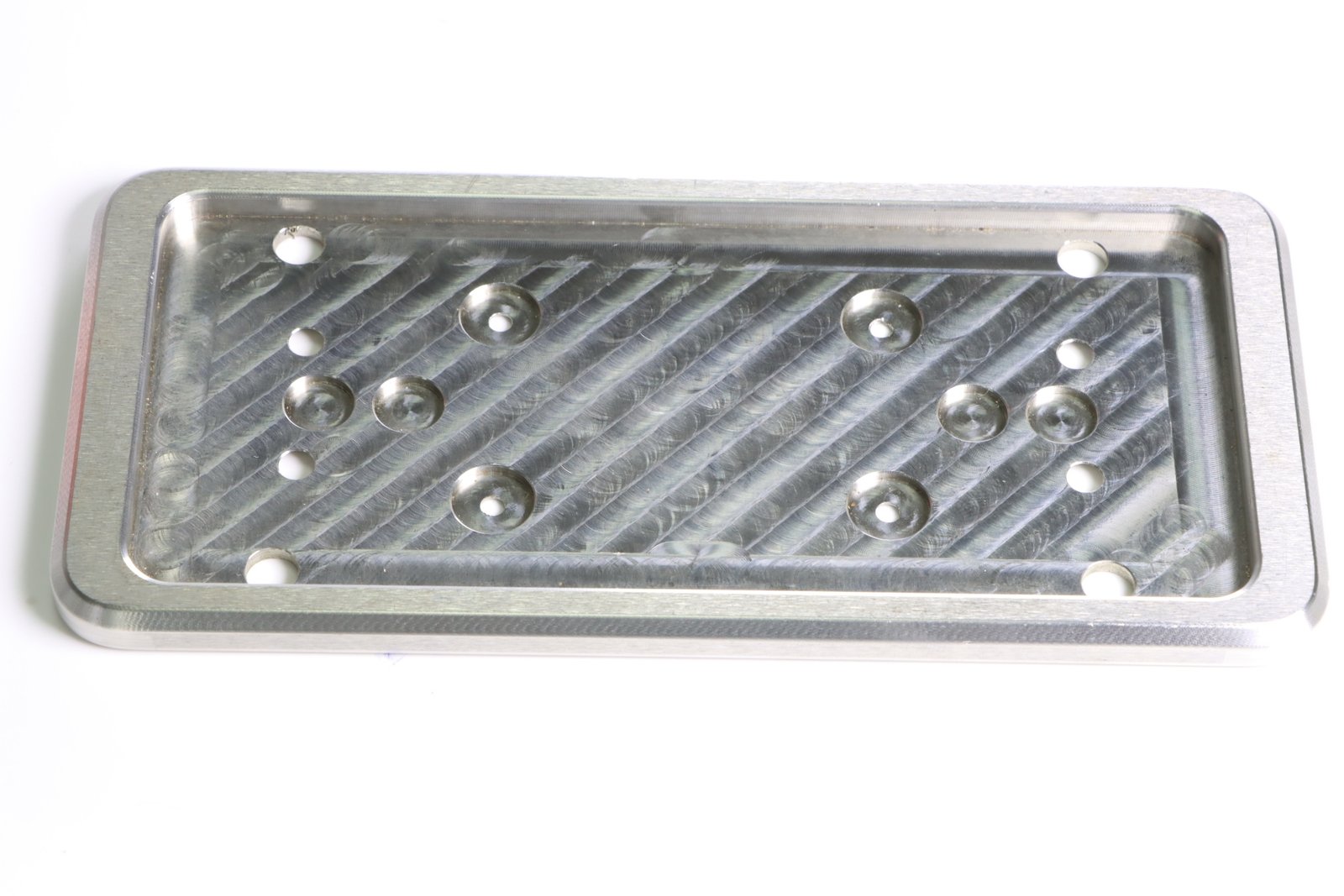

The ‘As Machined’ surface finish refers to parts directly off the CNC machine, retaining visible tool marks. It offers excellent dimensional accuracy and is ideal for functional components where aesthetics are secondary. This finish provides a cost-effective and rapid solution for prototyping, internal components, or parts that will undergo further processing or assembly. It ensures that critical dimensions and features are precise, making it suitable for a wide range of industrial applications.

| Parameter | Description |

| Color | Varies depending on the base material. |

| Applicable Materials | All metals and plastics that can be CNC machined. |

| Surface Roughness (Ra) | Typically Ra 3.2 μm (125 μin) or better. Finer finishes are achievable upon request. |

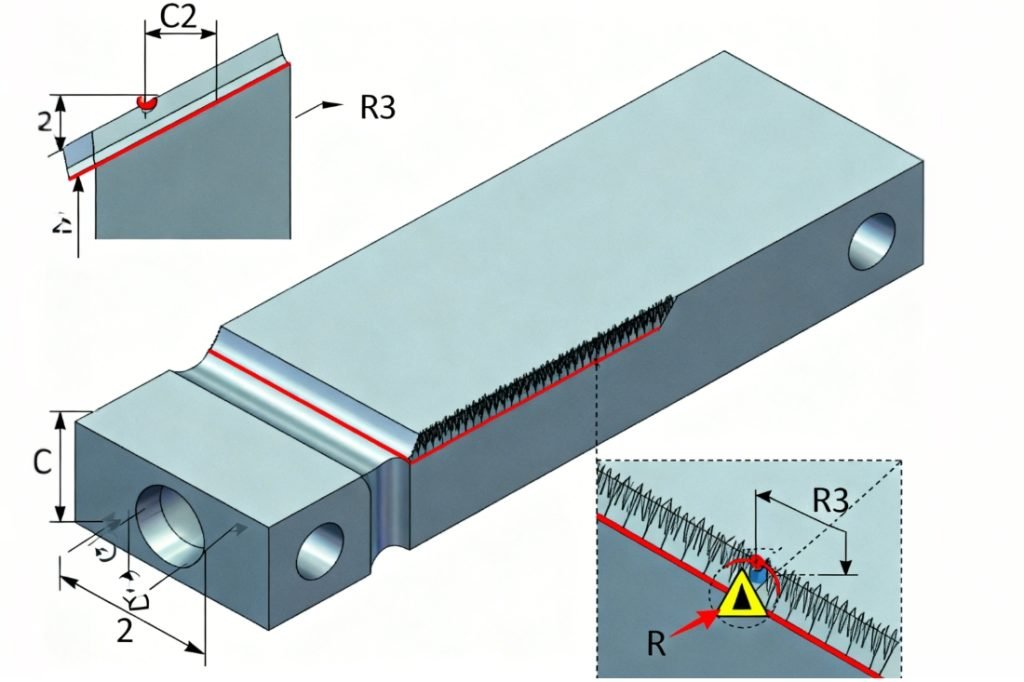

| Visual Appearance | Visible tool marks and a matte or satin finish. |

| Optional Process Types/Grades | Standard (Ra 3.2 μm), Fine (Ra 1.6 μm), Very Fine (Ra 0.8 μm). |

| Remarks | The direction of tool marks (lay) will vary depending on the machining strategy. For parts requiring a specific lay for functional or aesthetic reasons, please specify in your design notes. |

Standards and Compliance

We provide comprehensive dimensional inspection reports to verify that all critical dimensions meet your specifications.

Full material traceability and certifications are available upon request to ensure compliance with industry standards.

Adhere to ISO 2768 for general tolerances for linear and angular dimensions and geometrical tolerances for features without individual tolerance indications.

Pros and Cons of As Machined Surface Finish

Advantages

- Cost-Effective: As the most basic finish, it is the most affordable option, avoiding the additional costs of secondary finishing processes.

- Fast Turnaround: The absence of post-processing steps significantly reduces lead times, making it ideal for rapid prototyping and tight production schedules.

- High Dimensional Accuracy: The finish maintains the tight tolerances achieved during machining, ensuring functional precision for critical components.

- Versatility: Applicable to a wide range of metals and plastics, making it a versatile choice for various applications.

Disadvantages

- Aesthetic Imperfections: Visible tool marks and minor surface imperfections may not be suitable for consumer-facing products where aesthetics are a primary concern.

- Lower Corrosion Resistance: Without a protective coating, the raw material is more susceptible to corrosion and environmental degradation.

- Higher Friction: The textured surface can result in higher friction compared to polished or coated finishes, which may be a consideration for parts in dynamic contact.

Design Considerations

Tolerances

Clearly specify critical tolerances on your drawings. While we adhere to ISO 2768, tighter tolerances can be achieved upon request.

Tool Mark Direction (Lay)

If the direction of tool marks is important for your application (e.g., for fluid flow or aesthetic reasons), please indicate the desired lay on your design.

Sharp Edges

Standard practice is to deburr and break sharp edges. If sharp edges are required for your design, please specify this clearly.

Internal Features

For internal or hard-to-reach features, the as-machined finish is often the only practical option.

Quality Control & Inspection

At Fecison, our commitment to precision extends to every stage of the manufacturing process, including rigorous quality control for 'As Machined' parts. We ensure that even without additional surface treatments, your components meet the highest standards for dimensional accuracy and functional integrity. Our QC capabilities include:

- Coordinate Measuring Machine (CMM): Our advanced CMMs provide highly accurate three-dimensional measurements, verifying critical dimensions and geometric tolerances with exceptional precision.

- Optical Comparators: Used for non-contact measurement and inspection of complex profiles and small features, ensuring conformity to design specifications.

- Digital Calipers and Micrometers: Standard precision tools for verifying linear dimensions with high accuracy.

- Surface Roughness Testers: Employed to measure and confirm the Ra values of the ‘As Machined’ surface, ensuring it meets specified roughness requirements.

- First Article Inspection (FAI): Comprehensive inspection of the first part produced to ensure all specifications are met before full production commences.

- In-Process Inspections: Regular checks throughout the machining process to maintain consistency and catch any deviations early.

FAQs

Yes, for most metals (aluminum, steel) and plastics, but specify for soft materials to avoid excessive burrs.

Need to discuss surface finishes for your project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

As Machined Parts

Ready to Start Your Project?

Contact our team today to discuss your requirements and receive a customized quote for your needs.