Anodizing

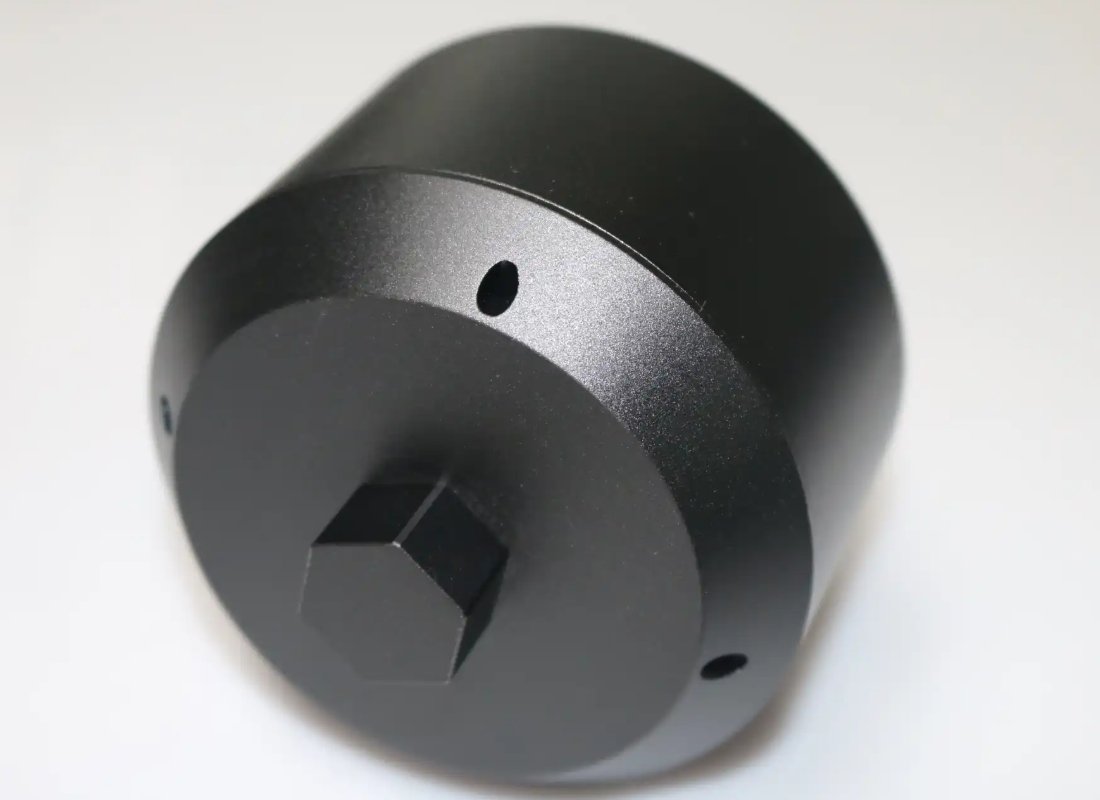

Anodizing Surface Finish: Enhanced Durability & Aesthetics for Metal Parts

- Corrosion Resistance

- Decorative Finish

- Wear Resistance

- Electrical Insulation

Anodizing Overview

Anodizing is an electrolytic passivation process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. Primarily used for aluminum, it can also be applied to titanium and magnesium. This electrochemical treatment enhances the material’s natural oxide layer, improving its sturdiness, wear resistance, and aesthetic appeal. It’s ideal for applications requiring increased surface hardness, improved adhesion for paints, or a decorative, colored finish.

| Parameter | Description |

| Color | Wide range of colors available |

| Applicable Materials | Primarily Aluminum alloys. Also applicable to Titanium, Magnesium, Zinc, etc. |

| Surface Roughness (Ra) | Generally, anodizing does not significantly alter the base material’s surface roughness. Pre-anodizing surface finish (e.g., as-machined, polished, blasted) will largely determine the final texture. |

| Visual Appearance | Range from clear/transparent to opaque, matte to glossy, depending on the anodizing type, sealing process, and pre-treatment. Colored finishes are vibrant and durable. |

| Optional Process Types | Type I (Chromic Acid Anodizing), Type II (Sulfuric Acid Anodizing), Type III (Hardcoat Anodizing) |

| Remarks | The specific aluminum alloy significantly impacts the final anodized color and coating thickness. High-copper alloys (e.g., 2xxx series) may result in brownish tints. Parts with sharp edges or deep recesses may have inconsistent coating thickness. |

Anodizing Subtypes

Chromic Acid Anodizing

· The earliest anodizing process, using chromic acid to produce a thin, protective oxide layer.

· Primarily used where dimensional accuracy and strong paint adhesion are critical.

Sulfuric Acid Anodizing

· The most widely used anodizing method, offering a balance between protection, appearance, and cost.

· Provide a durable oxide coating that can be dyed in various colors for decorative use.

Hardcoat Anodizing

· Also known as hard anodizing, creates a thick, dense oxide layer for superior wear, abrasion, and corrosion resistance.

· Ideal for parts exposed to harsh or high-friction environments.

Anodizing Specification

Type II: Conventional Anodizing

Features

Decorative or functional, cost-effective, suitable for dyeing

Color

Clear or dyed in multiple shades

Coating Thickness

5–25 µm (0.0002"–0.001")

Corrosion Resistance

Good

Hardness

300–500 HV

Typical Dimensions

Up to ~3,000 mm depending on tank and part geometry

Dimensional Tolerance

±0.005 mm typical

Cost Level:

★★☆☆☆

Economical for large-scale production

Applications

Consumer electronics, automotive trim, architectural panels, general industrial parts

Type III: Hard Anodizing

Features

Maximum wear resistance, superior hardness, dielectric insulation

Color

Gray to dark brown or black (limited dyeing)

Coating Thickness

25–150 µm (0.001"–0.006")

Corrosion Resistance

Excellent

Hardness

400–600 HV

Typical Dimensions

Up to ~2,000 mm; smaller parts yield more uniform coating

Dimensional Tolerance

±0.01 mm (tight control may require masking)

Cost Level:

★★★☆☆

Moderate, depends on coating thickness

Applications

Aerospace components, hydraulic parts, tooling, military and marine equipment

Discover the Perfect Anodizing Finish for Your Project

Explore our full range of anodizing options to achieve the ideal balance of durability and appearance.

Advantages of Anodizing Surface Finish

Enhanced Corrosion Resistance

Anodizing creates a dense, protective oxide layer that significantly improves the material's resistance to corrosion, especially in harsh environments.

Increased Wear Resistance

Particularly with Type III (Hardcoat) anodizing, the surface hardness is substantially increased, providing excellent resistance to abrasion and wear.

Aesthetic Appeal

Anodizing allows for a wide range of vibrant colors, offering decorative finishes that are integral to the material, not just a coating.

Electrical Insulation

The anodic oxide layer is non-conductive, providing electrical insulation properties, which can be beneficial in certain applications.

Improved Adhesion

The porous nature of the anodic layer before sealing provides an excellent surface for subsequent painting, priming, or adhesive bonding.

Lightweight

Anodizing adds minimal weight to the component, maintaining the lightweight benefits of aluminum.

Things to Notice

Although anodizing has many advantages, it also has certain limitations. Special attention should be paid to the following points:

- Limited to Specific Metals: Primarily effective on aluminum and its alloys, with less common applications for titanium and magnesium. Not suitable for steel or other ferrous metals.

- Dimensional Changes: The anodizing process adds a layer to the surface, resulting in slight dimensional changes. This must be accounted for in precision designs.

- Color Inconsistency: Achieving perfectly consistent color across different batches or complex geometries can be challenging, especially with certain alloys.

- Fatigue Strength Reduction: Thicker anodic coatings (especially Type III) can sometimes reduce the fatigue strength of the base material due to the brittle nature of the oxide layer.

- Masking Required: Areas that must remain electrically conductive or have tight tolerances (e.g., threaded holes) need to be masked prior to anodizing, adding to cost and complexity.

Aluminum Anodizing Colors

At Fecision, we offer various colors options for your projects.Color differences in anodized aluminum may occur due to alloy composition, surface texture, anodizing thickness, and dyeing conditions. While these variations are natural, careful process control ensures consistent appearance and quality across parts.

Design Considerations

Surface Finish Prior to Anodizing

The final appearance of an anodized part is highly dependent on the surface finish before anodizing. Polished surfaces will yield a shinier anodized finish, while bead-blasted surfaces will result in a matte appearance.

Sharp Edges and Corners

Anodic coatings tend to build up less effectively on sharp edges and corners, potentially leading to thinner coatings in these areas. Design with generous radii where possible.

Holes and Recesses

Deep holes and recesses may experience reduced current density during anodizing, leading to thinner or inconsistent coatings. Design with adequate drainage and consider masking if specific areas need to be protected.

Tolerances

Account for the dimensional buildup of the anodic layer. For Type II, this is typically 50% of the coating thickness; for Type III, it can be up to 50% of the coating thickness. Adjust part dimensions accordingly.

Racking Marks

Parts must be electrically connected to the anodizing rack. This will leave small contact marks, usually in non-critical areas. Discuss racking strategies with Fecision to minimize their impact.

Color Uniformity

For critical aesthetic applications, discuss color expectations and potential variations with Fecision, especially for large parts or complex geometries. Consider using clear anodizing if color consistency is a major concern.

Anodized Parts

FAQs

While most aluminum alloys can be anodized, the specific alloy can significantly affect the final appearance and coating properties. For example, high-copper alloys may result in brownish tints, and high-silicon alloys can appear duller. We recommend consulting with our engineers for optimal alloy selection.

Need to discuss surface finishes for your project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your Project?

Contact our team today to discuss your requirements and receive a customized quote for your needs.