Have you ever wondered why some materials fail under pressure while others bend but don’t break? The answer lies in understanding the key properties of materials: strength, stiffness, and hardness. These characteristics are crucial in precision manufacturing, where even the smallest error can lead to significant consequences.

In industries like aerospace and automotive, selecting the right material can mean the difference between success and failure. For example, a component that’s too stiff might crack under stress, while one that’s not hard enough could wear out quickly. This is why knowing how these properties interact is essential.

Young’s Modulus, a measure of stiffness, plays a vital role in predicting how a material will behave under load. By understanding these properties, you can make informed decisions for applications requiring durability and wear resistance. Let’s dive deeper into how these factors impact precision manufacturing and real-world applications.

What is Material Strength?

Material strength is a key factor in determining how components perform under pressure. It refers to a material’s ability to withstand an applied force without experiencing permanent deformation or fracture. This property is critical in industries like aerospace, automotive, and construction, where materials must endure extreme conditions.

Definition of Material Strength

Strength is measured by how much stress a material can handle before it fails. Tensile strength, for example, is the maximum stress a material can endure while being stretched or pulled. Compressive strength, on the other hand, measures resistance to being crushed. Yield strength is the point at which a material begins to deform permanently.

According to ASTM standards, these measurements help engineers predict how materials will behave under load. The stress-strain curve is a valuable tool for understanding these properties, showing the relationship between applied force and material deformation.

Why Strength Matters in Metal Manufacturing

In metal manufacturing, selecting the right strength is crucial for product performance. For instance, Fecision Steel uses high-strength materials for its wire baskets to ensure they can handle heavy loads without bending or breaking. This ensures durability and reliability in industrial applications.

Choosing a material with insufficient strength can lead to fitting failures, compromising structural integrity. On the other hand, overly strong materials may be unnecessarily expensive or difficult to work with. Understanding strength helps you balance cost, performance, and safety in your designs.

Factors that Influence Strength in Metals

Understanding what makes metals strong is essential for selecting the right material for your project. The ability of metals to resist deformation depends on several key factors, including their composition and the processes they undergo.

Composition and Alloying

The composition of a metal plays a significant role in its strength. For example, adding carbon to steel increases its ultimate tensile strength. This is why high-carbon steels are often used in applications requiring durability.

Alloying is another critical factor. Combining metals like chromium and nickel with steel creates alloys such as 304 stainless steel, which offers excellent corrosion resistance and strength. Similarly, titanium alloys like Ti-6Al-4V are known for their high strength-to-weight ratio.

Heat Treatment and Processing

Heat treatment can dramatically alter a metal’s properties. Processes like annealing soften metals, making them easier to work with, while quenching increases hardness and strength. For aluminum alloys, quenching is often used to enhance their mechanical properties.

Case hardening is another effective method. It increases the surface strength of fittings, making them more resistant to wear and tear. The Brinell hardness test is often used to correlate hardness with strength, providing valuable insights for material selection.

Understanding these factors helps you choose the right metal for your needs, ensuring both performance and longevity.

Significance of Strength in Metal Manufacturing

The ability of a material to handle stress directly impacts its performance in real-world applications. In metal manufacturing, strength is a critical factor that ensures structural integrity, durability, and safety. Without adequate strength, components can fail under load, leading to costly and dangerous consequences.

Impact on Structural Integrity

Yield strength is essential for preventing plastic deformation in materials. For example, bridge collapses often result from insufficient yield strength, highlighting the importance of proper material selection. Design engineers rely on ISO 898-1 standards to ensure fasteners meet required strength levels, preventing structural failures.

Hydraulic press components also depend on material strength to handle high loads safely. AT-Machining’s DFM feedback emphasizes the need for materials that balance strength and machinability, ensuring both performance and safety.

Role in Durability and Safety

High-cycle fatigue resistance is another key aspect of material strength. Components exposed to repeated stress, like engine parts, must withstand wear over time. This ensures long-term durability and reduces the risk of unexpected failures.

Safety factors in manufacturing are directly tied to material strength. By choosing materials with the right properties, you can create products that perform reliably under demanding conditions, protecting both users and investments.

Types of Strength

Different types of strength define how materials respond to various forces. Whether it’s pulling, compressing, or bending, each type plays a critical role in material performance. Understanding these subtypes helps you select the right material for specific applications.

Tensile Strength

Tensile strength measures how much stress a material can handle when pulled apart. It’s often tested using ASTM E8/E8M standards. For example, aluminum has a tensile strength of 68 MPa, while titanium can reach up to 1,000 MPa. This makes titanium ideal for aerospace applications where high strength is essential.

Compressive Strength

Compressive strength determines a material’s ability to resist being crushed. Concrete, for instance, has a compressive strength of around 20-40 MPa, while granite can withstand up to 200 MPa. This is why granite is often used in construction for heavy-duty structures.

Yield Strength

Yield strength is the point at which a material begins to deform permanently. Common CNC materials like stainless steel have a yield strength of 250 MPa, while aluminum alloys range from 100-300 MPa. This property ensures components can handle stress without failing.

Fracture Strength

Fracture strength refers to the stress level at which a material breaks. A bolt shear failure is a common example. Understanding this property helps engineers design components that can withstand extreme conditions without catastrophic failure.

What is Material Stiffness?

When designing components, have you considered how materials resist deformation? Stiffness is a critical property that determines how much a material bends under stress. Unlike strength, which focuses on failure points, stiffness measures a material’s ability to return to its original shape after force is applied.

Definition of Material Stiffness

Stiffness is defined by Hooke’s Law, which states that the force needed to deform a material is proportional to the displacement (F=kx). The constant “k” represents stiffness. Materials with high stiffness, like steel, resist deformation even under significant stress. In contrast, flexible materials like rubber bend easily but return to their original shape.

How Stiffness Differs from Strength

Stiffness and strength are often confused, but they measure different properties. Strength refers to how much stress a material can handle before breaking, while stiffness measures how much it resists bending. For example, glass is stiff but brittle, meaning it resists deformation but shatters under high stress. Rubber, on the other hand, is flexible but not strong.

Young’s Modulus, also known as elastic modulus, quantifies stiffness. Steel has a Young’s Modulus of 200 GPa, making it highly stiff, while aluminum’s 69 GPa makes it less rigid. This is why lathe beds, which require minimal deflection, are often made from steel.

In precision machining, stiffness is crucial to maintain accuracy. Deflection limits ensure that parts meet exact specifications, even under load. Understanding stiffness helps you choose materials that balance rigidity and performance for your applications.

Main Factors that Affect Stiffness in Metals

Why do some metals resist bending better than others? The answer lies in their stiffness, a property that determines how much a material deforms under applied forces. In manufacturing, stiffness is crucial for ensuring precision and minimizing deformation, especially in CNC machining and structural applications.

Elastic Modulus

Elastic modulus, also known as Young’s Modulus, is the primary factor that defines stiffness. It measures a material’s ability to return to its original shape after being subjected to stress. For example, steel has a high elastic modulus of 200 GPa, making it highly resistant to bending. In contrast, materials like rubber have a low modulus, allowing them to stretch easily.

In the elastic region, the relationship between stress and strain is linear, as described by Hooke’s Law. This means that for a given force, materials with a higher modulus will deform less. Understanding this property helps you select materials that maintain their shape under load, ensuring accuracy in precision applications.

Material Composition

The composition of a metal significantly influences its stiffness. Alloying elements, grain structure, and processing methods all play a role. For instance, carbon fiber composites achieve high stiffness due to their tightly bonded molecular structure. Similarly, titanium alloys, with a modulus of 116 GPa, are stiffer than magnesium alloys, which have a modulus of 45 GPa.

Grain structure also affects stiffness. Metals with fine, uniform grains tend to be stiffer than those with coarse grains. Heat treatment processes like annealing can alter grain structure, further influencing stiffness. By controlling these factors, you can tailor materials to meet specific stiffness requirements.

| Material | Elastic Modulus (GPa) |

| Titanium | 116 |

| Magnesium | 45 |

In CNC machining, stiffness is critical for minimizing tool deflection, which can affect precision. The formula for tool deflection highlights the importance of selecting materials with the right modulus for your application. By understanding these factors, you can make informed decisions that enhance performance and durability.

The Role of Stiffness in Metal Manufacturing

How does stiffness impact the quality of your CNC machined parts? In metal manufacturing, stiffness is a critical factor that determines how well a material resists deformation under load. This property is especially important in CNC machining, where precision and tight tolerances are essential.

Minimizing Deformation

Deformation can compromise the accuracy of your parts. For example, a 10mm endmill under a 500N load must stay within a deflection limit of 0.005″ to meet tight tolerances. Stiff materials like steel or titanium are often used to minimize this issue.

Surface finish is another area where stiffness plays a role. Materials with higher stiffness produce smoother finishes, measured by Ra values. This is crucial for parts requiring high precision, such as aerospace components.

Ensuring Precision in CNC Machining

In CNC machining, stiffness ensures that cutting tools maintain their position under load. Linear guides in CNC mills, for instance, must be rigid to prevent unwanted movement. This rigidity helps achieve the desired precision in every cut.

Marlin Steel’s wire baskets are a great example of how stiffness enhances performance. Their rigidity ensures they can handle heavy loads without bending, making them ideal for industrial applications.

| Material | Stiffness (GPa) |

| Steel | 200 |

| Titanium | 116 |

| Aluminum | 69 |

When selecting materials for fixturing, prioritize stiffness to ensure stability and accuracy. Materials like steel and titanium are excellent choices for maintaining precision in demanding applications.

What is Material Hardness?

Have you ever thought about why some materials resist scratches better than others? This property is known as hardness, and it plays a crucial role in determining how materials perform under pressure. Hardness measures a material’s resistance to localized surface deformation, such as indentation or scratching.

Definition of Material Hardness

Hardness is a material’s ability to withstand surface deformation when subjected to force. It’s often tested using methods like the Rockwell C scale, which measures the depth of indentation. For example, tool steels are rated on this scale to ensure they meet specific hardness requirements.

Materials like diamond, with a hardness of 10,000 HV (Vickers hardness), are extremely resistant to scratches. In contrast, mild steel has a hardness of around 120 HV, making it less durable under similar conditions. This difference highlights the importance of selecting the right material for applications requiring wear resistance.

Hardness vs. Strength and Stiffness

While hardness measures resistance to surface deformation, strength refers to a material’s ability to withstand stress without breaking. Stiffness, on the other hand, measures how much a material resists bending. For instance, glass is hard but lacks toughness, making it brittle under high stress.

In applications like ball bearings, hardness ensures long-term wear resistance. ISO 6508 standards are often used to test hardness, ensuring materials meet specific performance criteria. Understanding these differences helps you choose the right material for your needs.

Main Factors that Affect Hardness in Metals

What makes some metals more resistant to wear and tear than others? The answer lies in two key factors: material composition and surface treatments. These elements determine how well a metal can withstand surface deformation, making them critical for applications like CNC machining and tool manufacturing.

Material Composition

The composition of a metal plays a significant role in its hardness. Alloying elements like carbon, chromium, and nickel can enhance hardness by altering the metal’s microstructure. For example, high-carbon steels are known for their exceptional hardness, making them ideal for cutting tools.

Grain structure also matters. Metals with fine, uniform grains tend to be harder than those with coarse grains. Heat treatment processes, such as quenching, can further refine grain structure, increasing hardness. This is why materials like tool steels undergo specific treatments to achieve desired hardness levels.

Surface Treatments

Surface treatments are another way to enhance hardness. Carburizing, for instance, increases surface hardness up to 60 HRC by infusing carbon into the metal’s outer layer. This method is commonly used for gears and bearings.

Nitriding is another effective process, especially for steels like 4140. It introduces nitrogen into the surface, creating a hard, wear-resistant layer. Anodizing, on the other hand, is used for aluminum to improve its surface hardness and corrosion resistance.

| Hardening Method | Hardness Gain | Application |

| Through-Hardening | Uniform hardness throughout | Structural components |

| Case Hardening | High surface hardness | Gears, bearings |

Cutting tool coatings like TiN (Titanium Nitride) and AlCrN (Aluminum Chromium Nitride) are also used to enhance hardness. These coatings provide a protective layer that resists wear, extending tool life in CNC machining applications.

Understanding these factors helps you choose the right materials and processes for your needs, ensuring durability and performance in demanding environments.

Importance of Hardness in Metal Manufacturing

Why do some materials last longer under harsh conditions? The answer lies in their hardness, a property that determines how well they resist wear and tear. In metal manufacturing, hardness is critical for ensuring durability and extending the lifespan of components.

Wear Resistance

Harder materials are less prone to abrasive wear, especially in demanding environments like mining or desert conditions. For example, mining equipment often requires high hardness to withstand constant friction and impact. Hydraulic seals, another critical component, benefit from increased hardness to prevent leaks and maintain performance over time.

Case studies show that materials with higher hardness, such as carbide tools, outperform traditional high-speed steel (HSS) in titanium machining. This not only improves efficiency but also reduces downtime and maintenance costs.

Tool Longevity

Tool lifespan is directly tied to hardness. Carbide tools, with their superior hardness, can last up to 10 times longer than HSS in high-stress applications. This translates to significant cost savings, particularly in industries like aerospace and automotive manufacturing.

Mold longevity is another area where hardness plays a vital role. Harder molds resist deformation and wear, extending their usable life and reducing replacement costs. MIL-SPEC hardness requirements ensure that military-grade components meet stringent durability standards, further highlighting the importance of this property.

By prioritizing hardness in material selection, you can enhance product performance, reduce operational costs, and ensure reliability in even the most challenging conditions.

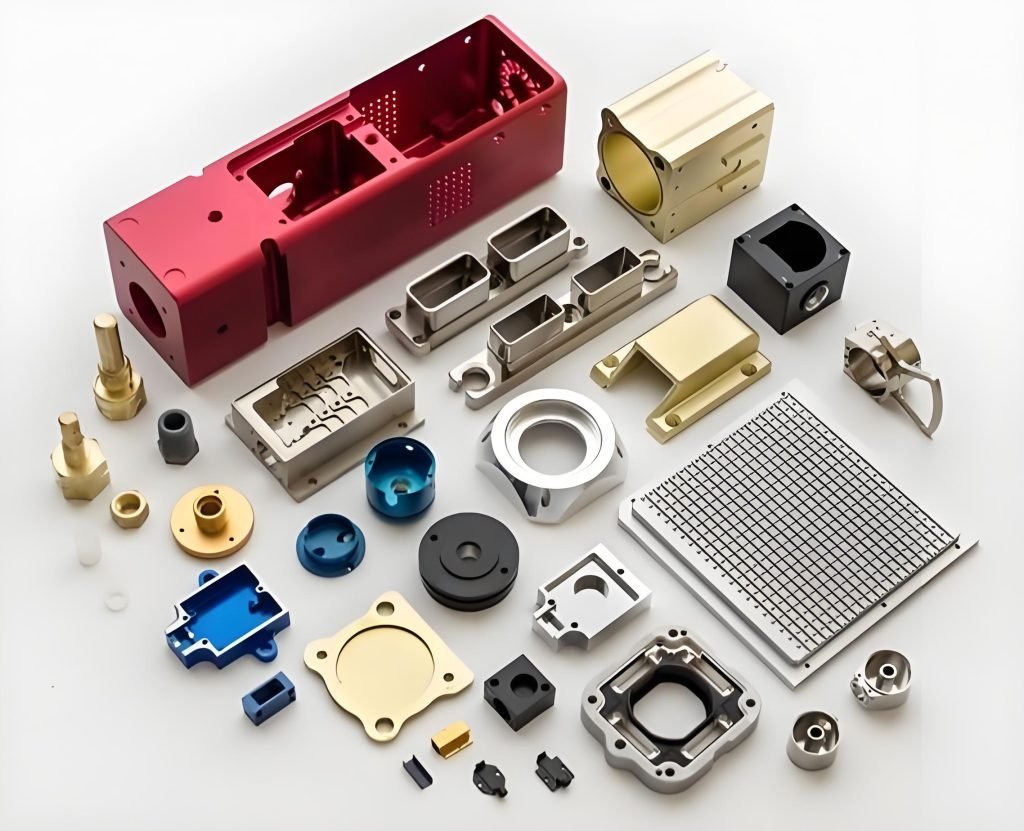

Strength, Stiffness, and Hardness Properties of Common Materials

Choosing the right material for your project can make or break its success. Understanding the unique properties of materials like steel, aluminum, and titanium ensures better performance in specific applications. Each material offers distinct advantages in terms of strength, stiffness, and hardness, making them suitable for different industries and uses.

Comparison of Steel, Aluminum, and Titanium

Steel is known for its high strength and stiffness, making it ideal for structural applications. Stainless steel, in particular, offers an optimal balance for corrosive environments. Aluminum, on the other hand, is lightweight and has good stiffness, making it a popular choice in aerospace. Titanium stands out for its exceptional strength-to-weight ratio, which is crucial in medical devices and high-performance applications.

| Material | Strength (MPa) | Stiffness (GPa) | Hardness (HV) |

| Steel | 250-1200 | 200 | 120-800 |

| Aluminum | 68-570 | 69 | 25-120 |

| Titanium | 240-1400 | 116 | 200-400 |

Applications Based on Material Properties

For aerospace applications, 6061-T6 aluminum is often preferred for its balance of strength and weight. In contrast, 7075 aluminum offers higher strength but is less corrosion-resistant. Marine fittings benefit from 17-4 PH stainless steel, which provides excellent corrosion resistance and hardness. Titanium’s strength-to-weight ratio makes it a top choice for medical implants and devices.

When selecting materials, consider the trade-offs between hardness and stiffness. For example, while steel is stiffer, titanium offers better corrosion resistance and weight savings. Using AT-Machining’s material database can help you make informed decisions based on your specific needs.

Understanding Stress and Strain in Mechanical and Structural Components

What happens when materials are pushed to their limits? The answer lies in understanding stress and strain, two fundamental concepts in material science. Stress measures the internal forces within a material, while strain quantifies its deformation. Together, they help predict how materials behave under load, ensuring safety and performance in mechanical and structural applications.

Stress-Strain Curve Explained

The stress-strain curve is a graphical representation of a material’s response to applied forces. It includes key points like the elastic limit, yield point, and ultimate tensile strength. In the elastic region, materials return to their original shape after the force is removed. Beyond the yield point, plastic deformation occurs, leading to permanent changes.

For example, copper exhibits ductile behavior, stretching significantly before breaking. In contrast, cast iron is brittle, fracturing with minimal deformation. Understanding these differences helps you select the right material for specific applications.

Elastic vs. Plastic Deformation

Elastic deformation is temporary, meaning the material regains its original shape once the stress is removed. This behavior is governed by Hooke’s Law, which relates stress to strain through the modulus of elasticity. Plastic deformation, on the other hand, is permanent and occurs beyond the yield point.

Spring design is a practical example of elastic deformation. Springs rely on materials that can return to their original shape after being compressed or stretched. ASTM E111 modulus testing ensures these materials meet performance standards, guaranteeing reliability in real-world applications.

Poisson’s ratio, another critical factor, describes how materials compress in one direction when stretched in another. This property is essential in compression testing, where materials must maintain structural integrity under pressure.

Choosing the Right Property for Your Application

Selecting the right property depends on your application. Use hardness for wear resistance, strength for load-bearing components, and stiffness for precision parts. For instance, Fecision’s Quick Disconnect Fittings prioritize stiffness to ensure accurate alignment in fluid systems.

ASME standards provide guidelines for component design, helping you balance these properties. Here’s a decision matrix to simplify your selection:

| Application | Priority Property |

| Wear Resistance | Hardness |

| Load-Bearing | Strength |

| Precision | Stiffness |

By understanding these terms and their applications, you can make informed decisions that enhance performance and durability in your projects.

Conclusion

How do material properties shape the success of your manufacturing projects? Understanding the interplay between strength, stiffness, and hardness is essential for precision manufacturing. These properties ensure components perform reliably under stress, resist deformation, and withstand wear over time.

Testing methods like Rockwell and tensile tests provide critical insights into material behavior. By analyzing these results, you can make informed decisions that enhance product durability and performance. Fecision combines property analysis with DFM expertise to optimize your designs.

For fitting designers, consulting with Fecision’s engineers ensures your materials meet specific application needs. Explore our material selection guide to find the best options for your project. Ready to optimize your designs? Request an instant DFM analysis today.