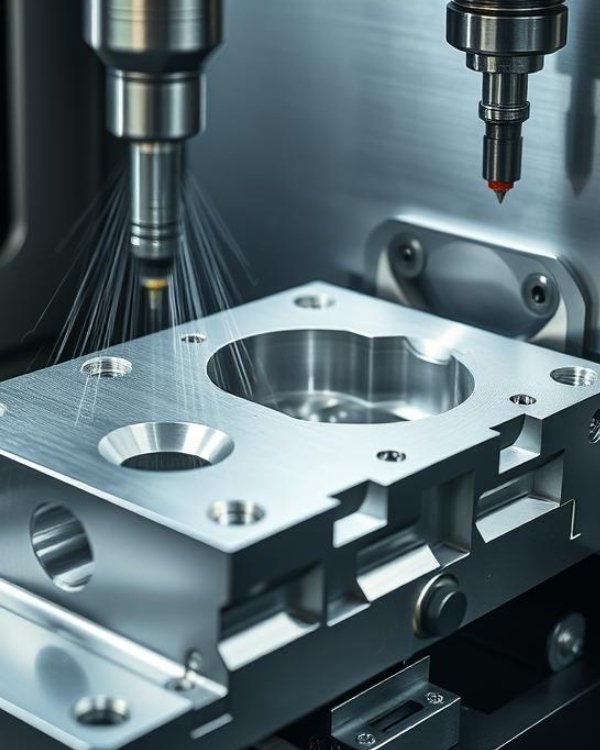

Steel Machining Services

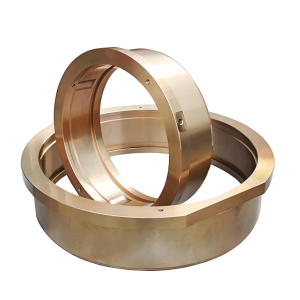

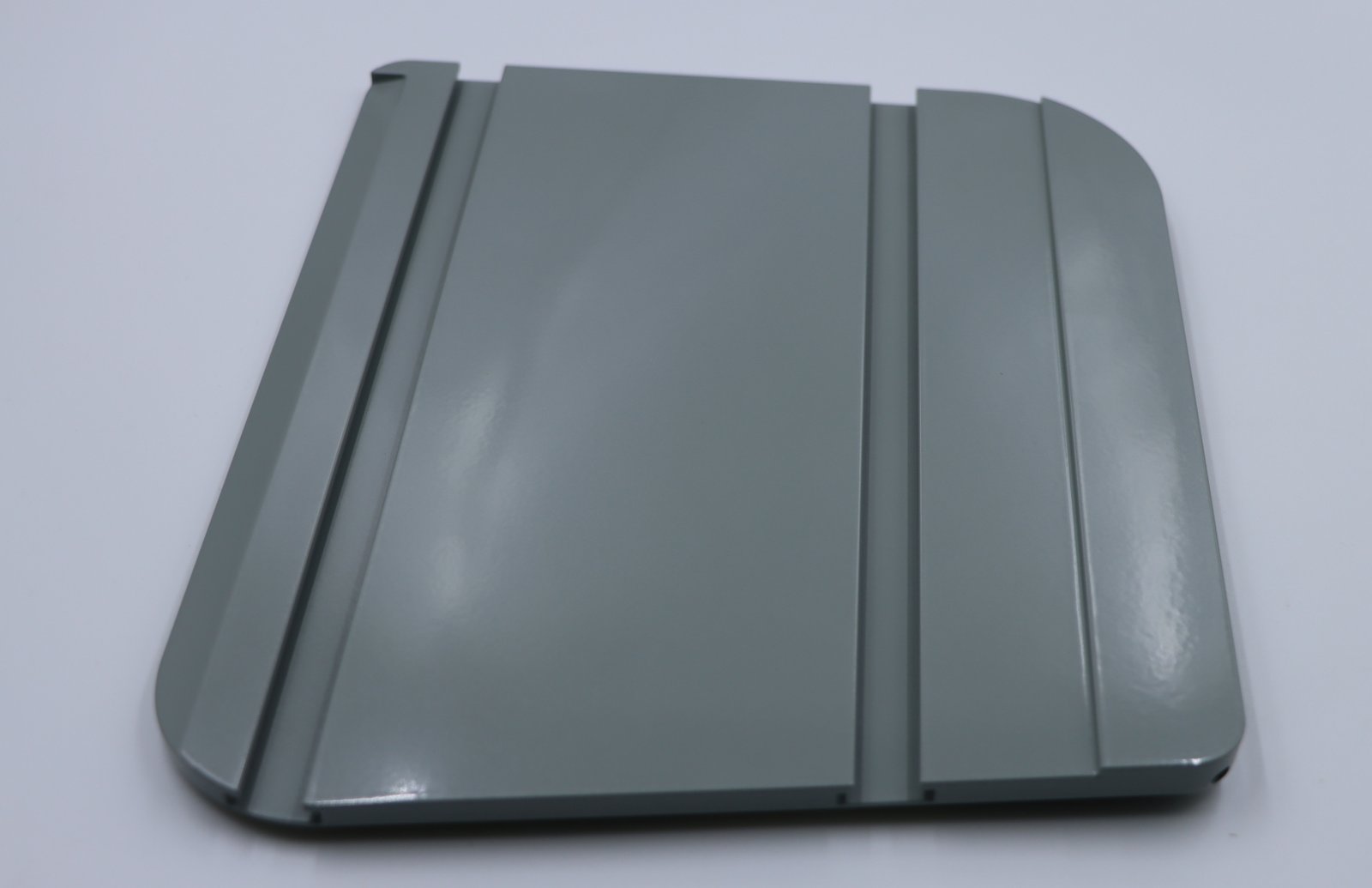

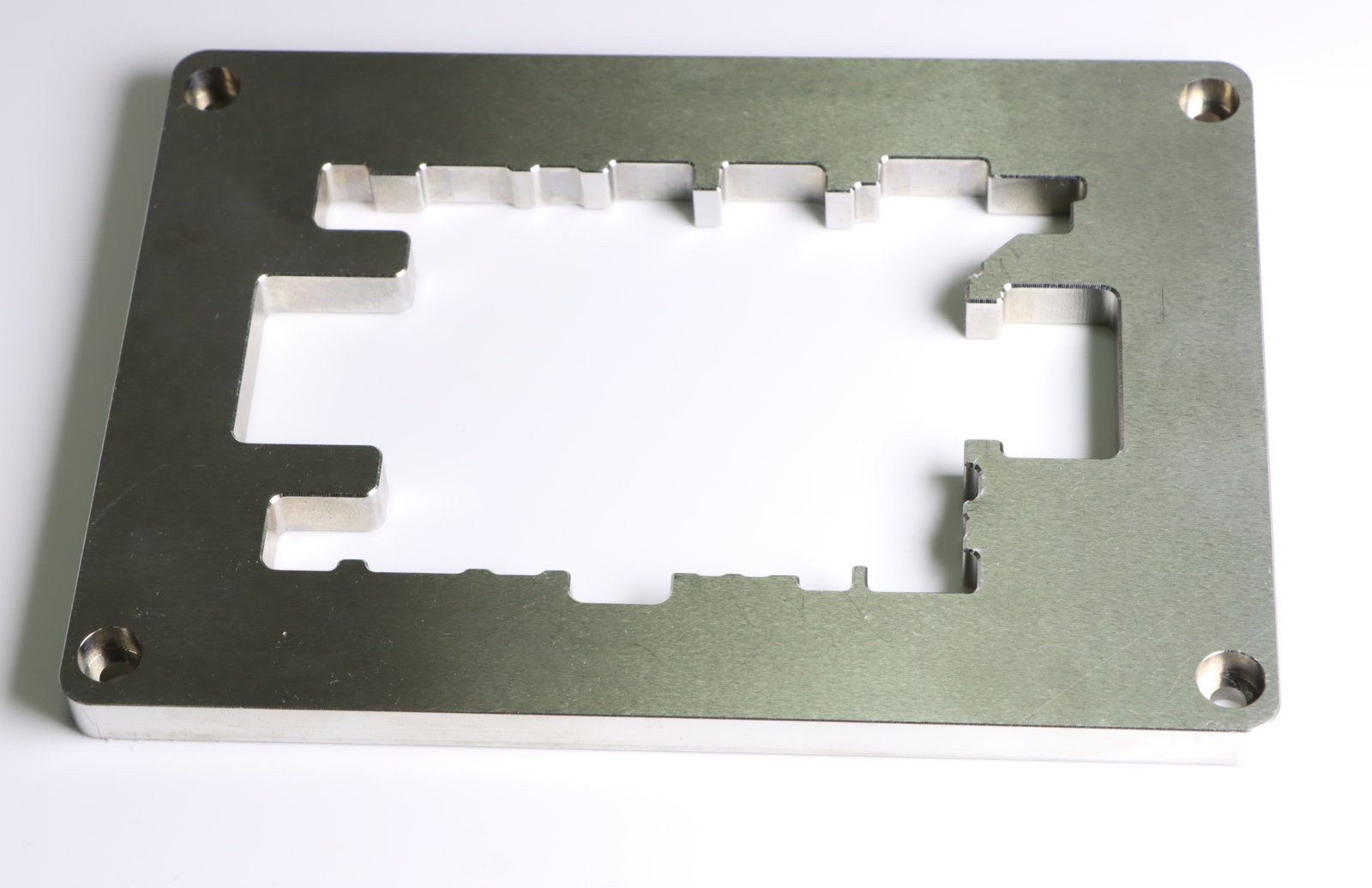

At Fecision, we specialize in precision steel CNC machining services that deliver exceptional quality, accuracy, and reliability. Our advanced manufacturing capabilities enable us to transform your designs into high-performance steel components with tight tolerances and superior surface finishes.

Various Options

Functionality

Cost-effectiveness

| Specification | Capability |

| Machining Tolerance | Standard: ±0.005″ (±0.127mm) |

| Precision: ±0.001″ (±0.025mm) | |

| Maximum Part Dimensions | 24″ x 18″ x 12″ (610mm x 457mm x 305mm) |

| Minimum Feature Size | 0.020″ (0.5mm) |

| CNC Machines | 3-axis, 4-axis, and 5-axis CNC mills and lathes |

| Thread Types | UNC, UNF, NPT, Metric, Custom |

| Production Volume | Prototypes to 100,000+ units |

| Quality Control | ISO 9001:2015 certified, CMM inspection |

Steel for CNC Machining

Steel remains one of the most versatile and widely used materials in CNC machining due to its exceptional combination of strength, durability, and cost-effectiveness.

Key Properties

- Strength-to-Weight Ratio: Steel offers excellent structural integrity while maintaining reasonable weight.

- Hardness and Wear Resistance: Depending on the alloy and heat treatment, steel can provide exceptional hardness and resistance to wear.

- Thermal Stability: Steel maintains its mechanical properties across a wide temperature range.

- Machinability: Varies by grade, with low-carbon steels being easier to machine than high-carbon or alloy steels.

- Corrosion Resistance: Stainless steel grades offer excellent resistance to rust and corrosion.

- Cost-Effectiveness: Steel provides an excellent balance of performance and affordability compared to exotic metals.

- Heat Treatment Options: Steel can be hardened, tempered, or annealed to achieve specific mechanical properties.

- Surface Finish Potential: Steel can be machined to achieve excellent surface finishes and can accept various coatings.

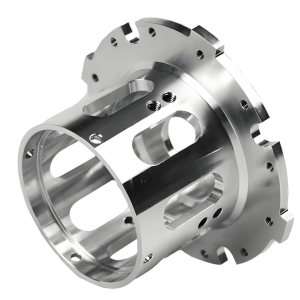

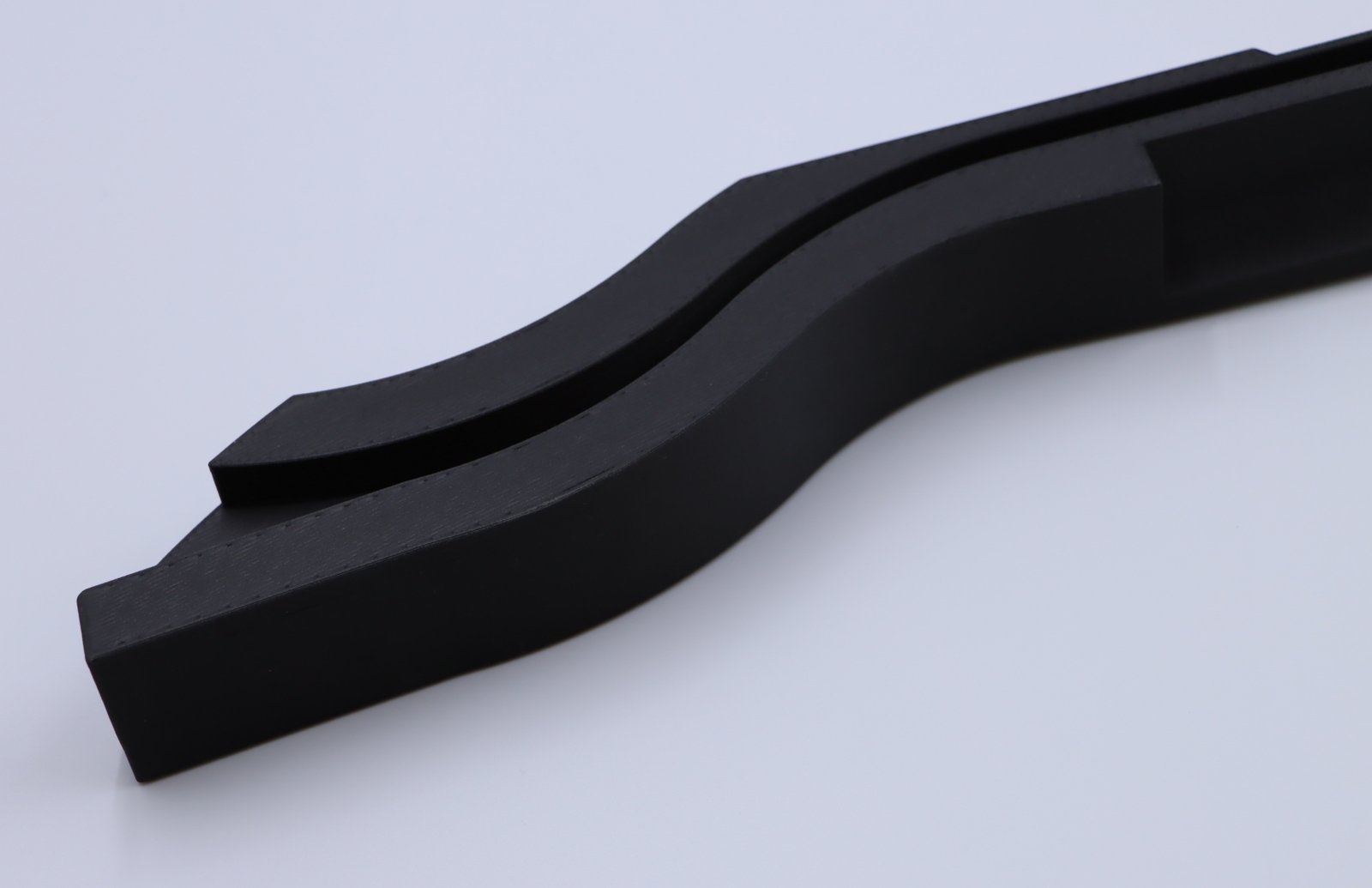

3-Axis Milling

Ideal for flat surfaces, holes, slots, and pockets in steel parts with standard geometries.

4-Axis Machining

Enables rotation around one axis for complex features and improved access to multiple sides.

5-Axis Machining

Ultimate flexibility for creating complex geometries and undercuts in a single setup.

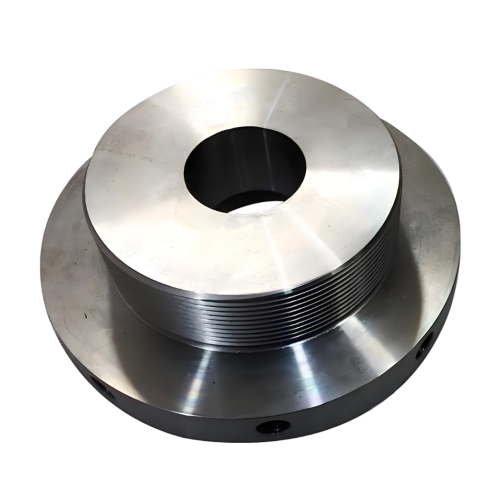

CNC Turning

Precision machining of cylindrical steel components with tight tolerances.

Multi-Axis Turning

Live tooling capabilities for milled features on turned parts.

Swiss-Type Machining

Ultra-precise turning for small, complex steel components.

Speak With Our Engineering Team

Our engineering team can work with your specific requirements.

Pros and Cons of Steel CNC Machining

When considering materials for your CNC machining project, it's important to understand both the advantages and limitations of steel.

This balanced perspective will help you make informed decisions about material selection for your specific application.

Advantages of Steel CNC Machining

- Superior Strength: Steel offers exceptional mechanical strength, making it ideal for structural and load-bearing components.

- Excellent Durability: Steel parts withstand wear, impact, and fatigue better than many alternative materials.

- Versatility: With numerous alloys available, steel can be tailored to specific application requirements.

- Heat Resistance: Steel maintains its properties at elevated temperatures where other materials might fail.

- Cost-Effective: Steel provides excellent value, especially for medium to high-volume production runs.

- Weldability: Most steel grades can be easily welded for assembly or repair.

- Magnetic Properties: Steel’s ferromagnetic nature is advantageous for certain applications.

Limitations of Steel CNC Machining

- Tool Wear: Harder steel grades can accelerate cutting tool wear, increasing tooling costs.

- Machining Time: Steel typically requires slower cutting speeds than aluminum or plastics.

- Weight: Steel’s higher density results in heavier components compared to aluminum or composites.

- Corrosion Susceptibility: Carbon steels require additional finishing to prevent rust and corrosion.

- Energy Consumption: Machining steel requires more power and generates more heat than softer materials.

- Post-Processing Requirements: Some steel parts require heat treatment or stress relief after machining.

- Complex Geometries: Extremely intricate features can be more challenging to machine in harder steel grades.

Subtypes of Steel for CNC Machining

Fecision works with a comprehensive range of steel grades to meet diverse application requirements.

Each steel type offers unique properties that make it suitable for specific uses in industries ranging from automotive and aerospace to medical and general manufacturing.

Carbon Steels

- Core Characteristics: Carbon steel is primarily composed of iron (Fe) and carbon (C), with minimal impurities (e.g., Si, Mn). Its mechanical properties are mainly determined by carbon content—higher carbon content leads to higher hardness and strength but lower ductility.

- Common Applications: Widely used in construction, machinery, automotive, and general manufacturing due to its low cost and good processability.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

Q235

375–500

≥235

~170

130–160

≥26

7.85

400

T10

600–700

≥300

~250

210-250

≥10

7.85

350

1010

320 - 420

170 - 210

160 - 180

60 - 80

30 - 40

7.85

425

1020

420 - 550

240 - 290

190 - 220

70 - 95

25 - 35

7.85

425

1040

550 - 700

310 - 380

260-290

110 - 140

15 - 25

7.85

400

1045

600–700

≥355

280

190–220

≥16

7.85

450

1018

440 - 590

290 - 370

190 - 220

111-137

28-35

7.85

425

12L14

400 - 500

220 - 270

180 - 200

65 - 90

20 - 30

7.85

400

Alloy Steels

- Core Characteristics: Alloy steel is carbon steel with added alloying elements (e.g., Cr, Ni, Mo, Mn) to enhance specific properties (e.g., strength, toughness, corrosion resistance). Classified by total alloy element content.

- Common Applications: Used in high-performance components for automotive, aerospace, and heavy machinery.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

Q345

470–630

≥345

~230

140–180

≥21

7.85

450

Q355

470–630

≥355

~230 - 260

130–170

≥22

7.85

450

40Cr

≥1000 ( heat treatment)

≥800 ( heat treatment)

~450

240–280

≥9

7.85

500

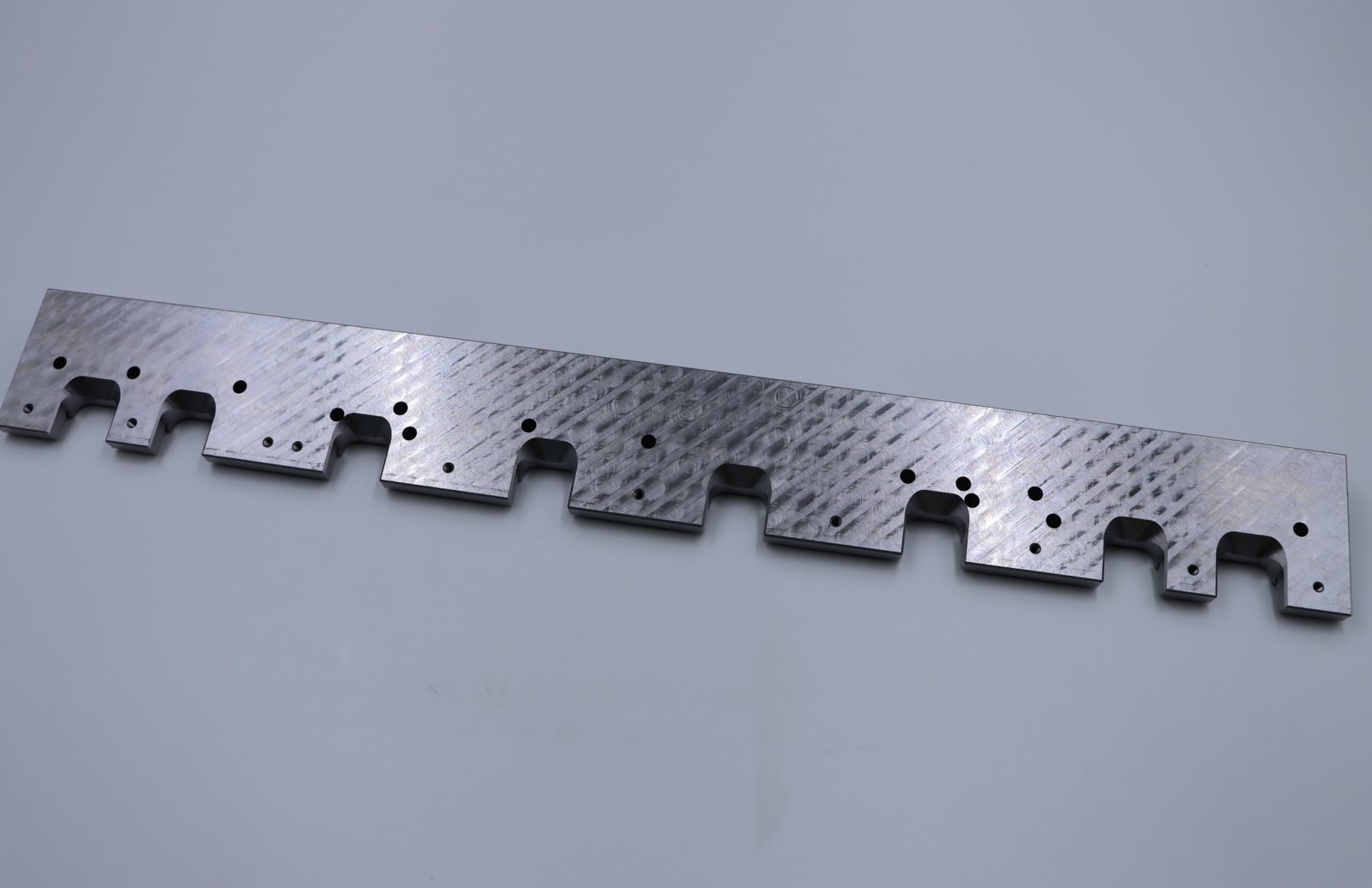

Tool Steels

- Core Characteristics: Tool steel emphasizes high hardness, wear resistance, and heat resistance for manufacturing cutting tools, molds, and gauges.

- Common Applications: Carbon tool steel for hand saws, files; Alloy tool steel for cold stamping dies, hot forging dies; High-speed tool steel for milling cutters, drills.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

A2

1800-2200

1600 - 1900

550-650

57-62

5-8

7.85

315

D2

2000-2500

1800-2100

600-700

58-63

3-5

7.75

260

Structural Steels

- Core Characteristics: Structural steel prioritizes load-bearing capacity, ductility, and weldability. Divided into engineering structural steel (for large structures) and mechanical structural steel (for machine parts).

- Common Applications: Engineering structural steel for bridges, buildings, steel structures; Mechanical structural steel for gears, shafts, connecting rods.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

Q460

550-720

≥460

~280

160-200

≥17

7.85

420

20CrMnTi

≥850 (heat treatment)

≥1100 (heat treatment)

~60 (T6)

250-300

≥10

7.85

480

Steel CNC Machining Surface Finishing Options

The right surface finish not only enhances the appearance of your steel CNC machined parts but can also improve their performance, corrosion resistance, and longevity.

Fecision offers a comprehensive range of surface finishing options to meet your specific requirements.

Mechanical Finishes

As-Machined

The natural finish after CNC machining with visible tool marks. Cost-effective for non-cosmetic or internal components.

Bead Blasting

Creates a uniform matte finish by propelling fine glass beads at the surface. Excellent for removing tool marks and creating a consistent appearance.

Polishing

Produces a smooth, reflective surface through progressive abrasive processes. Ideal for parts requiring low friction or aesthetic appeal.

Chemical Finishes

Black Oxide

Creates a black surface conversion coating that provides mild corrosion resistance while maintaining dimensional accuracy.

Passivation

Chemical process that enhances the corrosion resistance of stainless steel by removing free iron from the surface.

Bluing

Traditional finish that creates a blue-black appearance on steel while providing minimal corrosion protection.

Plating and Coating

Zinc Plating

Electroplating process that deposits a layer of zinc for excellent corrosion protection. Available in clear, yellow, or black finishes.

Nickel Plating

Provides a bright, decorative finish with good corrosion resistance and hardness. Ideal for both functional and aesthetic applications.

Powder Coating

Applies a durable, colored polymer coating that offers excellent corrosion protection and aesthetic appeal in various colors.

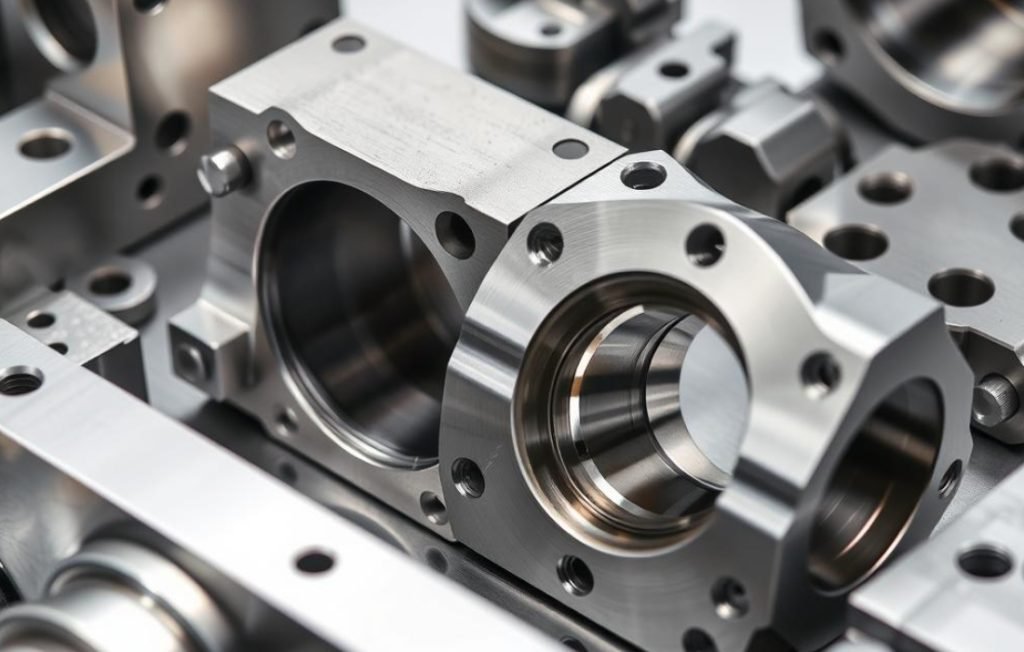

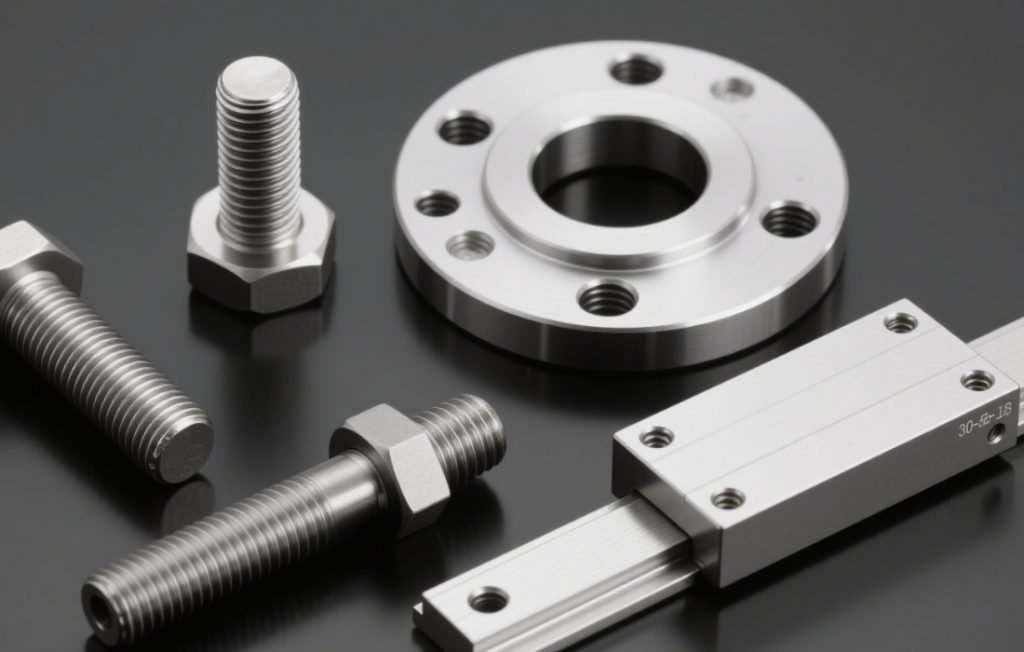

Applications of CNC Machined Steel Parts

Steel CNC machined components are integral to countless industries due to their exceptional strength, durability, and versatility.

At Fecision, we produce precision steel parts for diverse applications across multiple sectors.

Aerospace

The aerospace industry demands the highest levels of precision and reliability, making custom steel CNC machining essential for critical components.

- Structural Components: Brackets, fittings, and mounting hardware

- Landing Gear Parts: Bushings, pins, and structural elements

- Engine Mounts: Precision brackets and support structures

- Control System Components: Linkages, levers, and actuator parts

Automotive

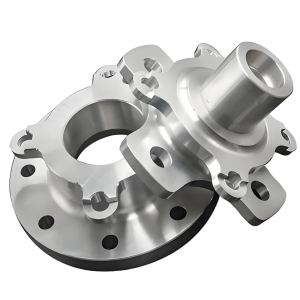

The automotive sector relies heavily on precision steel CNC machining for critical components that must withstand extreme conditions and maintain tight tolerances.

- Engine Components: Camshafts, crankshafts, connecting rods, and valve bodies

- Transmission Parts: Gears, shafts, and housings

- Suspension Components: Control arms, brackets, and mounting hardware

- Brake Systems: Calipers, master cylinders, and ABS components

Medical

Medical devices and equipment require exceptional precision and biocompatibility, making stainless steel CNC machining a preferred manufacturing method.

- Surgical Instruments: Forceps, scalpel handles, and retractors

- Implant Components: Bone plates, screws, and joint replacement parts

- Diagnostic Equipment: Housings, frames, and mechanical components

- Laboratory Equipment: Fixtures, stands, and precision mechanisms

Industrial

Heavy machinery and industrial equipment rely on robust steel components that can withstand harsh operating conditions and continuous use.

- Hydraulic Components: Valve bodies, pistons, and cylinders

- Power Transmission: Gears, shafts, sprockets, and couplings

- Tooling and Fixtures: Jigs, molds, dies, and production tooling

- Robotic Components: Structural elements, end effectors, and mounting brackets

Steel CNC Machining FAQs

Quality assurance at Fecision involves multiple layers of verification:

- ISO 9001:2015 certified quality management system

- In-process inspections during machining

- Coordinate Measuring Machine (CMM) verification for critical dimensions

- Material certifications and traceability

- First article inspection reports for production runs

- Final visual and dimensional inspection before shipping

We can also provide custom inspection protocols and documentation based on your specific requirements.

We accept all major 3D CAD file formats, including:

- STEP (.stp, .step)

- IGES (.igs, .iges)

- SolidWorks (.sldprt, .sldasm)

- AutoCAD (.dwg, .dxf)

- Parasolid (.x_t, .x_b)

- CATIA (.CATPart, .CATProduct)

- Pro/ENGINEER and Creo (.prt, .asm)

For optimal results, we recommend STEP or IGES formats as they are universally compatible. We also accept 2D drawings in PDF format to supplement 3D models with specific tolerances and annotations.

Need to discuss steel machinig project?

Our engineering team specializes in industry-specific solutions tailored to your exact requirements.

Ready to Get Started?

Contact us today to discuss your steel CNC machining project or request a quote.