Stainless Steel Machining Services

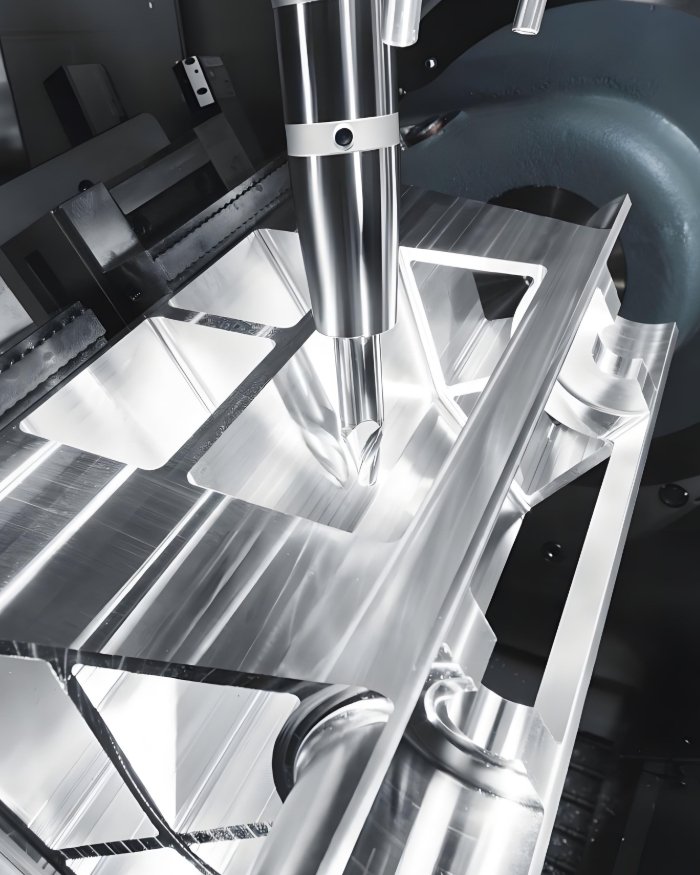

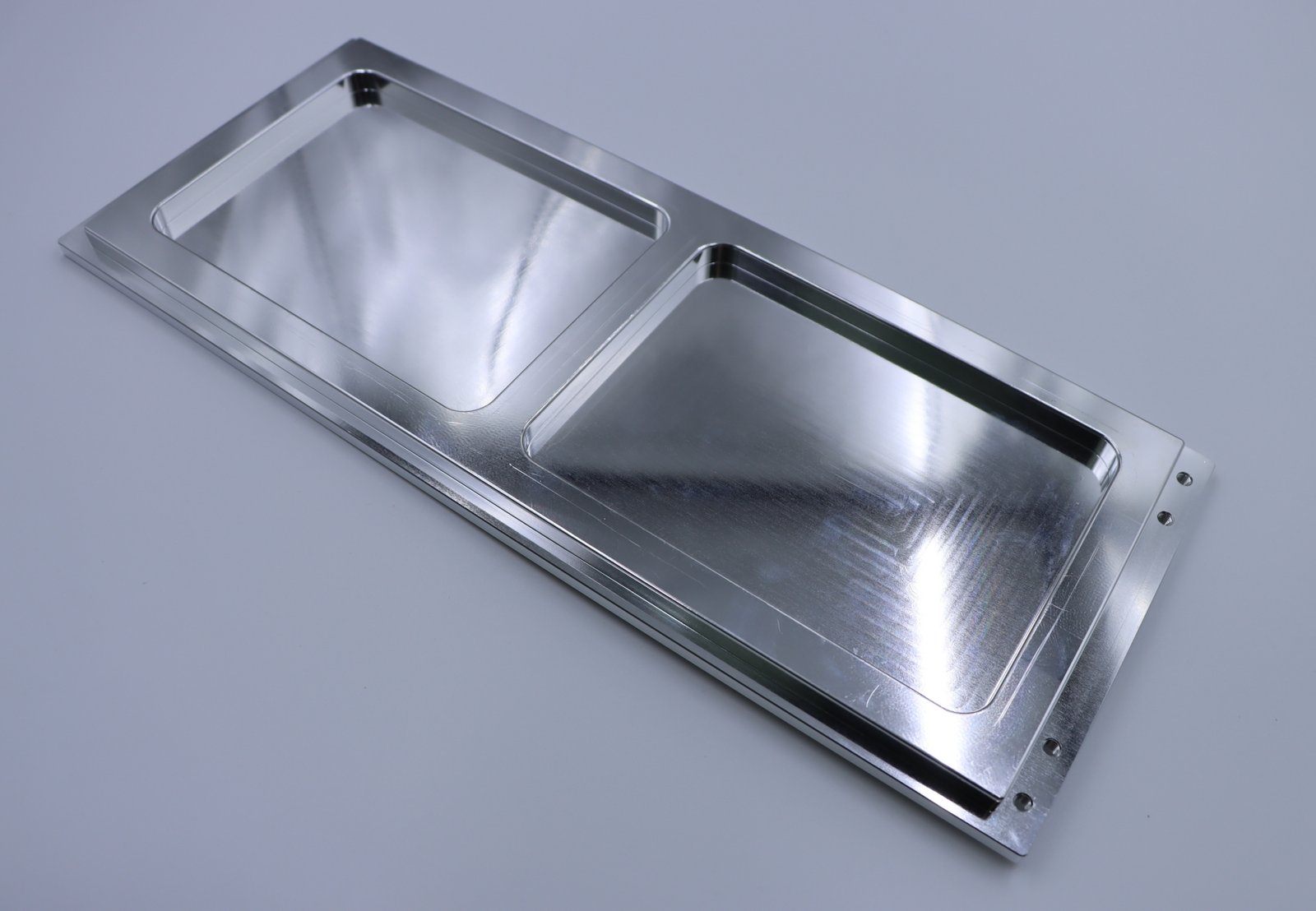

Stainless steel CNC machining combines advanced computer-controlled precision with one of manufacturing’s most versatile and durable materials. This specialized process creates high-quality components with exceptional corrosion resistance, strength, and dimensional accuracy for demanding applications across industries.

Various Options

Functionality

Cost-effectiveness

| Specification | Capability | Notes |

| Standard Tolerance | ±0.005″ (0.127mm) | General machining tolerance |

| Precision Tolerance | ±0.001″ (0.0254mm) | Available for critical features |

| Material Thickness | 0.020″ to 6.0″ (0.5mm to 152mm) | Varies by grade and application |

| Maximum Part Size | 24″ × 36″ × 18″ (610mm × 914mm × 457mm) | Larger sizes available upon request |

| Surface Roughness | Ra 0.8 to 3.2 μm | Finer finishes available with post-processing |

| Machining Equipment | 3-axis, 4-axis, and 5-axis CNC machines | Selected based on part complexity |

CNC Machining of Stainless Steel

Fecision stainless steel CNC machining services deliver custom components with tight tolerances, superior surface finishes, and consistent quality. Whether you need prototypes or production runs, our expertise ensures your parts meet exact specifications while maximizing the inherent benefits of stainless steel.

Our comprehensive approach to stainless steel CNC machining ensures consistent quality and precision through every stage of production. Each step is optimized specifically for the challenges of working with stainless steel materials.

Machining Process

- DFM (Design for Manufacturability) analysis

- Material selection guidance

- Tolerance optimization

- 3D model preparation

- CAM programming optimized for stainless steel

- Tool selection for specific steel grades

- Cutting parameter optimization

- Fixture design and setup

- Roughing operations with heavy material removal

- Semi-finishing to approach final dimensions

- Finishing passes for dimensional accuracy

- Feature-specific operations (threading, etc.)

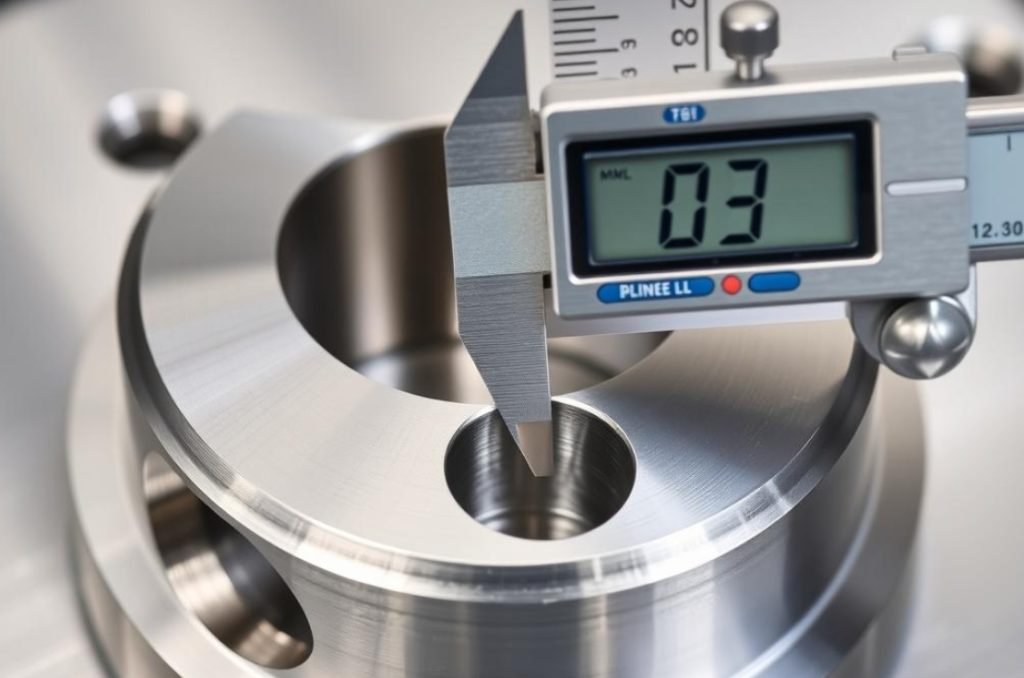

- In-process inspection

- CMM (Coordinate Measuring Machine) verification

- Surface finish measurement

- Material certification verification

- Deburring and edge breaking

- Selected surface treatments

- Passivation for corrosion resistance

- Final cleaning and preparation

- Comprehensive quality documentation

- Custom packaging for protection

- Material traceability documentation

- On-time delivery logistics

Speak With Our Engineering Team

Discuss your project details with our expert CNC machining engineers.

Strengths and Limitations of Stainless Steel for CNC Machining

Strengths of Stainless Steel

- Exceptional corrosion resistance in harsh environments

- High strength-to-weight ratio compared to many metals

- Excellent heat resistance up to 1700°F (925°C) for certain grades

- Superior hygiene properties for medical and food applications

- Aesthetic appeal with various finishing options

- Long service life with minimal maintenance

- 100% recyclable material for sustainability

Limitations of Stainless Steel

- Work hardening during machining requires specialized techniques

- Accelerated tool wear compared to softer materials

- Higher machining costs versus aluminum or mild steel

- Poor thermal conductivity creates heat management challenges

- Stringy chip formation can complicate the machining process

- Some grades have limited machinability ratings

- Requires proper coolant and cutting strategies

Types and Grades of Stainless Steel for CNC Machining

Different applications require specific stainless steel grades to achieve optimal performance.

Our stainless steel CNC machining capabilities extend across all major types, each offering unique properties and machining characteristics.

Austenitic

Stainless Steels

- Characteristics: Non-magnetic, excellent corrosion resistance, high toughness, weldable and formable. Contains high chromium (16-26%) and nickel (8-25%). Most widely used stainless steel category.

- Common Applications: Food processing equipment, architectural trim, medical devices, chemical containers, marine components.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

201

520-750

275

180

≤241

40

7.86

815

301

515-1380*

205

170-240*

≤207-430*

40-10*

7.93

870

303

515-655

205

170

≤201

40

7.93

870

304

515-720

205

170

≤201

40

7.93

870

304L

485-690

170

150

≤201

40

7.93

870

316

515-720

205

170

≤217

40

8.0

870

316L

485-690

170

150

≤217

40

8.0

870

Ferritic

Stainless Steels

- Characteristics: Magnetic, low cost (low or no nickel), good oxidation resistance, but limited toughness and weldability. Chromium content: 10.5-30%.

- Common Applications: Automotive exhaust systems, household appliances (refrigerator panels), decorative trim, heat exchangers.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

403

415-635

240

170

≤183

20

7.7

815

409L

380-550

205

140

≤170

18

7.7

650

Martensitic

Stainless Steels

- Characteristics: Magnetic, heat-treatable (via quenching/tempering) for high hardness, moderate corrosion resistance. Chromium: 11-17%; higher carbon content than ferritics.

- Common Applications: Knives, valves, pump shafts, surgical instruments, bearings.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

410

517-725

275

205

≤207

20

7.7

650

420

725-1035

485

275

≤235

12

7.7

600

440C

1790-2000

690

345

≤269

5

7.7

120

2Cr13

635-830

345

240

≤217

18

7.75

600

3Cr13

735-930

440

270

≤235

15

7.75

550

4Cr13

835-1080

540

300

≤255

12

7.75

500

Duplex

Stainless Steels

- Characteristics: Combined austenitic-ferritic structure (≈50% each), high strength (twice that of austenitics), excellent resistance to stress corrosion. Chromium: 21-27%; nickel: 4-7%.

- Common Applications: Oil/gas pipelines, desalination plants, chemical processing equipment, offshore structures.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

2205

620-850

450

290

≤290

25

7.8

315

2507

800-1000

550

345

≤310

25

7.8

315

Precipitation Hardening

Stainless Steels

- Characteristics: High strength (via aging treatment to form precipitates), good corrosion resistance, moderate toughness. Used where strength-to-weight ratio is critical.

- Common Applications: Aerospace components (aircraft frames), high-pressure valves, precision molds, springs.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

17-4 PH

860-1310

725-1100

380

270-388

10–15

7.8

315

17-7 PH

930-1380

760-1170

415

280-390

10-15

7.8

370

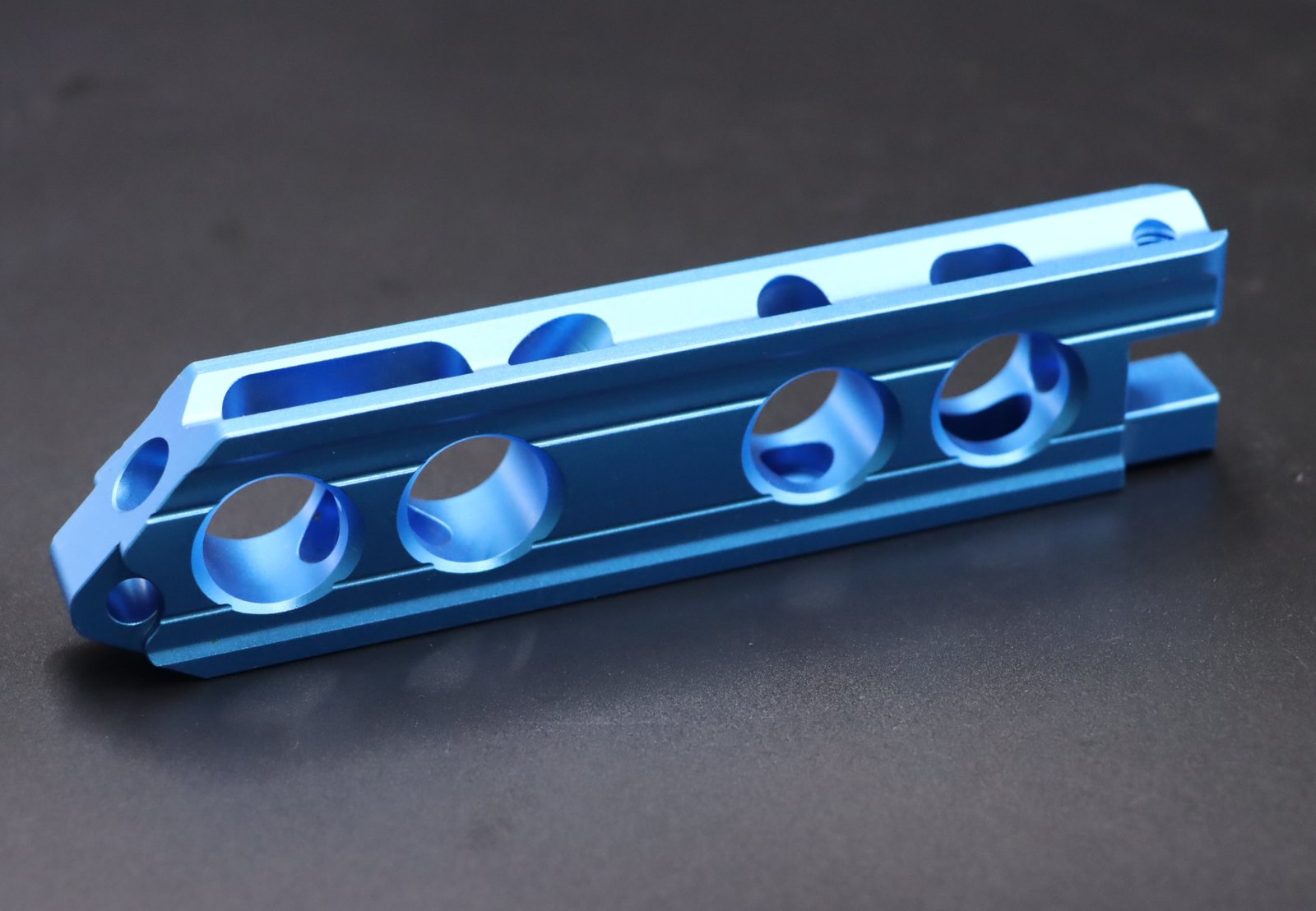

Surface Finish Options for Stainless Steel

The appearance and performance of stainless steel machined parts can be significantly enhanced through various finishing processes.

We offer comprehensive surface treatment options to meet aesthetic, functional, and corrosion resistance requirements.

Mechanical Finishes

- Polishing: Mirror (Ra 0.1μm) to satin (Ra 0.5μm) finishes

- Bead Blasting: Uniform matte texture (Ra 1.6-3.2μm)

- Brushing: Directional grain pattern for aesthetic appeal

Chemical Treatments

- Passivation: Enhanced corrosion resistance

- Electropolishing: Microscopic smoothing and brightening

- Chemical Etching: Surface texturing and marking

Coating Applications

- PVD Coating: Decorative and wear-resistant layers

- Powder Coating: Colored protective finishes

- Teflon Coating: Non-stick and chemical resistance

Applications of CNC Machined Stainless Steel Parts

The exceptional properties of stainless steel make it ideal for demanding applications across numerous industries.

Our CNC machining stainless steel expertise delivers precision components for critical applications where reliability and performance are essential.

Aerospace & Defense

- Hydraulic system components

- Structural fasteners and brackets

- Fuel system components

- Navigation and control hardware

Automotive

- Exhaust system components

- Fuel delivery systems

- Turbocharger components

- Structural brackets and mounts

Medical

- Surgical instruments and implants

- Laboratory equipment components

- Pharmaceutical processing equipment

- Medical device housings and frames

Chemical Processing

- Valve bodies and trim

- Pump components and impellers

- Heat exchanger parts

- Pressure vessel components

Marine & Offshore

- Pump and valve components

- Propeller and shaft hardware

- Deck equipment and fittings

- Underwater sensor housings

Food & Beverage

- Processing equipment components

- Sanitary fittings and valves

- Mixing and blending equipment

- Conveyor and handling systems

Stainless Steel Machining FAQs

Need to discuss stainless steel machinig project?

Our team of experts is ready to help you achieve exceptional results with your stainless steel components. From material selection to final delivery, we provide comprehensive support throughout your project.

Ready to Start Your Stainless Steel Machining Project?

Contact us today to discuss your project requirements and discover how our specialized stainless steel machining capabilities can help you achieve your manufacturing goals with confidence.