Did you know that snap fit joints represent one of the most versatile and cost-effective connection methods in modern product design? These ingenious mechanical fastening systems utilize the elastic properties of materials to create secure connections without requiring additional hardware.

You can dramatically reduce assembly time while maintaining structural integrity, making them ideal for both mass production and custom applications. By understanding the fundamental principles behind these joints, you’ll be able to optimize your designs for efficiency, durability, and ease of assembly.

As you explore the world of snap fit joints, you’ll discover their advantages and learn how to implement them effectively in your product designs.

Understanding Snap Fit Joints

By understanding snap fit joints, you can unlock the potential for more efficient and cost-effective product design. Snap fit joints are a type of mechanical connection that allows for easy assembly and disassembly of parts.

Definition and Basic Principles

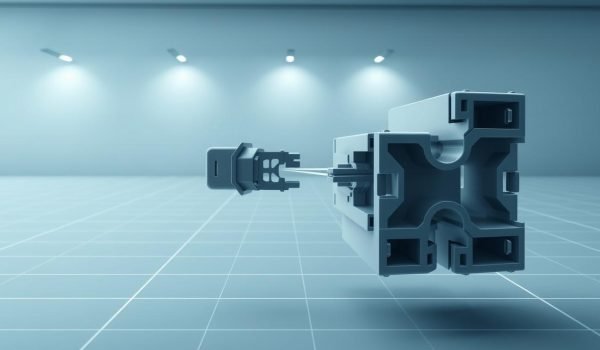

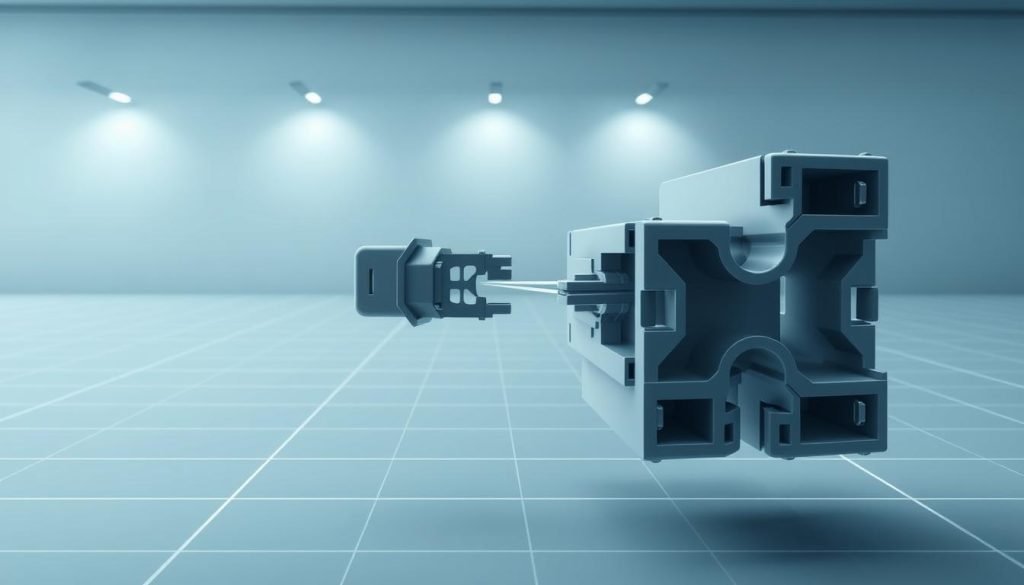

Snap fit joints are designed to catch a feature in the mating component, deflecting during assembly and then securing the parts together. This type of joint is commonly used in various industries due to its simplicity and effectiveness. The design of snap fit joints determines whether the connection will be permanent or temporary, depending on whether the joints can be released by tools or force.

How Snap Fit Joints Work

The working principle of snap fit joints involves a sequence of deflection, engagement, and retention, creating a secure mechanical connection. During assembly, you apply force to bring the components together, causing the protruding feature to deflect temporarily. Once the feature clears the interference, it springs back to its original position, creating a mechanical interlock that resists separation. The forces involved in snap fit operation include insertion force, retention force, and removal force. Properly designed snap fit joints distribute stress evenly, preventing stress concentration that could lead to premature failure.

The success of a snap fit joint depends on the material’s ability to undergo sufficient elastic deformation without experiencing plastic deformation or failure during assembly. By understanding how snap fit joints work, you can design more efficient and reliable products.

Types of Snap Fit Joints

Understanding the different types of snap fit joints is crucial for effective product design. Snap fit joints are categorized into various types based on their design and functionality, each with its unique characteristics and applications.

Cantilever Snap Fits

Cantilever snap fits are one of the most common types of snap fit joints. They feature a cantilever beam on one component that snaps into a groove or undercut on the mating component. This design allows for easy assembly and disassembly, making it ideal for applications where parts need to be frequently connected and disconnected.

The cantilever design provides a flexible and robust connection, suitable for various materials, including plastics, metals, and composites. The length and thickness of the cantilever beam can be adjusted to achieve the desired deflection force and retention strength.

Torsional Snap Fits

Torsional snap fits involve a twisting motion to engage or disengage the joint. This type is particularly useful in applications where a secure, locking mechanism is required. The torsional design provides a high level of retention force, making it suitable for use in demanding environments.

The torsional snap fit is often used in components that require a high degree of rotational stability, such as in automotive or aerospace applications.

Annular Snap Fits

Annular snap fits are used for joining circular or annular components. They feature a snap fit around the circumference of the parts, providing a secure and evenly distributed connection. This design is commonly used in applications such as bottle caps, containers, and other circular assemblies.

The annular design allows for a strong and reliable joint, capable of withstanding various environmental conditions.

U-shaped and L-shaped Snap Fits

U-shaped and L-shaped snap fits represent specialized variations of cantilever designs, offering enhanced performance characteristics for specific application requirements. The U-shaped configuration features a double-sided cantilever that provides flexibility from both ends, while the L-shaped snap fit excels at providing lateral support and locking.

These designs are particularly valuable in applications requiring strong gripping force, such as electronic housings, consumer product casings, and automotive interior trim components. They offer practical solutions for easy assembly and disassembly while maintaining robust connections.

Both U-shaped and L-shaped snap fits can be manufactured from various materials, including plastics, metals, and composites, providing design flexibility across different industries and applications. Their unique geometries often eliminate the need for complex mold features, potentially reducing manufacturing costs and complexity.

Key Design Considerations for Snap Fit Joints

When designing snap fit joints, several key considerations must be taken into account to ensure optimal performance. You need to carefully evaluate various design factors to create effective snap fit joints that meet your specific application requirements.

Material Selection

Material selection plays a crucial role in the design of snap fit joints. You must choose a material that provides the necessary strength, flexibility, and durability for your specific application. The material’s properties will directly impact the joint’s performance, so it’s essential to select a material that meets your requirements.

Stress and Strain Analysis

Performing a stress and strain analysis is vital to ensure that your snap fit joint can withstand the expected loads and stresses. You should analyze the joint’s behavior under various conditions to identify potential failure points and optimize the design accordingly.

Deflection Force Calculations

Deflection force calculations are necessary to determine the force required to assemble and disassemble the snap fit joint. You must calculate the deflection force to ensure that it’s within the acceptable range for your application, taking into account factors like material properties and joint geometry.

Tolerance Requirements

Tolerance requirements play a significant role in snap fit joint performance, as they directly affect both assembly forces and the security of the final connection. You must carefully consider manufacturing tolerances when designing snap fits, as variations in part dimensions can significantly impact the engagement depth, assembly forces, and retention strength.

For plastic injection molded parts, material shrinkage must be factored into tolerance calculations, with typical shrinkage rates ranging from 0.5% to 2% depending on the specific polymer and processing conditions. The gap between mating components typically ranges from 0.1mm to 0.5mm, with tighter tolerances providing more consistent assembly forces but potentially increasing manufacturing costs.

Design tolerances for plastic snap fits generally fall within ±0.1mm to ±0.2mm, while metal snap fits may require tighter tolerances of ±0.05mm to ±0.1mm to ensure proper function. Tolerance stacking across multiple features must be analyzed to prevent cumulative errors that could lead to either interference fits that are impossible to assemble or loose connections that fail to engage properly.

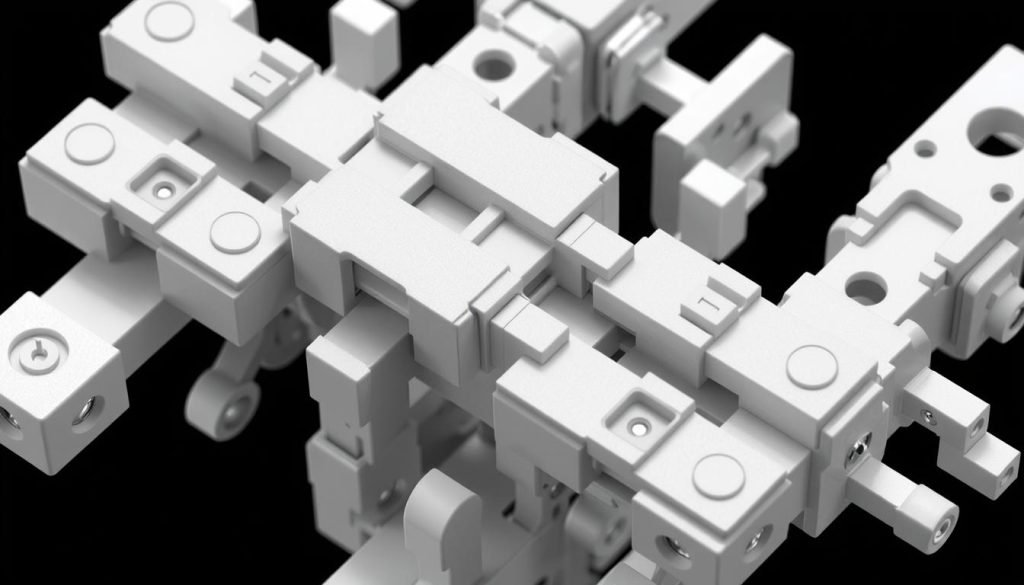

Manufacturing Methods for Snap Fit Joints

To produce snap fit joints, manufacturers can choose between traditional injection molding and modern 3D printing techniques. The choice of manufacturing method depends on factors such as production volume, material requirements, and design complexity.

Injection Molding Process

Injection molding is a widely used method for producing high-volume snap fit joints. This process involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. Injection molding offers high precision, consistency, and cost-effectiveness for large production runs. The process allows for the creation of complex geometries and intricate details, making it suitable for producing snap fit joints with precise tolerances.

3D Printing Applications

3D printing has revolutionized the production of snap fit joints, especially for prototyping and small-batch production. Various 3D printing technologies, such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA), offer distinct advantages. FDM provides cost-effectiveness, SLS delivers superior mechanical properties, and SLA creates highly detailed parts. The layer-by-layer nature of 3D printing introduces anisotropic mechanical properties, meaning that snap fit strength and flexibility vary depending on the load direction relative to the print layers. This technology enables the production of complex snap fit geometries that would be impossible or prohibitively expensive to manufacture with traditional methods.

Common Issues with Snap Fit Design

When designing snap fit joints, several common issues can arise that may impact the performance and reliability of the final product. These issues can be broadly categorized into three main areas: stress concentration problems, material creep and fatigue, and tolerance and fit issues.

Stress Concentration Problems

Stress concentration is a significant issue in snap fit design, as it can lead to material failure. Sharp corners or abrupt changes in geometry can create stress concentrations, which can be mitigated by using smooth transitions and rounded corners. You should carefully analyze the design to minimize these concentrations and ensure the longevity of the joint.

Material Creep and Fatigue

Material creep and fatigue are other critical concerns in snap fit design. Under constant stress, materials can creep over time, leading to a loss of retention force. You must consider the material properties and the expected service conditions to design snap fits that can withstand these stresses. Fatigue is also a concern, particularly if the snap fit is subject to repeated assembly and disassembly.

Tolerance and Fit Issues

Tolerance and fit issues frequently plague snap fit designs, causing problems ranging from impossible assembly to loose connections. You must carefully balance tolerances to avoid both extremes. Manufacturing variations, material shrinkage, and environmental factors can all impact the effective fit of snap joints. Design strategies to address these issues include incorporating compliance features and using pilot features for initial alignment.

Best Practices for Effective Snap Fit Joints

To ensure the effectiveness of snap fit joints, it’s crucial to follow best practices in their design. Snap fit joints are a popular choice for various applications due to their ease of use and efficiency. However, their performance depends heavily on careful design considerations.

Optimizing Cantilever Design

Optimizing cantilever design is critical for the success of snap fit joints. You should consider the length, thickness, and material properties to achieve the desired balance between flexibility and strength. A well-designed cantilever snap fit ensures smooth assembly and disassembly while minimizing stress concentrations.

Reinforcement Techniques

Reinforcement techniques can significantly enhance the performance of snap fit joints. You can use various methods, such as adding ribs or modifying the snap fit geometry, to improve durability and resistance to stress. These techniques are particularly important for products that undergo frequent assembly and disassembly.

Design for Assembly and Disassembly

Designing snap fit joints with assembly and disassembly in mind is essential for creating user-friendly products. You should incorporate features like lead-in chamfers, alignment pins, and accessible release mechanisms to facilitate easy assembly and disassembly. This approach not only improves the user experience but also reduces the risk of damage during these processes.

By following these best practices, you can create snap fit joints that meet the specific requirements of your product, enhancing its overall performance and user satisfaction.

How to Install and Maintain Snap Fit Joints

To get the most out of snap fit joints, it’s essential to understand both the installation process and the maintenance required over time. Proper installation ensures that the joints function as intended, while regular maintenance can significantly extend the lifespan of the assembled parts.

Proper Installation Techniques

When installing snap fit joints, it’s crucial to follow the manufacturer’s guidelines or design specifications. You should align the parts carefully and apply even pressure to avoid damaging the snap features. For complex assemblies, consider using tools designed for the specific joint type to facilitate proper engagement.

Maintenance and Inspection Tips

Regular inspection is key to maintaining snap fit joints. Check for signs of wear, deformation, or disengagement, especially in joints that bear heavy loads or are subjected to vibration. Keep the joints clean and free from contaminants, as dirt and debris can interfere with proper fit and potentially accelerate wear. For products used in harsh environments, periodic cleaning with appropriate solvents can help maintain the integrity of the snap fit components.

Benefits and Drawbacks of Snap Fit Joints

Snap fit joints offer a range of benefits and drawbacks that designers must consider when developing products. These joints are widely used in various industries due to their unique characteristics.

Advantages in Product Design

Snap fit joints provide several advantages in product design, including a clean and aesthetic appearance due to their “invisible” nature. They simplify the assembly process, reducing the need for additional fasteners and thus saving time. The use of snap fit joints also allows for efficient use of materials and can contribute to a product’s overall strength when designed correctly.

By optimizing snap fit designs, manufacturers can improve product reliability and reduce production costs. The right material selection is crucial for maximizing the benefits of snap fit joints.

Limitations and Challenges

Despite their advantages, snap fit joints come with several limitations and challenges. Material constraints are a significant limitation, as snap fits require materials with appropriate elasticity and strength. The long-term reliability of snap fits can be compromised by factors such as creep, environmental exposure, and temperature fluctuations.

Snap fits typically offer lower strength compared to mechanical fasteners, limiting their application in high-load or safety-critical connections. The precision required for successful snap fit implementation can increase manufacturing costs, and disassembly challenges can complicate repairs or component replacement.

Applications of Snap Fit Joints

Snap fit joints have become an integral part of various industries, revolutionizing the way products are designed and assembled. Their versatility and functionality make them a crucial component in numerous applications.

Consumer Electronics

In consumer electronics, snap fit joints are used to assemble various components, such as battery covers and casings. They provide a secure and durable connection, ensuring that the product remains functional and aesthetically pleasing.

Automotive Industry

The automotive industry relies heavily on snap fit joints for various applications, including interior trim components and dashboard assemblies. They offer a reliable and efficient way to assemble parts, reducing production time and costs.

Medical Devices

Medical devices often require precise and reliable connections, making snap fit joints an ideal solution. They are used in various medical applications, such as diagnostic equipment and implantable devices, where precision and durability are critical.

Packaging Solutions

Packaging solutions represent one of the highest-volume applications for snap fit joints. They provide secure closure, tamper evidence, and consumer convenience across various product categories, including food containers and cosmetic packaging.

Conclusion

Snap fit joints have emerged as a valuable tool in product design, offering a balance of simplicity, functionality, and cost-effectiveness. You’ve gained insight into various snap fit types, including cantilever, torsional, and annular designs, each with unique advantages for specific applications.

By understanding design considerations, manufacturing methods, and best practices, you can create reliable snap fit connections that enhance your products’ performance and longevity. As product design evolves, snap fit joints will remain essential, continuing to find new applications across industries.