When it comes to injection molding, precision is everything. Whether you’re producing high-tolerance components or scaling up for mass manufacturing, even the smallest parts of an injection mold play a crucial role.

One such often-overlooked component is the locator ring in injection molding. Though it seems minor, this ring ensures the mold aligns perfectly with the machine’s nozzle every single time.

So, if you’ve ever wondered why your parts aren’t coming out quite right, this simple ring could be the unsung hero (or hidden culprit). Let’s understand what it is and how it works.

What is the Locating Ring in Injection Molding?

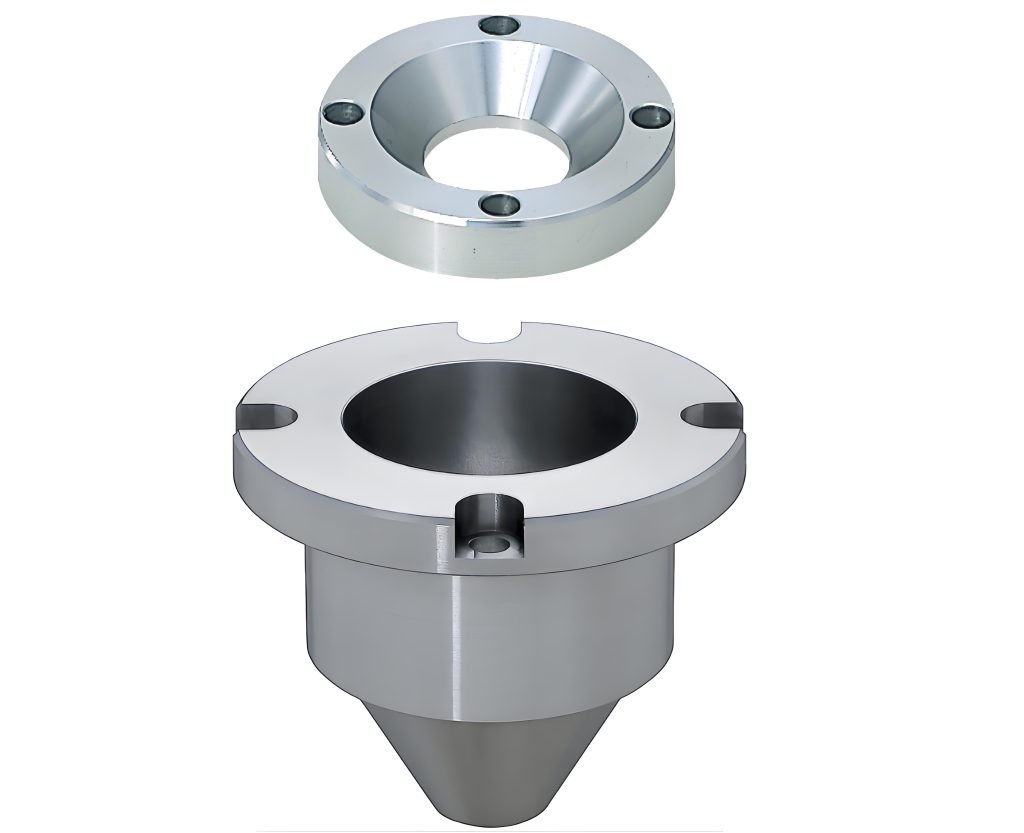

The locating ring is a circular metal component that sits on the mold’s top plate, right where the injection molding machine’s nozzle meets the mold. Its primary job is to align the mold perfectly with the machine’s nozzle during installation.

It’s like a guide or “target” that helps position the mold exactly where it needs to be. Without it, even a slight misalignment between the mold sprue and the machine nozzle can lead to serious issues like leaks, poor fills, or equipment damage.

Locating rings are usually standardized in size based on the molding machine’s platen and are either bolted on or integrated into the mold base. While small and often overlooked, this component is essential for repeatable, efficient, and damage-free molding setups.

Core Functions of the Locating Ring

From proper alignment to equipment protection, this component acts as a bridge between mold and machine. Here’s a breakdown of its key functions:

1. Aligns the Mold to the Machine Nozzle

The locating ring precisely centers the mold’s sprue with the machine’s injection nozzle. But why does this matter? Because even a 0.5 mm misalignment can cause serious defects like flashing or incomplete filling.

A centered sprue promotes smooth material flow into the cavity, reducing injection force inconsistencies and material shear. Without this alignment, molten plastic can leak or apply uneven force.

2. Ensures Repeatable, Centered Molding Cycles

In mass production, repeatability is everything. The locating ring locks the mold into the same position every time, which creates uniformity across thousands of shots.

This consistency ensures the part dimensions stay within tight tolerances, even across long production runs. It also reduces reliance on operator precision during mold setup and decreases human error.

3. Prevents Misalignment and Equipment Wear

A mold mounted even slightly off-center can stress machine components, especially the injection unit and platens. The locating ring absorbs and distributes alignment forces, which prevents direct impact on the nozzle tip.

It also reduces the risk of mold slippage or improper contact that can damage tie bars, bushings, and nozzle seats. Ultimately, this extends the machine’s life and cuts maintenance costs.

4. Acts as a Reference for Mold Mounting

During setup, the locating ring serves as a physical guide to quickly position the mold. It eliminates the guesswork and visual alignment, making installations faster and more accurate.

This is especially valuable in high-speed environments or where multiple mold changes occur daily. It improves safety, too, by preventing improper clamp alignment that can lead to tool crashes.

5. Facilitates Uniform Pressure Distribution

A centered mold ensures that clamping and injection pressures are evenly applied across the mold face. Without this balance, you risk part defects like warping, flash, or unbalanced fill patterns.

The locating ring keeps the mold flat and flush against the platen, which helps maintain optimal clamp tonnage.

Consequences of Improper or Missing Locating Ring

Skipping or misusing a locating ring in injection molding might seem harmless until defects start piling up or the machine breaks down. This small component plays a massive role in maintaining production quality, equipment health, and cost control.

Here’s what can go wrong when it’s installed incorrectly:

1. Misalignment Leading to Defects

Without a proper injection molding locating ring, the mold may not align accurately with the nozzle. Even slight misalignment, such as just 0.2 mm, can lead to serious part quality issues like:

- Short shots (incomplete fills)

- Flash (plastic leaking out at the mold parting line)

- Warping due to uneven flow

2. Increased Downtime and Maintenance

Improperly seated molds take longer to install, troubleshoot, and run. Operators may need to manually adjust alignment, which slows production and increases human error.

Additionally, poorly aligned molds increase wear on seals, bushings, and other hardware, leading to:

- Frequent seal replacements

- Nozzle wear or leakage

- Emergency stops due to misfeeds or flashing

All of this means more unplanned downtime, higher maintenance costs, and less output.

3. Risk of Equipment Damage

Over time, operating without a locating ring can do more than harm your product; it can damage your machine. Misaligned molds apply uneven pressure on platens, tie bars, and injection units, causing:

- Excessive wear on crucial injection mold parts

- Nozzle damage from off-center pressure

- Mold base distortion or cracking

In worst-case scenarios, expensive injection mold components or even entire platens may need replacement.

Avoid These Costly Locating Ring Mistakes

Neglecting proper selection and maintenance of locating rings can lead to significant issues in injection molding operations.

1. Installing the Incorrect Size or Type

Using a locating ring that doesn’t match the machine’s specifications can cause misalignment between the mold and the injection nozzle. Standard locating rings typically have an outer diameter of 3.990 inches.

Deviations from this standard can result in improper seating, defects in the final product, and equipment wear. Therefore, whenever you match the locating ring, ensure that it is compatible with your machine model.

2. Ignoring Wear and Tolerance Limit

As time passes, the locating rings can wear down, compromising their ability to maintain precise alignment. Typically, the injection molds are machined to tolerances of ±0.127 mm, but tighter tolerances may require precision up to ±0.0508 mm.

Worn-out rings can easily exceed these tolerances and cause misalignment and part defects. So, make sure to implement a regular inspection schedule to monitor wear and replace locating rings that no longer meet tolerance requirements.

3. Not Considering Thermal Expansion

During operation, molds can experience temperatures ranging from 30°C to 150°C, while molten plastic can reach 180°C to 300°C. This thermal expansion can affect the fit and operational performance of the locating ring.

The best way to solve this problem is by choosing locating rings made from materials with suitable thermal expansion properties. It’s also important to ensure the design tolerances can handle changes caused by temperature.

Partner with Fecision for Precision Mold Tooling That Lasts

A well-fitted locating ring in injection molding might seem like a small detail, but it makes a major difference in mold performance. This single component plays a vital role in maintaining quality and accuracy.

If you’re working with complex tooling or high-precision products, it’s best to invest in expert craftsmanship, such as the one offered at Fecision.

We are a trusted injection mold parts supplier globally, offering full-service solutions in mold tooling, CNC machining, and molding services.

Get in touch with us today and discover how we can help you achieve your goals!