Precision Manufacturing for Advanced Robotics Applications

The robotics industry continues to evolve at an unprecedented pace, driven by advancements in artificial intelligence, machine learning, and sensor technology.

As automation becomes increasingly prevalent across all sectors, manufacturers require precision components and tooling solutions that can meet the exacting standards of modern robotic systems while maintaining reliability in demanding operational environments.

- CE certification (EU market)

- ISO 10218 certified manufacturing partners

- Quality management system per ISO 9001:2015/13485:2016/14001:2015

- DFM and product validation

- Real-time Process Tracking System

- One-stop service for manufacturing, finishing and logistics

Why Choose FECISION for Robotics Manufacturing

Robotics Manufacturing Expertise

At FECISION, we understand the critical challenges facing robotics manufacturers and integrators. Our state-of-the-art facilities and advanced manufacturing capabilities enable us to deliver high-precision molds, tooling, and components that meet the exacting standards of the robotics industry.

From end effectors to structural components, we provide comprehensive manufacturing solutions for the entire robotics supply chain.

Our Robotics Manufacturing Capabilities Include:

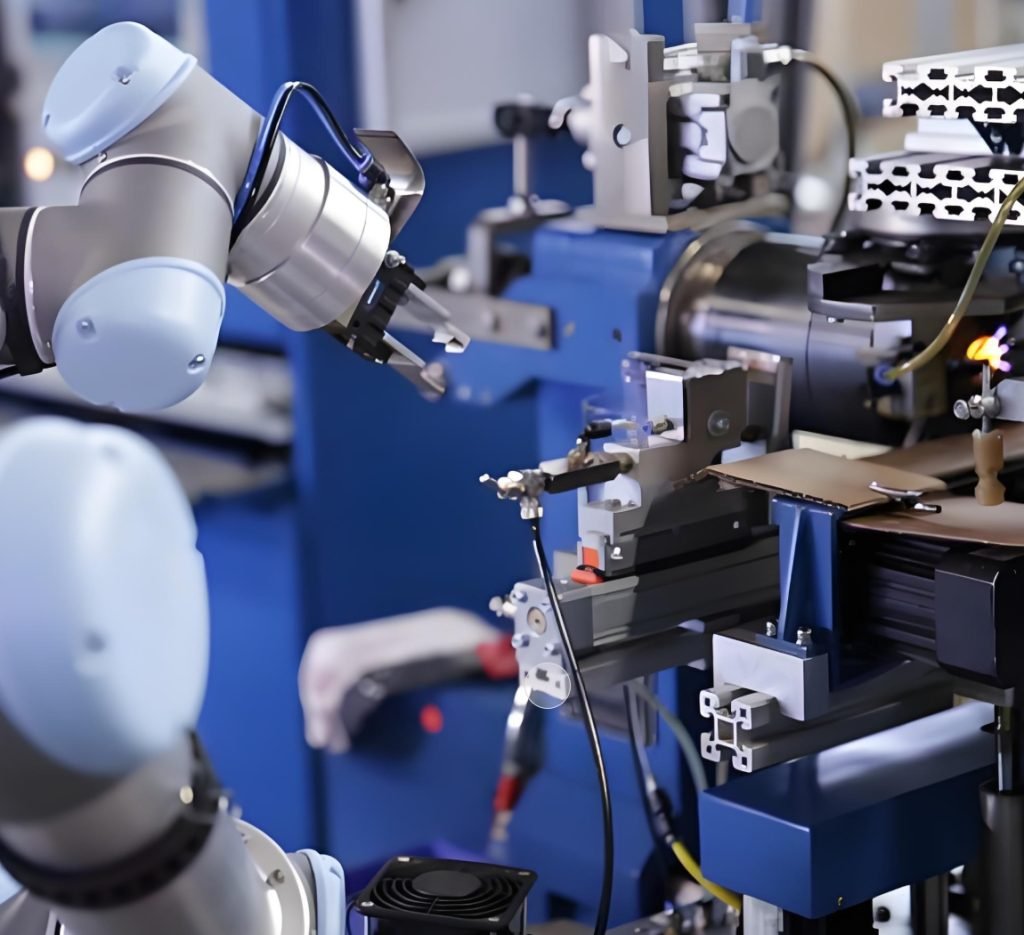

Mold Tooling for End of Arm Tooling (EOAT) Manufacturing

CNC Machining for Robotic Gripper System Parts

Collaborative Robot Components Production

Robotic Material Removal Tools

Parts Die Casting for Robotic Tool Changers

Collision Sensors & Protection Devices Shell Molding

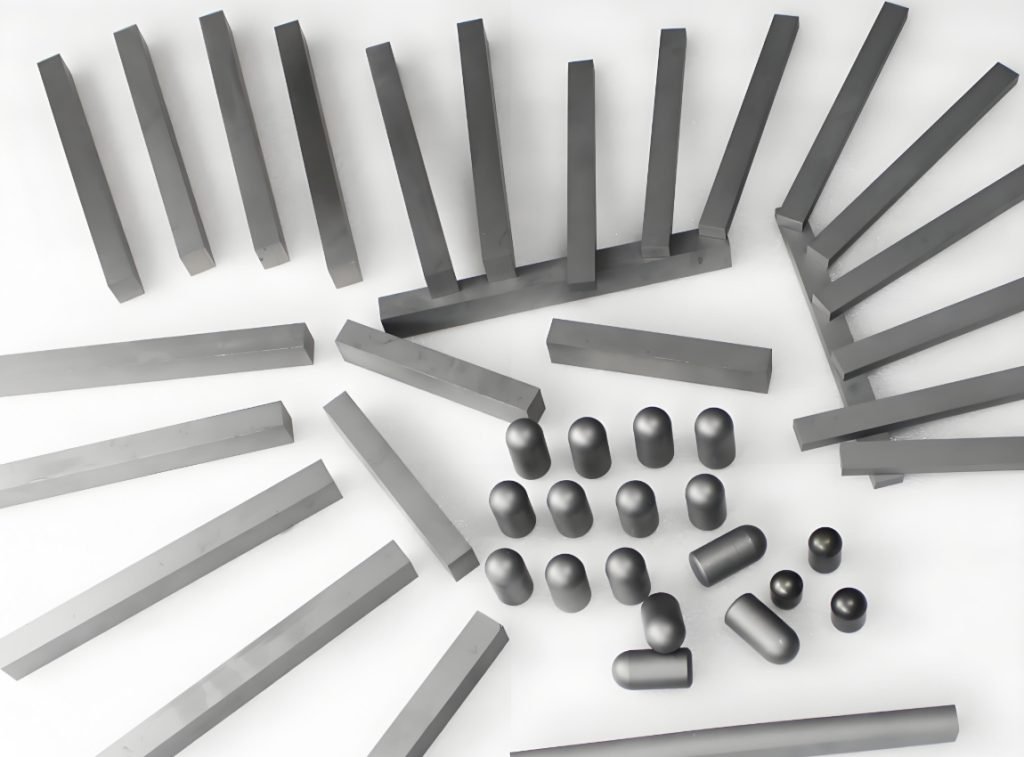

Advanced Materials for Robotics Applications

The robotics industry demands materials that meet strict performance, durability, and safety requirements. Our components utilize:

√ Lightweight Alloys

Aluminum and titanium alloys for weight-optimized robotic components

√ High-Strength Engineering Plastics

Advanced polymers for robotic-grade components

√ Composite Materials

Carbon fiber and reinforced composites for optimal strength-to-weight ratio

√Wear-Resistant Alloys

Specialized materials for high-cycle robotic applications

√ ESD-Safe Materials

Static-dissipative compounds for electronics handling applications

√ Food-Grade Materials

FDA-compliant materials for food processing robotics

Compliance and precision are critical factors in robotic system performance. Our manufacturing expertise includes:

Precision Machined Components

Ultra-precise parts with tolerances to ±0.005mm

Compliance Device Manufacturing

Custom-designed components for lateral and axial compliance

Remote Center Compliance (RCC) Systems

Specialized devices for robotic assembly applications

Vibration Dampening Components

Parts engineered to minimize vibration in high-speed robotic systems

Precision Machined Components

Ultra-precise parts with tolerances to ±0.005mm

Interchangeable Component Systems

Modular designs for maximum flexibility and serviceability

Robotics Manufacturing Process

1. Design Collaboration

- Working with robotics engineers to optimize designs for manufacturability

2. Material Selection

- Choosing optimal materials based on performance requirements and operational environment

3. Prototyping

- Rapid production of prototype components for testing and validation

4. Tooling Development

- Creating precision tooling for production manufacturing

5. Process Validation

- Comprehensive process validation including statistical process control

6. Production Manufacturing

- Implementing efficient production processes with rigorous quality controls

7. System Integration Support

- Assisting with integration of manufactured components into complete robotic systems

8. Continuous Improvement

- Ongoing optimization of processes to enhance quality and performance

Robotics Manufacturing from Prototype to Production

Fecision offers a highly efficient and simplified supply chain solution. Whether you’re in the stage of creating prototypes, moving on to test units, initiating mass-production, or dealing with subsequent phases, Fecision has got you covered.

Prototype

- For the purpose of validating your materials and designs, get prototypes that come as close as feasible to your final design.

Prototype

DVT

Production

EVT

PVT

- Comprehensive functionality testing on the prototype

- Identify any flaws or areas for improvement in the design

Applications in Robotics Industry

Our precision manufacturing capabilities serve diverse robotics applications:

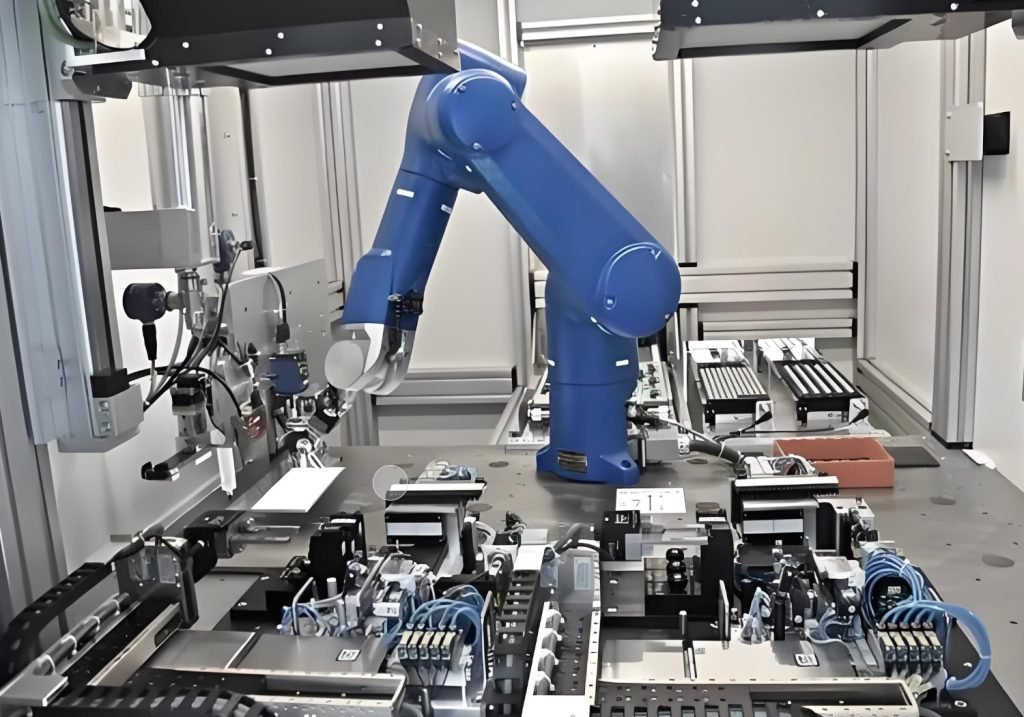

Industrial Automation

- Robotic welding system components

- Material handling end effectors

- Robotic palletizing components

- Machine tending systems

- Robotic dispensing equipment

- Automated assembly systems

Service Robotics

- Precision mobility components

- Robotic joint mechanisms

- Lightweight structural elements

- Service robot end effectors

- Human interaction components

- Specialized service attachments

Autonomous Systems

- Sensor mounting components

- Navigation system housings

- Environmental protection enclosures

- Autonomous vehicle components

- Drone components and fixtures

- Mobile robot structural elements

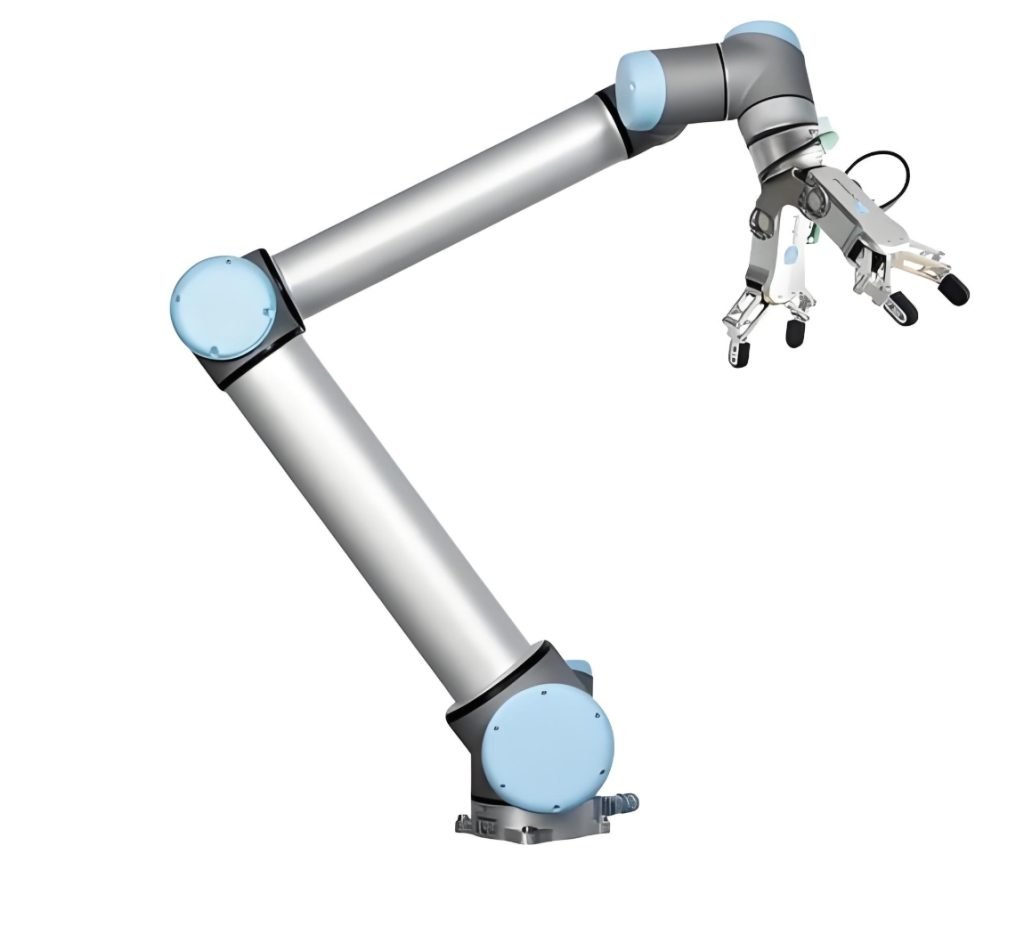

Collaborative Robotics

- Safety-rated end effectors

- Force-limited gripper components

- Human-robot interface components

- Collaborative workstation fixtures

- Cobot tool changers

- Sensor integration components

Specialized Applications

- Medical robotics components

- Food processing robotic parts

- Pharmaceutical automation components

- Clean room robotic systems

- Hazardous environment robotics

- High-precision inspection robotics

ISO 10218 Certification

Meeting international standards for industrial robot safety

CE Certification

Compliance with European safety, health, and environmental requirements

Advanced Metrology

State-of-the-art measurement systems for dimensional verification

Quality Assurance for Robotics Manufacturing

Quality is paramount in electronics and semiconductor manufacturing.

Functional Testing

Verification of component performance under simulated conditions

Material Certification

Complete traceability of all materials used in production

Durability Testing

Accelerated life testing to ensure long-term reliability

Integration Validation

Testing components within complete robotic systems

Customized Robotic Parts

Common

Application

With the qualification of CE and ISO10281 Robotics industry quality management system certification, Fecision has multiple solutions for Robotic part production, aiming to provide qualified products with precision and exellent function.

- Rotary Encoder Flang

- Six-axis Joint Connector

- Robot Battery Tray

- AGV Drive Wheel

- Harmonic Reducer Housing

- IO Module Housing

- Control Cabinet Heat Sink

- Flexible Gripper Mold

- Pneumatic Finger Claw

- Positioning Pin

Robotics Manufacturing Case Studies

Collaborative Robot End Effector

We developed a custom end effector system for a collaborative robot application, incorporating advanced safety features and precision gripping capabilities while reducing overall weight by 30% compared to conventional designs.

Industrial Automation System

Our team manufactured high-precision components for an industrial automation system, utilizing advanced materials and manufacturing processes to ensure reliability in a 24/7 production environment with over 1 million cycles per month.

Automotive Electronics Assembly

FECISION produced precision-machined components for a next-generation service robot, delivering parts with exceptional dimensional accuracy and surface finish while meeting strict weight and durability requirements.

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.