When it comes to selecting materials for custom parts manufacturing, understanding the differences between various plastic alternatives is crucial. You are faced with a choice between several options, but two materials stand out due to their similarity in appearance and widespread use: polycarbonate and acrylic.

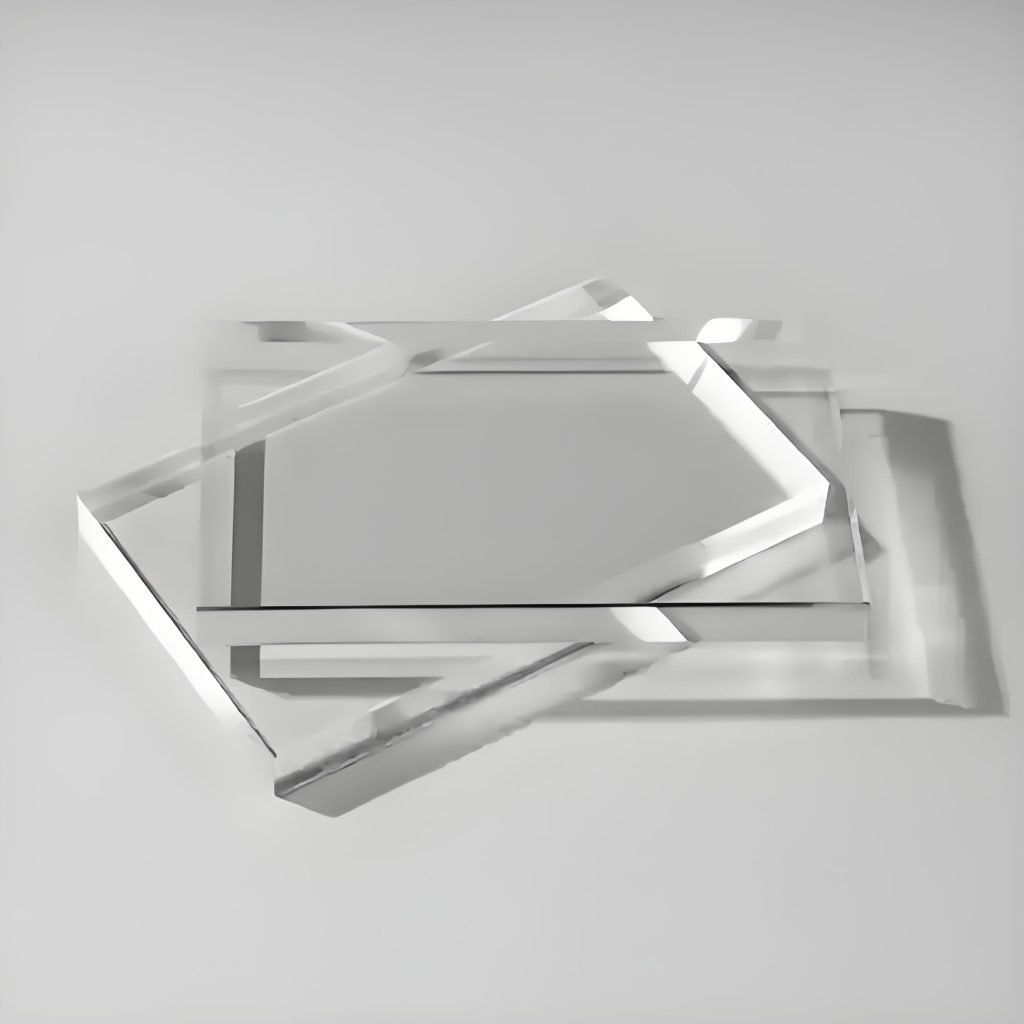

Both materials serve as popular alternatives to traditional glass in many applications, offering significant advantages in terms of weight and strength. Acrylic sheeting is known for its shinier finish, while polycarbonate sheeting is renowned for its strength.

As you navigate the process of material selection, it’s essential to consider the distinct properties of these materials to make an informed decision that suits your specific needs.

What is Polycarbonate Plastic?

Polycarbonate is a type of plastic known for its exceptional strength and resistance. It’s a versatile material used in various applications, from consumer products to industrial components. You might be familiar with polycarbonate under brand names like Lexan or Makrolon.

Chemical Composition and Key Properties

Polycarbonate is produced through the reaction between bisphenol A and phosgene (COCl2). This process gives polycarbonate its unique properties, including high impact resistance – 250 times that of glass – and significant strength, being 30 times stronger than acrylic. Polycarbonate sheets offer 88% light transmittance, making them suitable for applications requiring transparency. Additionally, polycarbonate is available in various grades, including flexible versions and bullet-resistant materials.

The material’s thermoplastic nature allows it to be molded and shaped at high temperatures, with a continuous working temperature of 240°F. Polycarbonate also exhibits low flammability and is durable against chips and cracks. Its high resistance to acids and other chemicals, such as gasoline, further expands its range of applications.

Advantages and Limitations of Polycarbonate

The advantages of polycarbonate include its durability, chemical resistance, and heat resistance, making it ideal for demanding applications. However, it also has some limitations. While generally more expensive than some other plastics, polycarbonate’s higher cost is often justified by its performance. It can be susceptible to scratching, and prolonged UV exposure may cause yellowing. Despite these limitations, polycarbonate remains a popular choice for custom parts due to its overall balance of properties.

When considering polycarbonate for your projects, weigh its benefits against its drawbacks to determine if it’s the right material for your needs.

What is Acrylic Plastic?

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is a widely used material in industries ranging from construction to crafting. It’s synthesized from methyl methacrylate through a polymerization process, resulting in a thermoplastic material with unique properties.

Chemical Composition and Key Properties

Acrylic’s chemical composition as PMMA contributes to its notable characteristics. It boasts 92% light transmittance, making it clearer than glass, and has 17 times the impact resistance of glass. Additionally, acrylic is resistant to yellowing or discoloration from UV exposure and can withstand continuous temperatures up to 180°F. Its durability against scratches and dents, along with the ability to be polished smooth, adds to its appeal.

Advantages and Limitations of Acrylic

The advantages of acrylic include its exceptional optical clarity, UV stability, and polishability. However, it also has limitations: it’s more brittle and has lower impact resistance compared to polycarbonate, and its working temperature is limited to 180°F continuous. Despite these limitations, acrylic remains a popular choice for applications requiring transparency and durability, such as in signage, displays, and glazing.

Polycarbonate vs Acrylic: Property Comparison

To make an informed decision between polycarbonate and acrylic, it’s essential to compare their properties side-by-side. This comparison will help you understand which material is best suited for your custom parts based on factors like strength, optical clarity, weight, flexibility, and temperature resistance.

Strength and Impact Resistance

Polycarbonate is significantly stronger than acrylic, with more than 30 times the impact resistance of glass, while acrylic has 10-24 times the impact resistance of glass. This makes polycarbonate the preferred choice for applications where high impact resistance is critical. For instance, polycarbonate is often used in safety equipment and automotive parts.

Optical Clarity and UV Resistance

Acrylic tends to be slightly clearer than polycarbonate, offering 92% light transmittance compared to polycarbonate’s 88%. Additionally, acrylic generally has better resistance to UV yellowing over time, maintaining its clarity longer. This makes acrylic a popular choice for applications requiring high optical clarity, such as display cases and lighting fixtures.

Weight and Flexibility

Both polycarbonate and acrylic sheets weigh about 50% less than comparable glass sheets, making them similar in weight. However, they differ in flexibility; acrylic is more rigid and prone to cracking, whereas polycarbonate is available in both rigid and flexible grades, offering more versatility for various applications.

Temperature Resistance and Flammability

Polycarbonate can withstand temperatures up to 240°F, while acrylic begins to soften at around 180°F. This makes polycarbonate more suitable for high-temperature environments. Furthermore, polycarbonate has better fire resistance properties than acrylic, making it a safer choice for applications where exposure to heat or flames is a concern.

Manufacturing and Fabrication Options

To choose the right material for your custom parts, you need to know how polycarbonate and acrylic sheets are manufactured. The production processes for these materials significantly impact their properties and applications.

How Polycarbonate Sheets Are Manufactured

Polycarbonate sheets are primarily produced through the extrusion process. Raw polycarbonate resin is melted and forced through a die to create sheets of uniform thickness. This process allows for the production of sheets in various lengths, widths, and thicknesses.

How Acrylic Sheets Are Manufactured

Acrylic sheets are manufactured using bulk polymerization. The monomer (methyl methacrylate) and a catalyst are mixed, poured into a mold, and heated to form the acrylic polymer. The sheets are then cured, resulting in a rigid and transparent material.

Fabrication Considerations: Cutting, Drilling, and Forming

Both polycarbonate and acrylic sheets can be fabricated using various techniques. Acrylic is generally easier to cut but more prone to cracking, while polycarbonate is more difficult to cut but more forgiving during drilling and machining. Thermal forming capabilities also differ, with acrylic being more easily heat-formed and polycarbonate capable of cold-forming in some applications.

| Material | Cutting | Drilling | Forming |

|---|---|---|---|

| Polycarbonate | Difficult | Forgiving | Cold-forming possible |

| Acrylic | Easy | Prone to cracking | Easily heat-formed |

Common Applications and Best Uses

The versatility of polycarbonate and acrylic plastics is evident in their diverse applications across various industries. Understanding their ideal uses can help you make informed decisions for your custom parts.

Ideal Applications for Polycarbonate

Polycarbonate is renowned for its exceptional impact resistance and temperature tolerance, making it ideal for safety glazing, machine guards, bulletproof barriers, and automotive components.

Ideal Applications for Acrylic

Acrylic’s superior optical clarity and UV stability make it perfect for retail displays, aquariums, picture frames, signage, and decorative elements where aesthetic quality is critical.

Cost Considerations and Value Analysis

While polycarbonate typically costs about 35% more than acrylic, its durability and resistance to impact and temperature fluctuations may offer better long-term value for certain applications. When choosing between these materials, consider factors like replacement frequency and maintenance requirements to understand their overall value proposition.

Conclusion: Choosing the Right Material for Your Custom Parts

To select the ideal material for your custom parts, you must weigh the characteristics of polycarbonate and acrylic. Consider factors like strength, optical clarity, temperature resistance, and budget.

Polycarbonate is ideal for high-impact applications and harsh outdoor conditions, while acrylic suits display applications and aesthetic priorities. Evaluate your project’s specific needs and consult with material experts when necessary.

By understanding the differences between these materials and considering manufacturing and fabrication aspects, you can make an informed decision. For assistance with your custom parts projects, contact Fecision, experts in working with both polycarbonate and acrylic materials.