Are you struggling to choose the right material for your 3D printing projects? The choice of material significantly impacts the quality, durability, and functionality of the final product.

In the realm of low-cost FFF/FDM 3D printing, two thermoplastics stand out: a biodegradable thermoplastic derived from renewable resources and a modified version of PET with added glycol. Understanding their differences is crucial for making an informed decision.

This guide will help you navigate the properties, advantages, limitations, and applications of these popular 3D printing materials, ensuring you select the best material for your specific project requirements.

Understanding 3D Printing Materials

The Importance of Material Selection in 3D Printing

Material selection directly impacts the success of 3D printing projects, affecting everything from print quality to the functionality of the final product. Different materials offer varying levels of strength, flexibility, temperature resistance, and other properties that determine their suitability for specific applications. Understanding these properties is crucial before starting a 3D printing project to avoid wasted time, materials, and potential print failures.

Overview of Thermoplastics in Additive Manufacturing

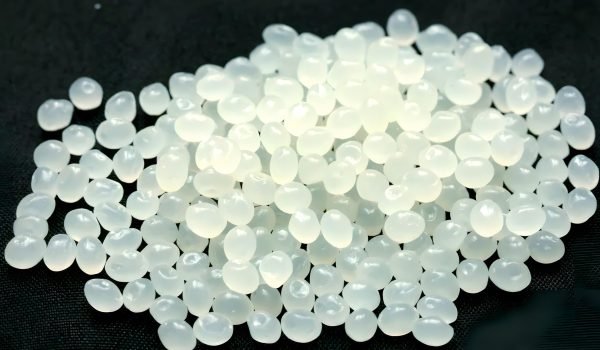

Thermoplastics are widely used in low-cost FFF/FDM 3D printing due to their properties and versatility. They have revolutionized the accessibility of 3D printing technology for hobbyists, educators, and professionals. The quality of the filament used in 3D printing affects the printing process and final results. Thermoplastics like PLA and PETG are popular choices, offering a range of benefits and limitations that make them ideal for various 3D printing processes.

By understanding the importance of material selection and the properties of different thermoplastics, you can make informed decisions to ensure the success of your 3D printing projects.

What is PLA?

You might be wondering what PLA is; it’s a plastic made from renewable resources like corn starch or sugarcane. PLA, or Polylactic Acid, is a type of plastic that is derived from renewable resources, making it an environmentally friendly option for 3D printing.

Origin and Composition of PLA

PLA is a biodegradable thermoplastic that is produced through the fermentation of plant sugars to produce lactic acid, which is then polymerized to create polylactic acid. This process gives PLA its unique molecular structure, contributing to its properties.

Key Properties of PLA

PLA is known for its low melting temperature, typically around 150-160 degrees Celsius, making it easy to print with. Its key physical and mechanical properties include tensile strength, hardness, and brittleness. The table below summarizes some of the key properties of PLA.

| Property | Value | Description |

|---|---|---|

| Melting Temperature | 150-160°C | Low melting temperature, easy to print |

| Tensile Strength | 40-60 MPa | Moderate strength, suitable for most applications |

| Impact Resistance | Low | Brittle, may break under impact |

Manufacturing Process of PLA Filament

The manufacturing process of PLA filament involves several steps, from the fermentation of plant sugars to produce lactic acid to the polymerization process that creates the final material. The quality of the PLA filament can vary depending on the manufacturer, affecting printing results.

Advantages and Limitations of PLA

PLA’s popularity in 3D printing stems from its ease of printing, low warping, and aesthetic versatility. As a beginner-friendly material, PLA is ideal for those new to 3D printing.

Benefits of Using PLA for 3D Printing

One of the primary benefits of PLA is its ease of use. It prints at a lower temperature (between 180-220°C) and doesn’t require a heated bed, making it energy-efficient and safer, especially for beginners and in educational settings. PLA is also known for its minimal warping, ensuring that prints remain intact during the printing process.

Additionally, PLA offers several aesthetic advantages, including a glossy finish and a wide range of available colors. This makes it perfect for projects where visual appeal is important. Furthermore, PLA is derived from renewable resources and is biodegradable under specific conditions, offering an environmentally friendly option for 3D printing projects.

| Property | Description | Benefit |

|---|---|---|

| Printing Temperature | 180-220°C | Energy-efficient and safer for beginners. |

| Warping | Minimal | Ensures prints remain intact during printing. |

| Aesthetic Finish | Glossy, various colors | Ideal for visually appealing projects. |

Drawbacks and Constraints of PLA

Despite its benefits, PLA has several limitations. Its low heat resistance means it softens at temperatures above 60°C, making it unsuitable for applications exposed to higher temperatures. PLA is also brittle, affecting the durability of printed objects, especially those subject to stress or impact.

Moreover, PLA’s sensitivity to UV light and moisture can cause degradation over time, limiting its use in outdoor applications. Understanding these constraints is crucial for determining the suitability of PLA for specific projects.

| Limitation | Description | Impact |

|---|---|---|

| Heat Resistance | Softens above 60°C | Unsuitable for high-temperature applications. |

| Brittleness | Prone to breakage under stress | Affects durability of printed objects. |

| UV and Moisture Sensitivity | Degradation over time | Limits use in outdoor applications. |

Common Applications of PLA

The ease of use and low melting point of PLA make it an ideal material for various 3D printing applications. You can leverage PLA’s unique properties to create a wide range of products, from prototypes to consumer goods.

Ideal Use Cases for PLA

PLA is particularly suited for applications where its ease of printing and aesthetic qualities are beneficial. You can use PLA for creating detailed prototypes, concept models, and visual aids. Its ability to produce high-detail prints and availability in various colors make it perfect for these purposes.

Some of the ideal use cases include prototyping, creating decorative items, and producing educational models. PLA’s biodegradability also makes it suitable for temporary or disposable items where environmental impact is a concern.

Industries That Benefit from PLA

Various industries benefit from PLA’s unique properties. You can find PLA being used in product design, architecture, healthcare, and entertainment. For instance, architectural models and medical teaching aids are commonly created using PLA due to its ease of use and the detailed prints it produces.

Additionally, PLA is used in the production of consumer goods such as toys, decorative items, and household goods. Its safety and affordability make it a preferred material in educational settings.

What is PETG?

As a variant of Polyethylene Terephthalate, PETG incorporates glycol to enhance its characteristics for 3D printing. This modification makes PETG a preferred choice among 3D printing enthusiasts due to its improved properties compared to standard PET.

Origin and Composition of PETG

PETG is derived from Polyethylene Terephthalate (PET), a common plastic used in consumer products. The addition of glycol during the polymerization process prevents crystallization, making PETG clearer and less brittle than PET. This results in a material that is not only durable but also has improved optical clarity.

Key Properties of PETG

PETG boasts a range of beneficial properties, including high strength, flexibility, and resistance to chemicals and impact. These characteristics make it suitable for a wide range of applications, from prototypes to end-use products. Its durability and resistance to environmental factors further enhance its appeal in 3D printing.

Manufacturing Process of PETG Filament

The manufacturing process of PETG filament involves the polymerization of ethylene glycol and terephthalic acid, followed by an extrusion process that shapes the material into the final filament form. Variations in quality can occur based on the manufacturing process, affecting the final product’s performance and printability.

Advantages and Limitations of PETG

As a 3D printing material, PETG offers several advantages that make it worth considering. You can leverage its unique properties to create durable and versatile prints.

Benefits of Using PETG for 3D Printing

PETG is renowned for its excellent durability, impact resistance, and chemical resistance, making it an ideal choice for functional parts that need to withstand stress and strain. When you use PETG for 3D printing, you benefit from its superior heat resistance compared to PLA, with a higher glass transition temperature of around 80°C. This property makes PETG suitable for applications exposed to moderate heat.

Additionally, PETG’s flexibility contributes to its impact resistance, and its excellent layer adhesion results in stronger prints with better structural integrity.

Drawbacks and Constraints of PETG

Despite its benefits, PETG has some limitations. You may encounter challenges such as stringing and oozing during printing, which can affect the surface quality of printed objects. Printing with PETG requires careful calibration of the printer and often a heated print bed, which can be more demanding than printing with PLA.

Furthermore, PETG can be more difficult to post-process, as it is harder to sand, paint, or otherwise modify after printing compared to PLA. Understanding these constraints is crucial to optimizing your 3D printing experience with PETG.

Common Applications of PETG

The durability and chemical resistance of PETG make it a popular choice for many applications. As a versatile 3D printing material, PETG is used in various industries due to its ability to withstand higher temperatures and its balanced mechanical properties.

Ideal Use Cases for PETG

PETG is particularly suited for applications that require durability, chemical resistance, and temperature resistance. It is often used for creating functional prototypes that need to withstand stress and strain. Additionally, PETG’s strength and impact resistance make it ideal for producing mechanical parts and components.

For instance, PETG is used in crafting consumer goods such as containers, mechanical parts, and protective casings. Its resistance to UV light and moisture also makes it suitable for outdoor applications.

| Application | Benefits of PETG | Examples |

|---|---|---|

| Functional Prototypes | Durability, Temperature Resistance | Prototypes for mechanical testing |

| Consumer Goods | Chemical Resistance, Impact Resistance | Containers, Protective Casings |

| Outdoor Applications | UV Resistance, Moisture Resistance | Outdoor fixtures, Mechanical parts |

Industries That Benefit from PETG

Various industries benefit from PETG due to its unique properties. The automotive industry uses PETG for producing durable components and parts. In healthcare, PETG is used for creating medical devices and equipment. The food packaging industry also benefits from PETG’s chemical resistance and food-safe properties.

Other industries that use PETG include consumer electronics, where it is used for making protective covers and other components. The material’s transparency and optical clarity also make it suitable for applications requiring visual clarity.

| Industry | Use of PETG | Benefits |

|---|---|---|

| Automotive | Durable components, parts | Strength, Temperature Resistance |

| Healthcare | Medical devices, equipment | Chemical Resistance, Sterilizability |

| Consumer Electronics | Protective covers, components | Impact Resistance, Visual Clarity |

PLA vs PETG: A Detailed Comparison

Understanding the differences between PLA and PETG is essential for selecting the best material for your 3D printing projects. Both materials have their unique characteristics, advantages, and limitations.

Printability and Ease of Use

PLA is generally considered more beginner-friendly due to its lower printing temperature (180-220°C) and minimal warping. It adheres well to most surfaces without requiring extensive adjustments. PETG, on the other hand, requires slightly higher temperatures (220-250°C) and benefits from a heated bed to ensure proper adhesion.

Strength and Durability

Both PLA and PETG offer good performance in terms of strength, but there are key differences. PLA has a slightly higher tensile strength than PETG. However, PLA is more brittle, making it less resistant to impact or sudden forces. PETG is more flexible, allowing it to better withstand bending and impact forces.

| Material | Tensile Strength | Impact Resistance |

|---|---|---|

| PLA | Higher | Lower |

| PETG | Lower | Higher |

Temperature Resistance

PLA has a lower melting temperature and glass transition temperature, making it unsuitable for applications exposed to high temperatures. PETG has a higher melting temperature and glass transition temperature, making it more suitable for such applications. PLA softens at around 60°C, while PETG can withstand temperatures up to 80°C.

Flexibility and Impact Resistance

PETG’s greater flexibility makes it less brittle and more resistant to impacts compared to PLA. This characteristic makes PETG a better choice for applications that require durability and flexibility.

Resistance to Environmental Factors

PETG generally offers superior resistance to environmental factors like UV light, moisture, and chemicals compared to PLA. This makes PETG a better choice for outdoor or harsh environment applications.

Post-Processing Capabilities

PLA is generally easier to post-process than PETG. PLA can be sanded, painted, and chemically smoothed with relative ease. PETG, while still capable of being post-processed, requires more effort and specific techniques.

Conclusion

As you’ve explored the differences between PLA and PETG, it’s clear that the right choice depends on your specific 3D printing needs. PLA is ideal for beginners and projects where ease of printing and aesthetic quality are priorities, such as decorative items and prototypes.

PETG, on the other hand, offers superior durability, heat resistance, and suitability for functional parts and mechanical components. Its resistance to UV light and water makes it perfect for outdoor use.

When deciding between PLA and PETG, consider the specific requirements of your project, including temperature resistance, impact resistance, and durability. Beginners may start with PLA to learn the basics before moving to PETG for more advanced projects. Ultimately, both materials have their place in a 3D printing enthusiast’s arsenal, and understanding their strengths will help you make the best choice for your applications.