What You Need to Know About PLA vs ABS Right Now

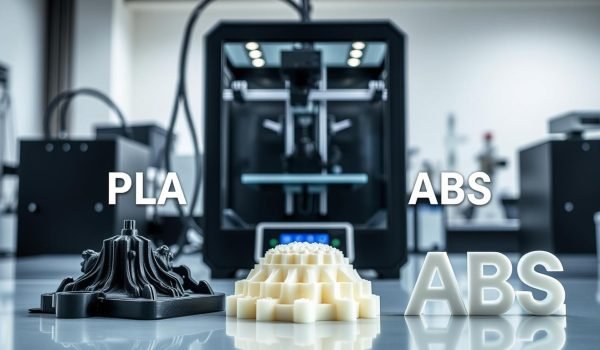

Choosing the right filament means balancing print ease, surface quality, and how the part will be used.

At a glance, pla prints at lower temperatures and often gives a glossier finish. abs requires higher nozzle heat and benefits from a heated bed or enclosure to reduce warping. Both materials can deliver similar tensile strength, but abs offers better ductility and a higher glass transition (around 105°C versus ~60°C for pla).

Typical printing speeds overlap: expect about 60 mm/s for pla (it can go much faster) and roughly 40–60 mm/s for abs. For dimensional work, use these practical rules: details ~0.8 mm, minimum features ~1.2 mm, tolerance ~0.5 mm for interlocking parts, and wall thickness of 1–2 mm for reliable components.

Quick decision guide: choose pla if you want sharp detail and easier prints. Choose abs if you need heat resistance, impact tolerance, or a tougher part. Check your printer: if it lacks reliable temperature control or an enclosure, start with pla to avoid adhesion and warping problems.

Characteristics and Properties of PLA and ABS

Look at each material’s core traits to pick the right filament for function and finish. This section summarizes mechanical and thermal properties so you can match parts to performance needs.

PLA (Polylactic Acid): bio-sourced, stiff, easy to print

Polylactic acid is derived from renewable feedstocks and prints at lower temperatures. It is typically stiffer and gives crisp features with minimal warping.

Typical values: tensile strength ~37 MPa, density ~1.3 g/cm3, melting ≈173°C, glass transition ≈60°C. It is more brittle and less resistant to heat and chemicals.

ABS (Acrylonitrile Butadiene Styrene): tough, durable, higher heat tolerance

Acrylonitrile butadiene styrene is a ductile terpolymer engineered for impact resistance. It tolerates higher temperatures but needs better temperature control when printing.

Common figures: tensile strength ~27 MPa, elongation 3.5–50%, flexural modulus 2.1–7.6 GPa, density 1.0–1.4 g/cm3, melting ≈200°C, glass transition ≈105°C.

Mechanical and thermal traits that matter

Strength and tensile strength alone don’t tell the whole story. PLA has higher nominal tensile strength but lower elongation, so it snaps sooner under bend loads.

ABS offers more ductility and impact resistance, making it better for housings, snap fits, and handheld components where toughness matters.

Density ranges overlap; ABS can yield lighter parts for the same volume. If you’ve used nylon, expect PLA to be stiffer and ABS to be less brittle.

PLA vs ABS: The Key Differences That Impact Your Prints

Printability and warping: lower temp PLA vs higher temp ABS

Printability favors pla: it runs at lower temperatures, warps less, and delivers sharp details on open-frame printers. You can push print speeds toward 60 mm/s and well beyond with tuning when you need fast iterations.

By contrast, abs often prints best in the 40–60 mm/s range. It needs a heated bed and an enclosure to reduce corner lift and layer separation during printing.

Strength profile: stiffness vs impact resistance and ductility

In strength terms, pla gives stiffness and precise dimensionality. That makes it ideal for look-and-fit prototypes and parts with fine features.

ABS provides more ductility and impact resistance. For handheld parts, housings, or items near warm equipment, its higher heat tolerance adds reliability compared with nylon-like behavior.

Cost, availability, and color variety in market

Both materials are widely available, but pla often ships in more color options and specialty blends. Raw abs can be slightly cheaper per kilogram, though brand and shipping affect price more than base cost.

For most applications, choose the filament that matches your timeline: pick the easier-to-tune option for quick prototypes and the tougher option when heat, handling, or long-term durability matter.

PLA vs ABS: Surface Finish and Post Processing

The out-of-printer surface sets the tone for every finishing choice you’ll make. FDM parts show layer lines, so deciding on a finish early saves time and prevents rework.

By default, PLA often gives a glossier finish while ABS tends to look more matte. That contrast affects how much sanding, sealing, or polishing you’ll need to reach a showroom surface.

How to smooth and seal

If you want a high-gloss, sealed shell on ABS filament, acetone vapor smoothing can level layers and reduce visible seams. Use a ventilated setup and test small parts first to avoid over-softening.

For PLA, careful sanding through progressive grits then polishing yields a smooth, glossy finish. PLA softens with heat, so use light pressure, fresh sandpaper, and cooling breaks.

Machining, priming, and painting

Both materials accept drilling and light machining; clamp parts to prevent chatter and start with pilot holes. Primer and paint adhere well when you use plastic-compatible primers and filler primers to hide remaining layer lines.

Print Settings, Accuracy, and Dimensional Stability

Fine-tuning printer settings is where design intent meets repeatable accuracy. Use this guidance to get reliable parts with either filament family and to reduce guesswork during printing.

Typical print speeds and when to adjust

Start pla near 60 mm/s and only push faster after you tune extrusion and cooling. For the tougher heat-resistant option, keep speeds in the 40–60 mm/s range for best dimensional control.

Tolerances, minimum features, and wall thickness guidance

Target details around 0.8 mm and set minimum features to at least 1.2 mm. For assemblies, budget ~0.5 mm clearance so interlocking parts fit without filing.

Use 1–2 mm wall thickness as a baseline and add perimeters where fasteners or loads concentrate. Orient parts to distribute shrink and use brims or an enclosure for long, flat faces when needed.

Run calibration cubes, document slicer profiles, and adjust tolerances based on your printer’s behavior so future prints match your applications and properties consistently.

Heat Resistance and Environmental Exposure

Thermal limits decide whether a printed part will hold shape or slowly sag in real use. The glass transition temperature is the key number to watch: roughly 105°C for abs and about 60°C for pla.

What those temperatures mean for parts

Glass and transition values set the practical ceiling for service temperature. If a part reaches that temperature under load, it can soften, creep, or deform.

Think about cars left in sun, enclosures around hot electronics, or fixtures near lamps. PLA can start to droop near 60°C. ABS tolerates higher temperatures, so it gives you more margin but is not immune to heat-related failure.

Design and testing tips

Factor both ambient heat and internal heat from components. Use thicker walls, fillets, and consistent cross-sections in areas that carry stress. Match your printing temperature and thermal control to the part’s intended environment to reduce built-in stress and warping while printing.

If you expect prolonged high temperatures, consider higher-performance filament blends or run a simple heat soak test before full production. That quick check can prevent costly reprints and ensure your parts survive real-world conditions.

Is PLA or ABS More Environmentally Friendly?

Assessing environmental and indoor air impacts helps you pick the safer filament for your shop or classroom. You should balance raw‑material origin, recyclability, and the air quality effects of printing when choosing a material for parts that you print often.

Bio-sourced and end-of-life considerations

Polylactic acid is derived from renewable crops and can biodegrade under industrial composting in about 50 days. In water it may break down over much longer periods, while in everyday use it remains stable.

Acrylonitrile butadiene and butadiene styrene blends do not biodegrade but are recyclable in some local streams. Recycling availability varies, so check municipal programs or shop recycling options before assuming a clean end-of-life path.

Indoor air and printing safety

During printing, some materials emit stronger odors and potentially harmful fumes. ABS often smells stronger; plan for an enclosure and good ventilation when running long jobs.

PLA typically has low odor, making it friendlier for shared spaces. For either material, use a filtration system with HEPA and activated carbon if indoor air quality is a priority.

How to Decide Between PLA and ABS for Your Project

The simplest way to choose a filament is to match part demands to material strengths. Start by listing the part’s function, where it will live, and how it will be handled. That quick checklist steers your choice toward aesthetics or durability.

If aesthetics and fine details lead, choose PLA

If looks and crisp features matter, pick the filament that prints clean details with minimal tuning. For prototypes and display pieces, this material prints faster and is easier on open-frame printers.

It also sands and paints well, so you can get a polished finish without complex post-processing.

If heat, impact, and durability matter, choose ABS

When parts face knocks, flex, or warm environments, the other option is abs better because of higher ductility and heat resistant properties. Use it for housings, handles, and items near electronics or inside vehicles.

Expect a longer setup time to reduce warping, but the result holds up under stress and higher service temperatures.

Common Pitfalls and Practical Tips

Common print issues often hide in setup details you can fix in minutes.

Reducing ABS warping with bed adhesion and enclosures

For abs, use a heated bed and an enclosure to keep ambient temperatures steady. This cuts corner lift and layer splitting during long prints.

Improve first-layer adhesion with PEI sheets, glue stick, or a textured plate. Add brims or rafts for long, flat features to stop edges from peeling up.

Keep printing temperature steady and avoid drafts. Level the bed precisely and check Z-offset—small errors become big problems on larger footprints.

Use filters or external ventilation when printing abs to reduce odors on long jobs. Stick to 40–60 mm/s for reliable results.

Dialing in PLA retraction to control oozing and stringing

To tame stringing on pla, increase retraction distance and speed, lower nozzle temperature slightly, and enable combing or wipe in your slicer.

Dry filament if you see popping or surface pitting; moisture weakens interlayer bonds. Print calibration towers to tune temperature, retraction, and flow before final runs.

Handle parts by hand carefully right off the bed—warm parts can be fragile or prone to deformation. Document slicer profiles so your team reproduces good results without guessing.

Conclusion

A clear choice flows from matching part function, surface goals, and how much heat or handling the item will face.

For aesthetic prototypes and fast iteration, choose the filament that prints with crisp detail and a glossy finish—it gives you speed and accuracy with minimal tuning.

When components need impact resistance and higher service temperatures, pick the tougher option with a higher glass transition temperature and better heat resistance. Both materials can reach reliable dimensional accuracy when you design for minimum features, wall thickness, and proper tolerances.

If finish is critical, plan for sanding or acetone smoothing. For fatigue or flexible needs, consider nylon or TPU instead. Prototype in the easier material, validate performance, then move to the tougher choice for heat and real-world resistance.