Surprising fact: global resin capacity for polyether ether ketone sits near just 10,000 tonnes per year while demand from aerospace, medical, and semiconductor sectors keeps climbing.

In this guide you’ll find a clear view of key properties, grades, processing basics like drying and crystallinity control, and injection molding tradeoffs. You’ll also see real-world applications across aerospace, oil & gas, medical, and food equipment where thermal and chemical stability matter.

Finally, get practical next steps: how to select the right grade, what to expect on price from high-temperature synthesis, and how Fecision helps you request samples, DFM feedback, and production quotes for custom parts.

What Is Polyether Ether Ketone and Why It Outperforms Conventional Options

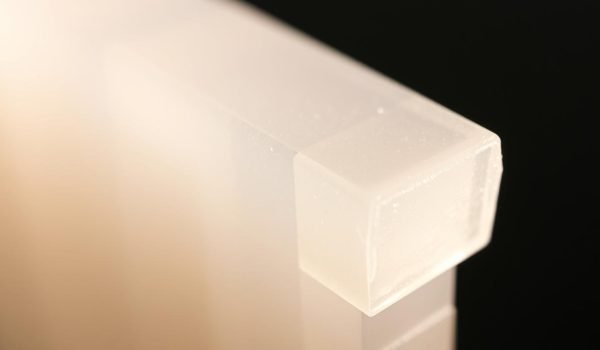

When parts must resist heat, chemicals, and wear, designers often turn to a narrow family of high‑performance polymers. Polyether ether ketone sits in the PAEK family as a semicrystalline resin with an aromatic backbone that gives it exceptional thermal and mechanical behavior.

PAEK family structure and performance

The stiff aromatic chain in this ether ketone yields high dimensional stability and wear resistance under load. Synthesis occurs via nucleophilic substitution—4,4′-difluorobenzophenone and hydroquinone at about 300°C in diphenyl sulfone—so the supply base is specialized.

This structure explains why engineers choose the material when you need strong, lightweight parts that tolerate elevated temperatures and cycling.

Key baseline properties at a glance

Core numbers help you benchmark quickly: glass transition ≈143°C and melting near 343°C. Typical tensile strength sits around 90–100 MPa with a flexural/Young’s modulus near 3.6–4.0 GPa.

It shows excellent chemical resistance and UL94 V‑0 flame performance, and it remains stable in ultra‑high vacuum. Radiolucency and biocompatibility extend its applications into medical imaging and implant designs.

Grades of PEEK Plastic and How to Pick the Right Material for Your Requirements

Not every formulation fits every job—grade selection dictates how a part performs under load and heat. Match your requirements by weighing stiffness, wear, and regulatory needs before you specify a supplier.

Unfilled options for purity and fatigue resistance

Unfilled resin gives the highest elongation and fatigue life. It is FDA-compliant for repeated food contact and is common in medical devices where purity and radiolucency matter.

30% glass-filled for dimensional stability

Glass reinforcement raises flexural modulus and reduces thermal expansion. Use it for structural parts that must hold tight tolerances at elevated temperatures, but expect increased counterface wear.

30% carbon-filled for load-bearing and heat dissipation

Carbon-filled formulations boost compressive strength and cut thermal expansion. Thermal conductivity can improve by roughly 3.5× versus unfilled, making them a strong choice for bearings and hot, loaded assemblies.

Bearing blends with PTFE and graphite

Bearing grade compounds blend ~20% ptfe with carbon fiber and graphite. That mix gives the lowest friction, excellent machinability, and long wear life in dynamic parts.

Quick comparative notes

All grades maintain high baseline tensile strength and chemical resistance, but fillers change creep, surface finish, and machining behavior. Choose a grade that aligns with your validation path—food or medical approval, tribology, or tight thermal limits—and confirm exact properties with the supplier before production.

PEEK Properties, Processing, and Injection Molding: Advantages and Limitations You Should Know

Before you specify a part, know the thermal and processing limits that control final properties and cost.

Mechanical and thermal performance

The material delivers tensile strength near 98 MPa and flexural strength around 165 MPa. Modulus sits about 3.8–4.0 GPa, so you get metal‑like stiffness at much lower weight.

Creep and fatigue resistance keep parts stable at high temperatures beyond 500°F, and the resin meets UL94 V‑0 for flame performance.

Chemical and environmental resistance

Expect excellent resistance to solvents, oxidation, UV, and gamma. Note vulnerability to halogens and strong acids at elevated concentration and temperature.

Processing fundamentals

Melting behavior centers on a Tm near 343°C and requires tight crystallinity control. Dry pellets below 0.02% moisture to avoid voids and degradation.

Use inert atmospheres and short residence times to prevent oxidative breakdown during molding.

Injection molding advantages and limits

Good flow and self‑lubricity let you mold thin walls and complex geometry that rival metal parts. Limitations include anisotropic shrinkage, higher tool temperatures, increased tool wear from abrasive fillers, and a premium price driven by complex synthesis.

Mitigate risks with balanced gating, robust steel or coatings, uniform thickness, and validated process windows before production.

Where PEEK Excels: High-Performance Applications and Sustainability Considerations

Design teams often prioritize long life, light weight, and chemical resistance when specifying parts for harsh service. You’ll map this resin to critical applications across aerospace brackets and cable insulation, oil & gas seals and pump components, radiolucent medical implants, FDA‑compliant food equipment, and semiconductor vacuum tooling.

Choose grades to suit the job: bearing compounds with PTFE and graphite lower friction; 30% glass‑filled grades boost flexural modulus and dimensional control; carbon‑filled options raise thermal conductivity and lower expansion for load‑bearing parts.

Design tips for harsh environments: keep wall thickness uniform to control crystallinity, add fillets to reduce stress concentrations, and set stack‑up tolerances that allow for anisotropic shrinkage. Quantify steady and transient temperatures so parts retain tensile strength and chemical resistance during sterilization, washdown, or bake‑outs.

Sustainability gains come from long service life, corrosion avoidance versus metals, and mass reduction that cuts energy use in mobile systems. Balance price and value by using this high‑performance material where failures or outages are costly, and specify inspection and test protocols tailored to critical applications.

Custom PEEK Parts for Your Application at Fecision

Fecision turns advanced polymer know-how into production-ready parts for demanding designs.

You’ll get end-to-end support selecting the right grade—unfilled for purity and fatigue life, 30% glass for stiffness, 30% carbon for thermal control, or PTFE/graphite bearing blends for low friction and machinability.

We guide DFM decisions on thickness transitions, gating, venting, and crystallinity control for molding. For CNC work, we program feeds and fixturing to limit heat and stress so tight tolerances hold after machining.

Stocked sheets and bar speed prototypes and reduce lead time. You can standardize thickness to cut cycle time and improve consistency across product families.

To order, select material, grade, and finish, then add cart the configuration. Upload drawings, note tolerances, sterilization cycles, and media exposure, and request a formal quote with price and lead-time options.

We protect quality by controlling pellet drying below 0.02% moisture and using hardened tool steels or coatings for abrasive blends. Submit a request and we’ll return manufacturability notes, risk items, and a recommended process window so you can scale from prototype to production with confidence.

Conclusion

You now have a clear plan to move from design to validated parts using a top-tier engineering material.

The resin combines high-temperature capability (Tm ~343°C, Tg ~143°C) with strong mechanical performance—tensile ~90–100 MPa and modulus near 3.6–4.0 GPa—and excellent wear and chemical resistance.

Choose grades to match needs: unfilled for purity, glass or carbon for stiffness, and PTFE/graphite blends for low friction. Control drying below 0.02% moisture, manage crystallinity, and design for anisotropic shrinkage to hit tolerances.

Ready to act? Add cart your preferred sheets and configurations, request documentation, or submit a request for a tailored quote. Fecision provides price transparency, manufacturability feedback, and production options from prototype to full run.