Mold Base

- Structural Stability: Provides a solid foundation to support all mold components.

- Precision Machining: Ensures accurate alignment and fit for seamless mold assembly.

- Durability: Withstands high pressures and repeated cycles without deformation.

- Customizability: Available in various sizes and configurations to fit diverse mold designs.

Expert Craftsmanship

20+ Years of Expertise

Tailored Solutions

Custom designs

Rigorous Quality Control

ISO 9001-Certified Quality

Competitive Pricing

Cost-effective solutions

Global Support

Reliable delivery & technical assistance

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

AS9100 Quality Managment

No Minimum Order Quantities

In-Process Inspection with CMM

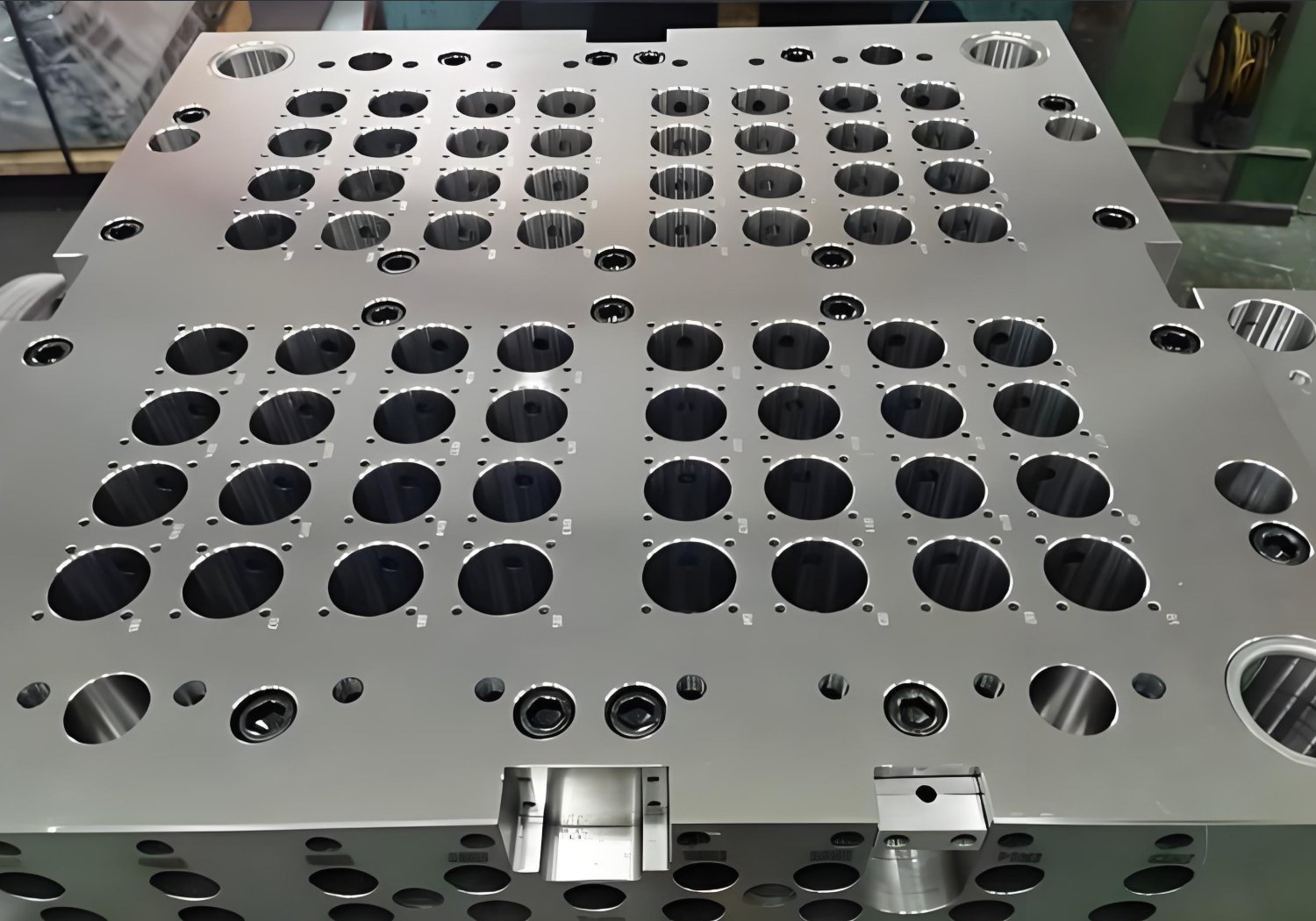

Mold Bases: Foundations for Injection Molding

A mold base is the foundational structure of an injection mold, serving as the framework that holds all mold components together. It provides the necessary support, alignment, and mounting capabilities for the mold’s cavity and core inserts.

As a critical component in injection molding systems, the mold base ensures precise alignment between moving parts, maintains consistent pressure distribution, and facilitates efficient cooling during the molding process.

Mold bases are essential for producing high-quality plastic parts consistently, with applications across automotive, medical, consumer goods, and industrial sectors. The quality of a mold base directly impacts production efficiency, part quality, and overall mold longevity.

Key Functions

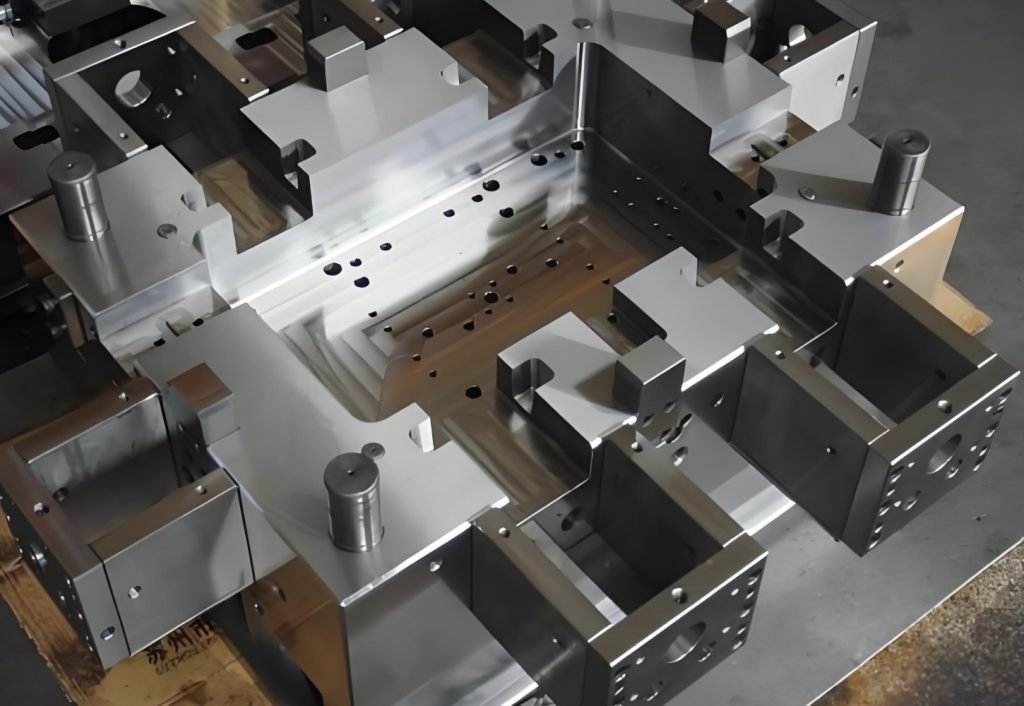

Our Capabilities and Services

Fecision specializes in manufacturing high-precision mold bases for various industries.

Our advanced manufacturing capabilities and experienced engineering team ensure that every mold base meets the most demanding specifications.

Custom Mold Bases

Tailor-made mold bases designed to your exact specifications, with engineering support to optimize design for performance and cost-efficiency.

Standard Injection Mold Bases

Ready-to-use standard mold bases available in various sizes and configurations, providing cost-effective solutions for common applications.

Surface Treatments

Specialized surface treatments including nitriding, chrome plating, and heat treatment to enhance wear resistance and extend mold life.

Design Engineering

Expert design assistance to optimize mold base structure, cooling efficiency, and overall performance for your specific application.

Precision Machining

Advanced CNC machining capabilities ensuring tight tolerances and exceptional surface finishes for critical mold base components.

Assembly & Delivery

Complete mold base assembly services with strict quality control, and reliable delivery options to meet your production schedule.

Fecision Mold Component Tooling Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Composition Of A Mold Base

A mold base consists of several key components working together to ensure proper functionality during the injection molding process.

Top & Bottom Plates

The outer plates that provide structural integrity and mounting surfaces for attaching the mold base to the injection molding machine.

Cavity & Core Plates

Cavity & Core Plates Plates that contain the cavity (where molten plastic is injected) and core (which forms the internal shape of the part).

Clamping Fixtures

Secure tools that hold workpieces firmly during machining, enhancing precision and stability in manufacturing tasks.

Guide Pins & Bushings

Precision components that ensure accurate alignment between moving plates during mold opening and closing cycles.

Ejector System

Includes ejector plates, pins, and return pins that work together to remove the finished part from the mold cavity.

Cooling Channels

Precision-drilled channels that circulate cooling fluid to control mold temperature and reduce cycle times.

Locating Rings

Components that ensure proper alignment between the mold base and the injection molding machine's nozzle.

Sprue Bushing

Funnel-shaped component that connects the machine nozzle to the mold cavity, directing molten plastic into the mold.

Leader Pins & Bushings

Guide components that ensure proper alignment between the fixed and moving halves of the mold base during operation.

Types of Mold Bases

Various types of mold bases are available to suit different injection molding applications, part designs, and production requirements.

Two-Plate Mold Bases

Three-Plate Mold Bases

Hot Runner Mold Bases

Stack Mold Bases

Insert Mold Bases

Custom Mold Bases

Common Materials for Mold Bases

P20 Tool Steel

A pre-hardened tool steel offering an excellent balance of machinability, hardness, and cost-effectiveness for general-purpose mold bases.

H13 Tool Steel

A hot-work tool steel offering exceptional heat resistance and toughness, ideal for high-temperature molding applications.

420 Stainless Steel

A martensitic stainless steel offering excellent corrosion resistance, ideal for medical, food, and high-humidity applications.

Aluminum Alloys

Lightweight materials offering excellent thermal conductivity, ideal for prototyping and low-volume production runs.

Not Sure Which Material Suits Better?

Speak with our engineering team and discuss your specific project needs.

Post-Processing & Surface Treatments

Our mold bases undergo advanced treatments to enhance durability and performance:

Heat Treatment

Optional Coating

Nitriding

Precision Grinding

Specifications and Tolerances of Mold Bases

| Specification | Standard Range | Tolerance | Notes |

| Length | 200mm – 2000mm | ±0.05mm/m | Larger sizes available on request |

| Width | 200mm – 1500mm | ±0.05mm/m | Custom widths available |

| Height | 100mm – 800mm | ±0.03mm | Depends on plate thickness |

| Plate Thickness | 10mm – 150mm | ±0.1mm | Thicker plates available |

| Guide Pin Diameter | 8mm – 50mm | H6 | Precision ground |

| Bushing Diameter | 9mm – 52mm | H7 | Matched to guide pins |

| Parallelism | – | 0.02mm/m | Between mating surfaces |

| Flatness | – | 0.03mm/m | For all major surfaces |

| Hole Position | – | ±0.02mm | Critical alignment features |

| Surface Finish | – | Ra 1.6μm | Higher finishes available |

Contact us for tailored specifications to match your requirements.

Design Considerations for Mold Bases

Mold Complexity

The mold base must be designed to fit the specific injection molding machine it will be used with, including dimensions, clamping force, and ejector system compatibility.

★ Machine tonnage rating

★ Platen size and spacing

★ Ejector stroke and pattern

★ Nozzle size and location

Structural Integrity

Mold bases must withstand significant clamping forces and injection pressures. Proper design ensures structural stability and prevents deflection during operation.

★ Plate thickness calculations

★ Ribbing and reinforcement

★ Corner design and stress distribution

★ Material selection based on forces

Maintainability

Mold base design should facilitate easy maintenance, repair, and component replacement. Accessibility to critical components reduces downtime and extends service life.

★ Access to wear components

★ Standardized fasteners and components

★ Cleaning and maintenance access

★ Component replacement simplicity

Cooling System Design

Efficient cooling is essential for reducing cycle times and ensuring part quality. Cooling channel layout, size, and distribution are carefully engineered for optimal thermal performance.

★ Uniform cooling distribution

★ Channel diameter and spacing

★ Flow rate and pressure considerations

★ Connection type and location

Ejection System Design

The ejection system must reliably remove parts from the mold without damage. Design considerations include ejector type, placement, and force distribution.

★ Ejector pin size and placement

★ Return pin design and location

★ Plate thickness and rigidity

★ Guidance and alignment features

Cost Optimization

Design decisions balance performance requirements with cost considerations. Optimized designs reduce material usage and machining time while maintaining functionality.

★ Material utilization efficiency

★ Machining time reduction

★ Standard component usage

★ Balancing complexity with functionality

Our team is available to provide personalized recommendations for your mold design.

Why Fecision for Custom Mold Bases?

Precision Manufacturing

Advanced CNC machining centers and strict quality control ensure mold bases meet the tightest tolerances.

Engineering Expertise

Experienced engineers provide design assistance to optimize your mold base for performance and cost.

Competitive Pricing

Cost-effective solutions without compromising on quality or performance.

Quality Materials

Only high-grade materials from trusted suppliers are used to ensure durability and performance.

On-Time Delivery

Efficient production planning and scheduling ensure your mold bases are delivered when you need them.

Custom Solutions

Tailored mold base designs to meet your specific application requirements and challenges.

Process for Manufacturing Mold Components

Manufacturability Evaluation

The initial step involves assessing the manufacturablity of the mold component. If it's deemed feasible, we proceed with production immediately. If not, we will provide a detailed DFM (Design for Manufacturability) report to the customer. If necessary, mold flow analysis is performed to simulate the flow of molten material within the mold.

Material Selection

Next, choose the right material for mold parts. Common materials for mold components include steel alloys, aluminum, stainless steel, specialty alloys, etc. If needed, a prototype may be made using rapid prototyping techniques (e.g., 3D printing, CNC machining) to test the design for fit, function, and manufacturability.

Mold Components Manufacturing

Once the design and materials are finalized, the mold component undergoes CNC machining. If required, the mold component may undergo heat treatment, depending on the material and intended application. For certain components, surface hardening methods such as nitriding or carburizing are applied to increase wear resistance.

Shipping

For molds with multiple components, such as multi-cavity molds or molds with inserts, the individual components are carefully assembled into the final mold system. Once our engineers confirm the product meets all requirements, it will be shipped. We maintain ongoing communication to ensure the customer is fully satisfied with the product they receive.

Ready to Discuss Your Mold Base Requirements?

Our team of experts is ready to help you with your custom mold base project.

Contact us today to get started.