Mold Fasteners: Precision-Engineered for Industrial Applications

Fecision specializes in manufacturing custom fasteners that meet the exacting demands of industrial mold applications. Our precision-engineered fasteners deliver superior load distribution, thermal stability, and vibration resistance—essential qualities for maintaining mold accuracy and extending operational lifespan.

Expert Craftsmanship

20+ Years of Expertise

Tailored Solutions

Custom designs

Rigorous Quality Control

ISO 9001-Certified Quality

Competitive Pricing

Cost-effective solutions

Global Support

Reliable delivery & technical assistance

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

AS9100 Certified Aerospace

No Minimum Order Quantities

In-Process Inspection with CMM

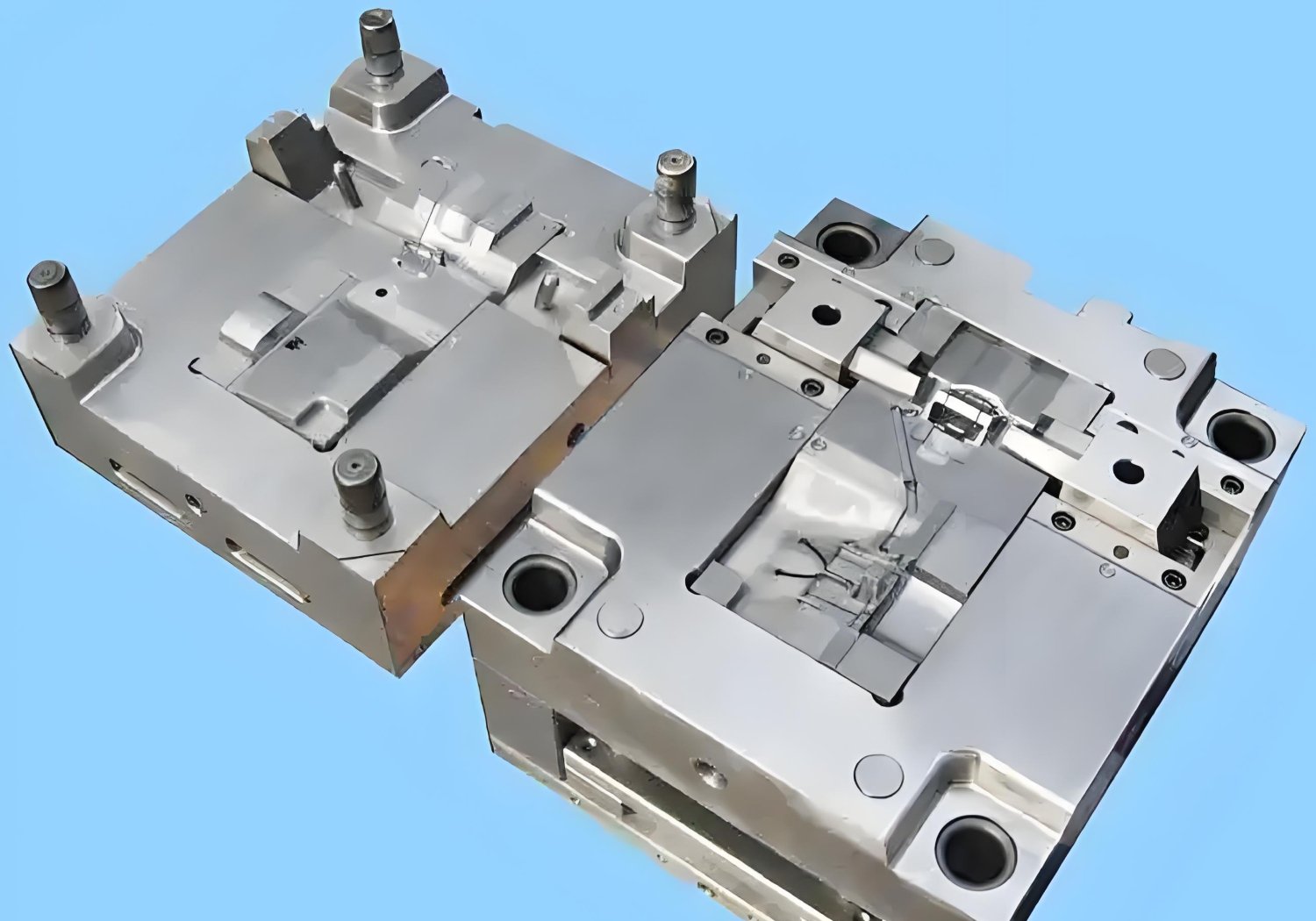

Custom Fastener Manufacturing Services

Fasteners provides critical connections for mold manufacturing, ensuring structural integrity, precision alignment, and operational reliability.

Fecision delivers uncompromising quality in custom fastener manufacturing for mold applications across industries. Our engineering team works directly with your specifications to create fasteners that perfectly match your requirements—from material selection to dimensional precision.

Our advanced manufacturing facilities combine CNC precision with rigorous quality control processes to ensure every fastener meets exact specifications. We maintain ISO 9001 certification and comply with international standards for fastener production.

Key Functions

- Fastens mold components together to maintain structural stability.

- Ensures precise alignment of mold parts during high-pressure molding.

- Prevents loosening or failure under repeated cycles.

- Supports consistent, high-volume production with reliable performance.

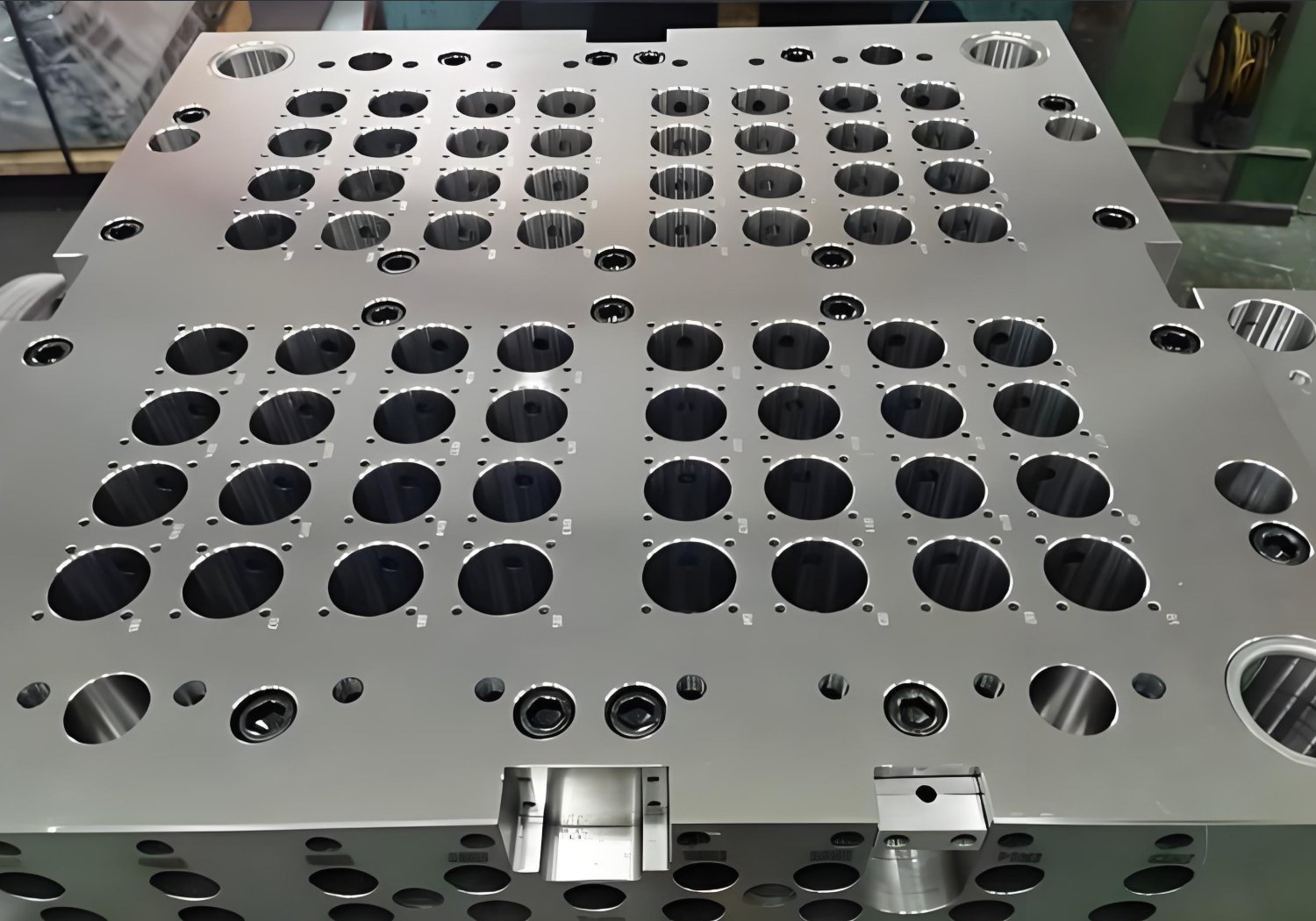

Comprehensive Range of Mold Fasteners

Our extensive catalog includes every type of fastener needed for mold manufacturing and maintenance.

Each product category offers multiple material options, size configurations, and finish treatments to meet your specific application requirements.

Bolts

Nuts

Screws

Studs

Rivets

Threaded Inserts

Retaining Rings

Pins

Washers

Detailed Fastener Type Specifications

Types of Bolts

Provide secure connections in demanding industrial environments:

- Hex Head Bolts: Standard industrial fasteners with six-sided heads

- Socket Head Cap Bolts: Feature cylindrical heads with hexagonal recesses

- Flange Bolts: Include built-in washers to distribute load across a wider surface area

- Carriage Bolts: Feature smooth, rounded heads with square necks

Types of Nuts

Provide secure locking capabilities for mold assemblies:

- Hex Nuts: Standard six-sided nuts for general fastening applications

- Lock Nuts: Feature nylon inserts or distorted threads to prevent loosening under vibration

- Flange Nuts: Include built-in washers to distribute load and prevent damage to mating surfaces

- T-Slot Nuts: Secure components to T-slotted mold bases and platens

- Wing Nuts: Feature wing-like projections

Types of Screws

Provide versatile solutions for mold assembly and adjustment:

- Machine Screws: For use with pre-tapped holes or nuts, available with various head styles

- Self-Tapping Screws: Feature cutting edges that form threads as they’re installed, eliminating the need for pre-tapping

- Set Screws: Headless fasteners, available with various point styles

- Shoulder Screws: With smooth cylindrical shoulders that serve as bearing surfaces

Types of Rivets

Provide permanent connections for mold components:

- Solid Rivets: Single-piece fasteners that require access to both sides of the joint for installation

- Blind Rivets: Two-piece fasteners that can be installed from one side of the joint

- Tubular Rivets: Feature hollow bodies that deform to create secure connections

- Drive Rivets: Self-setting fasteners that are installed by driving a pin through the rivet body

Post-Processing & Surface Treatments

Our fasteners undergo advanced treatments to enhance durability and performance:

Heat Treatment

Precision Thread Rolling

Zinc Plating

Optional Coating

Premium Fastener Materials

The performance and longevity of mold fasteners depend significantly on material selection.

Fecision offers a comprehensive range of material options to meet the specific requirements of your application environment.

| Material | Properties | Recommended Applications | Temperature Range | Corrosion Resistance |

| Stainless Steel (304/316) | Excellent corrosion resistance, good strength, non-magnetic (316) | Food processing molds, medical molds, outdoor applications | -320°F to 1600°F | Excellent |

| Alloy Steel (4140/8740) | High strength, good toughness, heat treatable | High-load applications, structural components | -50°F to 800°F | Moderate (with coating) |

| Titanium | Exceptional strength-to-weight ratio, excellent corrosion resistance | Aerospace molds, lightweight applications | -350°F to 1000°F | Excellent |

| Brass | Good corrosion resistance, non-sparking, good electrical conductivity | Electrical molds, explosive environments | -320°F to 400°F | Good |

| Tool Steel (A2/D2/H13) | Excellent wear resistance, high hardness, good toughness | Injection molds, high-wear applications | -50°F to 1000°F | Moderate |

Our metallurgical experts can help you select the optimal material for your specific application requirements, considering factors such as load capacity, operating temperature, chemical exposure, and cost constraints.

Fastener Selection Guide

Load Capacity Considerations

Calculate static and dynamic loads

Consider safety factors for critical applications

Evaluate tensile, shear, and fatigue strength requirements

Account for thermal expansion and contraction

Consider vibration and shock loading

Environmental Factors

Operating temperature range

Exposure to chemicals and solvents

Humidity and moisture conditions

Galvanic corrosion potential

Cleanliness requirements (food, medical)

Application-Specific Requirements

Accessibility for installation and maintenance

Frequency of assembly/disassembly

Electrical conductivity needs

Magnetic properties considerations

Weight and space constraints

Need Expert Guidance?

Our engineering team can provide personalized recommendations based on your specific application requirements.

Fecision Mold Component Tooling Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Global Fastener Standards Compliance

Fecision manufactures fasteners in compliance with international standards to ensure consistency, interchangeability, and quality. Our comprehensive standards coverage includes:

Our Quality Certifications

ISO 9001:2015 Quality Management System

ISO 14001:2015 Environmental Management System

IATF 16949 Automotive Quality Management

AS9100D Aerospace Quality Management

RoHS Compliance for Electronic Applications

Every fastener we produce undergoes rigorous inspection and testing to ensure compliance with applicable standards and specifications. Our comprehensive quality documentation provides full traceability for critical applications.

ISO Standards

International Organization for Standardization specifications for metric fasteners

DIN Standards

German Institute for Standardization specifications widely used in European manufacturing

ASTM Standards

American Society for Testing and Materials specifications for material properties and testing methods

JIS Standards

Japanese Industrial Standards for fasteners used in Asian manufacturing

ASME Standards

American Society of Mechanical Engineers specifications for pressure vessel and power generation applications

Why Fecision for Mold Components?

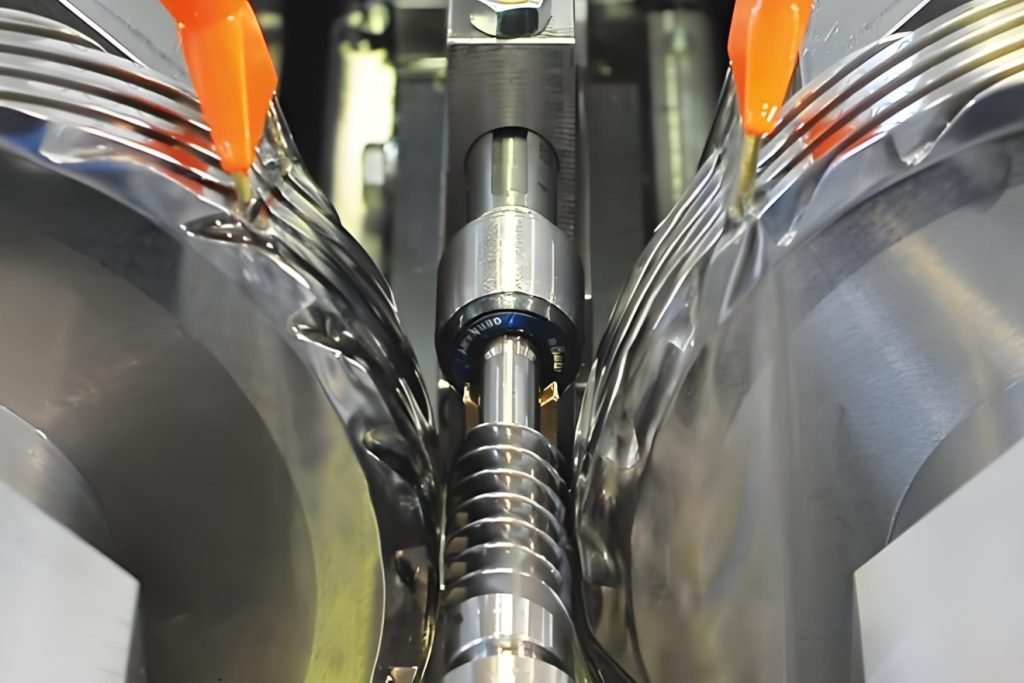

Precision and Accuracy

Using state-of-the-art CNC machining, EDM, and other advanced manufacturing techniques, Fecision ensures all mold components meet tight tolerances and high-quality standards.

Customization

Fecision understands the unique needs of each project. Our team works closely with customers to provide tailored solutions, ensuring that each component fits perfectly within the target mold system.

Rapid Prototyping

Fecision offers rapid prototyping for mold components, enabling customers to test and refine designs quickly before moving into full production.

End-to-End Services

From initial design and DFM (Design for Manufacturability) analysis to final mold assembly and testing, Fecision handles every aspect of the mold component manufacturing process.

Process for Manufacturing Mold Components

Manufacturability Evaluation

The initial step involves assessing the manufacturablity of the mold component. If it's deemed feasible, we proceed with production immediately. If not, we will provide a detailed DFM (Design for Manufacturability) report to the customer. If necessary, mold flow analysis is performed to simulate the flow of molten material within the mold.

Material Selection

Next, choose the right material for mold parts. Common materials for mold components include steel alloys, aluminum, stainless steel, specialty alloys, etc. If needed, a prototype may be made using rapid prototyping techniques (e.g., 3D printing, CNC machining) to test the design for fit, function, and manufacturability.

Mold Components Manufacturing

Once the design and materials are finalized, the mold component undergoes CNC machining. If required, the mold component may undergo heat treatment, depending on the material and intended application. For certain components, surface hardening methods such as nitriding or carburizing are applied to increase wear resistance.

Assembly & Shipping

For molds with multiple components, such as multi-cavity molds or molds with inserts, the individual components are carefully assembled into the final mold system. Once our engineers confirm the product meets all requirements, it will be shipped. We maintain ongoing communication to ensure the customer is fully satisfied with the product they receive.

Ready to Enhance Your Mold Performance?

Contact Fecision today to discuss your custom fastener requirements or to request a quote for standard products.