Precision Molding Parts Manufacturer

- Speed: 15-day lead time for prototypes.

- Global Compliance: CE, RoHS, and REACH certifications for EU/NA markets.

- Cost Efficiency: 20% lower pricing vs. German/Japanese competitors.

Start your project now

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

AS9100 Quality Management

No Minimum Order Quantities

In-Process Inspection with CMM

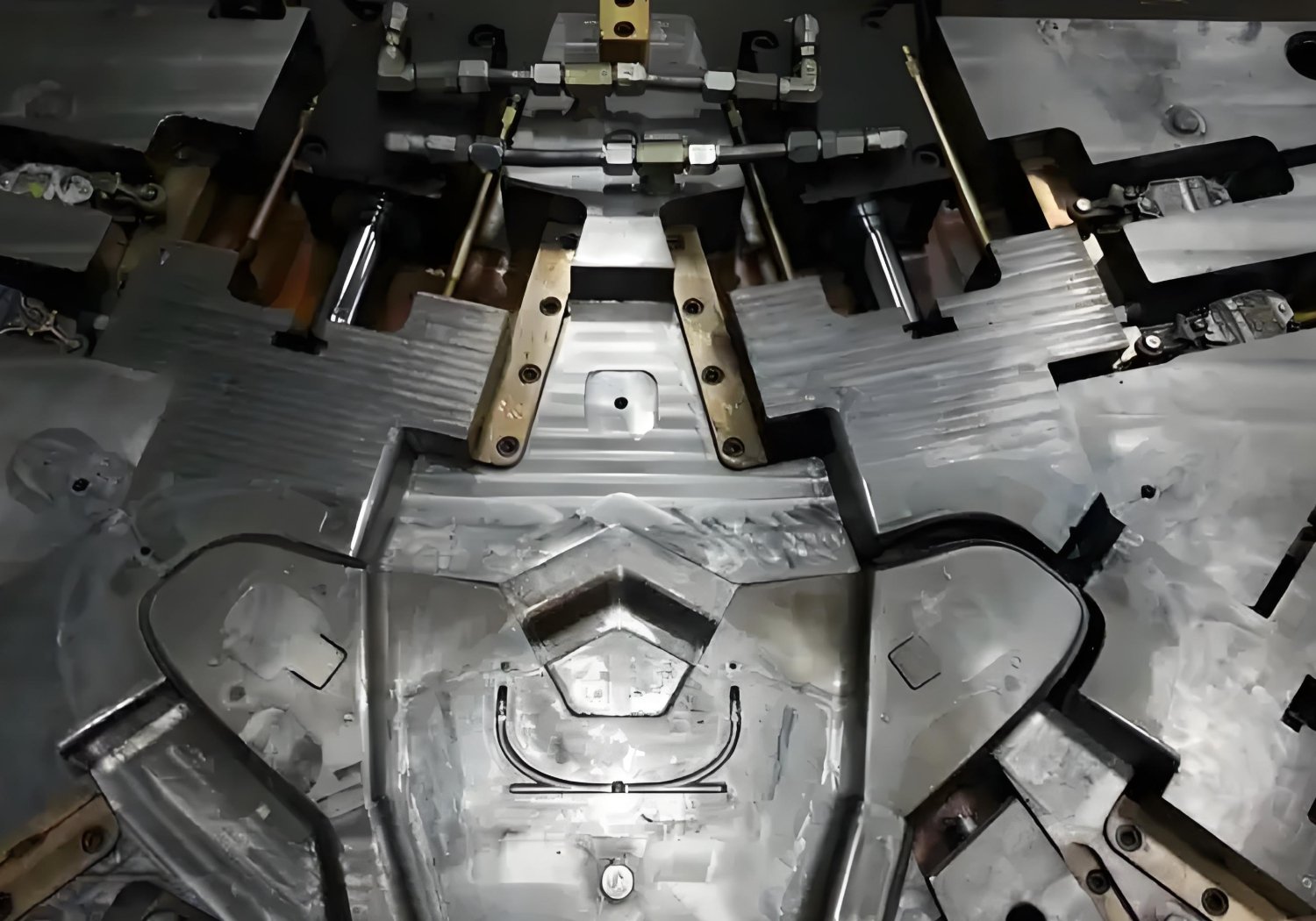

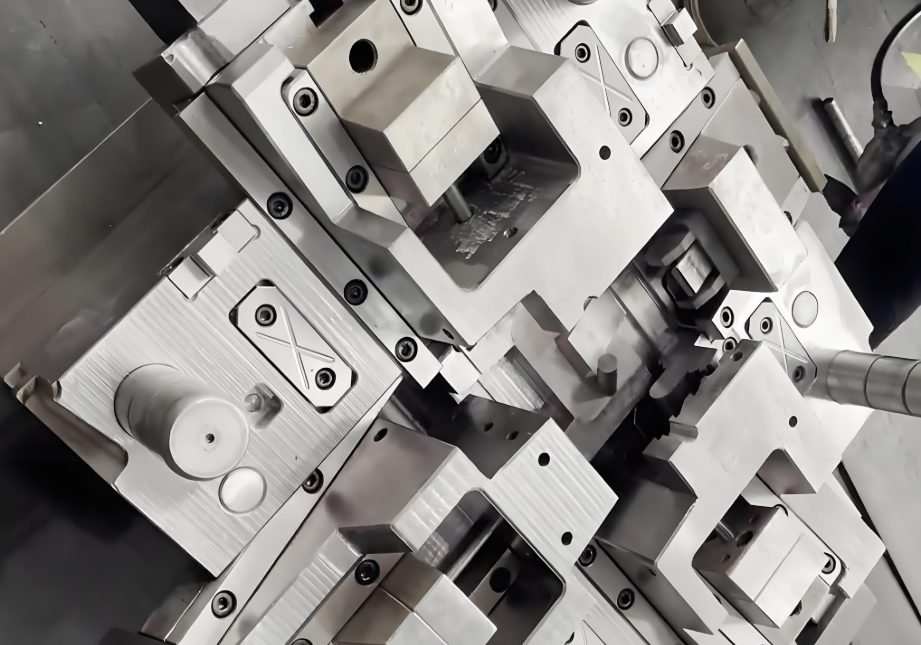

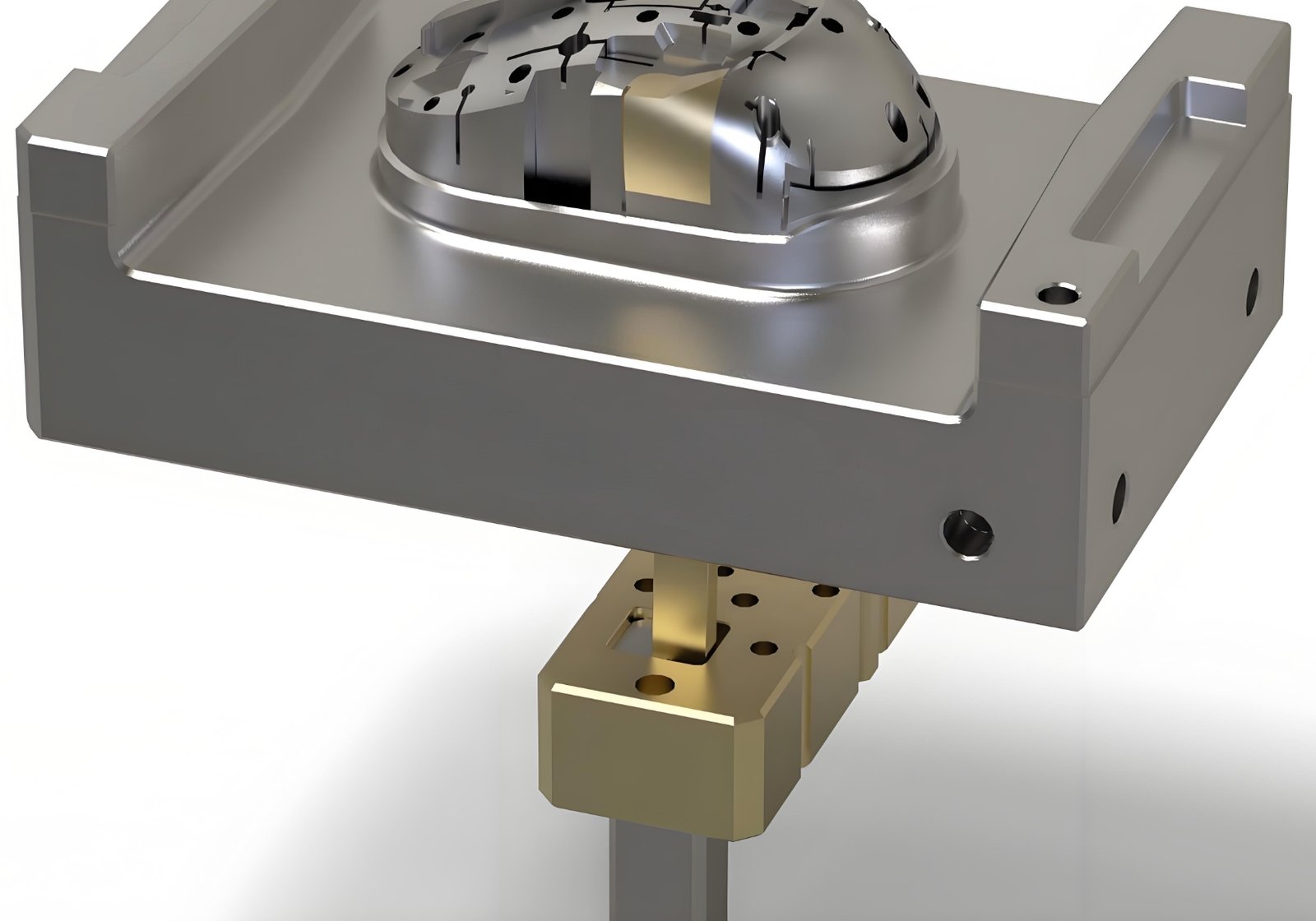

Molding Components

Molding components form the foundation of every injection mold, directly shaping the final product’s accuracy and surface finish.

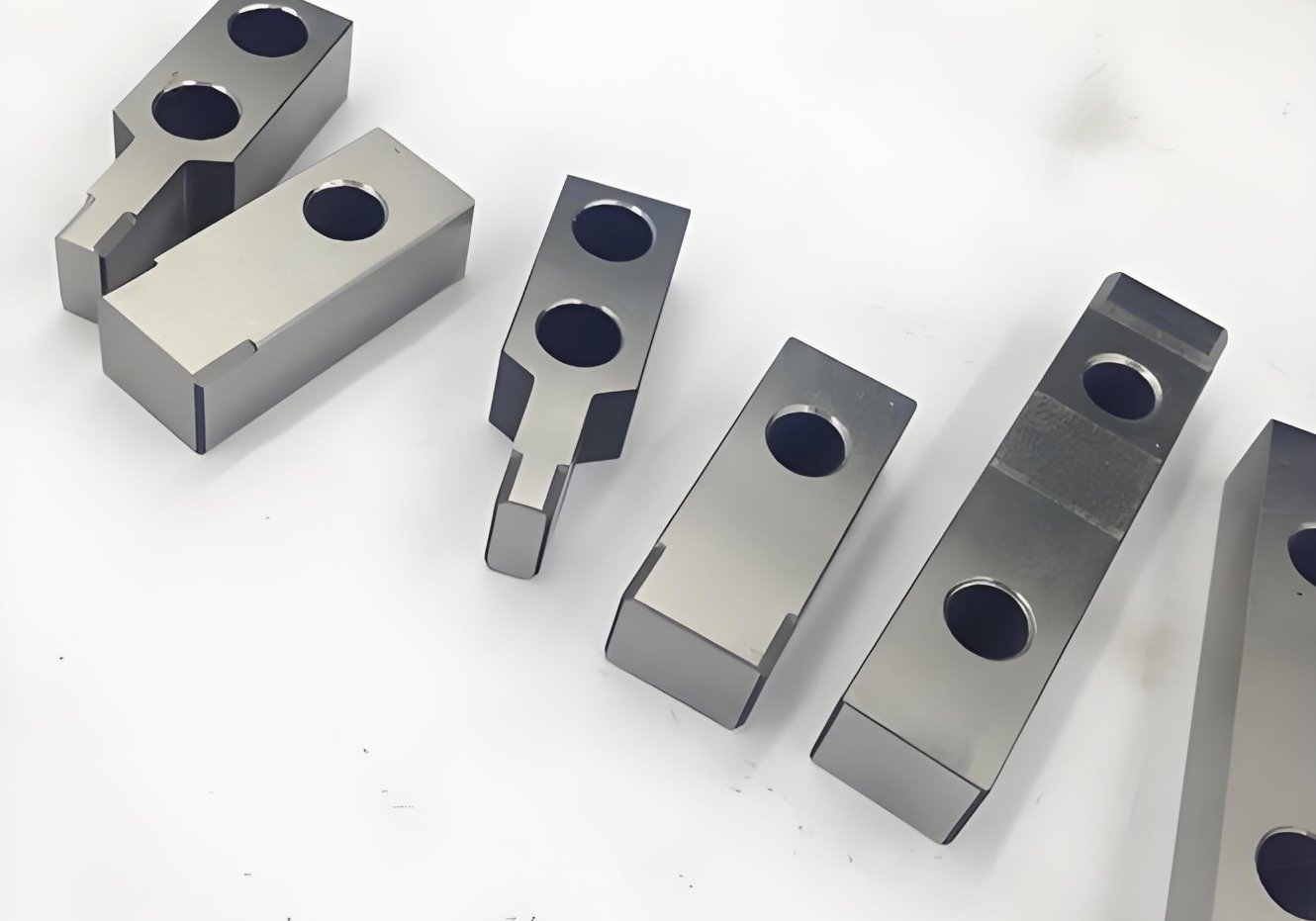

At Fecision, we specialize in manufacturing high-precision cores, cavities, slides, and inserts for industries demanding micron-level tolerances and long-lasting durability.

- ±0.002mm Tolerance: For medical micro-molding and automotive-grade precision.

- 15-Day Rapid Prototyping: From design to functional samples.

- Material Versatility: H13, P20, stainless steel, and DLC-coated components.

- Engineering Support: DFM analysis, emergency repairs, and lifecycle optimization.

Key Features

Ultra-Precision

≤0.002mm tolerance for micro-medical devices (e.g., IV connectors) and thin-wall electronics.

Complex Geometry

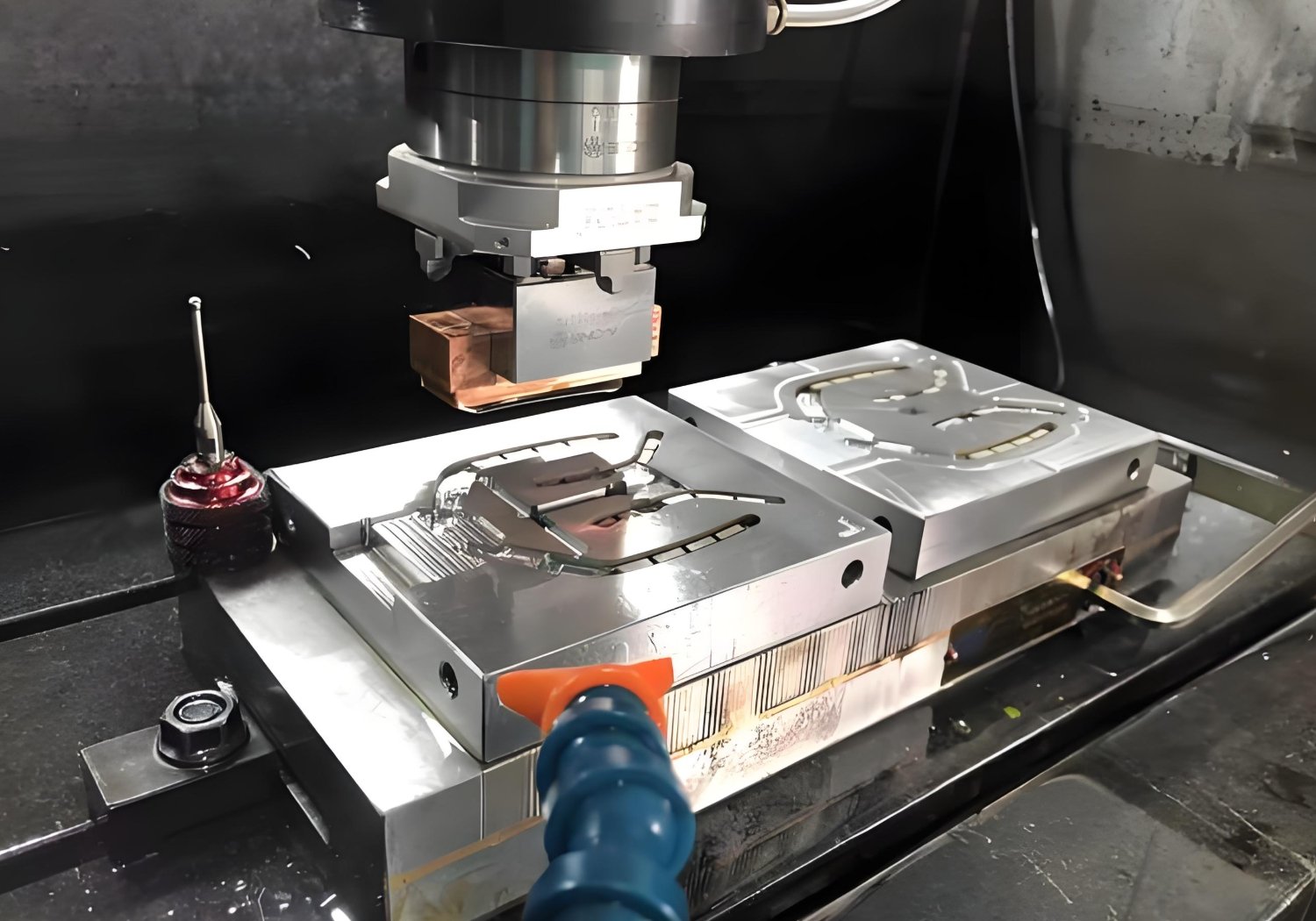

Multi-axis CNC/EDM machining for undercuts and micro-features.

Extended Durability

Vacuum heat treatment (48-62 HRC) + TiN/DLC coatings for 1M+ cycles.

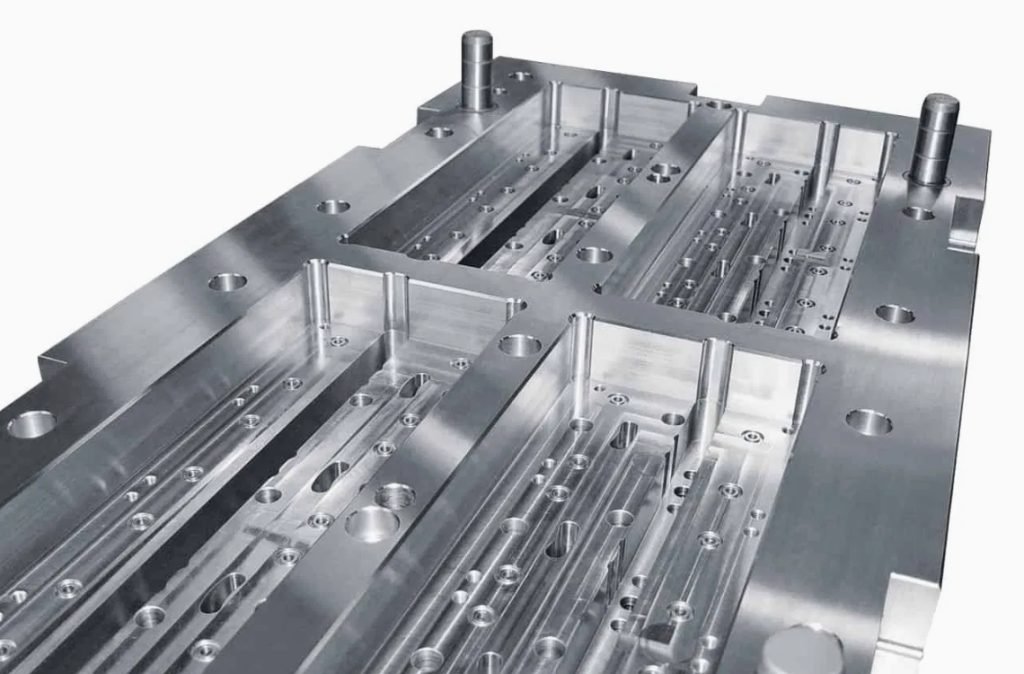

Category of Molding Components

Mold Cavity

Mold Core

Core Pins

Core Pin Retainer

Cavity Interlock

Insert

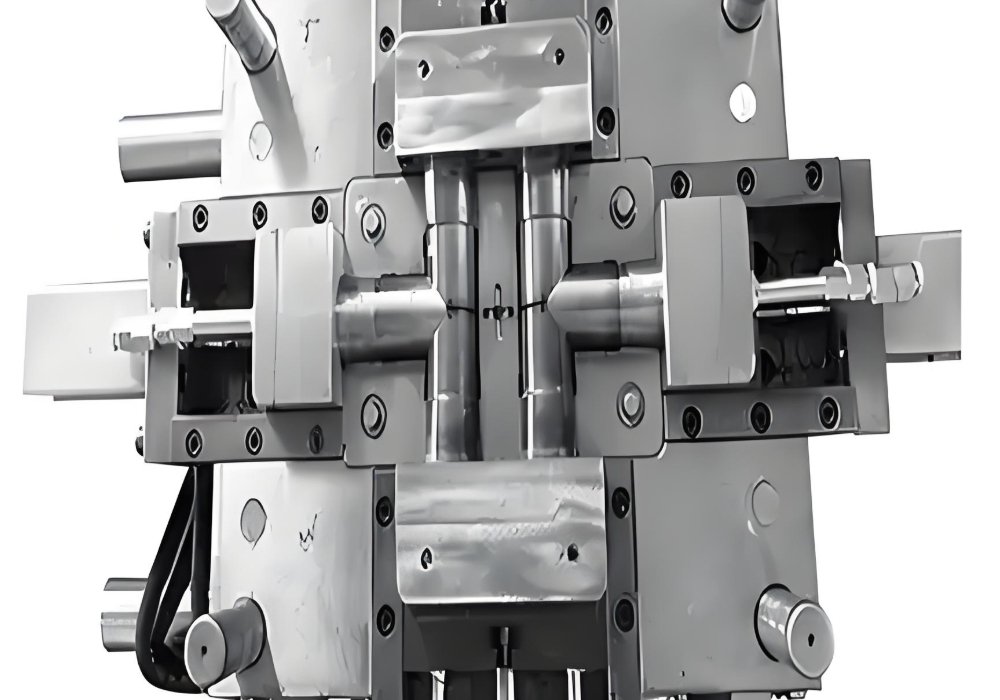

Slider

Lifter

Thread Ring

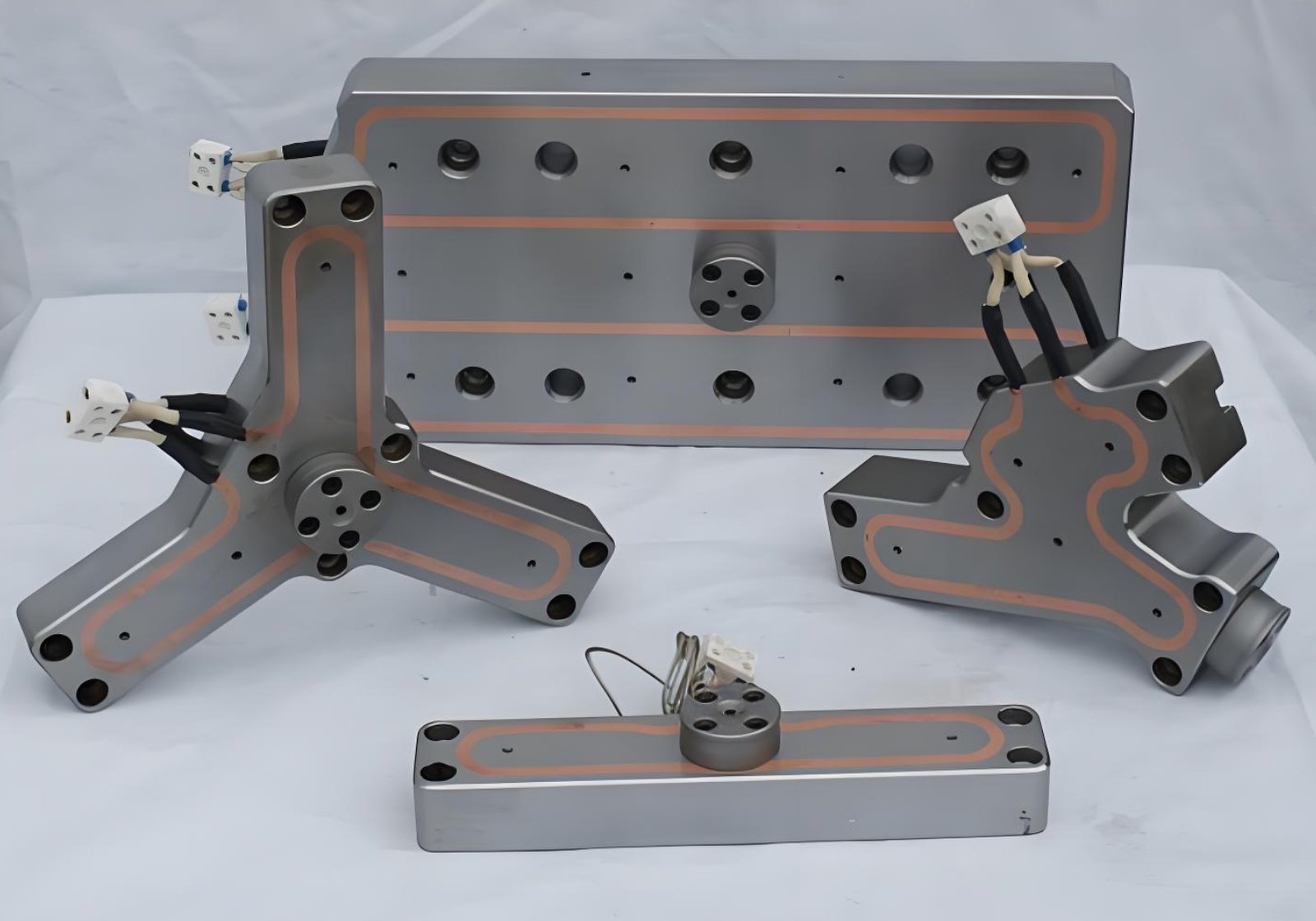

Fecision Mold Component Tooling Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

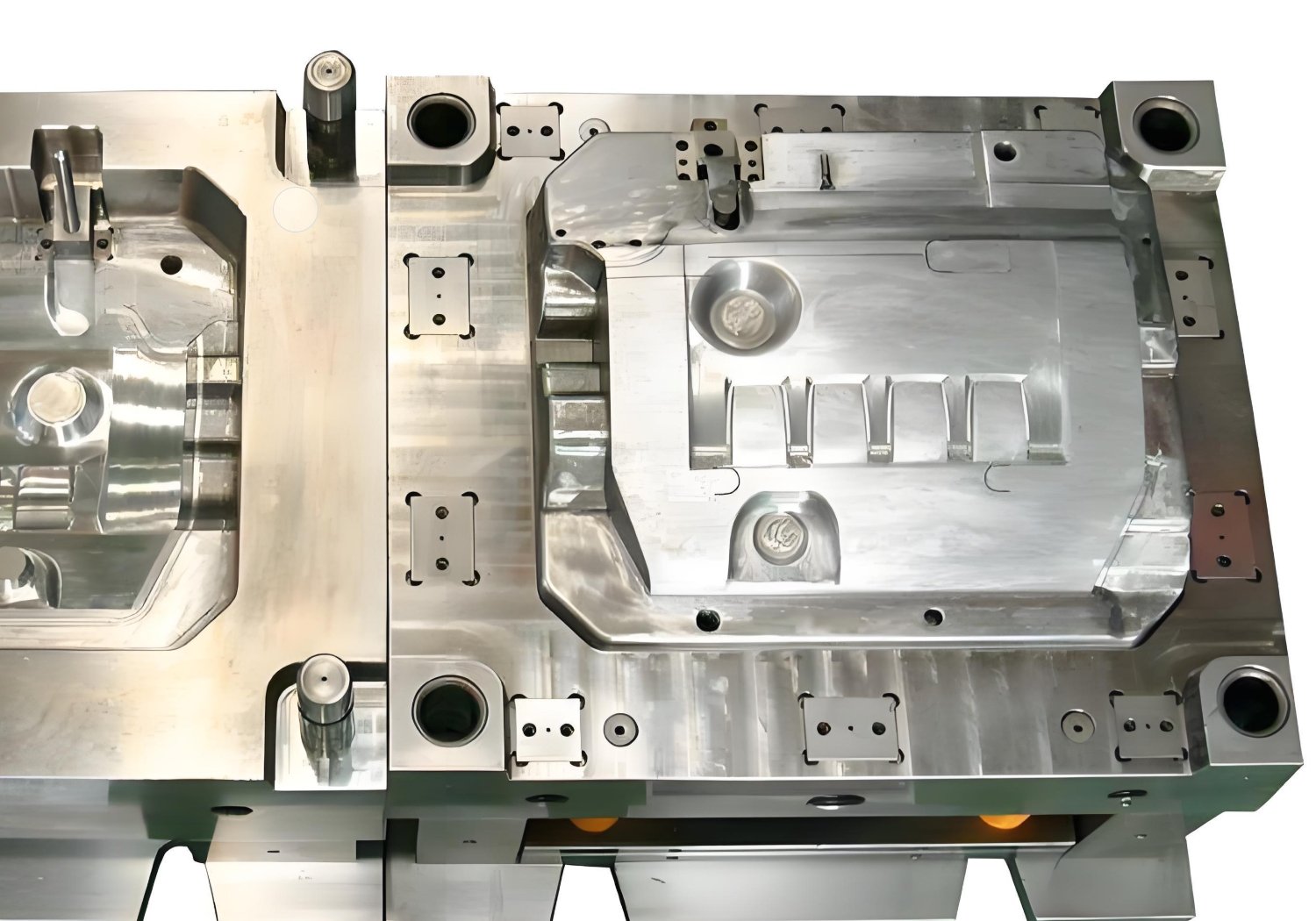

Technical Specs for Mold Components

Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing.

| Category | Parameter | Typical Value/Standard |

| Material Properties | Hardened steel grade (e.g., H13, S136) | AISI H13 (HRC 48-52) |

| Thermal conductivity (tool steels) | 24-30 W/m·K | |

| Dimensional Accuracy | Linear tolerance (core/cavity) | ±0.01 mm |

| Coaxiality (ejector pins) | ≤0.005 mm | |

| Surface Treatment | Surface roughness (polished cavities) | Ra ≤0.2 μm |

| Nitriding hardness | HV 800-1000 (DIN 50190) | |

| Machining Parameters | CNC positioning accuracy | ±0.005 mm (5-axis) |

| Wire-cut precision (LS-WEDM) | ±0.003 mm | |

| Quality Control | 3D measurement accuracy (CMM) | ±0.002 mm |

| Mold base standard | HASCO/DME |

Manufacturing Capabilities

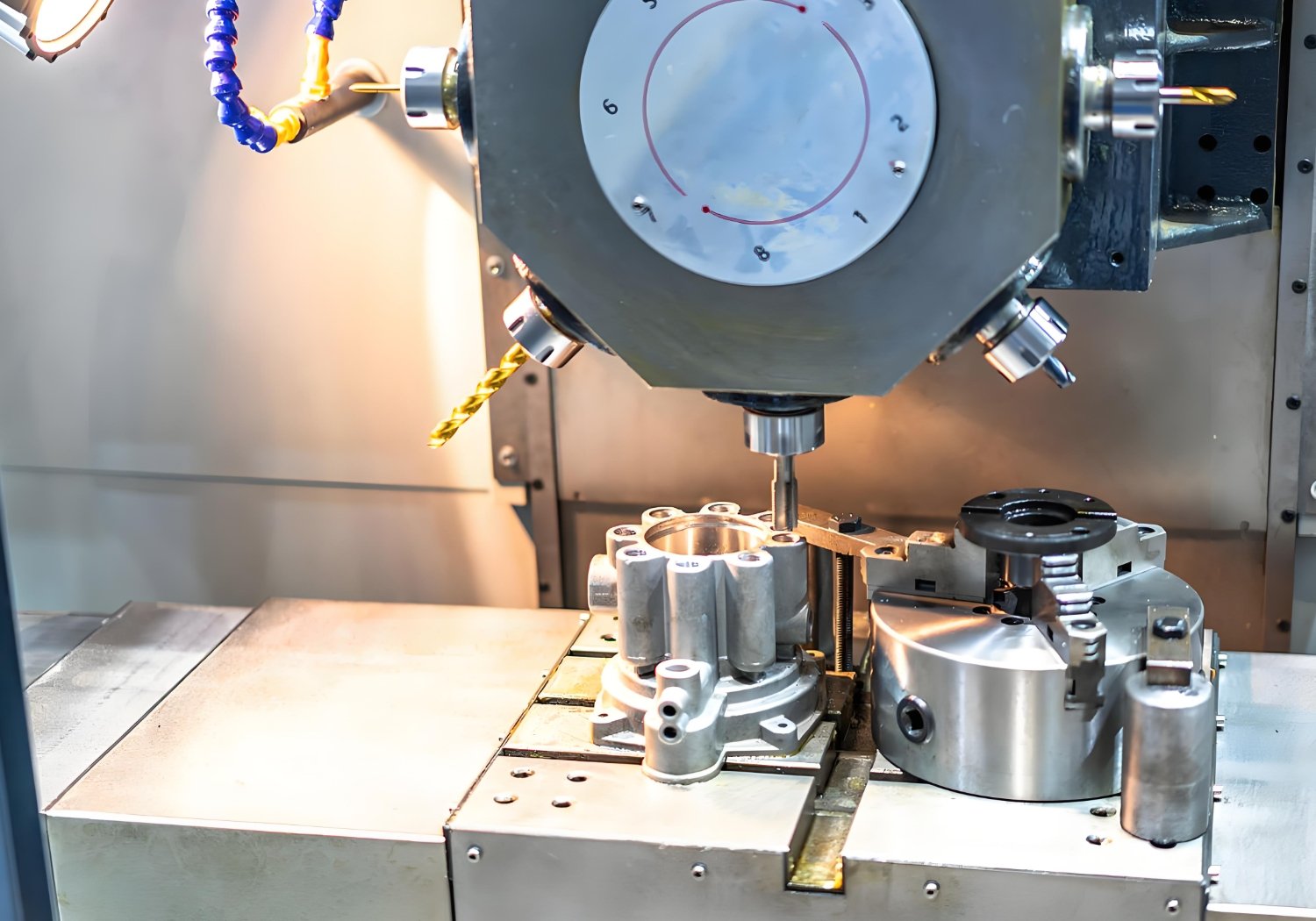

5-Axis CNC Machining

- Achieves Ra 0.1μm surface finish for optical-grade cavities.

Wire EDM

- Sharp internal corners (R0.02mm) for microfluidic medical components.

Grinding/Polishing

- Mirror finish (#12000 grit) for glossy consumer electronics housings.

Post-Processing & Surface Treatments

Heat Treatment

- Vacuum hardening + cryogenic treatment (-196°C) to minimize stress cracks.

Coatings

- DLC (Diamond-Like Carbon): Reduces friction by 60% for PC/PMMA transparent parts.

- TiN (Titanium Nitride): HV 2300 hardness for glass-filled nylon molds.

Texturing

- Laser etching for leather-grain finishes (automotive interiors).

Why Fecision for Mold Components?

Precision and Accuracy

Using state-of-the-art CNC machining, EDM, and other advanced manufacturing techniques, Fecision ensures all mold components meet tight tolerances and high-quality standards.

Customization

Fecision understands the unique needs of each project. Our team works closely with customers to provide tailored solutions, ensuring that each component fits perfectly within the target mold system.

Rapid Prototyping

Fecision offers rapid prototyping for mold components, enabling customers to test and refine designs quickly before moving into full production.

End-to-End Services

From initial design and DFM (Design for Manufacturability) analysis to final mold assembly and testing, Fecision handles every aspect of the mold component manufacturing process.

Process for Manufacturing Mold Components

Manufacturability Evaluation

The initial step involves assessing the manufacturablity of the mold component. If it's deemed feasible, we proceed with production immediately. If not, we will provide a detailed DFM (Design for Manufacturability) report to the customer. If necessary, mold flow analysis is performed to simulate the flow of molten material within the mold.

Material Selection

Next, choose the right material for mold parts. Common materials for mold components include steel alloys, aluminum, stainless steel, specialty alloys, etc. If needed, a prototype may be made using rapid prototyping techniques (e.g., 3D printing, CNC machining) to test the design for fit, function, and manufacturability.

Mold Components Manufacturing

Once the design and materials are finalized, the mold component undergoes CNC machining. If required, the mold component may undergo heat treatment, depending on the material and intended application. For certain components, surface hardening methods such as nitriding or carburizing are applied to increase wear resistance.

Shipping

For molds with multiple components, such as multi-cavity molds or molds with inserts, the individual components are carefully assembled into the final mold system. Once our engineers confirm the product meets all requirements, it will be shipped. We maintain ongoing communication to ensure the customer is fully satisfied with the product they receive.

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.