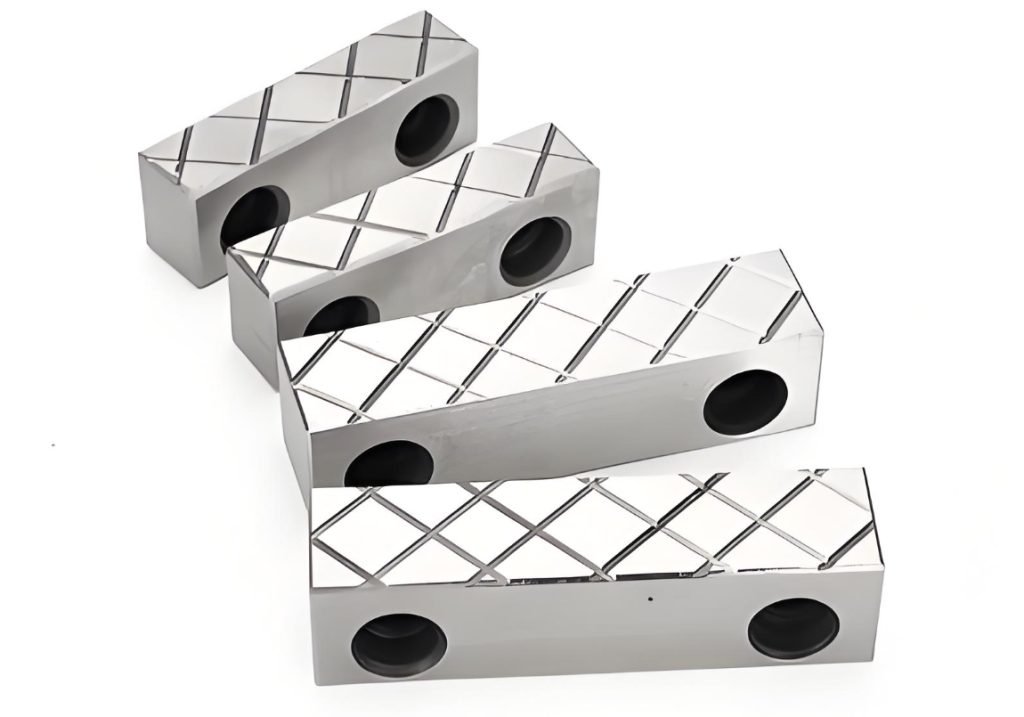

Wear Plate

- Robust Clamping: Locks punches firmly to prevent slippage.

- Accurate Positioning: Maintains punch alignment for flawless molding.

- Long-Lasting Design: Resists wear under high-pressure conditions.

- Adaptable Fit: Works with diverse punch sizes and mold setups.

Expert Craftsmanship

20+ Years of Expertise

Tailored Solutions

Custom designs

Rigorous Quality Control

ISO 9001-Certified Quality

Competitive Pricing

Cost-effective solutions

Global Support

Reliable delivery & technical assistance

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

No Minimum Order Quantities

In-Process Inspection with CMM

Wear Plates for Precision Injection Molding

Key Features

Processing Materials

Tool Steel (D2)

- Offers high hardness and exceptional wear resistance, perfect for heavy-duty applications.

Bronze with Graphite Plugs

- Features self-lubricating properties to reduce friction and prolong the life of moving parts.

Stainless Steel (420)

- Provides corrosion resistance, ideal for molds exposed to moisture or corrosive substances.

Custom Alloys

- Provides corrosion resistance, ideal for molds exposed to moisture or corrosive substances.

Surface Treatments and Post-Processing

Heat Treatment

Nitriding

PVD Coating (TiN, CrN)

Technical Specs for Mold Wear Plates

Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing.

| Parameter | Specification |

Surface Finish | Ra 0.4μm (Precision ground) |

| Hardness | 58-62 HRC (D2), 45-50 HRC (Bronze), 48-52 HRC (420 SS), Custom Hardness |

Tolerance | ±0.01mm (Custom tolerances available) |

Thickness Range | 5mm to 20mm (Custom thicknesses available) |

Standard Sizes | 100x50mm, 150x75mm, 200x100mm (Custom sizes upon request) |

Lead Time | 2-4 weeks for standard sizes; 4-6 weeks for custom configurations |

How to Choose

Mold Size

Ensure it fits the mold; custom sizes or pre-drilled holes help.

Wear Type

Choose based on wear type—hard steel for heavy loads, self-lubricating bronze for high speeds.

Environment

Select materials that handle the setting, like stainless steel for moisture or chemicals.

Cost & Durability

Durable options may cost more now but save later.

Need help? Our experts are ready to assist with tailored advice.

Fecision Mold Component Tooling Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Why Fecision for Mold Components?

Precision and Accuracy

Using state-of-the-art CNC machining, EDM, and other advanced manufacturing techniques, Fecision ensures all mold components meet tight tolerances and high-quality standards.

Customization

Fecision understands the unique needs of each project. Our team works closely with customers to provide tailored solutions, ensuring that each component fits perfectly within the target mold system.

Rapid Prototyping

Fecision offers rapid prototyping for mold components, enabling customers to test and refine designs quickly before moving into full production.

End-to-End Services

From initial design and DFM (Design for Manufacturability) analysis to final mold assembly and testing, Fecision handles every aspect of the mold component manufacturing process.

Process for Manufacturing Mold Components

Manufacturability Evaluation

The initial step involves assessing the manufacturablity of the mold component. If it's deemed feasible, we proceed with production immediately. If not, we will provide a detailed DFM (Design for Manufacturability) report to the customer. If necessary, mold flow analysis is performed to simulate the flow of molten material within the mold.

Material Selection

Next, choose the right material for mold parts. Common materials for mold components include steel alloys, aluminum, stainless steel, specialty alloys, etc. If needed, a prototype may be made using rapid prototyping techniques (e.g., 3D printing, CNC machining) to test the design for fit, function, and manufacturability.

Mold Components Manufacturing

Once the design and materials are finalized, the mold component undergoes CNC machining. If required, the mold component may undergo heat treatment, depending on the material and intended application. For certain components, surface hardening methods such as nitriding or carburizing are applied to increase wear resistance.

Shipping

For molds with multiple components, such as multi-cavity molds or molds with inserts, the individual components are carefully assembled into the final mold system. Once our engineers confirm the product meets all requirements, it will be shipped. We maintain ongoing communication to ensure the customer is fully satisfied with the product they receive.

Get Started Today!

Upgrade your mold components with our precision wear plates.

Contact us now for a quote or expert consultation!