Custom High-Quality Mold Components

With a focus on precision, durability, and efficiency, our components are designed to optimize your production process and enhance the performance of your molds.

Trust Fecision to deliver the mold components to make your projects a success.

Start your project now

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive AS9100 Quality Management

No Minimum Order Quantities

In-Process Inspection with CMM

Custom Mold Parts Tailored to Your Specifications

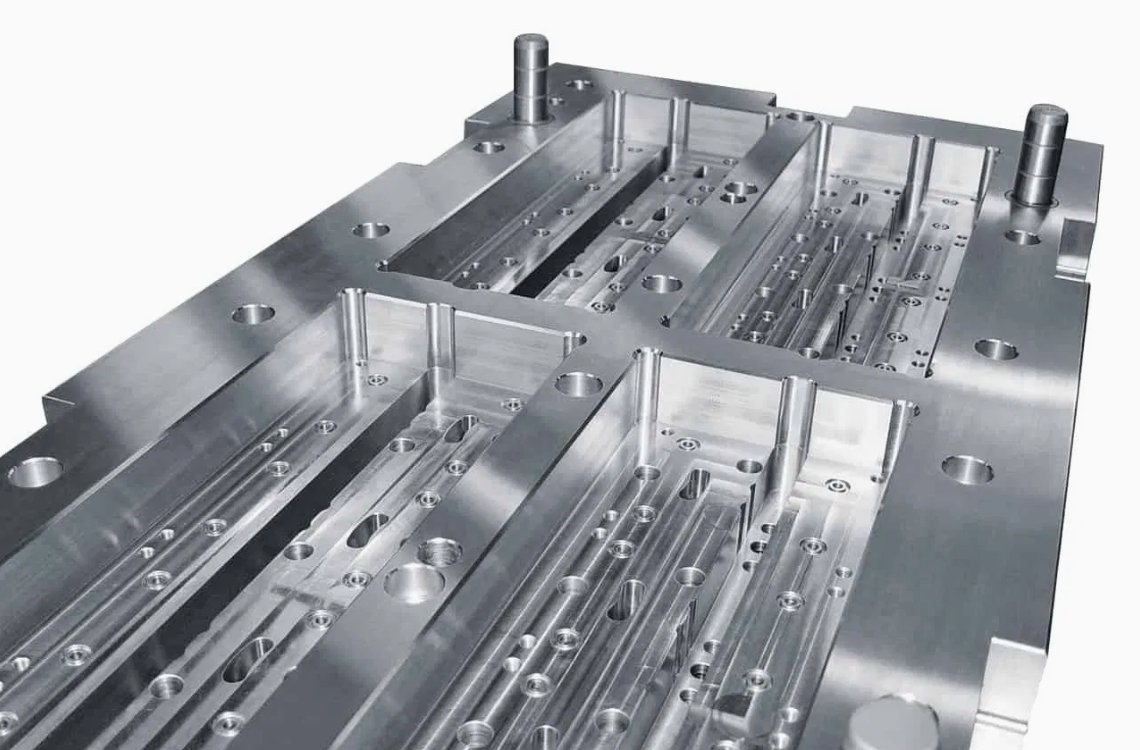

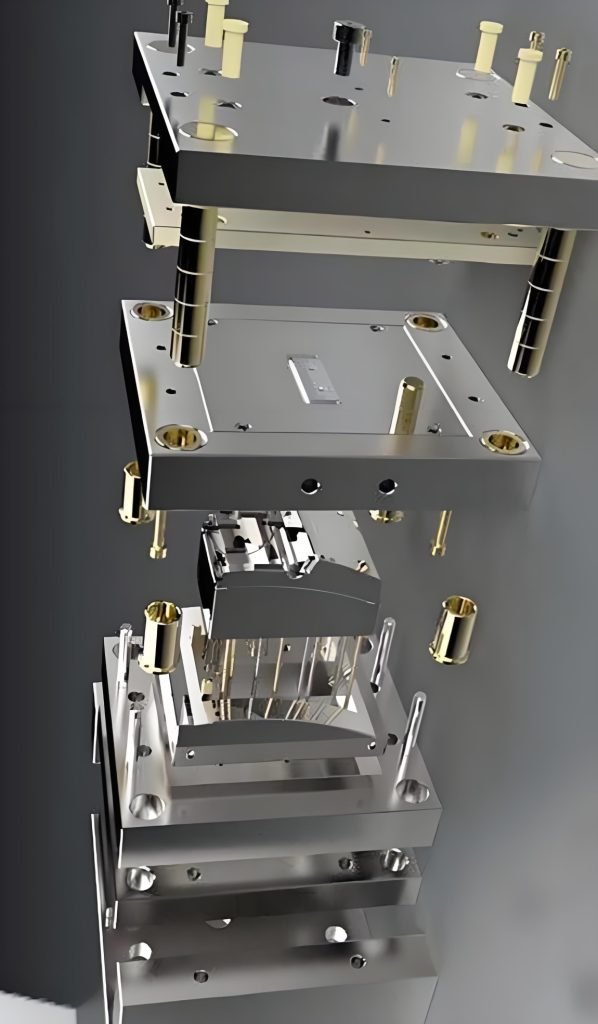

Mold components are essential parts of a mold used in manufacturing processes like injection molding and die casting. They are precision-engineered parts that form the core of molding systems, determining the shape, quality, and consistency of manufactured products. These critical elements must maintain dimensional accuracy even under extreme temperatures, pressures, and repetitive use.

From simple cavities to complex multi-cavity systems with intricate cooling channels, mold components directly impact production efficiency, part quality, and overall manufacturing costs. The performance of these components dictates the precision, surface finish, and repeatability of the final products.

The fundamental components of a mold can be broadly categorized into 8 key parts as follows.

Key Characteristics of High-Quality Mold Components

Exceptional dimensional accuracy and stability

Superior surface finish for high-quality part

High wear resistance for extended service life

Optimal thermal conductivity for efficient cooling

Precision alignment features for consistent part quality

List of Mold Components

There are different types pf mold components that can be classified into different categories.

Classification

Function

Parts

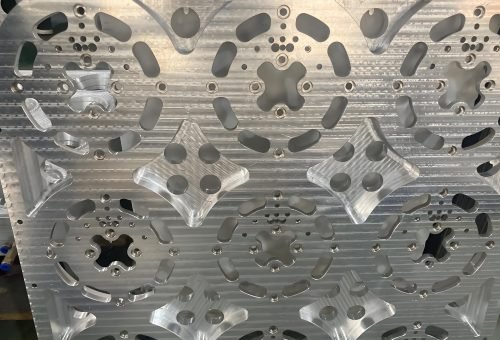

Molding Components

Core components directly involved in product formation, responsible for shaping the final product

Cavity, Core, Core Pin, Core Pin Retainers, Cavity Interlocks, Inserts, Sliders, Lifters, Thread Ring

Runner System Components

Responsible for transporting molten material from the injection molding machine nozzle to the mold cavity

Hot Runner, Sub-runner, Runner Plate, Sprue Bushing, Gates, Nozzles, Mainfold, Runner Shut-off Insert

Ejection System Components

Used to eject the product from the mold

Ejector Pins, Ejector Sleeves, Ejector Blades, Ejector Plates, Ejector Rod, Return Pin, Ejector Block, Ejector Spring, Stripper Plate, Pulerl Pin, Wear Plate

Guiding & Locating Components

Ensure accurate alignment and smooth operation of the mold

Guide Pins, Guide Pillars, Guide Bushings, Side Guide Block, Guide Rail, Guide Slider, Locating Pins, Locating Rings, Locating Blocks, Alignment Locks, Slide Retainers, Ejector Guide Pins, Return Spring, Stop Pins, Stop Block, Stop Discs, Mating Blocks, Angle Pins, Leader Pin, Dowels

Cooling System Components

Used to adjust mold temperature, ensure product quality and shorten molding cycle

Cooling Pin, Cooling Tubes, Baffles, Cascades, Cooling Nipples, Waterline Elbow, Fittings, Connector Plug, O-ring/Seal, Cooling Inserts, Pipe Plugs

Venting System Components

Evacuate air and gases from the mold to prevent air entrapment defects

Vent Plug, Venting Bushing, Venting Ejector Pins, Venting Blocks, Vent Grooves, Air Vent Valves, Air Poppets, Porous Inserts, Porous Metal/Steel

Structural & Support Components

Provide support and connection to ensure mold stability

Mold Base, Mold Plate, Mold Pad, Support Pillars/Columns, Fasteners, Bolts & Nuts, Mold Plate Screw, Limit Blocks, Limit Pins, Punch Holder, Spacer Blocks

Special Mold Components

Components for special molds

Stamping Die: Punch/Male Die, Die/Female Die, Pressure Plate

Die Casting Mold: Overflow Wells, Vacuum Valves, Spreader

Wedge Block, Locking Wedge

Ready to Start Your Mold Component Project?

Contact us to discuss your requirements and get a personalized quote.

Our professional team of mold part experts is ready to help with your project.

Mold Components for Different Molding Processes

Specialized components designed for specific molding technologies, each engineered to meet the unique requirements of different manufacturing processes.

Injection Molding

Mold parts for plastic injection molding, including cavities, cores, ejector systems, and cooling inserts designed to withstand high pressure and temperature cycles.

✅ Cavity and core inserts

✅ Ejector pins and sleeves

✅ Sprue bushings and runners

Metal Stamping

Essential components for metal stamping dies to endure repeated impact, high shear forces, and continuous production cycles.

✅ Punch and die inserts

✅ Stripper plates and pads

✅ Guide pillars and bushings

Die Casting

High-strength mold components for metal die casting, engineered to withstand extreme temperatures and pressures while maintaining precision.

✅ Die inserts and cavities

✅ Ejection systems

✅ Cooling channel inserts

Thermoforming

Precision mold components for shaping heated plastic sheets into various forms, featuring excellent thermal conductivity and surface finish.

✅ Forming tools and dies

✅ Trim tools

✅ Heating system components

Compression Molding

High-strength mold components for metal die casting, engineered to withstand extreme temperatures and pressures while maintaining precision.

✅ Die inserts and cavities

✅ Ejection systems

✅ Cooling channel inserts

Metal Extrusion

Precision dies and tooling for continuous production of plastic profiles with consistent cross-sections and dimensional accuracy.

✅ Extrusion dies

✅ Calibration tools

✅ Profile cutting tools

Parts and Components of an Injection Mold

The building blocks of injection molds, each component playing a critical role in the production of high-quality plastic parts.

Core Components of an Injection Mold

These fundamental components form the basic structure of every injection mold, responsible for shaping the plastic material and controlling the molding process. They are designed for durability, precision, and consistent performance.

Advanced Injection Mold Components for Complex Designs

For complex part geometries and specialized molding requirements, advanced components provide solutions for undercuts, thread formation, multi-material molding, and other challenging design features.

Slider and Lifters

Mechanisms that create undercuts and complex geometries by moving perpendicular to the mold opening direction, retracting before part ejection.

Threaded Inserts and Cores

Rotating components that form internal or external threads in the molded part, often synchronized with the mold opening/closing cycle.

Hot Runner Systems

Maintains molten plastic in the runner system, eliminating runner waste and enabling faster cycle times and more consistent filling.

Valve Gates

Mechanically controlled gates that precisely regulate the flow of molten plastic into the cavity, improving part quality in multi-cavity molds.

Insert Molding Components

Specialized fixtures and positioning systems for accurately placing metal or plastic inserts within the mold cavity during the molding process.

Gas Assist Components

Systems that inject gas into thick sections of the molded part, reducing cycle time, minimizing warpage, and improving surface finish.

Fecision Mold Component Tooling Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Common Materials for Injection Mold Components

Selection of appropriate materials is critical for mold performance, with different alloys offering unique properties to meet specific application requirements.

Tool Steels

The most common materials for mold components, offering excellent combination of hardness, toughness, and wear resistance.

- AISI P20 (Pre-hardened)

- AISI H13 (Heat resistant)

- AISI S7 (Shock resistant)

- AISI D2 (High wear resistance)

Best for: General purpose molds, high-volume production, abrasive materials

Stainless Steels

Offer superior corrosion resistance and polishability, ideal for molds requiring high surface finish or used with corrosive materials.

- 420 Stainless Steel

- 440C Stainless Steel

- 1.2083 (Medical grade)

- 1.2316 (Corrosion resistant)

Best for: Medical molds, food-grade applications, corrosive environments

Special Alloys

Advanced materials for specialized applications requiring extreme temperature resistance, conductivity, or other unique properties.

- Beryllium Copper

- Aluminum Bronze

- Titanium Alloys

- Nickel-Based Superalloys

Best for: Medical molds, food-grade applications, corrosive environments

Material Properties Comparison

| Material | Hardness (HRC) | Wear Resistance | Corrosion Resistance | Thermal Conductivity | Polishability |

| P20 Tool Steel | 28-32 | Medium | Low | Medium | Good |

| H13 Tool Steel | 42-48 | High | Low | Medium | Good |

| 420 Stainless Steel | 48-52 | High | Good | Medium | Excellent |

| 1.2316 Stainless Steel | 30-34 | Medium | Excellent | Medium | Excellent |

| Beryllium Copper | 30-40 | Medium | Good | Excellent | Good |

| D2 Tool Steel | 58-62 | Very High | Low | Low | Fair |

Technical Specs for Mold Components

Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing.

| Category | Parameter | Typical Value/Standard |

| Material Properties | Hardened steel grade (e.g., H13, S136) | AISI H13 (HRC 48-52) |

| Thermal conductivity (tool steels) | 24-30 W/m·K | |

| Dimensional Accuracy | Linear tolerance (core/cavity) | ±0.01 mm |

| Coaxiality (ejector pins) | ≤0.005 mm | |

| Surface Treatment | Surface roughness (polished cavities) | Ra ≤0.2 μm |

| Nitriding hardness | HV 800-1000 (DIN 50190) | |

| Machining Parameters | CNC positioning accuracy | ±0.005 mm (5-axis) |

| Wire-cut precision (LS-WEDM) | ±0.003 mm | |

| Quality Control | 3D measurement accuracy (CMM) | ±0.002 mm |

| Mold base standard | HASCO/DME |

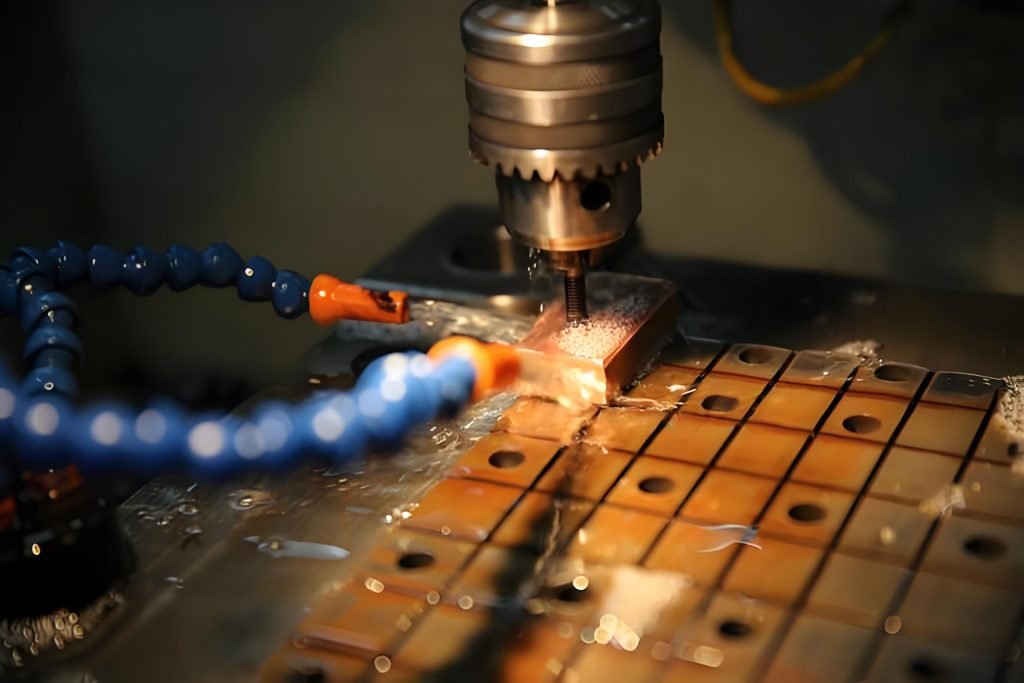

Processing Technology of Injection Mold Parts

Advanced manufacturing processes that enable the production of high-precision mold components with complex geometries and superior surface finishes.

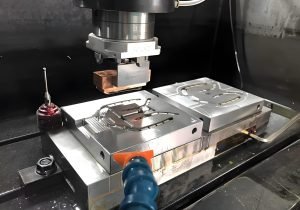

Precision CNC Machining

Computer-controlled machining processes that create complex mold components with exceptional accuracy and repeatability. Multi-axis machining centers enable the production of intricate geometries in a single setup.

CNC Milling

3-5 axis capabilities for complex 3D features

CNC Turning

Precision turning for cylindrical components

Tolerance Capability

Up to ±0.0001" (0.0025mm)

Surface Finish

Down to 4 RMS

Electrical Discharge Machining (EDM)

Non-contact machining process that uses electrical discharges to shape hard materials with extreme precision, ideal for complex cavities, thin walls, and intricate details that are difficult to machine with traditional methods.

Sinker EDM

For complex 3D cavities and shapes

Wire EDM

For precision cutting and contours

Tolerance Capability

Up to ±0.00005" (0.0013mm)

Surface Finish

Down to 8 RMS

Grinding & Polishing

Precision abrasive processes that achieve tight tolerances and superior surface finishes critical for mold performance and part quality.

- Surface grinding for flatness

- Cylindrical grinding for roundness

- Jig grinding for precision holes

- Progressive polishing for mirror finishes

Heat Treatment

Controlled heating and cooling processes that optimize the mechanical properties of mold materials for enhanced performance and longevity.

- Hardening and tempering

- Nitriding for surface hardness

- Carburizing for wear resistance

- Stress relieving

Surface Treatments

Specialized processes that modify the surface properties of mold parts to improve wear resistance, release properties, and corrosion resistance.

- PVD and CVD coatings

- Chromium plating

- Texturing for part aesthetics

- Release agents and coatings

Our Advanced Manufacturing Process

Design & Engineering

CAD modeling and DFM analysis to optimize component design for manufacturability, performance, and cost-effectiveness.

Heat Treatment

Controlled heat treatment processes to optimize material properties for the specific application requirements.

Material Selection

Choosing the optimal material based on application requirements, considering factors like hardness, wear resistance, and corrosion resistance.

Finishing & Coating

Precision grinding, polishing, and specialized coatings to achieve final dimensions, surface finish, and performance characteristics.

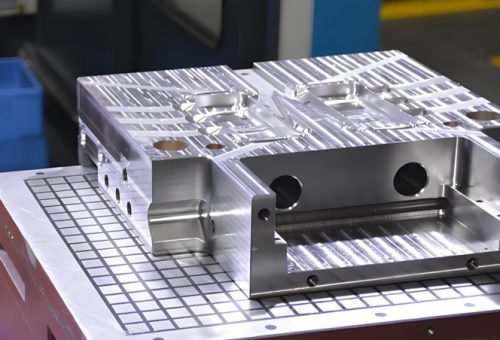

Precision Machining

Advanced CNC machining and EDM processes to create components with exceptional accuracy and surface finish.

Quality Inspection

Comprehensive inspection using advanced metrology equipment to verify dimensions, surface finish, and material properties.

Why Fecision for Mold Components?

Precision and Accuracy

Using state-of-the-art CNC machining, EDM, and other advanced manufacturing techniques, Fecision ensures all mold components meet tight tolerances and high-quality standards.

Customization

Fecision understands the unique needs of each project. Our team works closely with customers to provide tailored solutions, ensuring that each component fits perfectly within the target mold system.

Rapid Prototyping

Fecision offers rapid prototyping for mold components, enabling customers to test and refine designs quickly before moving into full production.

End-to-End Services

From initial design and DFM (Design for Manufacturability) analysis to final mold assembly and testing, Fecision handles every aspect of the mold component manufacturing process.

Process for Manufacturing Mold Components

Manufacturability Evaluation

The initial step involves assessing the manufacturablity of the mold component. If it's deemed feasible, we proceed with production immediately. If not, we will provide a detailed DFM (Design for Manufacturability) report to the customer. If necessary, mold flow analysis is performed to simulate the flow of molten material within the mold.

Material Selection

Next, choose the right material for mold parts. Common materials for mold components include steel alloys, aluminum, stainless steel, specialty alloys, etc. If needed, a prototype may be made using rapid prototyping techniques (e.g., 3D printing, CNC machining) to test the design for fit, function, and manufacturability.

Mold Components Manufacturing

Once the design and materials are finalized, the mold component undergoes CNC machining. If required, the mold component may undergo heat treatment, depending on the material and intended application. For certain components, surface hardening methods such as nitriding or carburizing are applied to increase wear resistance.

Shipping

For molds with multiple components, such as multi-cavity molds or molds with inserts, the individual components are carefully assembled into the final mold system. Once our engineers confirm the product meets all requirements, it will be shipped. We maintain ongoing communication to ensure the customer is fully satisfied with the product they receive.

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.

Mold Components FAQs

Yes, mold components can be designed and manufactured for both plastic injection molding and metal injection molding (MIM). The components are tailored for each process, with specific attention to factors like material compatibility, thermal conductivity, and part geometry.

The design of mold components is mainly influenced by part geometry and complexity, the material used, production volume and tolerance and accuracy.

The lead time for manufacturing mold components can vary based on factors such as complexity of the mold design, the materials used, required machining and finishing processes and production volume typically. It takes anywhere from a few days for simpler components to several weeks for more complex ones.

The lifespan of mold components largely depends on factors like the material used, the complexity of the part being molded, and the production volume. Mold components made from hardened steel for high-volume production can last hundreds of thousands to millions of cycles. Components in molds for lower-volume runs or non-abrasive materials may wear out more quickly.

Yes, Fecision offers custom manufacturing based on client specifications. Customization can include specialized shapes, unique sizes, and modifications to meet specific performance requirements or design challenges.

At Fecision, quality control is achieved through a combination of methods, including dimensional inspection using tools like CMM (Coordinate Measuring Machines), material testing to ensure the mold components meet the required hardness and durability, functional testing of components like ejector pins and cooling channels to ensure they perform as expected, and surface finish inspections for proper polishing and finishing standards.

Mold components are designed and manufactured to be compatible with the final mold assembly through tight tolerances, precise alignment, and regular communication with the assembly team. During the manufacturing process, components undergo testing and inspection to ensure they fit and function correctly in the mold assembly.

Mold components such as cores, cavities, ejector pins, and guide pins typically require surface finishing. This can involve processes like polishing, grinding, or coating to improve surface quality, reduce friction, and enhance durability, especially in high-volume applications.

To ensure durability and longevity, we use high-quality materials like hardened steel, stainless steel, or specialty alloys. We also apply heat treatments like quenching, tempering, or nitriding to enhance wear resistance and strength. Regular quality control checks during the manufacturing process ensure all components meet stringent durability standards.

Yes, Fecision specializes in the manufacturing of custom mold components for complex parts. With advanced technologies like CNC machining, EDM, and mold flow analysis, we can create highly detailed and precise components that meet the specific needs of your product.