CNC machining is at the center of modern manufacturing to create highly accurate parts. It uses computer-controlled tools to manufacture individual parts with tight tolerance and accuracy. The major processes – milling, turning, and mill-turn– are all ways to remove material in order to form a workpiece and are very important processes in the industry.

If you want your projects to be successful, it is very important to choose the right process. This guide will help you understand the differences between milling vs turning, vs mill-turning, as well as help you understand the necessary things to make an informed decision on the right process for success.

What Is Milling?

Definition

Milling is a CNC process that removes material from a stationary workpiece using a rotating, multi-point cutting tool. It is like a sculptor with a precise and computer-controlled machine. Milling is capable of producing a wide range of shapes and complexities that are challenging to produce using other processes.

The multiple axes in a milling machine will move the cutting tool in multiple directions and allow for a high degree of freedom. This is a distinct advantage of milling when producing flat surfaces, slots, holes, or 3D contours. Such capability brings incredible versatility and makes milling an important and widely used process in many industries.

Key Features

The milling machine is a versatile machine that can move a cutting tool on three, four, or five axes. The axes can allow for intricate or elaborate designs, and it is common for machines, such as a 5-axis mill, to be able to machine a part from almost every angle, without repositioning the part. This can save time and become much more precise.

Milling machines meet tolerances precisely, achieving tolerances as small as ±0.001 inches. This is essential to making parts that fit together perfectly. Milling can be performed on many different material types – metals like aluminum, titanium, and plastics like ABS. Because of this, milling has become a very important process for a wide scope of projects.

Benefits

The greatest advantage of milling is in creating complex geometries. This is ideal for intricate parts with multiple angles and unique shapes. It is well-suited for components in both aerospace and medical applications that require accuracy, precision, and strict dimensions. Because of its power and precision, it is a great tool for one-of-a-kind custom complex projects.

Milling is also extremely versatile, working with a combination of materials. This allows manufacturers to have a single machine to work on a variety of projects for manufacturers. While there may be other processes that may be faster, milling is the overall machine that can flexibly machine complex and detailed components and quality parts.

Applications

Milling is a versatile process that is used in countless industries. In aerospace, it creates lightweight, strong airframe and engine components. In automotive, it is to create strong, long-lasting engine blocks and transmissions. It can also produce very precise surgical instruments and implants for medical use. Besides, an example of milling in the electrical field includes custom heat sinks and enclosures, to which proper specifications are critical.

What Is Turning?

Definition

Turning is a CNC process where the workpiece rotates around a stationary cutting tool. Similar to a potter’s wheel, this process quickly removes material to shape a part. It is designed to create cylindrical components, such as shafts, bushings, and bolts, allowing high efficiency and precision with perfectly round shapes.

A lathe is the machine tool that is used for turning. It holds the workpiece in a chuck and spins the workpiece at a high speed. The cutting tool is then fed into the workpiece to create the desired shape. In general, turning is a great process to create simple, cylindrical forms and also complex parts with features such as threads, grooves, etc. Modern manufacturing would likely come to a stop without turning.

Key Features

The key feature of turning is the rotating workpiece. While in milling, it is the tool that rotates; in turning, it is the part that spins. This enables a very fast material removal process, which differentiates turning from others by being highly efficient. Being able to rotate the workpiece, turning is best suited for parts with a circular cross-section.

Another distinguishing aspect is the ability to perform high-speed cutting. The rapid technologies of material removal processes of turning offer a high degree of efficiency for high production volumes. Besides, turning also allows for a very smooth surface finish, often requiring little to no post-machining treatment, which in turn can save considerable time and expense in the finishing stage.

Benefits

Turning is considered the most speedy process, and it is the first choice in the mass production of cylindrical parts. It has the ability to produce thousands of identical parts in a short span of time. In addition, turning creates exceptionally smooth finishes, which is beneficial for parts that will be exposed to an aesthetic surface finish or on very tight tolerances for smoothness.

In comparison to milling, turning also tends to have lower setup costs when machining simple cylindrical parts. Typically, the machines are simpler to program and operate for simplistic operations. This provides a cost-effective solution for creating high production volumes of round parts.

Applications

Turning is used extensively in industries that rely on a lot of cylindrical parts. The automotive industry uses turning to make shafts, pistons, or bushings. The aerospace industry counts on turning to create engine shafts or components for landing gear. The medical field utilizes manufacturing surgical tools and implants. The oil and gas industry relies on it to create fittings or couplings for pipelines that need to be absolutely circular.

What Is Mill-Turn?

Definition

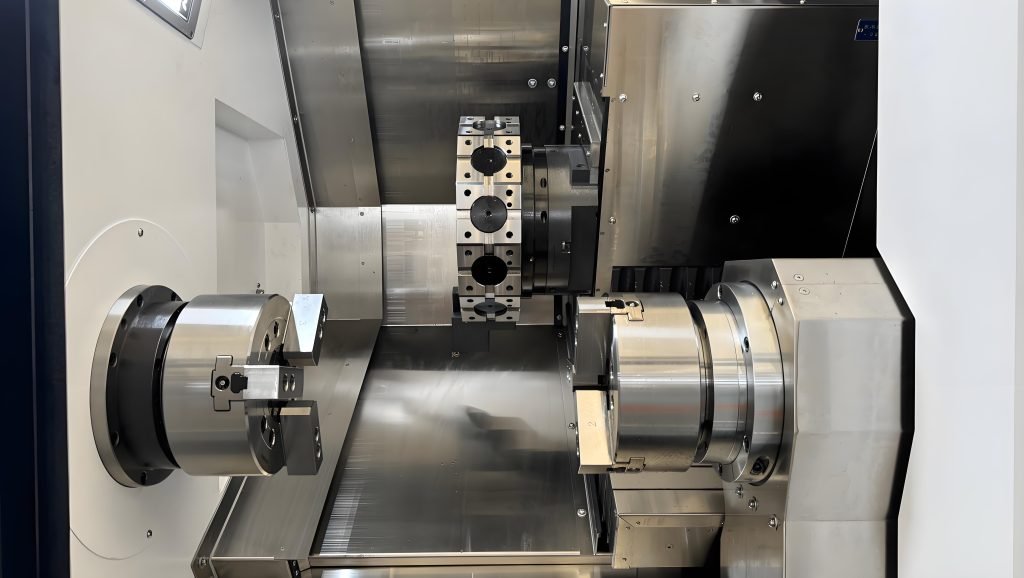

Mill-turn is a hybrid CNC machining process that utilizes both milling and turning on one machine. It can leverage both functions, so you benefit from having a lathe and milling machine all in one place. You can go through both operations on the workpiece without having to relocate it. The ability to do this enables huge time savings and enhances accuracy.

Mill-turn machines are essentially advanced lathes with additional milling capabilities. They have multiple tools, and since they can also use rotating milling tools, the range of what can be accomplished is impressive in terms of complex parts being both cylindrical and non-cylindrical.

Key Features

Mill-turns are great as the operations are integrated into one machine. You can create a basic cylindrical shape and then apply features like flats, holes, and keyways with milling tools without ever unchucking the part. This will save time and eliminate the need to move the workpiece from one machine to another, potentially reducing the risk of errors.

Because the part never leaves one machine, mill-turn provides unprecedented precision. It isn’t as likely to suffer from the alignment issues you would have when moving a part from one machine to another, making it ideal for components that have very tight tolerances and are more complex. Therefore, it continues to be used by manufacturers on projects with a range of materials and part geometries.

Benefits

The greatest advantage of mill turn machining is increased efficiency. By combining two processes into one, you cut down drastically on production time since you will spend less time setting up jobs and handling parts, giving your customer a finished part faster. Additionally, your accuracy will improve because the part stays fixed instead of being realigned after milling.

Mill-turn machines can do anything from simple turning to multiple-axis milling, so they are a very valuable machine for any manufacturer who has to create a mixture of parts. They shine in projects that require complex parts that would typically require multiple setups.

Applications

Mill-turn is a game-changer for industries requiring complex parts. It is used in aerospace for intricate aircraft components, and in the medical field for creating detailed surgical instruments and prosthetics. The automotive industry uses it for complex engine and steering parts, while electronics relies on it for precision hardware components that have turned and milled features.

Milling vs Turning vs Mill-Turn: Key Differences Explained

The following is a quick summary and may help you better distinguish between the differences of CNC milling vs CNC turning, vs CNC mill-turn.

| Feature | Milling | Turning | Mill-Turn |

| Workpiece Movement | Stationary, tool moves | Rotates, tool stationary | Rotating (turning) and stationary (milling) |

| Cutting Tools | Multi-point cutting tools | Single-point cutting tools | Both multi-point and single-point tools |

| Complexity | High (complex geometries) | Low to medium (cylindrical parts) | High (complex geometries) |

| Setup Time | Moderate | Fast | Longer (but fewer setups) |

| Axes | 3/4/5-axis (X, Y, and Z) | 2-axis (X and Z) | 3/4/5-axis (combined) |

| Production Speed | Slower for complex parts | Faster for cylindrical parts | Fast and efficient for complex cylindrical parts |

| Setup Time | Moderate | Fast | Longer (but fewer setups) |

| Best For | Complex 3D shapes | Cylindrical parts | Hybrid complex parts |

Milling vs Turning vs Mill-Turn: Which Should You Choose?

Regardless of whether you choose milling, turning, or mill-turn, it is all predicated on the requirements of the part.

When to Choose Milling?

Choose milling if the part requires machining that is defined by complex geometry, intricate designs, many angles, or uniqueness. It is the best option when the part is not considered circular or tubular shape. You could select milling if the part only has complex pockets or slots or multiple faces to be machined. If you find yourself in these situations, then milling provides you with the layout flexibility for unique shapes.

When to Choose Turning?

Choose turning for fast and efficient production of cylindrical parts with simple geometry, especially in high numbers. Turning is the most cost-effective and fastest process for a part that is simply a shaft, bushing, or screw, and for which you will be mass-producing a simple round part.

When to Choose Mill-Turn?

Choose mill-turn for the production of complex cylindrical parts with some turned features and some milled features. In this case, the part may start as a cylinder, yet also have turned features such as off-centered holes, flats, and keyways. Mill turn machining is the most efficient process for manufacturing a complex part, in a single setup, which saves you processing time with the benefit of the best accuracy.

Still not sure? Talking to an expert is the best way to find out. A conversation with a machining expert will help you work through your design, optimizing your design for style and process efficiency.

Why You Should Choose Fecision for Milling, Turning & Mill-Turn?

When it comes to getting your parts made, you need a partner you can trust. Fecision has the knowledge, expertise, and technologies to help facilitate all your milling, turning, and mill-turn requirements with a complete range of services and an emphasis on quality and precision.

Milling

Fecision uses advanced 3, 4, and 5-axis milling machines to manufacture complex workpieces with remarkable detail and accuracy, supported by our ISO 9001: 2015 certification of the highest quality standards. With in-process CMM inspection, we confirm that every part meets your specifications, as precision tolerances can be as tight as ±0.001″.

Turning

When you choose Fecision’s turning services, you can choose from many materials, for example, aluminum, stainless steel, brass, and various plastics, to achieve extraordinarily high precision and smooth surface finishes. Our services are competitively priced and without minimum order quantities, making us ideal for rapid prototyping or high-volume production.

Mill-Turn

Our mill-turn capabilities are second to none. By implementing a mill-turning CNC machine, we improve efficiency and accuracy in producing complex parts, with fewer program interruptions for setup. Our qualified engineers will provide Design for Manufacturability (DFM) feedback and optimized solutions to ensure a successful outcome on your project.

Upgrade your manufacturing—work with Fecision’s CNC machining experts now!

Conclusion

Milling, turning, and mill-turn are all powerful CNC processes. For complex, non-cylindrical parts, milling is the best option for the initial machining process. Turning is ideal for high-volume cylindrical components. And mill-turn includes both and is capable of producing detailed parts with both round and milled features. Selecting the proper CNC machining process is key to saving time and money while achieving quality throughout development and production.

Ready to start your next project? Contact Fecision today to discuss your milling, turning, and mill-turn needs. Our team is here to help you turn your ideas into reality.