You might be surprised to know that magnesium is the eighth most abundant element in the Earth’s crust. This lightweight metal plays a crucial role in various industrial applications due to its unique properties.

As a highly reactive metal, magnesium is often used in super-strong, lightweight materials and alloys. Its melting point is a critical property that influences its processing and performance in different applications.

Understanding the melting behavior of this versatile metal is essential for engineers and manufacturers working with it. You will gain insights into how magnesium’s melting properties affect its alloying capabilities and overall performance.

What is Magnesium?

Magnesium (Mg) is a silvery-white metal located in Group 2, Period 3 of the periodic table, with an atomic number of 12 and an atomic weight of 24.305. It boasts a remarkably low density of 1.74 g/cm³, making it approximately two-thirds lighter than aluminum. This lightweight metal is valued for its high strength-to-weight ratio, impact resistance, and excellent dent resistance.

Occurrence in Nature

Magnesium is too reactive to occur naturally as an element; instead, it’s found in minerals like dolomite and magnesite. It’s also the third most abundant element dissolved in seawater. Magnesium compounds are widespread throughout the Earth’s crust, constituting about 2% of its composition by weight, making it the eighth most abundant element on our planet.

The Melting Point of Magnesium

You need to know the melting point of magnesium to effectively utilize it in manufacturing. The melting point is a critical property that determines how magnesium is processed and applied in various industries.

Understanding Magnesium’s Melting Point of 650°C

Magnesium has a well-defined melting point of 650°C (1202°F), marking the temperature at which it transitions from a solid to a liquid state. This relatively low melting point compared to many structural metals gives magnesium an advantage in casting and forming processes, particularly where energy efficiency is crucial.

Comparison with Boiling Point

Notably, there’s a significant gap between magnesium’s melting point (650°C) and its boiling point of 1107°C (2025°F). This wide temperature range provides a broad working window for liquid processing. Understanding this temperature difference is vital for quality control in magnesium casting operations, as variations can affect the final properties of magnesium components.

Physical Properties of Magnesium

You might be surprised by the impressive physical properties of magnesium, which include its low density and high strength-to-weight ratio. Understanding these properties is crucial for appreciating why magnesium is a preferred material in many applications.

Density and Weight

Magnesium is notable for being the lightest of all structural metals, with a density of 1.74 g/cm³. This makes it approximately 33% lighter than aluminum and 75% lighter than steel. Such a low density is advantageous in weight-critical applications, making magnesium a popular choice in industries like aerospace and automotive.

Structural Characteristics

Pure polycrystalline magnesium has a hexagonal close-packed (HCP) crystal structure, which contributes to its brittleness. However, alloying magnesium with other elements can significantly improve its mechanical properties, making it more versatile for various applications.

Thermal Conductivity

Magnesium also exhibits good thermal conductivity, with a value of 156 W/m·K. This property allows magnesium to dissipate heat effectively, making it suitable for use in laptop casings, engine components, and other applications where heat management is crucial.

When exposed to air, magnesium forms a protective oxide layer on its surface, which helps prevent further corrosion. Although this layer is less stable than those formed on other metals like aluminum, it still provides a level of protection that is beneficial in many applications.

Chemical Properties Affecting Magnesium Melting Point

Magnesium’s melting behavior is significantly influenced by its chemical reactions with various elements. When exposed to air, magnesium readily reacts with oxygen to form magnesium oxide (MgO), which has a much higher melting point than pure magnesium.

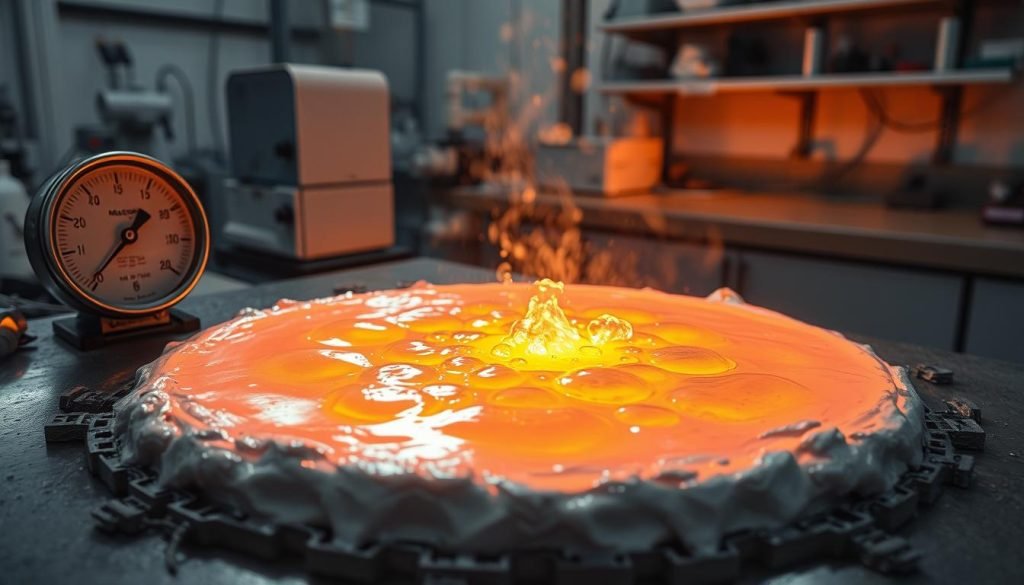

Reactivity with Oxygen

The reaction between magnesium and oxygen is highly exothermic, producing a bright light and significant heat. This reaction can lead to temperatures well above magnesium’s melting point, making it challenging to control the melting process.

Behavior with Water and Other Elements

Magnesium also reacts with water to produce magnesium hydroxide and hydrogen gas. This reaction becomes more vigorous at higher temperatures, posing a significant risk when handling molten magnesium. Additionally, magnesium reacts exothermically with nitrogen, carbon dioxide, and water, making it difficult to extinguish once ignited.

Formation of Oxide Layer

When magnesium is exposed to air, a thin layer of magnesium oxide forms on its surface. While this oxide layer provides some protection against further oxidation at room temperature, its protective effect diminishes as temperatures approach the melting point. Therefore, careful control of the atmosphere is necessary during melting operations to prevent excessive oxidation.

Factors That Influence Magnesium’s Melting Point

Several factors can affect the melting point of magnesium, a crucial aspect of its properties. Understanding these factors is essential for applications involving high temperatures.

Purity Levels

The purity level of magnesium significantly affects its melting point. Higher purity samples melt closer to the theoretical 650°C, while impurities can either raise or lower this temperature depending on their nature.

Pressure Conditions

Pressure conditions also play a role in determining magnesium’s exact melting point. Increased pressure typically causes a slight elevation in the temperature required for phase transition from solid to liquid.

Environmental Factors

Environmental factors, such as the presence of oxygen, can dramatically impact the melting process. The formation of magnesium oxide on the surface creates a barrier with a much higher melting point (2,852°C) than pure magnesium. Additionally, the presence of carbon dioxide can lead to reactions producing magnesium oxide and carbon, altering the melting characteristics.

Humidity and moisture also present challenges, as magnesium’s reaction with water produces hydrogen gas, affecting the melting process and creating safety hazards.

Magnesium Alloys and Their Melting Points

As you explore the world of metallurgy, you’ll find that magnesium alloys play a significant role in creating high-performance materials. These alloys are designed to enhance the properties of pure magnesium, making them suitable for a wide range of applications.

Common Magnesium Alloys

Common magnesium alloys include AZ91, which contains aluminum and zinc, AM60, which includes aluminum and manganese, and ZK60, which is alloyed with zinc and zirconium. Each of these alloys has a melting point that differs from pure magnesium due to their specific compositions.

How Alloying Elements Affect Melting Points

Alloying elements can either raise or lower magnesium’s melting point. For instance, aluminum typically lowers the melting point of magnesium alloys, while rare earth metals often increase it. Understanding these variations is crucial for manufacturing processes.

Aluminum-Magnesium Alloys

Aluminum-magnesium alloys are particularly important commercially. With aluminum content ranging from 3-9%, these alloys have melting points between 590-630°C, depending on the exact composition. The eutectic point in magnesium-aluminum systems occurs at approximately 437°C with 32% aluminum content.

Comparing Magnesium’s Melting Point with Other Metals

Comparing the melting points of different metals helps in selecting the right material for specific uses. You need to consider how magnesium stacks up against other common metals in terms of its melting behavior.

Magnesium vs. Aluminum

When comparing magnesium to aluminum, you’ll find that magnesium melts at a slightly higher temperature (650°C) than aluminum (660°C). Although the difference is minimal, it allows for the use of similar processing equipment for both metals, making magnesium a viable option in applications where aluminum is used.

Magnesium vs. Steel

The contrast between magnesium and steel is more dramatic, with steel’s melting point ranging from 1370-1530°C depending on carbon content. This makes magnesium much more energy-efficient to melt for casting operations, providing a significant advantage in manufacturing processes.

Position Among Common Metals

Magnesium’s melting point of 650°C falls in the mid-range compared to other common metals. It’s higher than tin (232°C) and lead (327°C) but significantly lower than iron (1538°C) and titanium (1668°C). This positions magnesium as a moderately low-temperature metal, contributing to its energy efficiency in manufacturing processes.

Industrial Applications of Magnesium’s Melting Properties

You can leverage magnesium’s melting properties to enhance production processes in multiple sectors. Magnesium’s relatively low melting point makes it an ideal material for various industrial applications.

Aerospace and Automotive Industries

In the aerospace and automotive industries, magnesium is used to produce lightweight structural components that reduce vehicle weight and improve fuel efficiency. Its melting properties enable more energy-efficient casting processes.

Electronics Manufacturing

Electronics manufacturing utilizes magnesium’s melting properties to create complex casings for devices like laptops and smartphones. The metal’s good flowability when molten allows for detailed designs.

Metallurgical Processes and Refractory Materials

Magnesium is used in metallurgical processes for desulfurization of iron and steel. Magnesium oxide, produced by oxidizing magnesium, serves as a refractory material in furnace linings due to its high melting point.

Conclusion

Understanding magnesium’s melting point is essential for harnessing its potential in various industries, from automotive to electronics. With a melting point of 650°C, magnesium offers a unique combination of properties that make it an attractive material for numerous applications.

By carefully controlling the melting process and understanding the factors that influence magnesium’s behavior at elevated temperatures, manufacturers can safely harness this metal’s beneficial properties. As demand for lightweight materials grows, magnesium and its alloys will continue to gain importance, driven by ongoing research into improving processing methods and developing new alloys with enhanced properties.