You’ve likely wondered about the magnetic properties of steel at some point, especially if you work with metals or have a keen interest in materials. The question doesn’t have a straightforward answer, as it depends on the composition and structure of the metal.

Steel, an alloy primarily made of iron and carbon, is widely used in various industries, from construction to kitchen appliances. Its magnetic properties are crucial for many applications, making it essential to understand what makes it magnetic. The presence of magnets and the type of stainless steel used can significantly affect its magnetic behavior. In this comprehensive guide, we’ll explore the factors that influence steel’s magnetism and its practical applications.

Understanding the Magnetic Properties of Steel

You might be wondering what makes steel magnetic, and it’s all related to its internal structure. The magnetic properties of steel are primarily determined by its composition and the alignment of its atoms.

What Makes Metal Magnetic?

Magnetism in metals is fundamentally related to the alignment of atoms within their crystalline structure. Ferromagnetic materials, like iron, cobalt, and nickel, have atoms that can align in a way that creates a magnetic field. This alignment is crucial for a metal to exhibit magnetic properties.

Is Steel Magnetic in Its Natural State?

In its natural state, pure steel contains iron atoms that can align when exposed to a magnetic field, making most basic steel varieties inherently magnetic. However, the addition of other elements like carbon can significantly affect how magnetic the resulting alloy becomes. The arrangement of atoms in steel’s crystalline structure determines its magnetic response.

Types of Steel and Their Magnetic Properties

Understanding the different types of steel and their magnetic properties is essential for selecting the right material for specific applications. You need to consider the composition and processing history of the steel to determine its magnetic behavior.

Ferritic and Martensitic Steel: The Magnetic Varieties

Ferritic stainless steels are naturally magnetic due to their body-centered cubic crystal structure, which is a result of high chromium content, typically between 10.5-27%. Martensitic steels, which contain carbon in addition to chromium, are hardened through heat treatment and maintain strong magnetic properties, making them ideal for applications requiring both hardness and magnetism, such as knife blades.

Austenitic Steel: The Non-Magnetic Option

Austenitic stainless steels, particularly the 300 series, contain significant amounts of nickel (8-10%) along with chromium, resulting in a face-centered cubic crystal structure that renders them non-magnetic in their annealed state. The presence of nickel is crucial in making austenitic steel non-magnetic.

How Processing Affects Steel’s Magnetism

The processing methods used on steel can dramatically affect its magnetic properties. For instance, cold working austenitic stainless steel can transform it from non-magnetic to partially magnetic due to the formation of martensite. Heat treatment, welding, and mechanical deformation also influence the magnetic permeability of steel by altering its microstructure and the alignment of its atoms.

How Does Magnetism Work in Steel?

You might be wondering how steel becomes magnetic. The magnetic properties of steel arise from the behavior of unpaired electrons in iron atoms, which create tiny magnetic fields. When steel is exposed to a magnetic field, the domains within the metal begin to align, creating a magnetic field.

The Science Behind Steel’s Magnetic Properties

Steel’s magnetic properties are due to the alignment of its atoms. When a nonmagnetic piece of steel is applied to a magnet, the atoms within it rearrange themselves, creating a permanent magnet. This alignment results in a magnetic field that doesn’t lose its strength.

Permanent vs. Temporary Magnetism in Steel

Steel can exhibit both permanent and temporary magnetism. Permanent magnetism occurs when the magnetic domains remain aligned even after the external magnetic field is removed. Temporary magnetism happens when steel loses its magnetic properties once the external field is removed. The type of magnetism depends on factors like composition and processing history.

Applications and Benefits of Magnetic Steel

You can find magnetic steel being used in a wide range of applications, from consumer electronics to industrial machinery. Its unique combination of strength and magnetic properties makes it a versatile material for various industries.

Common Uses of Magnetic Steel

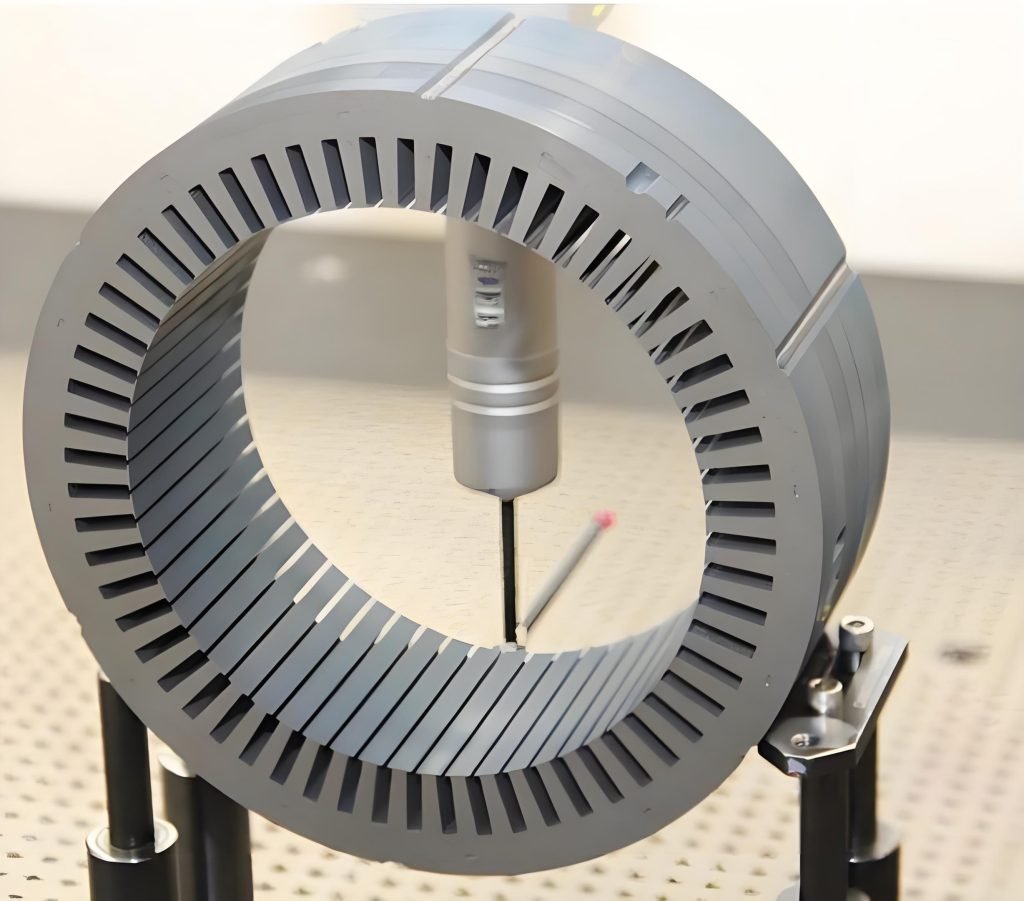

Magnetic steel is used in electric motors, maglev train systems, and various automotive applications. It’s also found in consumer products like refrigerator doors and cabinet latches, benefiting from its ability to create secure closures without mechanical fasteners.

Advantages of Using Magnetic Steel

The advantages of magnetic steel include its durability and ability to be engineered for specific magnetic field strengths. This makes it suitable for applications requiring precise magnetic properties, such as in generators and transformers.

Limitations and Considerations

While magnetic steel offers many benefits, it also has limitations, including potential interference with sensitive electronic equipment and susceptibility to demagnetization at high temperatures. Careful material selection is necessary based on the specific application requirements.

Conclusion: The Versatility of Steel’s Magnetic Properties

Steel, a versatile material, exhibits a range of magnetic properties due to its diverse compositions and structures. The ability to control its magnetism makes it invaluable across industries. Whether you’re designing products that require strong magnetic properties or must remain non-magnetic, understanding steel’s behavior is essential. Its applications continue to expand with advancing technology, highlighting its importance in our modern world.

FAQ

Is all stainless steel non-magnetic?

No, not all stainless steel is non-magnetic. While austenitic stainless steel is generally non-magnetic, ferritic and martensitic stainless steel can be magnetic due to their crystal structure.

How does processing affect the magnetism of steel?

Processing techniques such as cold working, heat treatment, or welding can alter the magnetic properties of steel. For instance, cold working can induce magnetism in some non-magnetic steel alloys.

What are the common applications of magnetic steel?

Magnetic steel is used in various applications, including magnetic hooks, lifting magnets, magnetic separators, and electric motors, due to its ability to be magnetized and retain magnetic properties.

Can the magnetism of steel be temporary?

Yes, some types of steel can exhibit temporary magnetism when exposed to a magnetic field. Once the field is removed, the steel loses its magnetic properties.

What are the advantages of using magnetic steel?

The advantages of using magnetic steel include its ability to be used in applications requiring magnetic properties, such as in magnetic resonance imaging (MRI) machines, magnetic storage devices, and lifting equipment.

Are there any limitations to using magnetic steel?

Yes, there are limitations, including potential corrosion issues, reduced ductility, and the possibility of demagnetization under certain conditions, such as high temperatures or mechanical stress.