You might be wondering if nickel, a commonly used metal, exhibits magnetic behavior. Understanding the properties of nickel is crucial for various industrial applications.

Nickel is one of the few elements that are ferromagnetic at room temperature, making it a valuable material in many uses, from electronics to manufacturing.

Ferromagnetism is a unique form of magnetism that allows materials to be magnetized, and nickel is among the select few that exhibit this property. In this article, we will explore the magnetic characteristics of nickel and its significance in different fields.

The Fundamental Properties of Nickel

As a transition metal, nickel exhibits a unique combination of physical and chemical properties. Nickel has the symbol Ni and atomic number 28. It is known for being a silvery-white lustrous metal with a slight golden tinge.

Physical and Chemical Characteristics

Nickel is characterized by its hardness and ductility, making it a valuable material in manufacturing. Its ability to withstand extreme temperatures and resist corrosion adds to its versatility. The metal’s lustrous appearance also makes it suitable for various applications where aesthetics are important.

Nickel’s electron configuration is notable, with two possible arrangements: [Ar]3d8 4s2 and [Ar]3d9 4s1, which are very close in energy. This unique electron configuration contributes to nickel’s properties and its position among transition metals.

Is Nickel Magnetic? Understanding Its Magnetic Nature

Nickel, a transition metal, exhibits unique magnetic properties that are worth exploring. You might be wondering whether nickel is magnetic or not, and the answer lies in understanding the concept of ferromagnetism.

Defining Ferromagnetism

Ferromagnetism is a fundamental property of certain materials that are capable of being magnetized. This means that these materials are attracted to magnets and can themselves become magnetized. The three elemental metals known to be ferromagnetic are iron, cobalt, and nickel.

To understand why nickel is ferromagnetic, it’s essential to look at its atomic structure. Nickel has an electron configuration that allows it to exhibit magnetic properties. When you compare nickel’s magnetic properties to other ferromagnetic elements like iron and cobalt, you’ll notice that nickel has a relatively weaker ferromagnetism.

Nickel’s Place Among Magnetic Elements

Nickel is one of the few metals that are naturally ferromagnetic. Its Curie temperature, which is the temperature above which a metal loses its ferromagnetic properties, is 358°C. This is relatively low compared to iron, which has a Curie temperature of 770°C.

You might be interested to know that nickel’s magnetic properties have been utilized in various applications, including the creation of magnetic alloys and compounds. Nickel contributes significantly to the magnetic properties of these materials, making it a crucial component in many industrial applications.

In comparison to other ferromagnetic elements like iron and cobalt, nickel has a unique magnetic behavior. While iron is the strongest ferromagnetic element, nickel’s ferromagnetism is weaker but still significant. Cobalt, on the other hand, has a higher Curie temperature than nickel, making it more suitable for high-temperature applications.

The Science Behind Nickel’s Ferromagnetic Properties

The science behind nickel’s ferromagnetism lies in its atomic structure and the way its electrons are configured. To understand why nickel exhibits ferromagnetic properties, you need to delve into its atomic level characteristics. Ferromagnetism in nickel is primarily due to the arrangement of its electrons and the resulting magnetic moments.

Atomic Structure and Electron Configuration

Nickel’s atomic number is 28, and its electronic configuration is [Ar] 3d8 4s2. The 3d electrons play a crucial role in determining nickel’s magnetic properties. In its ground state, nickel has unpaired electrons in its d-orbitals, which contribute to its magnetic moment. The alignment of these magnetic moments is what gives nickel its ferromagnetic properties. You can think of it like a collection of tiny magnets that align to create a larger magnetic field.

Curie Temperature and Magnetic Domains

Nickel’s Curie temperature is 355 °C (671 °F), which is the temperature above which it loses its ferromagnetic properties and becomes paramagnetic. Below this temperature, nickel is ferromagnetic due to the alignment of its magnetic domains. Magnetic domains are regions within the material where the magnetic moments are aligned. These domains form and interact within nickel’s crystal structure, and their alignment is affected by temperature. As you heat nickel, the alignment of its magnetic moments becomes disrupted, eventually leading to a loss of its ferromagnetic properties.

Magnetic domains can be manipulated to magnetize or demagnetize nickel. The concept of magnetic anisotropy is also crucial, as it relates to how nickel’s crystal structure influences the direction of its magnetic moments. Understanding these properties is vital for various engineering applications of nickel, especially in designing materials with specific magnetic characteristics.

Factors Affecting Nickel’s Magnetic Properties

Understanding the factors that influence nickel’s magnetic properties is crucial for optimizing its performance in various applications. Nickel, a ferromagnetic metal, exhibits magnetic properties that can be affected by several key factors.

Temperature Effects

Temperature plays a significant role in determining nickel’s magnetic properties. As temperature increases, nickel’s magnetic moment decreases until it reaches its Curie temperature, at which point it becomes paramagnetic. For nickel, this temperature is around 358°C. You should consider this when designing applications that operate over a range of temperatures.

Purity Levels

The purity of nickel also affects its magnetic properties. Impurities can alter the magnetic moment and the overall magnetic behavior of nickel. High-purity nickel tends to have more consistent and predictable magnetic properties. Therefore, controlling purity levels is essential for applications requiring precise magnetic characteristics.

Crystal Structure

Nickel’s face-centered cubic (FCC) crystal structure significantly influences its magnetic properties. The FCC structure allows for certain magnetic domain formations and behaviors. Crystal defects, grain boundaries, and dislocations within the structure can affect how magnetic domains form and interact. Mechanical processing can alter the crystal structure, thereby changing the magnetic properties. Additionally, the concept of magnetocrystalline anisotropy in nickel’s crystal lattice explains how the direction of magnetization is influenced by the crystal’s orientation.

Furthermore, manipulating the crystal structure during manufacturing can optimize nickel’s magnetic properties for specific applications. For instance, nanocrystalline nickel differs magnetically from bulk nickel due to its distinct structural characteristics. Understanding these differences is vital for leveraging nickel in advanced technologies.

Comparing Nickel to Other Magnetic Metals

Among magnetic metals, nickel is notable, yet its comparison to iron and cobalt reveals distinct differences. You might be wondering how these metals stack up in terms of their magnetic properties and applications. Let’s dive into the specifics.

Nickel vs. Iron

Iron is one of the most magnetic metals, with a strong ferromagnetic response. In contrast, nickel, while magnetic, has a weaker response compared to iron. You should consider the Curie temperature, the temperature at which a metal loses its magnetic properties, when comparing these metals. Iron has a Curie temperature of 770°C, whereas nickel’s is 358°C, indicating that iron remains magnetic at higher temperatures.

The saturation magnetization, or the maximum magnetic field a metal can be magnetized to, is also higher in iron than in nickel. This makes iron more suitable for applications requiring strong magnetic fields. However, nickel’s corrosion resistance and other properties make it preferable in certain environments.

Nickel vs. Cobalt

Cobalt is another magnetic metal with unique properties. When comparing nickel and cobalt, you notice that cobalt has a higher Curie temperature (1115°C), making it suitable for high-temperature applications. Cobalt also exhibits higher magnetic anisotropy, which can be beneficial in certain magnetic applications.

The cost and availability of nickel versus cobalt can impact their use in magnetic applications. Generally, cobalt is more expensive than nickel, which can be a deciding factor in some applications. You should also consider how these metals behave when alloyed with other elements and their manufacturing challenges.

In conclusion, while nickel, iron, and cobalt are all magnetic metals, their properties and applications differ significantly. Understanding these differences is crucial for selecting the right metal for your specific needs.

Can Nickel Become a Permanent Magnet?

As a ferromagnetic metal, nickel has the potential to become a permanent magnet under certain conditions. To understand this, we need to delve into the process of magnetization and the factors that influence nickel’s magnetic field strength.

Magnetization Process

The magnetization process involves aligning the magnetic domains within the nickel material. When nickel is exposed to a magnetic field, the domains that are aligned with the field grow at the expense of those that are not. This process can result in nickel becoming magnetized. However, the degree to which nickel can be magnetized depends on its purity, crystal structure, and the strength of the applied magnetic field.

You might be wondering what factors affect the magnetization of nickel. The purity of nickel plays a significant role; impurities can hinder the alignment of magnetic domains, reducing the overall magnetization. Additionally, the crystal structure of nickel influences its magnetic properties. Nickel’s face-centered cubic crystal structure is conducive to ferromagnetism, but any distortions or defects in this structure can impact its magnetic behavior.

Magnetic Field Strength of Nickel

The magnetic field strength that can be achieved with pure nickel magnets is relatively modest compared to other magnetic materials. Nickel’s saturation magnetization limits its maximum field strength. While nickel is ferromagnetic, its magnetic field strength is not as high as that of iron or rare-earth magnets.

When comparing the magnetic field strength of nickel to other common magnetic materials, it becomes clear that nickel is not the strongest magnet. For instance, Alnico permanent magnets, which are based partly on nickel, offer intermediate strength between iron-based and rare-earth magnets. The coercivity of nickel, or its ability to maintain magnetization, is also an important factor. Nickel has a relatively low coercivity, meaning it can lose its magnetization relatively easily.

Temperature also affects the field strength of nickel magnets. As temperature increases, nickel’s magnetic properties weaken, and it eventually reaches its Curie temperature, at which point it loses its ferromagnetic properties entirely. Despite these limitations, there are practical applications where nickel’s magnetic field strength is sufficient, such as in certain magnetic sensors or magnetic shielding applications.

Alloying nickel with other elements can significantly increase its magnetic field strength, as seen in Alnico magnets. However, there are trade-offs between field strength, temperature stability, and cost in nickel-based magnets. Understanding these trade-offs is crucial for selecting the appropriate magnetic material for a given application.

Methods for Altering Nickel’s Magnetic Properties

You can modify nickel’s magnetic characteristics using several techniques. Nickel, a ferromagnetic metal, has magnetic properties that can be altered for various applications. The methods include alloying with other metals, heat treatment techniques, and mechanical processing effects.

Alloying with Other Metals

Alloying nickel with other metals is a common method to alter its magnetic properties. By combining nickel with elements like iron, cobalt, or chromium, you can create alloys with specific magnetic characteristics. For instance, permalloy, a nickel-iron alloy, is known for its high magnetic permeability.

The addition of other metals can change the crystal structure of nickel, thereby affecting its magnetic behavior. The type and amount of the alloying element determine the final magnetic properties of the alloy.

Heat Treatment Techniques

Heat treatment is another effective method for modifying nickel’s magnetic properties. By heating nickel to specific temperatures and then cooling it at controlled rates, you can alter its crystal structure and magnetic domain configuration. The Curie temperature of nickel, which is 355 °C (671 °F), is a critical point above which bulk nickel becomes non-magnetic.

Heat treatment techniques can be tailored to achieve desired magnetic properties. For example, annealing can relieve internal stresses and improve magnetic permeability.

Mechanical Processing Effects

Mechanical processing can significantly affect nickel’s magnetic properties. Techniques such as rolling, drawing, and forging can introduce strain and alter the crystal structure, thereby changing the magnetic domain wall movement. Cold working, a form of mechanical processing, can increase the strength of nickel but may also affect its magnetic behavior.

Mechanical deformation can induce surface stresses that impact magnetic performance. Moreover, the grain size and orientation controlled through mechanical processing can influence the magnetic properties. Precision machining can create components with uniform magnetic characteristics.

Combining mechanical processing with heat treatment can optimize nickel’s magnetic properties for specific applications. Surface finishing techniques also play a crucial role in determining the final magnetic properties of nickel components.

Nickel Alloys and Their Magnetic Characteristics

Nickel, when alloyed with other elements, exhibits a range of magnetic behaviors. This versatility makes nickel alloys crucial in various technological and industrial applications. You will find that understanding these alloys is key to appreciating their utility.

Permalloy and Mu-Metal

Permalloy and Mu-Metal are notable nickel alloys known for their exceptional magnetic properties. Permalloy, an alloy of nickel and iron, is highly magnetically permeable, making it ideal for applications requiring efficient magnetic shielding. Mu-Metal, with its similar composition, offers even higher permeability, used in sensitive electronic equipment protection.

Alnico Magnets

Alnico magnets are another significant application of nickel in magnetic materials. These magnets are alloys primarily composed of aluminum, nickel, and cobalt. The addition of iron, copper, and sometimes titanium, affects their magnetic properties, enhancing their strength and stability. Alnico magnets are manufactured through either casting or sintering processes, each offering distinct advantages in terms of cost and magnetic property control.

Alnico magnets offer good temperature stability up to 500°C, making them suitable for high-temperature applications. Their typical magnetic properties include high remanence and moderate coercivity, positioning them between iron-based and rare-earth magnets in terms of strength. Historically, Alnico magnets were widely used before the advent of rare-earth magnets, and they still find applications where their unique combination of properties is beneficial.

The nickel content in Alnico magnets contributes significantly to their magnetic characteristics, enhancing their corrosion resistance and mechanical strength. You can appreciate how the specific composition of these alloys allows for tailored magnetic properties, making them suitable for a range of applications, from electric motors to sensors.

Industrial Applications of Nickel’s Magnetic Properties

Nickel’s ferromagnetic properties are harnessed in a multitude of industrial applications, transforming the way we live and work. The versatility of nickel makes it an essential component in various technologies that drive modern industries.

Electronics and Telecommunications

In the electronics and telecommunications sectors, nickel’s magnetic properties are utilized in the manufacture of various components. Nickel is used in the production of magnetic cores for inductors and transformers, which are crucial in electronic circuits. These components rely on nickel’s ability to enhance magnetic fields, thereby improving the efficiency and performance of electronic devices.

Power Generation and Distribution

The power generation and distribution industry benefits significantly from nickel’s magnetic properties. Nickel-containing alloys are used in the construction of generators and motors, where their magnetic characteristics play a key role in converting mechanical energy into electrical energy and vice versa. The reliability and efficiency of these devices are significantly enhanced by the presence of nickel.

Automotive and Aerospace Industries

In the automotive sector, nickel-based magnetic materials are integral to the functioning of various sensors and actuators. These components are crucial for the operation of modern vehicles, including electric and hybrid vehicles. Nickel’s magnetic properties are also utilized in fuel injection systems, anti-lock braking systems (ABS), and stability control sensors. In the aerospace industry, nickel’s reliability under extreme conditions makes it a valuable material for navigation and control instruments. Emerging applications in autonomous vehicle systems further underscore the importance of nickel’s magnetic properties in cutting-edge technologies.

Nickel in Consumer Products

As you explore the world of nickel, you’ll discover its presence in various consumer products that impact your daily life. Nickel’s unique properties make it an essential material in many applications, from everyday household items to advanced technologies.

Everyday Items Containing Magnetic Nickel

Nickel is used in a variety of consumer products, often in the form of alloys or compounds. You can find nickel in coins, jewelry, and certain stainless steel items due to its corrosion resistance and durability. Additionally, nickel’s magnetic properties make it useful in components like magnets and magnetic sensors used in various devices.

Nickel-Based Batteries and Energy Storage

One of the significant applications of nickel is in battery technology. Nickel is a key component in various rechargeable battery types, including nickel-cadmium (NiCd), nickel-iron (NiFe), nickel-metal hydride (NiMH), and nickel-hydrogen batteries. Nickel oxide hydroxide, containing Ni(III), is used as the cathode material in many of these batteries, contributing to their performance and energy density.

Nickel-based batteries offer several advantages, including high energy density and long cycle life, making them suitable for use in consumer electronics, power tools, and even electric vehicles. While other battery technologies like lithium-ion are also prevalent, nickel-based batteries continue to be used in specific applications where their unique properties are beneficial.

Machining Techniques for Nickel and Its Alloys

The machining of nickel alloys is a challenging task due to their high strength, corrosion resistance, and tendency to work harden. These properties make nickel alloys ideal for use in harsh environments, but they also complicate the machining process.

Challenges in Nickel Machining

One of the primary challenges in machining nickel alloys is their high strength and resistance to deformation, which can lead to tool wear and damage. Additionally, nickel alloys tend to work harden during machining, further complicating the process.

To address these challenges, manufacturers must select appropriate cutting tools and parameters. For instance, using tools with a positive rake angle and a sharp edge can help minimize the forces involved in cutting and reduce the risk of work hardening.

Cutting Tools and Parameters

The choice of cutting tools and parameters is critical in machining nickel alloys. Carbide tools are often preferred due to their hardness and wear resistance. Parameters such as cutting speed, feed rate, and depth of cut must be carefully optimized to achieve efficient machining without damaging the workpiece or the tool.

For example, high-speed machining techniques can be applied to nickel alloys to improve productivity. However, it’s crucial to balance the cutting speed with the feed rate and depth of cut to prevent overheating and tool wear.

Advanced Machining Methods

Advanced machining methods, including electrical discharge machining (EDM), electrochemical machining (ECM), laser cutting, and water jet cutting, offer significant advantages for certain nickel alloy parts. EDM is particularly useful for creating complex geometries, while ECM can machine intricate shapes without inducing stress.

Laser and water jet cutting are effective for cutting nickel sheet and plate. Ultrasonic machining is another technique that can be used for hard nickel alloys, offering precision and control. Furthermore, cryogenic cooling can improve the machinability of nickel by reducing tool wear.

Hybrid machining processes that combine multiple techniques can achieve precision tolerances and complex geometries. The integration of digital manufacturing technologies is also enhancing nickel machining processes, enabling more efficient production and higher quality components.

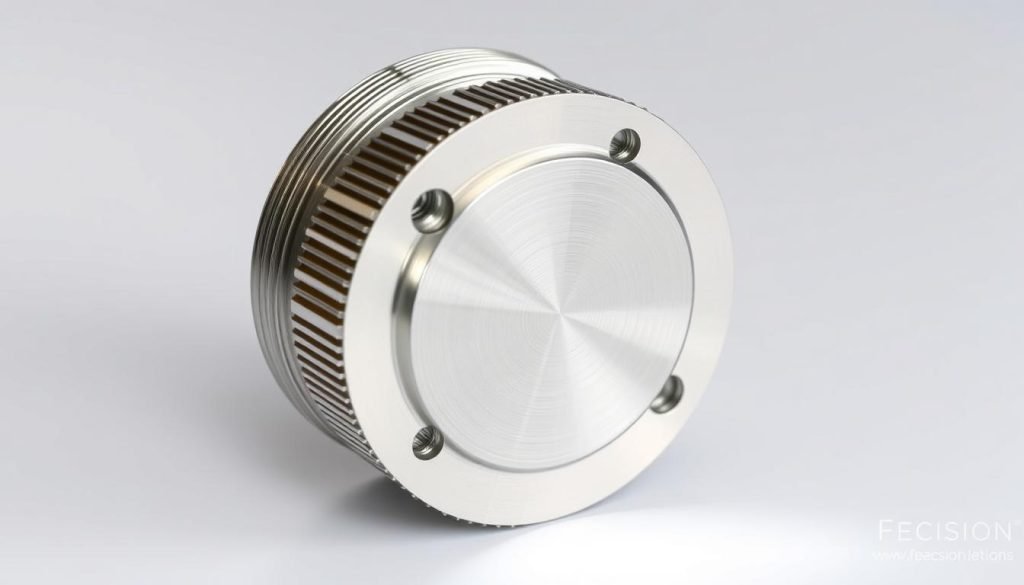

Precision Nickel Parts with Fecision Expert CNC Machining

Fecision’s expertise in CNC machining transforms nickel into precision parts that meet the most demanding specifications. With a focus on delivering high-quality components, Fecision utilizes advanced CNC machining to ensure precision and reliability in every nickel part produced.

Capabilities and Expertise

Fecision’s CNC machining capabilities are designed to handle complex nickel components with precision. Their expertise includes:

- Advanced CNC machining technology for precision nickel parts

- Quality control processes specific to nickel components, ensuring dimensional accuracy and material integrity

- Precision tolerances achievable when machining nickel parts, meeting stringent industry standards

Quality Control and Precision Standards

Fecision maintains rigorous quality control and precision standards for nickel components. This includes:

- Inspection equipment and methods to verify dimensional accuracy and surface finish

- Material certification and traceability procedures to ensure the authenticity and quality of nickel used

- Adherence to industry standards and certifications such as ISO and AS9100, relevant to nickel machining

- Non-destructive testing methods to ensure the internal quality of nickel parts

- Comprehensive documentation and reporting provided with precision nickel components, ensuring transparency and traceability

By leveraging Fecision’s CNC machining services, you can trust that your precision nickel parts will be manufactured to the highest standards of quality and precision, supported by robust quality control systems that ensure consistent results across production runs.

Environmental Considerations in Nickel Processing

Environmental considerations play a vital role in the processing of nickel, a metal integral to modern technology and infrastructure. As a significant component in stainless steel, alloys, and rechargeable batteries, nickel’s environmental impact is substantial. About 68% of world production is used in stainless steel, with further allocations to nickel-based and copper-based alloys, plating, alloy steels, and other applications.

Sustainability Challenges

The extraction and processing of nickel pose considerable sustainability challenges. Nickel recycling is crucial from both economic and environmental perspectives. Currently, recycling rates for nickel-containing products vary, but there’s a growing emphasis on improving these rates. The importance of recycling lies in its potential to reduce the environmental footprint associated with primary nickel production.

Nickel’s magnetic properties can significantly aid in its separation and recovery from various waste streams, including batteries and catalysts. Advanced recycling technologies are being developed to enhance the efficiency of nickel recovery.

Recycling and Recovery Methods

Methods for recovering nickel include advanced recycling technologies that can efficiently process nickel-containing waste. The quality of recycled nickel is comparable to that of virgin material, making it suitable for a wide range of applications. Recycling nickel achieves significant energy savings compared to primary production.

To optimize nickel recovery at the end of a product’s life cycle, manufacturers can design products with recyclability in mind. This approach aligns with the circular economy principles, promoting the reuse and recycling of materials. By adopting such strategies, the environmental impact of nickel processing can be mitigated.

Future Trends in Magnetic Nickel Applications

The future of magnetic nickel applications is being shaped by current research and development efforts. As scientists and engineers continue to explore new ways to enhance nickel’s magnetic properties, we can expect to see significant advancements in various industries.

Emerging Technologies

One of the key areas driving the future of magnetic nickel is the development of emerging technologies. Researchers are focused on enhancing nickel’s magnetic properties through novel processing techniques. For instance, the development of nickel alloys with improved magnetic performance at higher temperatures is a significant area of research. These alloys have the potential to revolutionize industries such as aerospace and automotive, where high-temperature applications are common.

Another exciting development is the research into nanostructured nickel materials. These materials exhibit unique magnetic characteristics that could lead to breakthroughs in data storage and energy applications. By manipulating the structure of nickel at the nanoscale, scientists can create materials with tailored magnetic properties.

Health and Safety Considerations When Working with Nickel

Nickel handling necessitates a thorough understanding of the associated health and safety considerations. Working with nickel and its compounds can pose several health risks, making it essential to implement appropriate safety measures.

Potential Hazards

Exposure to nickel can lead to various health issues, including skin irritation, respiratory problems, and allergic reactions. Nickel-plated objects, for instance, can provoke nickel allergy in some individuals. When handling nickel powders, solutions, or solid forms, it’s crucial to minimize exposure through proper handling procedures and the use of personal protective equipment (PPE).

Some of the key hazards associated with nickel include:

- Inhalation of nickel dust or fumes, which can cause respiratory issues

- Skin contact, leading to irritation or allergic dermatitis

- Eye contact, potentially causing irritation or damage

Safety Protocols and Best Practices

To mitigate the risks associated with nickel, several safety protocols and best practices should be adopted. This includes the use of appropriate PPE, such as gloves, masks, and protective eyewear, to prevent skin contact and inhalation of nickel particles. Engineering controls, like ventilation systems, should be implemented to minimize nickel exposure in the workplace.

Proper handling procedures for nickel materials, safe machining practices, and correct storage requirements are also vital. Regular decontamination of equipment and work areas, along with medical monitoring for workers regularly exposed to nickel, are recommended. Training personnel on the safe handling of nickel and having emergency response procedures in place are also crucial for maintaining a safe working environment.

Conclusion

As we’ve explored throughout this article, nickel is indeed ferromagnetic, with properties that are crucial for multiple industries. The key points about nickel’s magnetic properties confirm its importance in various applications. Nickel’s ferromagnetic nature is influenced by several factors, including temperature, purity levels, and crystal structure, which affect its magnetic behavior.

Understanding these properties is essential for effective manufacturing and application of nickel in different fields. Nickel’s importance is evident in its widespread use across multiple industries, from electronics and telecommunications to power generation and distribution, as well as in the automotive and aerospace sectors.

Fecision’s expertise in machining precision nickel components for demanding applications underscores the value of nickel in high-performance environments. However, it’s also crucial to balance the valuable properties of nickel with responsible handling and processing to mitigate potential hazards.

By understanding and harnessing the potential of nickel, you can drive innovation and achieve excellence in your projects. Whether you’re looking for high-quality nickel components or expert advice, we’re here to support your endeavors.