You might have wondered whether galvanized steel retains its magnetic properties. Galvanized steel, known for its durability and resistance to corrosion, is a staple in construction and manufacturing. But what happens when it’s exposed to a magnetic field?

The process of galvanization involves coating steel with a thin layer of zinc, which protects it from rust and corrosion. This zinc coating acts as a sacrificial cathode, giving up electrons more readily than iron, thus safeguarding the steel beneath. The question remains, does this zinc layer affect the magnetic properties of the steel?

Understanding the magnetic nature of galvanized steel is crucial for its application in various industries. Let’s explore the science behind its properties and how they impact its uses.

Understanding Galvanized Steel

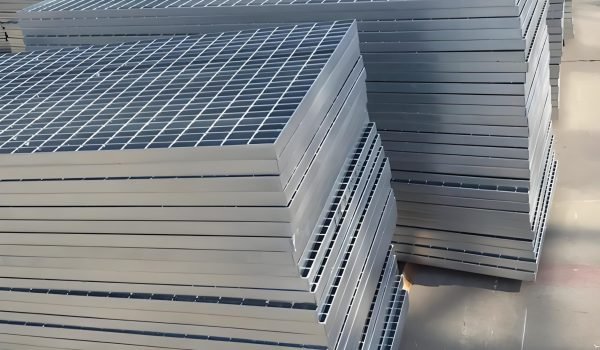

Galvanized steel has become a staple in many industries due to its unique properties. You might have seen it used in various construction projects or in the manufacturing of durable goods.

What is Galvanized Steel?

Galvanized steel is essentially regular steel that has been coated with a protective layer of zinc to prevent corrosion and extend its lifespan significantly. This process involves immersing clean steel in a bath of molten zinc at high temperatures.

The Galvanization Process

The most common method of galvanization is hot-dip galvanizing. During this process, the steel is immersed in a vat of molten zinc, creating a metallurgical bond between the steel and zinc. The zinc coating forms several layers with varying zinc-iron alloy compositions, providing comprehensive protection against environmental factors.

Why Steel is Galvanized

Steel is galvanized primarily to prevent rust and corrosion. The zinc layer acts as a sacrificial anode that corrodes preferentially to protect the underlying steel, even when the coating is scratched or damaged. Most carbon steels and low-alloy steels are suitable for galvanization.

The thickness of the zinc coating can be controlled during the galvanization process, with thicker coatings providing longer protection in more aggressive environments.

Is Galvanized Steel Magnetic?

The question of whether galvanized steel is magnetic is a common one, and the answer lies in its composition. To understand this, we need to delve into the properties of galvanized steel and the science behind its magnetism.

The Simple Answer

The simple answer is yes, galvanized steel is typically magnetic. This is because the core material is steel, which contains iron—one of the most strongly magnetic elements on the periodic table. The zinc coating, which is used to protect the steel from corrosion, does not affect its magnetic properties since zinc itself is not ferromagnetic.

The Science Behind Steel’s Magnetism

Steel’s magnetism is a result of its crystalline structure, where iron atoms align their magnetic moments in the same direction, creating a net magnetic field that can interact with external magnets. The addition of carbon to iron to form steel enhances its magnetic properties by influencing the crystal structure and the interactions between atoms in the alloy.

Iron, Carbon, and Magnetic Properties

The presence of carbon in the iron crystal lattice creates additional molecular configurations that affect the alloy’s magnetic properties. Different types of steel exhibit varying degrees of magnetic attraction based on their composition. For instance, carbon steel is strongly magnetic, while some stainless steels may be weakly magnetic or non-magnetic due to their nickel content.

The magnetic permeability of galvanized steel makes it useful in applications where magnetic properties are beneficial, such as in electrical transformers, motors, and certain construction applications. You can easily test the magnetism of galvanized steel using a magnet; if it sticks, the steel beneath the zinc coating is magnetic.

How Galvanization Affects Steel’s Magnetic Properties

Understanding how galvanization affects the magnetic properties of steel is crucial for various industrial applications. Galvanization, the process of applying a zinc coating to steel, primarily serves to protect the steel from corrosion.

The Role of the Zinc Coating

The zinc coating applied during galvanization acts as a barrier against corrosion but does not significantly alter the magnetic properties of the underlying steel. Since zinc is not ferromagnetic, it doesn’t exhibit magnetic properties, meaning the galvanization process preserves the existing magnetic properties of the steel by preventing corrosion.

Coating Thickness and Magnetic Attraction

The thickness of the zinc coating can affect how strongly a magnet will be attracted to galvanized steel. Thicker coatings create more distance between the magnet and the magnetic steel core, potentially reducing the apparent magnetic attraction. However, standard hot-dip galvanized coatings, typically 50-100 microns thick, are thin enough not to significantly impede magnetic attraction.

Testing Magnetism in Galvanized Steel

Testing the magnetism of galvanized steel is straightforward: a magnet will stick to the surface if the underlying steel is magnetic and the zinc coating isn’t excessively thick. In applications where precise magnetic properties are required, engineers must account for the slight reduction in magnetic field strength caused by the zinc coating’s distance effect.

Common Misconceptions About Galvanized Steel Magnetism

You might be surprised to learn that some common beliefs about galvanized steel magnetism are incorrect. Galvanized steel is widely used in various applications, and understanding its magnetic properties is crucial. Let’s debunk some common myths surrounding galvanized steel magnetism.

Myth-Busting: Zinc Coating and Magnetism

One common misconception is that the zinc coating on galvanized steel significantly reduces its magnetic properties. However, the thin zinc layer has a minimal impact on the steel’s ability to be attracted to magnets. Zinc is inherently non-magnetic, and its coating is typically very thin.

Myth: Magnetism Changes as Zinc Oxidizes

Some people believe that as the zinc layer oxidizes over time, the magnetic properties of the galvanized steel change. In reality, the oxidation process only affects the corrosion resistance of the zinc layer, leaving the magnetic properties of the steel core unchanged.

Myth: Zinc Acts as an Electromagnetic Insulator

Another myth is that the zinc coating acts as an electromagnetic insulator, blocking magnetic fields. This is false because magnetic fields can easily penetrate non-magnetic materials like zinc. Magnetism and electricity are different concepts, and the zinc layer does not significantly impact the steel’s magnetic properties.

By understanding the facts about galvanized steel magnetism, you can make informed decisions in your projects and applications.

Applications and Uses of Galvanized Steel

With its unique combination of strength, corrosion resistance, and magnetic properties, galvanized steel is a preferred choice in multiple sectors. You can find galvanized steel in various applications, from large-scale infrastructure projects to everyday household items.

Construction and Infrastructure

Galvanized steel is extensively used in construction and infrastructure projects due to its exceptional corrosion resistance and durability. Applications include structural supports, roofing, guardrails, light poles, and various building components. The zinc coating on galvanized steel provides a protective layer that withstands harsh environmental conditions, reducing maintenance costs over time.

Automotive and Manufacturing

In the automotive industry, galvanized steel is crucial for manufacturing body panels, chassis components, and structural elements that require both strength and corrosion resistance. This is particularly important in regions where road salt and moisture are concerns, as galvanized steel helps prevent rust and corrosion.

Household and Consumer Products

Galvanized steel is also used in household and consumer products, including appliances like refrigerators, washing machines, dryers, and various kitchen equipment. The magnetic properties of galvanized steel make it particularly useful in applications where decorative magnets are used, such as refrigerator doors.

When Magnetic Properties Matter

The magnetic properties of galvanized steel are valuable in electrical applications such as transformer cores, motor housings, and electrical enclosures. Unlike stainless steel, which may or may not be magnetic depending on its composition, galvanized carbon steel consistently maintains its magnetic properties, making it a reliable choice for applications where magnetism is required.

When selecting galvanized steel for applications where magnetic properties matter, it’s essential to consider the base steel type, as different steel compositions will exhibit varying degrees of magnetic attraction even after galvanization. Proper maintenance of galvanized steel includes regular cleaning with mild detergents, avoiding harsh chemicals that might damage the zinc coating, and touching up any damaged areas to maintain corrosion protection.

Conclusion: Making the Most of Galvanized Steel’s Properties

Galvanized steel’s unique blend of strength and corrosion resistance makes it a versatile material for various applications. You can rely on its magnetic properties for applications requiring magnetic attraction while benefiting from the zinc coating’s protective qualities.

When selecting galvanized steel, consider the thickness of the zinc layer and the type of base steel to ensure optimal performance. Proper maintenance, including regular cleaning and addressing any damage to the zinc coating, will help maintain its appearance and protective qualities.

By understanding the science behind galvanized steel’s properties, you can make informed decisions for your projects, whether in construction, manufacturing, or consumer products, and consult with materials specialists for specific applications.

FAQ

What is the primary purpose of galvanizing steel?

The primary purpose of galvanizing your steel is to protect it from corrosion by applying a layer of zinc, which acts as a barrier against moisture and oxygen.

How does the galvanization process work?

The galvanization process involves immersing your steel in a bath of molten zinc, which bonds to the surface, creating a protective coating that resists corrosion.

Does the zinc coating affect the magnetic properties of your steel?

The zinc coating does not significantly affect the magnetic properties of your steel, as the underlying iron and carbon content determine its magnetism.

Can you test the magnetism of galvanized steel?

Yes, you can test the magnetism of your galvanized steel using a magnet, and the results will depend on the thickness of the zinc coating and the composition of the underlying steel.

Are there any applications where the magnetic properties of galvanized steel are crucial?

Yes, in certain applications, such as in the manufacturing of automotive parts or electrical equipment, the magnetic properties of your galvanized steel can be important.

How does the thickness of the zinc coating impact the corrosion resistance of your galvanized steel?

A thicker zinc coating generally provides greater corrosion resistance, as it creates a more robust barrier against environmental factors that can cause rust.

Can galvanized steel be used in high-temperature applications?

While galvanized steel can be used in some high-temperature applications, it’s essential to consider the specific conditions and the potential for the zinc coating to degrade or react with other materials.