You’re probably familiar with the importance of conductivity in various industries, from electrical engineering to manufacturing. But have you ever stopped to think about the materials that make it all possible?

Let’s dive into the world of conductive materials and explore the properties that make aluminum a popular choice for electrical applications. With its unique combination of properties, aluminum has become a crucial material in modern manufacturing.

Its conductivity ranks fourth among all materials, behind silver, gold, and copper. But what makes it so valuable is its excellent electrical conduction properties, making it a cost-effective alternative to more expensive metals.

Understanding Electrical Conductivity in Metals

Metals are known for their ability to conduct electricity, but what makes them conductive? The answer lies in their atomic structure. In metals, the valence electrons are free to move due to metallic bonds, allowing them to carry electrical current.

What Makes a Material Conductive?

A material’s conductivity is determined by its atomic structure and the mobility of its electrons. Metals like aluminum have a high concentration of free electrons, making them good conductors.

How to Measure Electrical Conductivity

Electrical conductivity is measured in Siemens per meter (S/m) or using the International Annealed Copper Standard (IACS). Techniques like eddy current testing and the four-point probe method are used to measure a metal’s conductivity.

Is Aluminum Conductive?

You might be wondering if aluminum is a good conductor of electricity, and the answer lies in its properties. Aluminum is indeed a conductive metal, with a conductivity that is more than half that of copper by weight. This means that 1 gram of aluminum has the same conductivity as 2 grams of copper, making it a preferable choice for electrical applications where weight is a concern.

The Science Behind Aluminum’s Conductivity

Aluminum’s conductivity can be attributed to its atomic structure, which has three valence electrons per atom. These free electrons enable aluminum to conduct electricity efficiently. The conductivity of aluminum is approximately 61% IACS (International Annealed Copper Standard), which is a significant value for many electrical applications.

Factors Affecting Aluminum’s Conductivity

Several factors can affect aluminum’s conductivity, including temperature, purity levels, alloying elements, and mechanical treatment. For instance, anodizing aluminum creates an oxide layer that significantly reduces its conductivity, making anodized aluminum more like an insulator. Additionally, the formation of aluminum oxide on its surface can impact its conductivity and affect electrical connections.

Understanding these factors is crucial for optimizing aluminum’s conductivity in various applications. Research is ongoing to enhance aluminum’s conductivity, making it more competitive with copper in high-performance electrical applications.

Aluminum vs. Other Conductive Metals

In the world of electrical conductivity, aluminum stands out as a versatile and widely used metal, often compared to copper and other materials. As we explore the properties of aluminum in relation to other conductive metals, you’ll gain a deeper understanding of its advantages and limitations.

Aluminum vs. Copper Conductivity

Copper is a highly conductive metal, but it’s also expensive and heavy. Aluminum, on the other hand, offers about 60% of copper’s conductivity at a significantly lower cost and weight. With copper demand outpacing supply, aluminum is becoming an increasingly attractive alternative for electrical applications.

Comparing Aluminum to Silver, Gold, and Other Metals

While silver and gold have higher conductivity than aluminum, they’re not practical for most large-scale applications due to their high cost. Aluminum strikes a balance between conductivity and affordability, making it a popular choice for power transmission lines and other electrical systems.

Weight-to-Conductivity Ratio Advantages

Aluminum’s lightweight properties and relatively high conductivity make it an excellent choice for weight-sensitive applications. With a weight-to-conductivity ratio that’s about one-third that of copper, aluminum is ideal for use in electric vehicles, aerospace, and other industries where weight reduction is crucial.

Different Types of Aluminum and Their Conductivity

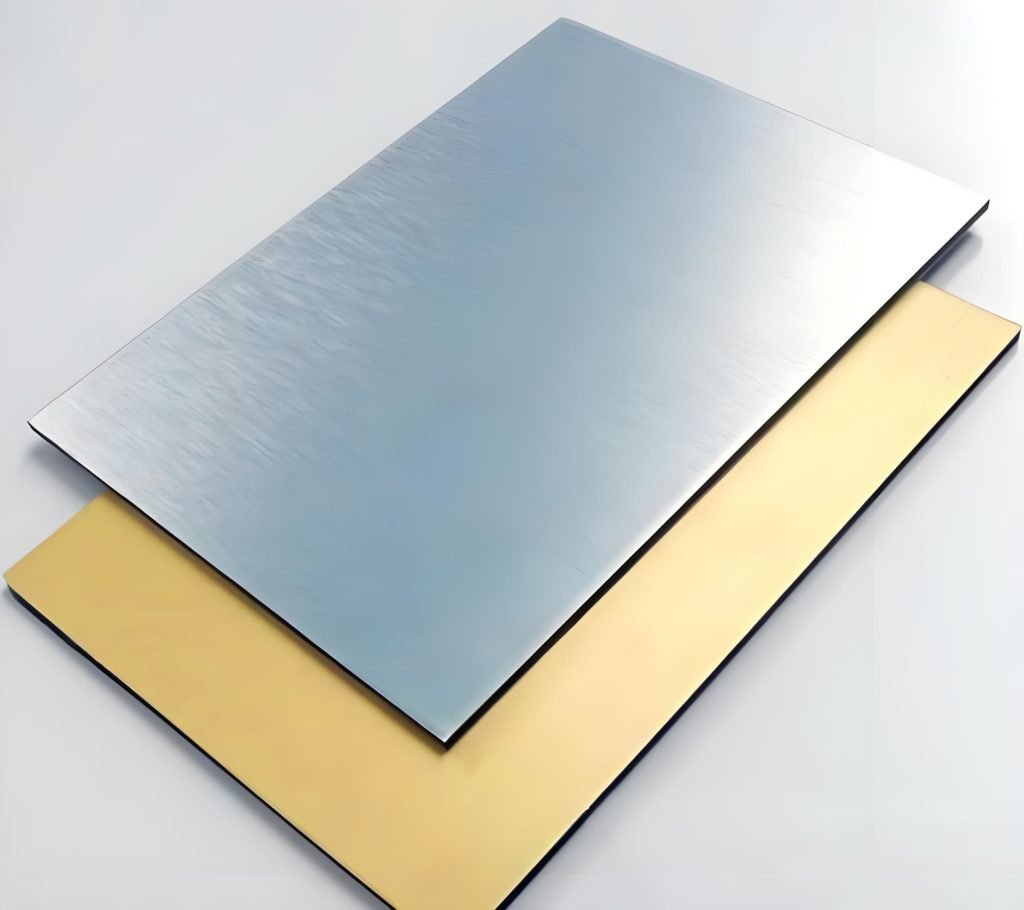

Aluminum’s conductivity is a key factor in its widespread use in electrical systems. Various grades and alloys of aluminum are utilized in electrical applications, each with its own conductivity properties.

The 1xxx series pure aluminum alloys offer the highest conductivity, up to 62% IACS, making them ideal for applications where maximum conductivity is required. The addition of alloying elements such as silicon, magnesium, and copper can affect aluminum’s conductivity, strength, and other properties.

Specialized aluminum conductor alloys like the AA8000 series are designed for electrical applications, providing improved creep resistance and connection reliability. Aluminum is used in various forms, including wire, cable, foil, and bus bars, each optimized for different electrical applications.

Aluminum foil, for instance, serves as both a conductor of electricity and a reflector of heat, making it suitable for electrical and thermal management contexts. Major applications that utilize aluminum as an electric conductor include power transmission lines, automotive wiring, solar panel frames and connectors, LED lighting heat sinks, and consumer electronics.

Proper connection techniques are crucial when using aluminum conductors to prevent issues like galvanic corrosion. For custom aluminum parts, suppliers like Tuofa CNC machining offer services including CNC machining, 3D printing, and surface finishing options like anodizing.

Research into ultra-conductive aluminum is ongoing, potentially rivaling copper’s conductivity while maintaining aluminum’s weight and cost advantages. This ongoing research and development highlight the importance of aluminum in the field of electrical engineering.

FAQ

Aluminum has about 61% of the electrical conductivity of copper, but its lower density makes it a more efficient conductor by weight, with a higher conductivity-to-weight ratio.

As temperature increases, the conductivity of aluminum decreases due to the increased vibration of its atoms, which hinders the flow of electrons.

Yes, aluminum is often used in high-voltage transmission lines due to its relatively high conductivity, lower cost, and significantly lower weight compared to copper.

The purity of aluminum directly impacts its conductivity; higher purity aluminum generally has higher conductivity because impurities can disrupt the flow of electrons.

While aluminum can be used as a substitute in some applications, its lower conductivity means that larger diameter wires are required to achieve the same conductivity as copper, which can be a limiting factor in certain situations.