When factories produce plastic parts with complex shapes, they often encounter trouble. It’s just like making a plastic thing with small clips or small holes on the side. Once it takes shape in the mold, it has to be taken out of the mold. But those small clips and small holes are very delicate parts. One can easily break them if not careful. So the factory was worried. How on earth could they take this plastic part out of the mold while still ensuring that those delicate small clips and small holes were not damaged?

This is where lifters and sliders come into play—two essential tools in injection molding. While both solve mold-release challenges, they work in completely different ways. Lifters act like “smart helpers” that push and tilt parts out of the mold, ideal for internal clips or threads. Injection molding slides, on the other hand, are like “side doors” that move sideways to free parts with external holes or textured surfaces.

Choosing the right tool can save time, reduce costs, and ensure your parts meet strict quality standards. Let’s read and find out the secrets!

Understanding Injection Molding Lifter vs Slider

What Is Injection Molding Lifter?

What is lifter in injection molding? When plastic parts are injection molded in factories, some parts may have some special structures, such as small clips and threads. After these structures are formed in the mold, they are very likely to get stuck inside the mold and cannot be directly removed. At this point, the injection demolding inclined top comes in handy. It is a small helper in injection molds, capable of smoothly pushing out plastic parts with these special structures that are stuck in the mold, allowing the parts to be taken out of the mold and completing production. Regular ejector pins can’t handle these complex shapes because they only move straight up. Lifters solve this by combining vertical and angled motion during ejection.

How It Works

There is something called an injection mold lifter, and it is placed diagonally in the mold. There is also a push plate in the mold. When the push plate rises, it will push the inclined top upwards as well. Because the inclined top is tilted, the upward force exerted by the push plate on it will cause the inclined top to move in two directions.

One action is to push the plastic part to be made upwards, and the other action is to pull it to the side. Why pull it to the side? Because some parts of the plastic components are stuck inside the mold (that is, the kind with an inverted structure inside), pulling them a little to the side can remove the parts from the stuck positions, allowing them to be taken out smoothly.

Just as if you were to pull the key out of the lock, the lifter also moves smoothly like this, without damaging the delicate parts of the plastic components. After the part is ejected, when the mold is closed again, the inclined ejection will return to its original position, ready for the next ejection of a new part.

What Is Injection Molding Slider?

During injection molding, some plastic products have external structures such as holes on the sides or protruding parts. Simple two-piece molds cannot produce these structures. At this point, we need something called a slider. The slider is like a “small part” that can move in the mold. When we make this toy with the mold, the slider will move to the side (either horizontally or diagonally), so that the mold can create those special shapes with small holes on the side and outward protrusions on the toy. After the toys are done, move the slider away and we can take the finished toys out of the mold.

How It Works

Let’s imagine making a small plastic box with small holes on the side. At this time, a slider will be used. The slider is like a small “jigsaw puzzle piece”. It is in the mold, connected to the movable side of the mold, and there are slanted guide posts (like small sticks) attached to it.

When the mold is opened, it is just like opening the lid of a big box. Those slanted guide posts will act like powerful little hands, pushing the slider to the side, just like pulling the drawer out of the cabinet. In this way, the slider was moved away from the position of the small hole on the side of the small plastic box. Because this small hole is formed in the mold by the slider, once the injection mold slider is moved away, the small hole becomes empty, and we can easily take out the finished plastic small box without getting stuck.

After taking out the small plastic box, if we want to make the next one, we need to close the mold again. At this point, those slanted guide posts will act like small guides, accurately pushing the slider back to its original position, ensuring that the small holes on each small box produced are in the same position and shape, and thus the quality is stable.

And because during the process of making small plastic boxes, the pressure inside the mold is particularly high, just like a strongman squeezing something. To prevent the slider from being crushed or deformed, a wear-resistant plate will be installed on the slider (just like putting a protective suit on the slider), and there will also be a device that can firmly fix the slider (just like a lock), so that the slider can work well all the time.

Differences Between Injection Molding Lifter and Slider

To understand how lifter and slider in injection molding differ, let’s break down their key characteristics based on functionality, movement, and practical use. Below is a clear comparison using a table format for easy reference:

Comparison Table

| Aspect | Lifter | Slider |

| Functionality | Ejects parts with internal undercuts (e.g., clips, threads) by combining vertical and angled motion. | Creates external features (e.g., side holes, slots) by moving sideways to release the part. |

| Movement Direction | Moves vertically + at an angle (e.g., 5°–15° tilt) during ejection. | Moves horizontally (or at a fixed angle) during mold opening. |

| Applications | Ideal for parts with hidden geometries inside the mold cavity. | Used for side features that block straight ejection. |

| Design Complexity | Simple design; relies on angled placement and ejector plate force. | More complex; and requires guide pins, wear plates, and locking systems. |

| Cost & Maintenance | Lower initial cost; minimal wear due to fewer moving parts. | Higher cost due to added components; regular lubrication and alignment checks are needed. |

| Operational Constraints | Limited by part thickness and undercut depth. | Requires sufficient mold space for horizontal travel; may slow cycle times. |

Detailed Analysis

- Functionality

Lifter

The lifter is a precision mechanism designed to release internal undercuts (e.g., clips, threads) by combining vertical and angled motion during ejection. When the ejector plate pushes the lifter upward, its tilted design converts vertical force into two directional movements:

Vertical ejection: Lifting the part out of the cavity.

Angled retraction: Pulling sideways to disengage from undercuts.

For example, in medical device molding, lifters smoothly release internal latches without damaging fragile features. Unlike conventional ejector pins (which only move straight), lifters ensure delicate geometries stay intact.

Slider

Sliders act as sideways mold cores that create external features like side holes or textured surfaces. During mold opening, tapered guide pins force the slider to retract horizontally, freeing the part’s external geometry.

Imagine molding a plastic connector with side ports:

- The slider forms the port during the injection.

- When the mold opens, the slider moves sideways like a drawer.

- The port is released cleanly, allowing easy part removal.

Sliders require wear plates and locking systems to withstand high injection pressure, ensuring consistent quality over thousands of cycles.

- Movement Direction

Lifter

Lifters combine vertical ejection force with side-core pulling motion during demolding. For example, when molding a plastic part with internal undercuts (e.g., medical device clips or battery cover threads), the lifter pushes the part upward while tilting at a preset angle (typically 5°–15°). This dual-direction motion ensures fragile features release smoothly without deformation.

Slider

Sliders perform horizontal core-pulling via tapered guide pins. During mold opening, the pins force the slider to retract sideways, like a drawer sliding open, to release external features (e.g., automotive side ports or cosmetic bottle cap threads). Wear-resistant plates and hydraulic interlocks ensure precision under injection pressure.

- Applications

Lifter

Lifters are designed to address small-to-medium internal undercuts in plastic components. These features, such as battery compartment latches or medical device threads, require angled ejection mechanics to avoid structural damage.

Slider

Sliders form external undercuts, such as anti-slip textures or automotive connector ports. A tapered guide pin system ensures horizontal retraction:

- Design & Cost

Lifter

Simpler to design but requires precise angle calculations. Costs less because it uses basic materials like hardened steel.

Slider

Needs extra parts like guide pins and wear plates, increasing both design time and production costs.

- Maintenance

Lifter

Rarely fails if angles are correctly set; occasional cleaning suffices.

Slider

Prone to wear on guide pins; needs frequent greasing and alignment adjustments.

Why This Matters

The choice between lifter vs slider in injection molding hinges on part geometry and production goals. Lifters excel at handling internal undercuts (e.g., battery latches or medical threads) through angled motion, combining vertical ejection with a controlled side pull. This makes them cost-effective for low-to-mid volume runs, as they avoid complex side-core systems.

Sliders, however, are essential for external features like textured grips or side ports. They retract horizontally via tapered guide pins, enabling precise release of larger geometries. While sliders accommodate high-volume production, they demand regular maintenance (e.g., lubrication, wear plate inspections) and add 15–20% to tooling costs. Optimizing this balance of slider lifter injection molding ensures durable molds and defect-free parts.

Custom Injection Molding Solutions: Precision for Complex Designs

To make a practical and durable mold, it is particularly important to understand the difference between the inclined top and the slider. If there are special structures inside the plastic parts, using a lifter is both simple and cost-effective. If the parts have complex shapes on the outside, they have to rely on sliders. However, sliders need maintenance after being used for a period of time, which is rather troublesome.

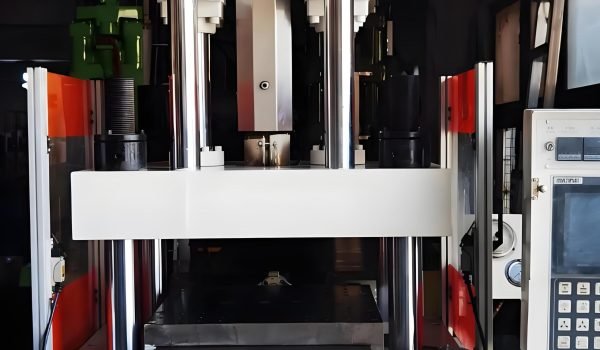

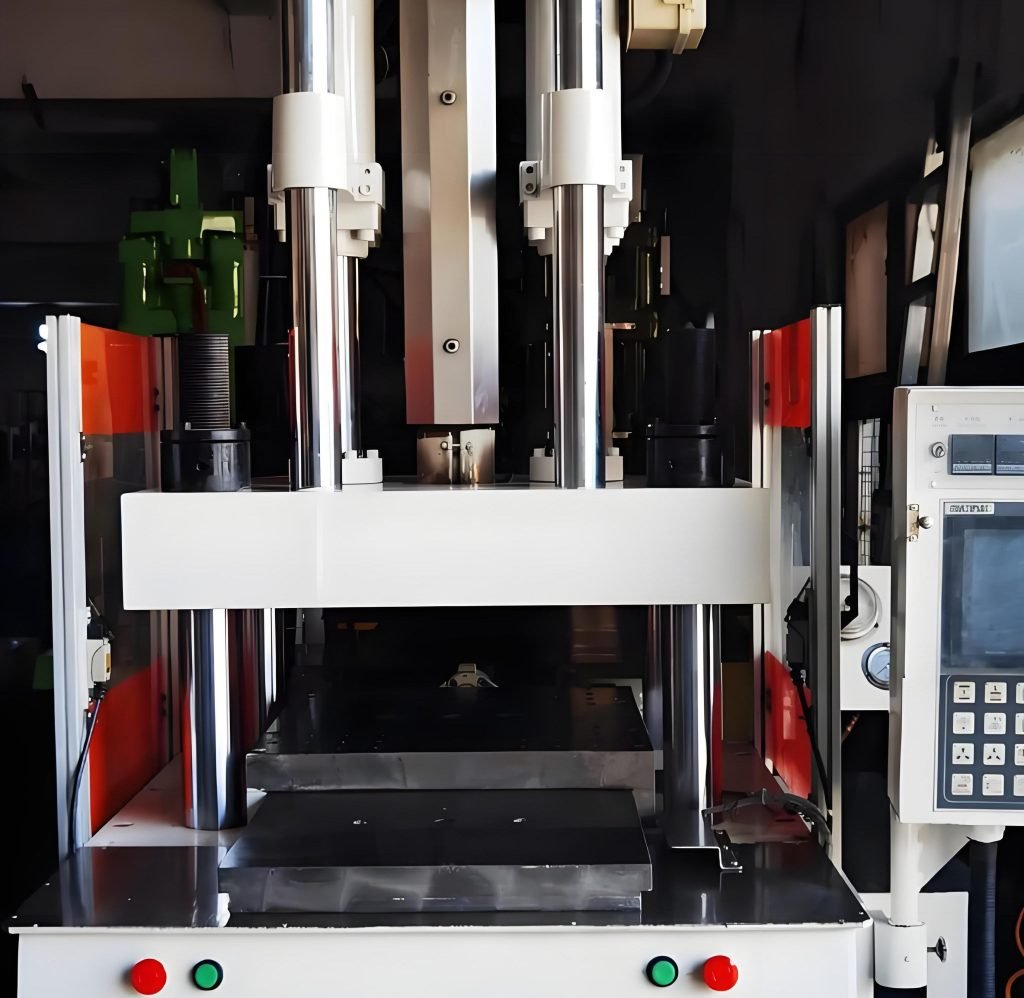

At Fecision, we specialize in high-precision injection molding, including complex mechanisms like sliders and lifters. Understanding these components is crucial for optimizing part design and functionality.

Sliders are ideal for undercuts, and our advanced molding machines ensure smooth operation with minimal wear. Meanwhile, lifters require precise angular ejection—something our team expertly handles for defect-free production.

Why Fecision?

- Free DFM Analysis: Submit your design for instant feedback on mold optimization.

- Rapid Turnaround: Prototypes will be produced in 1–3 weeks; mass production will be ready on approval.

Trusted by global leaders in automotive, medical, and electronics, we transform complex designs into market-ready parts. Need expert help with sliders, lifters, or any injection molding challenge? Contact Us today for a free design review and quote!