Precision Manufacturing for Industrial Equipment Applications

The industrial equipment sector forms the backbone of global manufacturing, with continuous advancements in machine tool technology, automation integration, and precision requirements.

As equipment manufacturers strive for higher performance, extended service life, and improved operational efficiency, they require manufacturing partners capable of delivering precision-engineered components that withstand extreme operational conditions while maintaining dimensional accuracy throughout their lifecycle.

- CE certification (EU market)

- Quality management system per ISO 9001:2015/13485:2016/14001:2015

- DFM and product validation

- Real-time Process Tracking System

- One-stop service for manufacturing, finishing and logistics

Why Choose FECISION for Industrial Equipment Manufacturing

Industrial Equipment Manufacturing Expertise

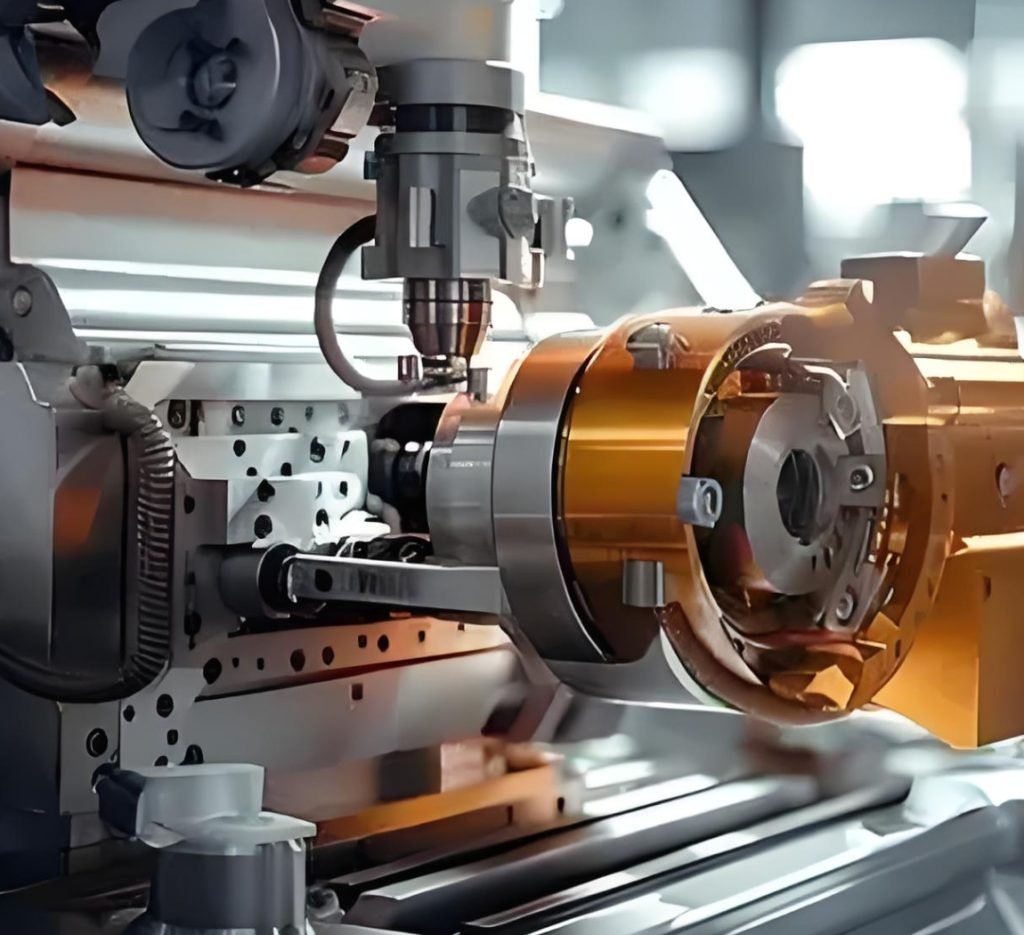

At FECISION, we understand the critical demands placed on industrial machinery components. Our state-of-the-art facilities and specialized manufacturing capabilities enable us to deliver high-precision molds, tooling, and components that meet the exacting standards of industrial equipment manufacturers.

From machine bases to precision spindle components, we provide comprehensive manufacturing solutions for the entire industrial equipment supply chain.

Our Industrial Equipment Manufacturing Capabilities Include:

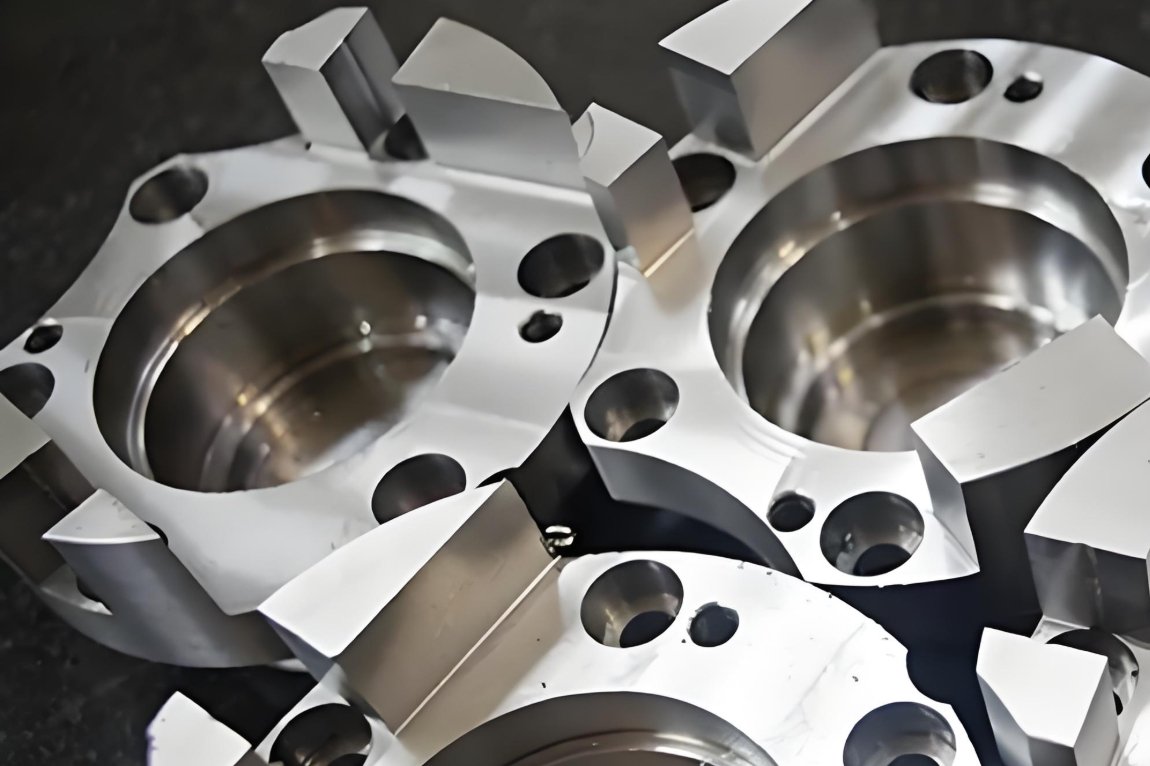

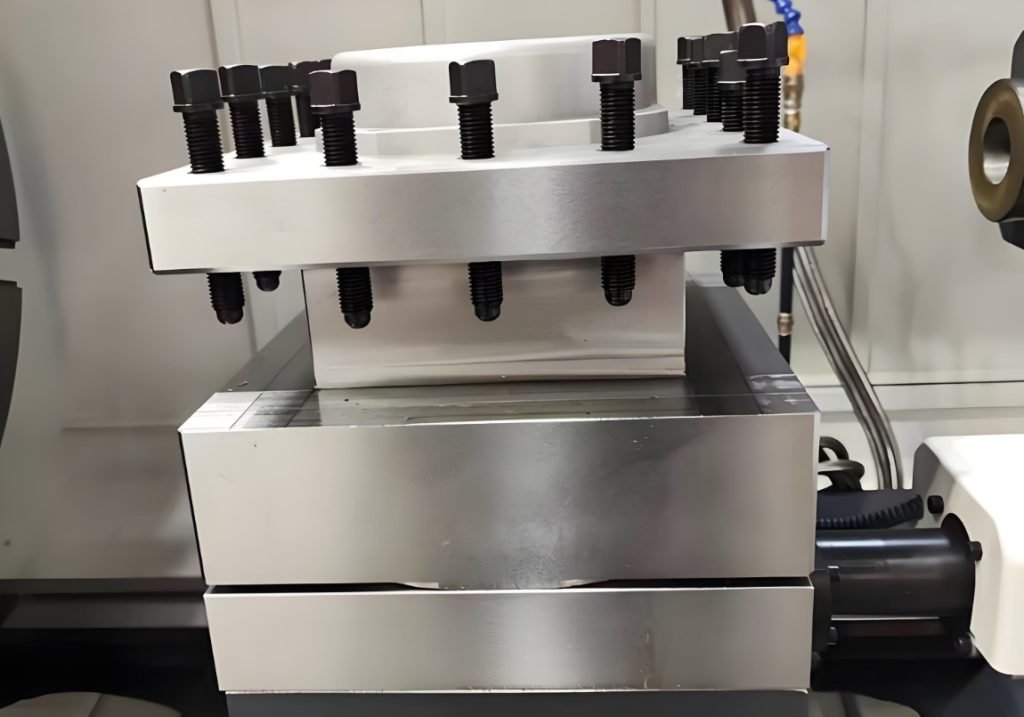

Precision Mold Tooling

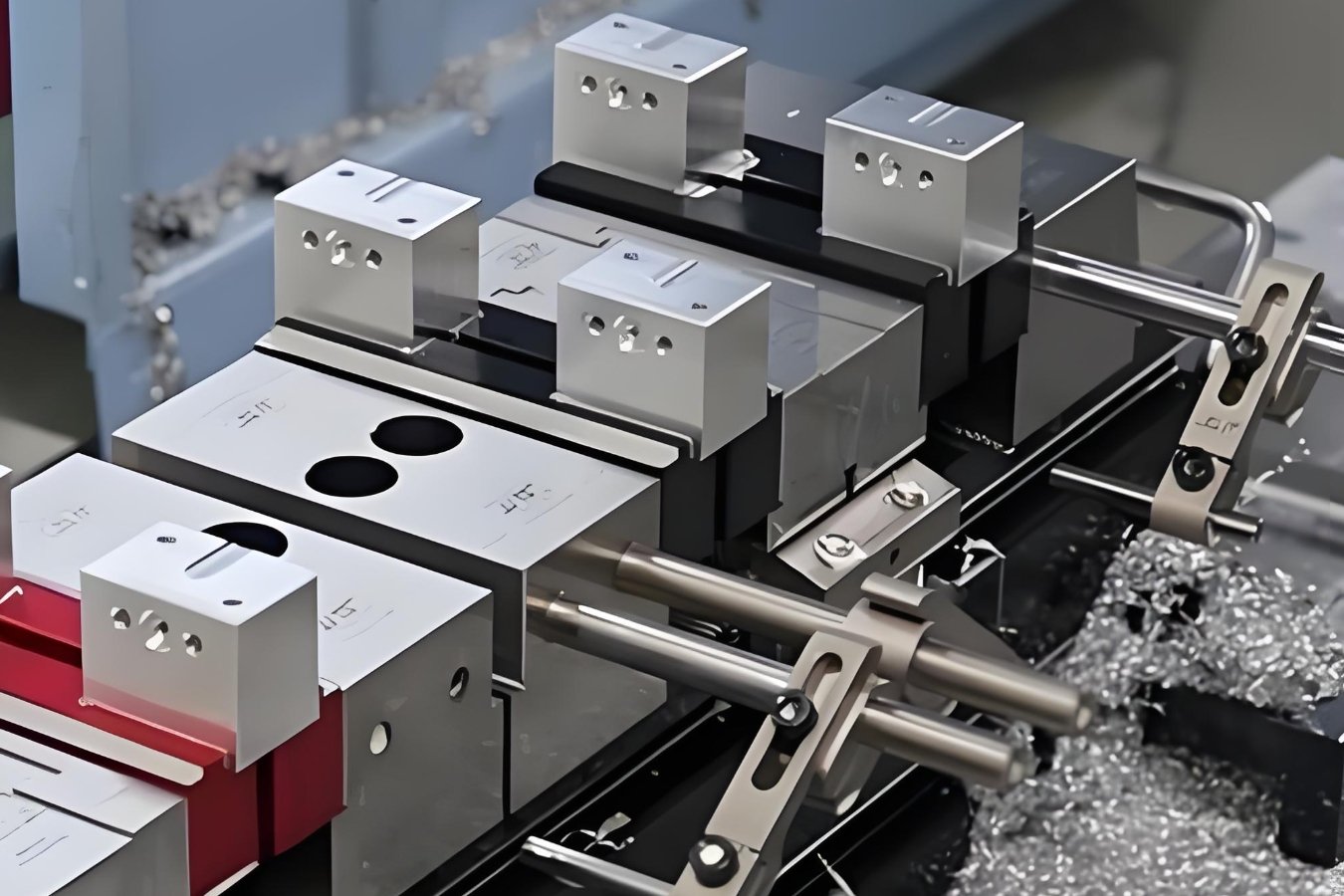

CNC Machining

Injection Molding

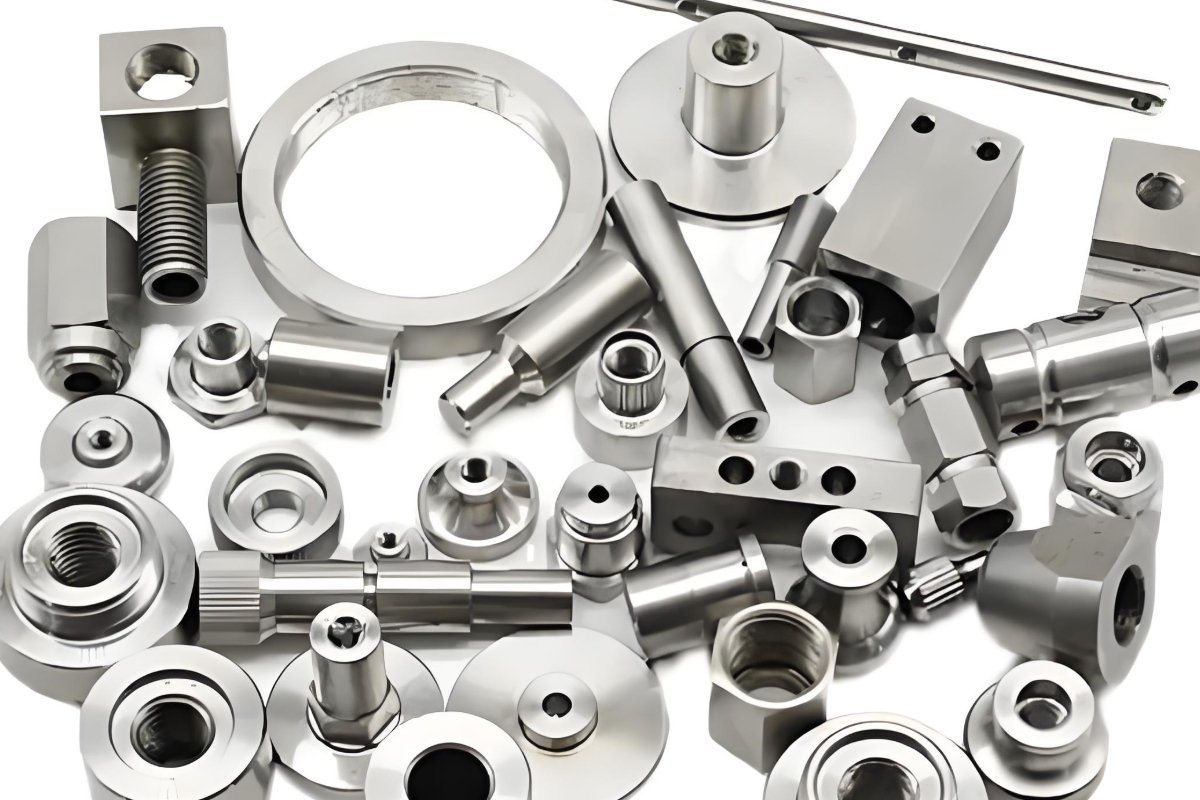

Metal Part Production

Machine Tool Component Manufacturing

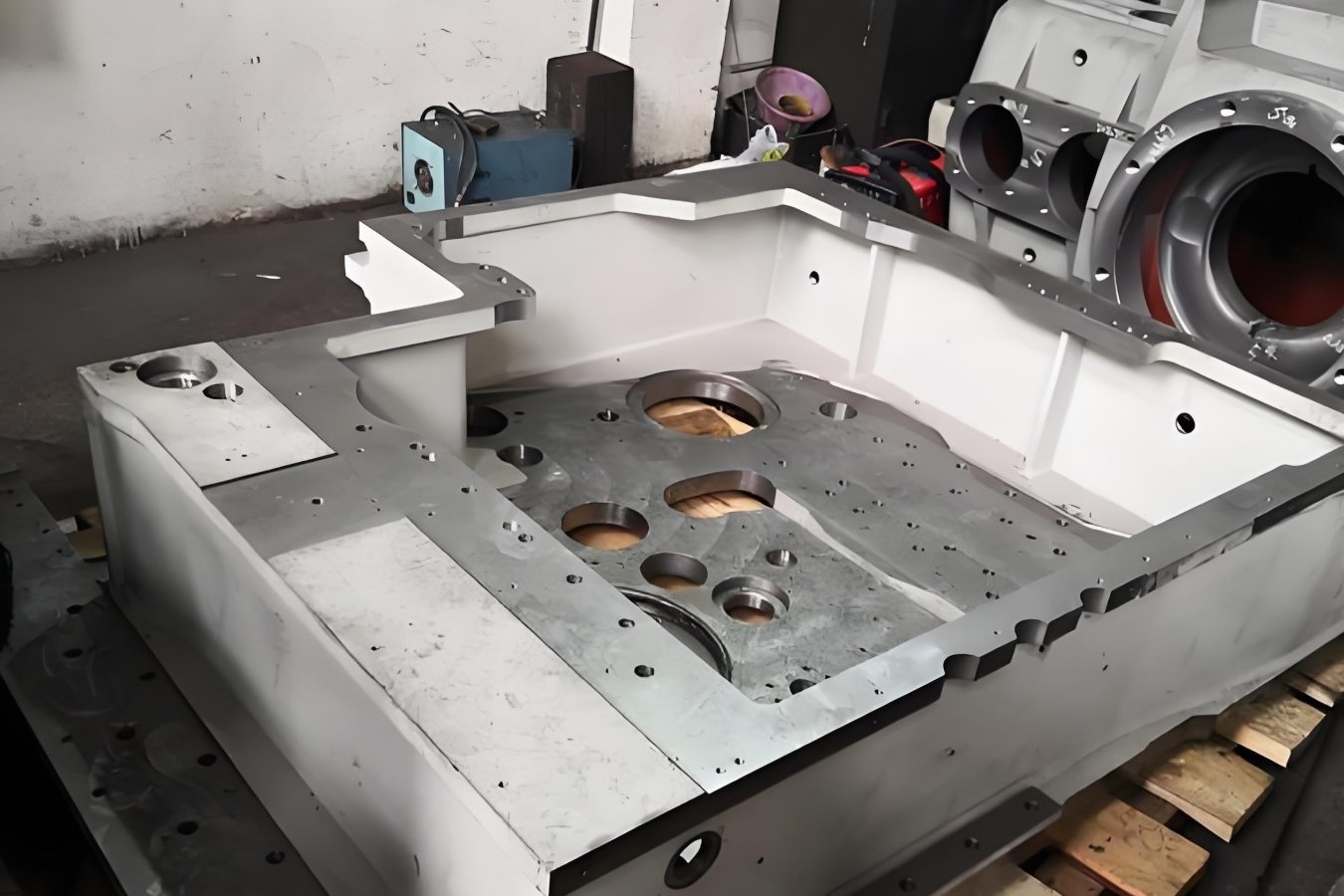

Industrial Equipment Frames and Bases

Precision Spindle Components

Industrial Guideways and Rails

Industrial Fixture and Workholding Solutions

Industrial Equipment Retrofit Components

Industrial-Grade Materials for Equipment Applications

The industrial equipment sector demands materials that deliver exceptional performance under challenging operational conditions. Our components utilize:

√ Wear-Resistant Alloys

Specialized steel alloys for components subject to continuous abrasion and wear

√ Vibration-Dampening Materials

Cast iron and composite materials engineered for stability and vibration control

√ High-Precision Tool Steels

Premium-grade tool steels for cutting tools and forming dies

√ Thermal-Stable Alloys

Materials with minimal thermal expansion for temperature-critical applications

√ Corrosion-Resistant Metals

Stainless steel and treated alloys for harsh industrial environments

√ Specialized Bearing Materials

Self-lubricating and high-load capacity materials for bearing applications

Precision Manufacturing for Industrial Equipment Performance

Precision and stability are fundamental requirements for industrial equipment components. Our manufacturing expertise includes:

√ Ultra-Precision Machining

Components manufactured to tolerances of ±0.002mm for critical applications

√ Geometric Dimensioning and Tolerancing

Advanced GD&T implementation for complex industrial components

√ Thermal Stability Engineering

Components designed to maintain precision across operating temperature ranges

√ Vibration Analysis and Mitigation

Parts engineered to minimize harmful vibrations in high-speed machinery

√ Surface Finish Optimization

Specialized surface treatments for optimal wear characteristics and performance

√ Flatness and Straightness Control

Precision manufacturing techniques for critical reference surfaces

Industrial Equipment Manufacturing Process

1. Engineering Collaboration

- Working with equipment designers to optimize components for manufacturability

2. Material Selection

- Choosing optimal materials based on operational requirements and environmental conditions

3. Prototyping

- Rapid production of prototype components for testing and validation

4. Tooling Development

- Creating precision tooling for production manufacturing

5. Process Validation

- Comprehensive process validation including statistical process control

6. Production Manufacturing

- Implementing efficient production processes with rigorous quality controls

7. Performance Testing

- Validating components under simulated operational conditions

8.Continuous Improvement

- Ongoing refinement of processes to enhance quality and performance

Industrial Equipment Components Manufacturing from Prototype to Production

Fecision offers a highly efficient and simplified supply chain solution. Whether you’re in the stage of creating prototypes, moving on to test units, initiating mass-production, or dealing with subsequent phases, Fecision has got you covered.

Prototype

- For the purpose of validating your materials and designs, get prototypes that come as close as feasible to your final design.

Prototype

DVT

Production

EVT

PVT

- Comprehensive functionality testing on the prototype

- Identify any flaws or areas for improvement in the design

Applications in Industrial Equipment Sector

Our precision manufacturing capabilities serve diverse industrial equipment applications:

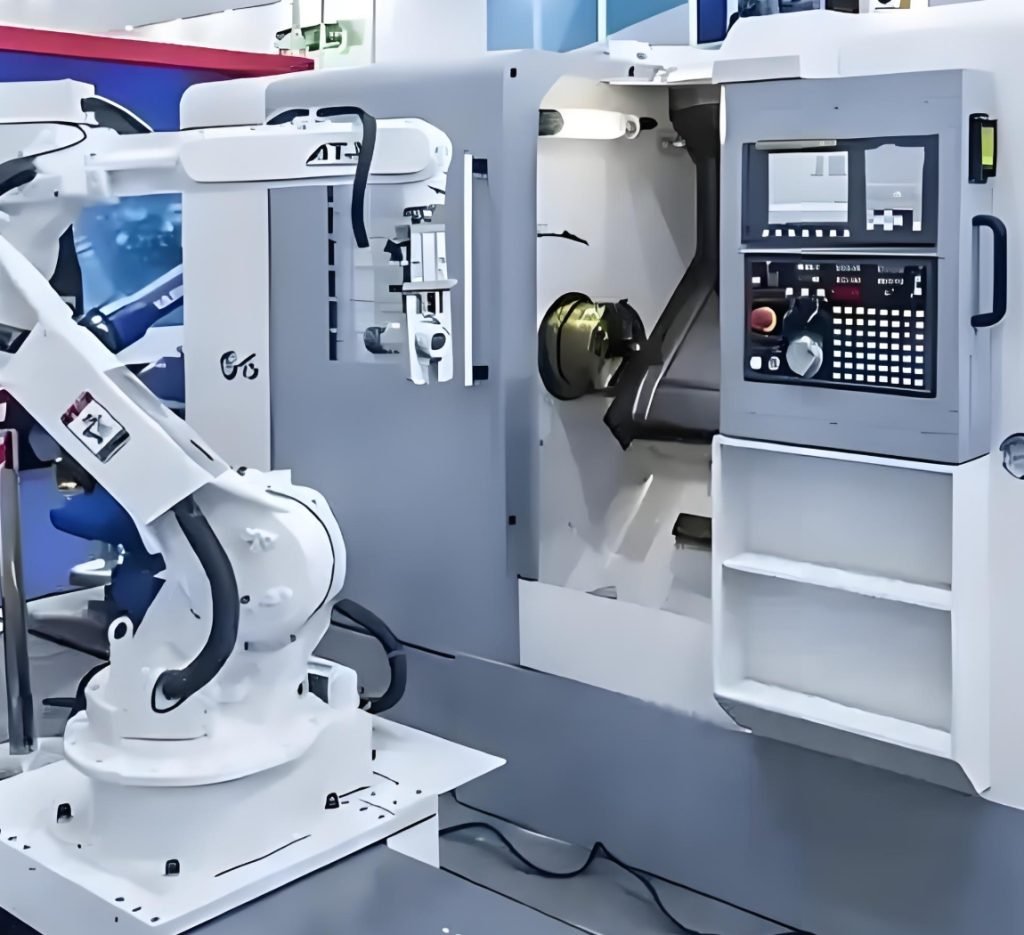

Metalworking Machinery

- Machine tool structural components

- CNC machine precision elements

- Industrial lathe components

- Milling machine parts

- Grinding equipment components

- EDM machine precision parts

Industrial Processing Equipment

- Food processing machinery components

- Pharmaceutical equipment parts

- Chemical processing equipment components

- Textile machinery parts

- Printing equipment components

- Packaging machinery parts

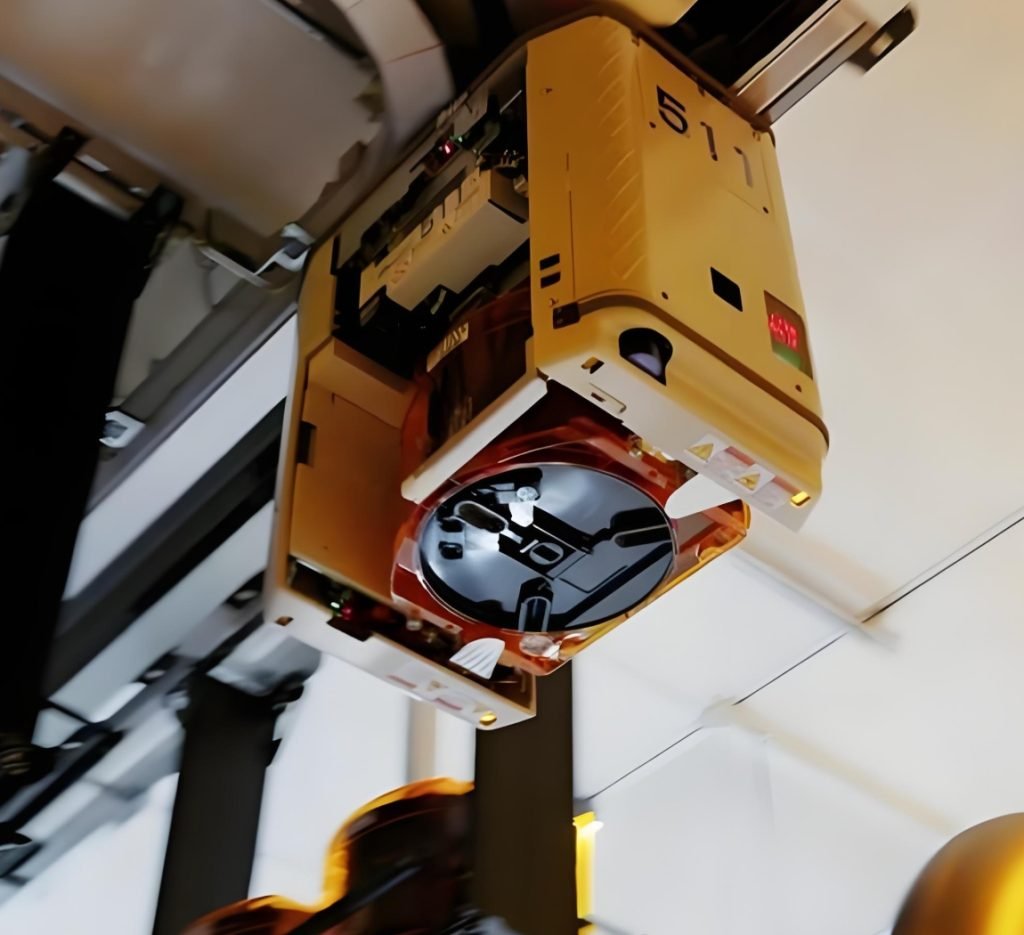

Material Handling Systems

- Conveyor system components

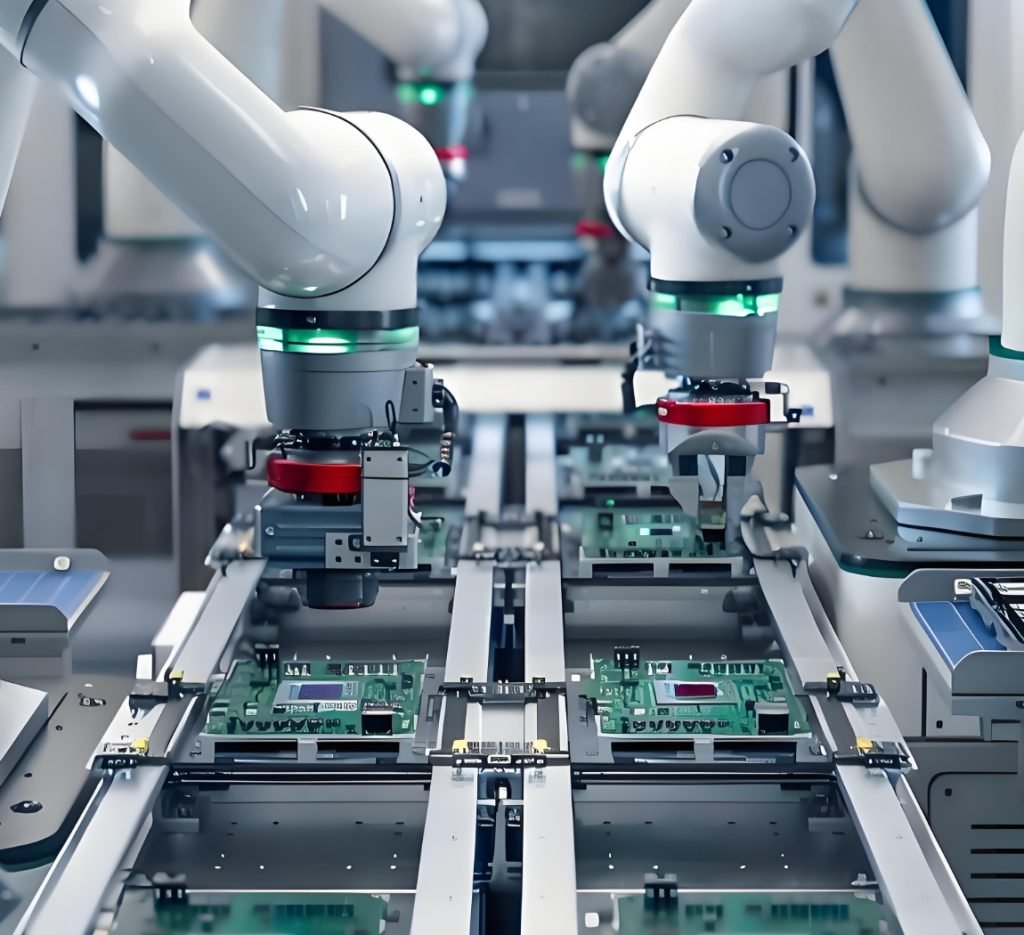

- Industrial robotic equipment parts

- Automated storage system components

- Lifting equipment parts

- Industrial sorting system components

- Warehouse automation equipment

Manufacturing Systems

- Assembly line equipment components

- Industrial press components

- Forming machine parts

- Industrial cutting equipment components

- Welding equipment parts

- Industrial coating system components

Specialized Industrial Equipment

- Heavy machinery components

- Industrial measurement equipment parts

- Testing equipment components

- Industrial cleaning equipment parts

- Industrial heating and cooling system components

- Specialized industrial tool components

ISO 9001:2015 Certification

Meeting international quality management standards

Advanced Dimensional Inspection

High-precision coordinate measuring machines for geometric verification

Surface Finish Analysis

Advanced equipment for surface roughness and texture measurement

Quality Assurance for Industrial Equipment Manufacturing

Quality is fundamental in industrial equipment manufacturing.

Hardness Testing

Comprehensive material hardness verification for wear-critical components

Load Testing

Structural testing for components under operational loads

Vibration Analysis

Testing for vibration characteristics and dampening performance

Geometric Accuracy Verification

Specialized equipment for flatness, straightness, and parallelism verification

Customized Industrial Equipment Parts

Common Application

Industrial equipment demands high-precision, durable components. The industry relies on strict standards like ISO 9001 and ISO 2768 to ensure quality, safety, and performance across automation, machining, and assembly systems. Fecision has multiple solutions for Industrial equipment part production, aiming to provide qualified products with precision and exellent function.

- Industrial Valve Body

- Press Connecting Rod

- Heat Exchanger Shell

- Machine Tool Bed

- Motor End Cover

- Robot Joint Housing

- CNC Lathe Spindle Box

- Injection Molding Machine Platen

- Stamping Die Set

- Hydraulic Cylinder Body

Industrial Equipment Manufacturing Case Studies

Precision Machine Tool Base

We developed precision molds for a next-generation semiconductor packaging application, achieving sub-micron tolerances while reducing cycle time by 25% compared to conventional methods.

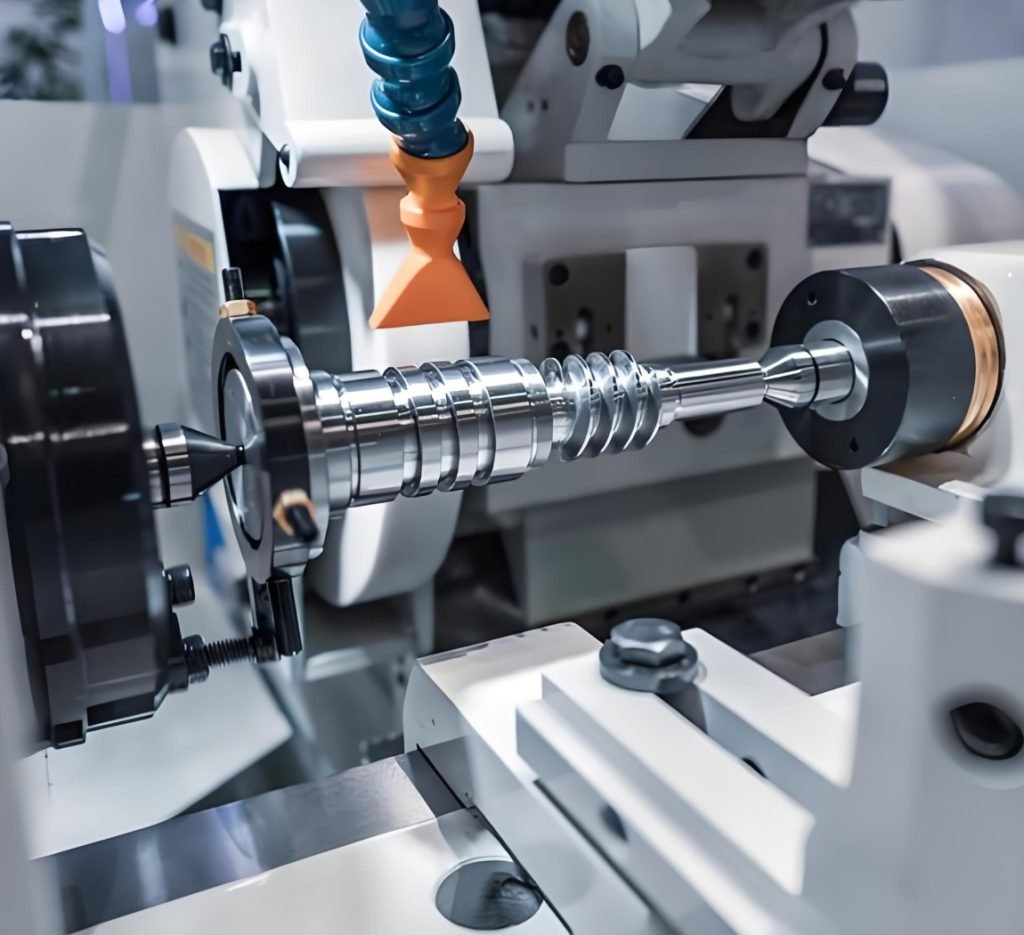

Industrial Spindle Assembly Components

Our team manufactured ultra-precision components for an industrial spindle assembly, achieving tolerances of ±0.002mm and surface finishes of Ra 0.2μm, resulting in extended service life and improved performance in high-speed machining applications.

Heavy-Duty Processing Equipment Parts

FECISION produced wear-resistant components for food processing equipment operating in harsh environments, utilizing specialized materials and surface treatments to extend component life by 300% compared to conventional solutions.

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.