Welcome to precision manufacturing, where getting every detail precise is the most important thing! This means producing products that are high-quality, reliable, and perform without any faults. There is no room for error.

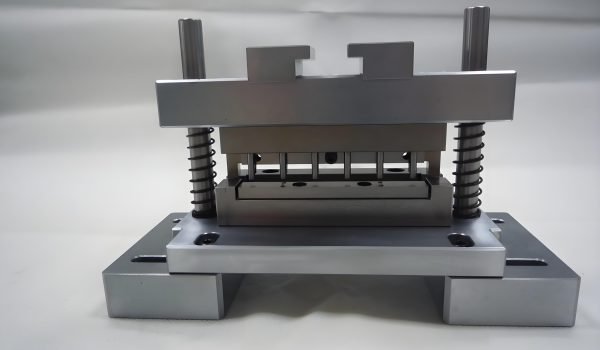

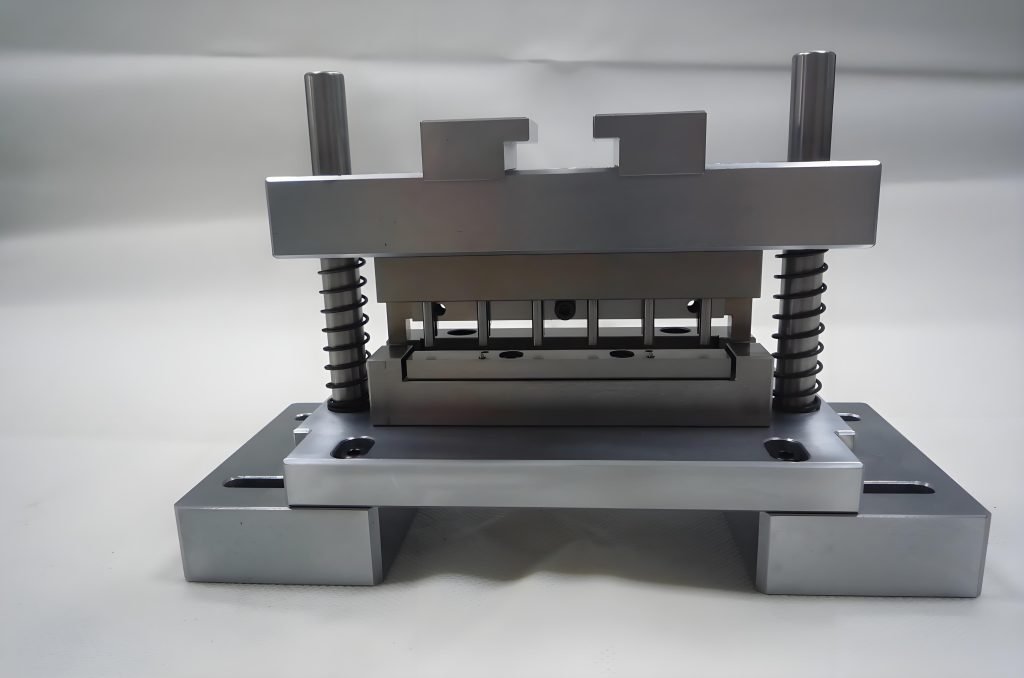

Jigs and fixtures are the unsung heroes of precision manufacturing. More specifically, they help to achieve precision, safety, and valuable time on tasks, especially when many of the tasks involve CNC machined processes.

What Are Jigs and Fixtures?

Now, let’s clarify what these tools are. While they both help with precision, they have slightly different jobs.

Jigs

A jig tool is a very specific apparatus for aiding in the guiding process of your cutting tools. For example, if you need to drill a hole in the exact right location or if you need to cut at a certain angle, a jig will determine precisely where your drill bit or cutting tool will be placed. It’s all about guiding the tool for precise tasks.

Some common types of jigs you might encounter include:

| Type of Jig | What It Does | Best For |

| Template Jig | Guides tools with flat cutouts. | Simple drilling or marking. |

| Plate Jig | A stronger version of a template jig. | Heavy-duty, stable applications. |

| Channel Jig | Guides tools along a straight path. | Linear cuts, repetitive tasks. |

| Diameter Jig | Works on a specific circular dimension. | Drilling on round or cylindrical parts. |

| Leaf Jig | Has a hinge for fast loading and unloading. | High-volume production, quick part changes. |

| Ring Jig | Ring-shaped for holding and guiding tools. | Boring, grinding, or finishing round parts. |

| Box Jig | Encloses the part, guiding tools from many sides. | Complex machining, multi-angle access. |

Fixtures

Conversely, CNC workholding fixtures are built to hold your workpiece in place. For machining operations such as milling, drilling, or turning, you do not want the part motion, even to the slightest degree. Workholding fixtures clamp down on the part and do not permit movement while machining. They’re all about stability.

Here are some common types of fixtures:

| Type of Fixture | Purpose | Typical Use |

| Turning | Holds parts for rotation on a lathe. | Cylindrical parts, shafts. |

| Milling | Secures workpieces for milling. | Flat surfaces, slots, contours. |

| Broaching | Positions parts for material removal by a toothed tool. | Keyways, splines, grooves. |

| Grinding | Ensures precise holding for fine finishing. | High-tolerance surfaces, polishing. |

| Boring | Holds parts for enlarging or refining holes. | Engine blocks, precision bores. |

| Indexing | Rotates parts to exact angles. | Gear cutting, multi-face machining. |

| Tapping | Keeps parts stable during thread tapping. | Threaded holes in production. |

| Welding | Holds components for accurate assembly. | Fabrication, auto frames. |

Key Differences

Even though they both contribute to precision, jigs and fixtures have distinct roles:

| Feature | Jigs | Fixtures |

| Function | Guides the cutting tool | Holds the workpiece securely |

| Tool Guidance | Yes | No |

| Workpiece Holding | Yes, but mainly for guiding | Yes, its primary function |

| Complexity | Can be simpler or complex | Often more complex due to holding requirements |

| Materials | Various, depending on application | Robust, durable materials for stability |

| Example | A template for drilling holes | A vise holding a block of metal for milling |

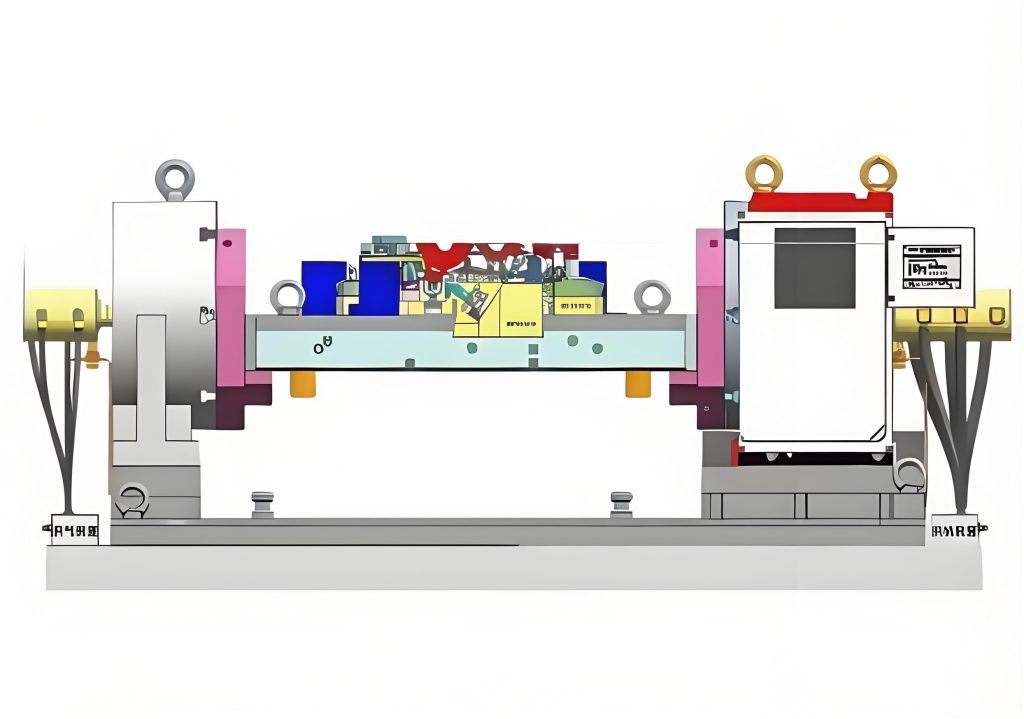

Why Are Jigs and Fixtures Important in CNC Machining?

Jigs and fixtures are not only beneficial; they are fundamental to modern CNC machining. They provide many advantages in the of precision, consistency, and cost of your products.

Enhancing Precision and Consistency

One of the benefits of using jigs and fixtures is the tremendous precision and consistency. Consider reproducing hundreds of identical parts without the use of jigs or fixtures. It would be a significant challenge to create without any variation. Jigs and fixtures are tools used to accurately position the part for machining, and then machining the part in exactly the same way each and every time.

This repeatability is an important factor in areas like aerospace components or medical devices where a minimal error could be a disastrous failure. With the use of suitable jigs and fixtures, you will get precisely every cut, every hole, every dimension.

Improving Efficiency and Reducing Costs

In addition to precision, jigs and fixtures enhance efficiency and save money. How? The ultimate impact jigs and fixtures achieve is strapping down the time needed to set up your machines without measuring and positioning every part individually. Simply load it into the jig or fixture, and you’re ready to go, which increases your manufactured components’ rate of speed.

When jigs and fixtures hold parts tightly and guide tools, they can prevent errors and also hours of redoing work. Less scrap and rework equals less material cost and wasted time, which can add up to significant savings in the end.

Supporting Complex Geometries

Modern product designs typically have extremely complex geometries and details. Trying to machine without any support would be very difficult. This is where jigs and fixtures perform very well, having the stability and tolerable positioning to machine complex designs.

For unique parts or very specialized parts, custom workholding fixtures can be extremely beneficial. They are specifically configured to securely hold parts that are shaped oddly so that the CNC machine can safely and accurately machine a complex design.

How to Design Jigs and Fixtures?

Designing a proper jig or fixture is not simply a matter of making something to hold a part. It involves an entire thought process as to how you will set the part up and adhere to a few key principles.

Pre-Design Considerations

Prior to even sketching, there are a number of important considerations for successful jig and fixture design.

First, be certain you fully understand the part you’re working with. What are dimensions? What is the material? What machining operations (milling, drilling, or turning) will be performed? You will also need to know the required tolerance (how much variation there is) and the required surface finish.

Next, consider the production volume and complexity. Are you making a few prototypes or thousands of identical parts? This will dictate the strength and automation requirements of your jig or fixture. For high-volume jobs, consider a jig or fixture that facilitates a quicker load and unload interface.

Last, you should always address ergonomics and the operator’s safety. Can the operator easily load and unload the part without straining? Are there pinch points and sharp edges? A good jig and fixture will make the job of the operator safer and easier.

Design Principles

Once you have your pre-design considerations sorted, you can dive into the core design principles:

Applying the 3-2-1 Principle for Accurate Workpiece Location

This is a fundamental concept in jig and fixture design. The 3-2-1 principle, also referred to as the six-point location principle, locates your workpiece in space to completely constrain it so that there is no unwanted movement can occur during machining.

- 3 points attached to the primary locating surface (i.e., the bottom of the part) stop rotation and movement in the Z-axis direction.

- 2 points attached to the secondary locating surface (i.e., side of the part) stop rotation and movement in one direction (i.e., Y-axis).

- 1 point attached to the tertiary locating surface (i.e., another side) stops rotation in the last axis (i.e., X-axis).

Selecting Suitable Materials Based on Strength and Durability

The material for your jig or fixture is also very important. It needs to be high enough in strength to support machining, and durable enough to withstand many cycles.

| Material | Characteristics | Ideal For |

| Aluminium | Lightweight, good machinability, corrosion resistant | Prototypes, lower volume production, general purpose |

| Tool Steel | High strength, hardness, wear resistance, can be heat-treated | High volume production, high precision, demanding applications |

| Hybrid Approach | Combines different materials (e.g., steel inserts in an aluminum body) | Balancing cost, weight, and wear resistance; complex designs |

Incorporating Modularity for Flexibility and Adaptability

Consider giving your jig or fixture the capability of modularity. This is when you design your jig or fixture, you can interchange or adjust some component parts. Modularity can give you great flexibility. If you are making similar parts with small differences, you may only have to swap out a few components in your fixture, as opposed to constructing a whole new one. It is great for saving you time and money, and enhancing your capacity to deal with future modifications.

Practical Tips

Always use Design for Manufacturability (DFM) as a guide. This means designing your jig or fixture to be easy and cost-effective for manufacturing. Can it be machined efficiently? Are there features you have introduced that will increase manufacturing costs? Keep it simple but usable.

Finally, don’t discount the power of prototyping and simulation. Before making a full commitment to a build, try testing your design with simulation software. This can establish stress points and clamping inefficiencies prior to manufacturing. For critical or more complex designs, remember to create a physical prototype of the model, even if it is a 3D-printed one; it can provide real-world insight and you can test the functionality and fit.

Key Elements of Jigs and Fixtures

A well-designed jig or fixture is comprised of multiple important components, each providing its proportionate contribution to the function of the tool. If you understand the significant aspects, you will be able to make effective and reliable tools.

Body and Structure

The body and structure are what hold everything together and give the jig or fixture the rigidity and stability so that it can perform its intended function. Body type selection depends primarily on the shape of the workpiece and the operational machining processes.

Some different types of bodies include:

| Type of Body | Description | Key Advantages & Use Cases |

| Plane Bodies | Flat plates serving as a mounting base. | Simple, easy to machine; great for flat or basic parts. |

| Channel & Box Bodies | Enclosed, rigid structures. | Excellent stability for odd shapes; helps with chip management. |

| Leaf or Built-Up Bodies | Hinged or modular assemblies. | Fast part changes, highly adaptable for complex operations. |

Locating Devices

Locating devices are the heart of precision in jigs and fixtures. The job is to ensure the workpiece is always located in the same location, every time. Without aligning and locating accurately, all efforts made will be wasted.

Common types of locating devices include:

| Type of Pin | Description | Function & Benefits |

| Locating Pins | Cylindrical pins that fit into part features. | Ensures precise, repeatable alignment of the workpiece. |

| Jack Pins | Supports the workpiece from underneath. | Prevents part deflection, enhances stability during machining. |

| Support Pins | Adjustable pins for varying heights or shapes. | Accommodates diverse parts, speeds up setup. |

Clamping Mechanisms

When securing a workpiece in the correct location, it also needs to be firmly held in that position. Clamping mechanisms are useful for providing secure clamping that would not distort or damage the part. The clamp must apply sufficient force to resist machining forces but not so much that it distorts the workpiece.

Some common clamping methods include:

| Clamp Type | How It Works | Best For |

| Bridge Clamp | Pushes down from above. | Large, flat parts with even pressure. |

| C-Clamp | Grips from the side. | General, versatile use. |

| Heel Clamp | Pivots to apply force. | Quick, repetitive tasks. |

| Toggle Clamp | Lever-operated, fast lock. | High-speed production. |

| Cam Clamp | Uses an off-center cam. | Quick part changes, consistent force. |

| Screw Clamp | Tightens with a screw. | Strong hold, adjustable force. |

Tool Guides and Bushes

For jigs used for accurate guiding of cutting tools, tool guides and bushes are the best way of being consistently accurate with the tool directed to the intended position without wandering. These are essential elements in jig manufacturing.

Types of bushes and their benefits include:

| Type of Bush | Description | Advantages | Common Applications |

| Renewable | Replaceable guide components. | Cost-effective, extends jig life. | High-wear drilling, mass production. |

| Press-Fit | Permanently installed via interference fit. | Maximum rigidity and precision. | High-accuracy drilling, precision applications. |

| Slip | Removable/replaceable sleeves. | Quick tool changes, multi-tool compatibility. | Jobs needing multiple drill sizes, prototyping. |

Conclusion: Precision Manufacturing Starts with Expert Design

We’ve covered a lot about jigs and fixtures, and hopefully, you now see just how important well-designed jig tools and CNC workholding fixtures are. They are truly important to achieve both high quality and high efficiency in any manufacturing process. Without them, it would be almost impossible to achieve the accuracy that is necessary for our complex parts today.

When it comes to creating your designs, working with a specialist is the best way to guarantee the highest quality jig manufacturing and fixture manufacturing. A qualified partner will understand the designs, the selection of materials, and manufacturing processes.

Why Choose Fecision?

At Fecision, we have deep expertise in creating custom workholding fixtures, including specialized 5-axis workholding fixtures for the most advanced machining operations. All our services are primarily end-to-end, so we can assist you from your first concept to designing jigs and fixtures, through CNC machining. We are all about high precision, turnaround, and cost efficiency. Your success is our priority.

Need jigs or fixtures for your next project? Don’t compromise on precision. Contact Fecision today for a quote!