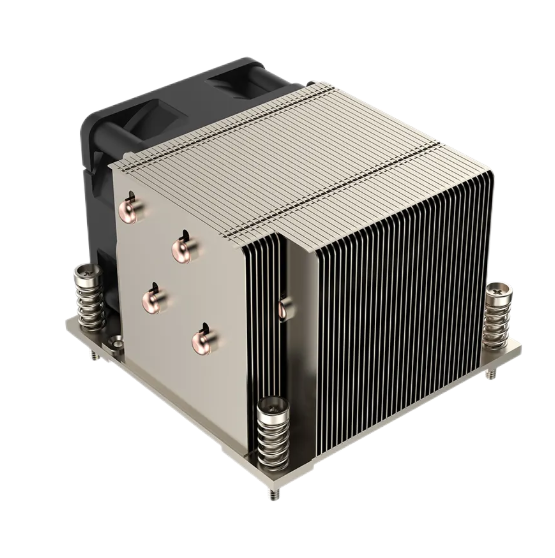

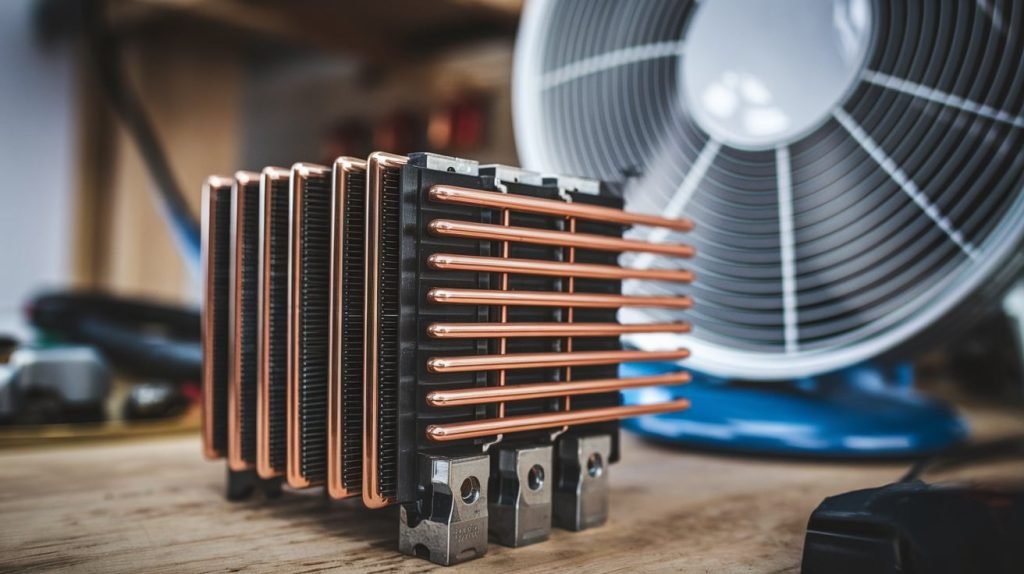

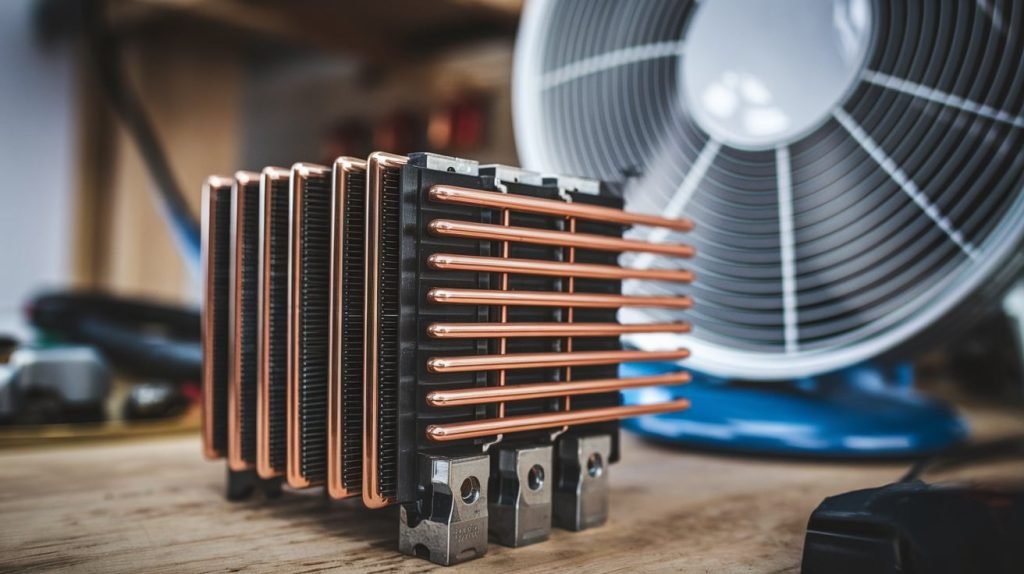

Active Heat Sink

Why

Fecision?

Precision At Fecision

Custom CNC Machining & Molded Solutions

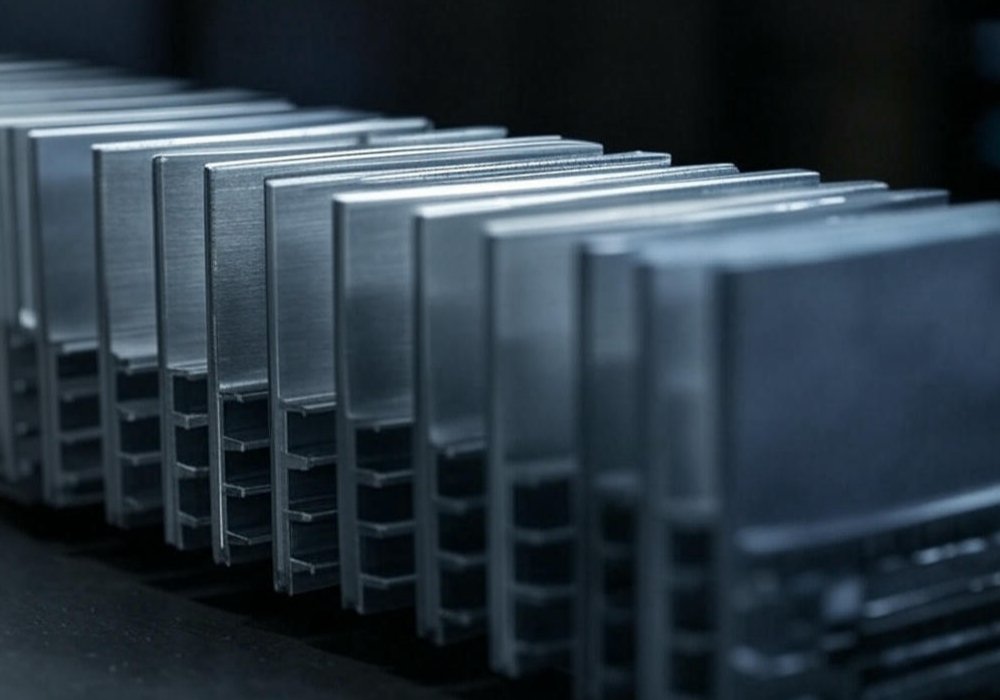

As a leading CNC machining and mold manufacturing service provider, we deliver tailored heat sink solutions using advanced materials and manufacturing techniques, including CNC milling, extrusion, die-casting, and bonded fin technology.

Optimized Thermal Performance

CFD-simulated designs for maximum heat dissipation

Durability

Corrosion-resistant finishes for harsh environments

Custom Designs

Collaborate with our engineers for application-specific solutions

Cost Efficiency

Competitive pricing for both low/high-volume orders

Global Compliance

Meet RoHS, REACH, and ISO 9001 standards

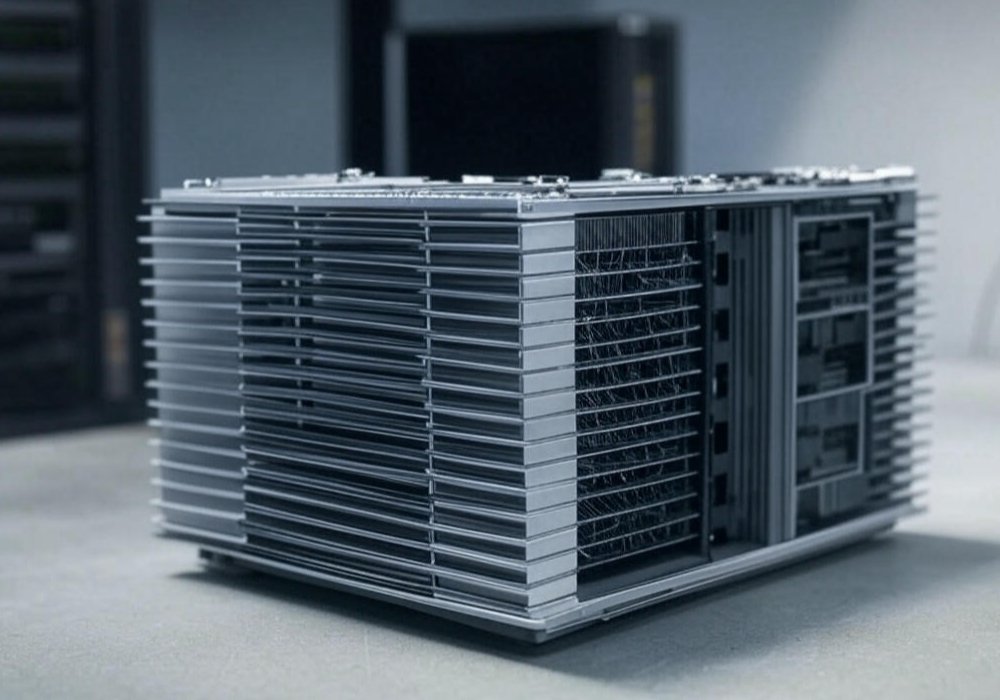

Active Heat Sinks

Key Characteristics

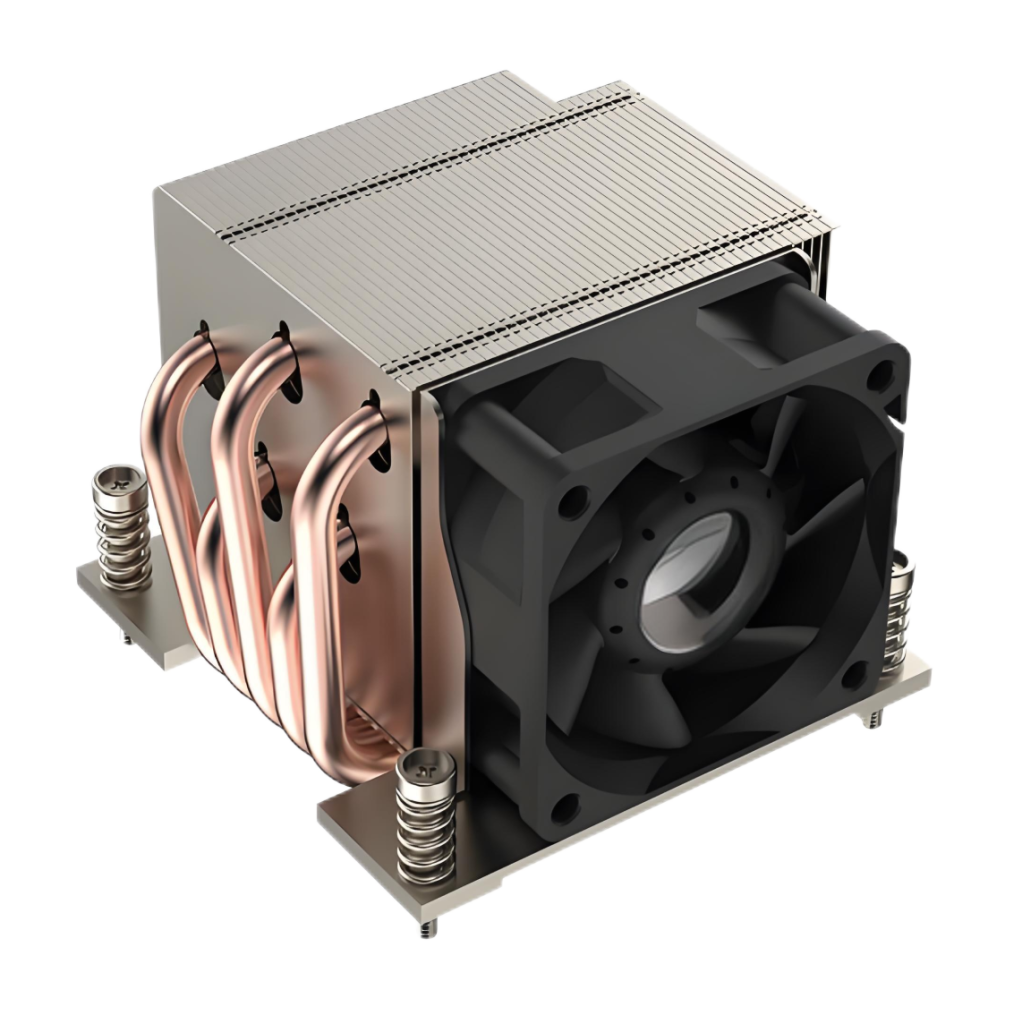

- Forced Air: High-CFM fans for server racks, GPUs.

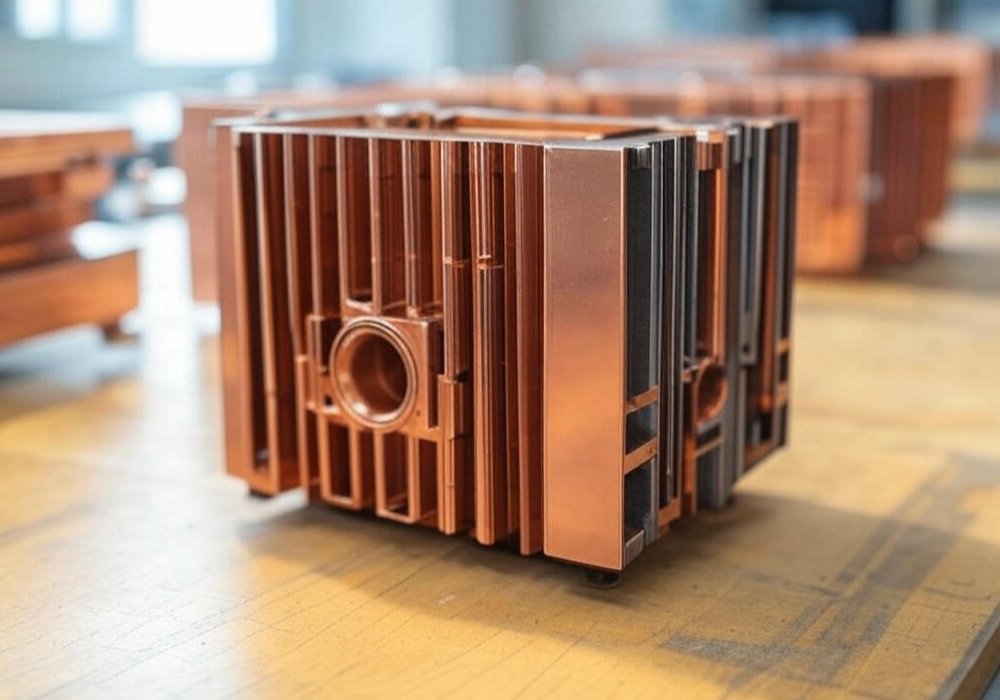

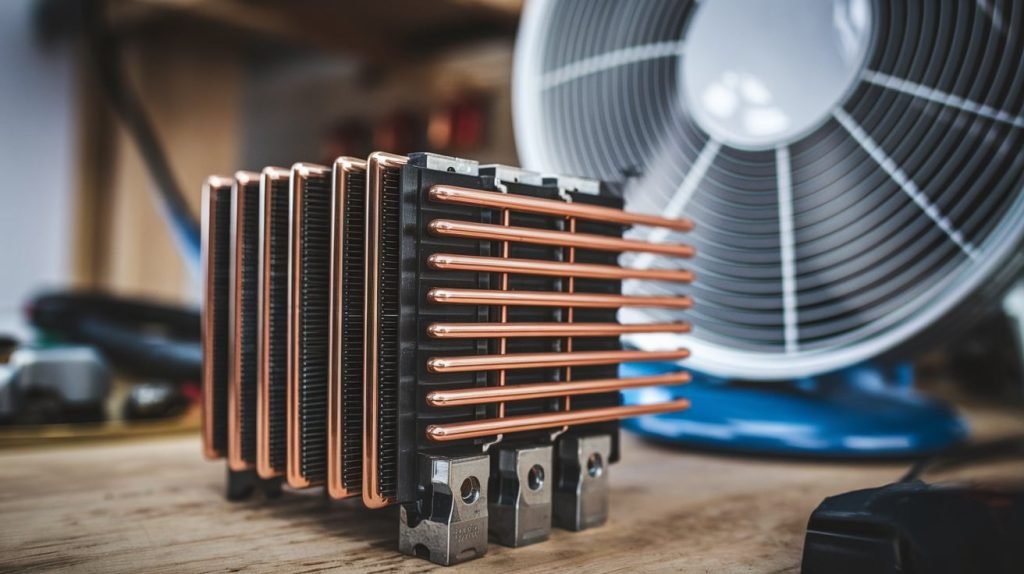

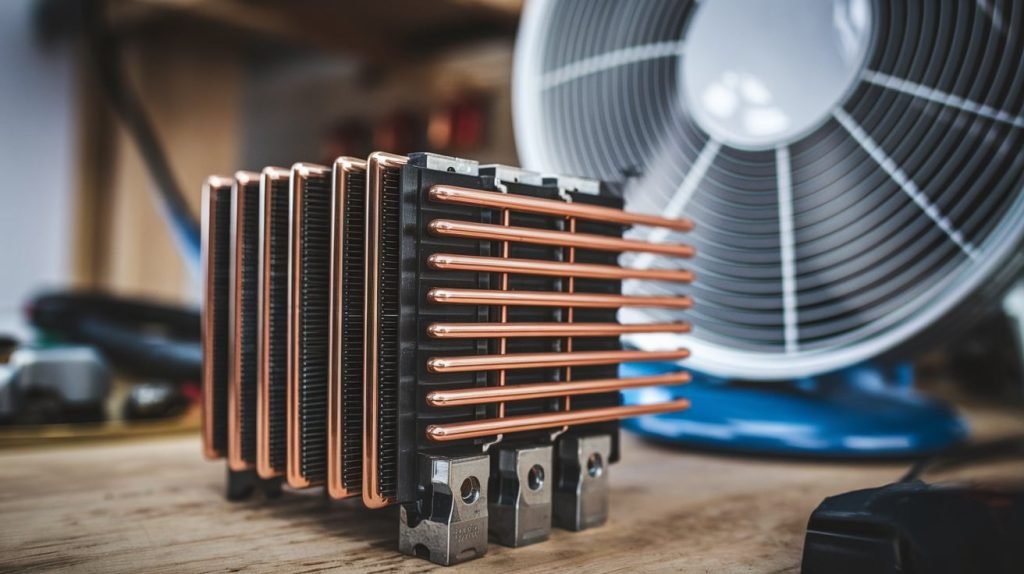

- Liquid Cooling: Cold plates with integrated tubing for EVs, lasers.

- Thermoelectric (TEC): Peltier modules for precision temperature control.

Technical Specification Table

| Parameter | Specifications |

| Cooling Methods | Forced Air, Liquid, Thermoelectric (TEC) |

| Materials | Aluminum 6061, Copper C110, Cold Plates |

| Thermal Resistance | 0.05–0.5°C/W (system-level) |

| Fan Specifications | 12V/24V DC, 20–80 CFM, 15–40 dBA |

| Liquid Flow Rate | 0.5–5 L/min (customizable) |

| Certifications | ISO 9001, IATF 16949, CE, UL, FCC |

Types of Active Heat Sinks

Fan-Cooled Heat Sinks

Liquid-Cooled Cold Plates

Hybrid Active-Passive Designs

Thermoelectric (TEC) Heat Sinks

Applications & Industries

Data Centers

Electric Vehicles

Industrial Laser

Medical Devices

Start your project now

Workflow

Customization Process

Share your thermal requirements, size constraints, and environmental conditions.

We provide 3D CAD models and thermal analysis reports.

Test functional prototypes for performance validation.

Seamless transition to full-scale manufacturing.

Built for Reliability & Safety

Certifications & Quality Assurance

ISO 9001:2015 & IATF 16949

CE, FCC, UL (Electrical Safety)

RoHS/REACH Compliance

IP67 Ratings (Liquid-Cooled Systems)

Request a Proposal

Other Products

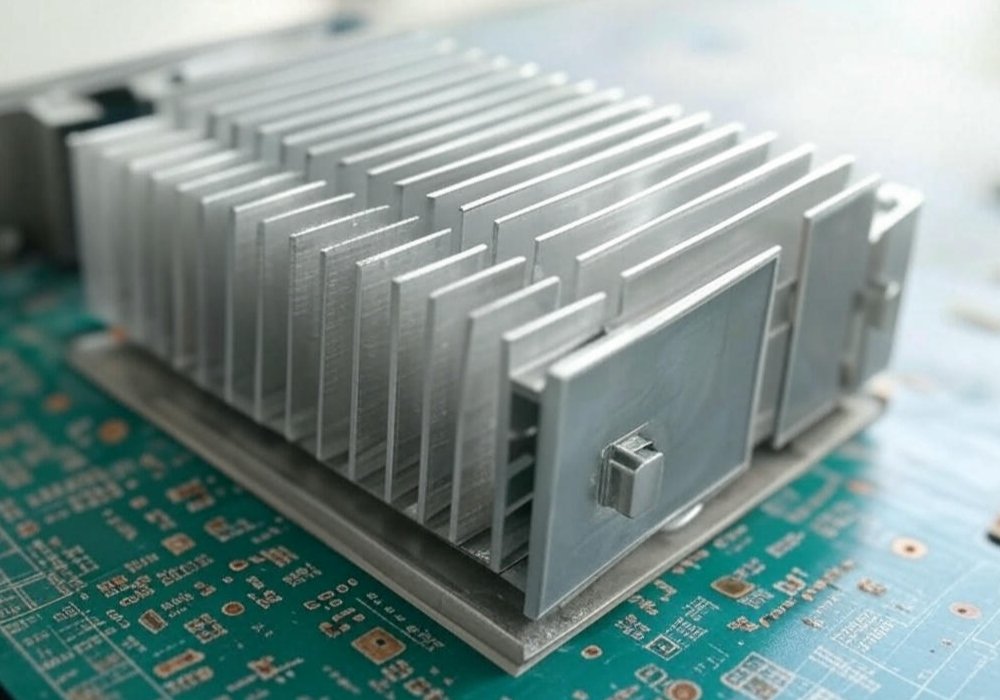

Passive Heat Sink

Aluminum Heat Sink

Copper Heat Sink

Hybrid Heat Sink

CNC-Machined Heat Sink

Extruded Heat Sink

Die-Cast Heat Sink

Stamped Heat Sink

Finned Heat Sink

Pin Fin Heat Sink

Folded Fin Heat Sink