Welding Jigs: Precision Workholding for Welds

Using advanced machining and design technologies, we ensure seamless integration and adaptability, delivering custom solutions that enhance welding precision and efficiency for applications like high-volume automotive welding or precision aerospace fabrication.

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

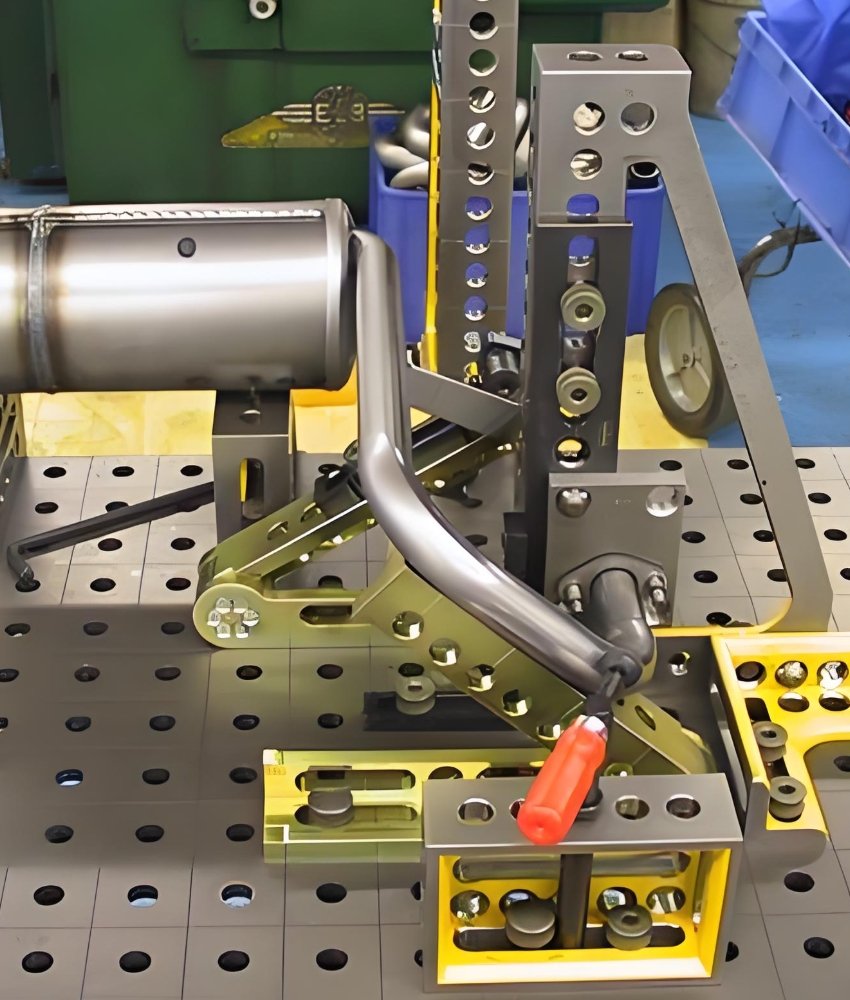

Custom Welding Jigs

Engineered for Superior Welds

Custom Manufacturing Expertise

Precision Welding Jigs

A welding jig is a specialized tool designed to hold workpieces in precise positions during the welding process. Unlike simple clamps, a welding jig provides a rigid framework that maintains exact alignment between multiple components, ensuring consistency and accuracy across identical projects.

The primary function of a welding jig is to eliminate the need for constant measuring, positioning, and readjusting during welding. By securing all components in their correct positions, jigs allow welders to focus entirely on creating quality welds rather than struggling with alignment issues.

Precision Welding

Stable Fixed Jigs

Enhance Versatility

Adjustable Jigs

Boosts Efficiency

Adaptable Modular Welding Jigs

Our Welding Jig Products

Welding jigs come in various designs, each optimized for specific applications and project requirements.

ecision provides different types of welding jigs to help you in selecting the most appropriate jig for your particular welding task.

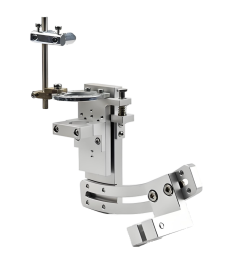

3-Axis Welding Jigs

Provide movement along three perpendicular axes (X, Y, and Z), offering maximum flexibility for complex welding projects. Allow precise positioning in three-dimensional space

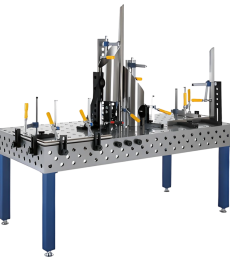

Modular Welding Jigs

Consist of interchangeable components that can be assembled in various configurations. Adaptable to different project requirements without the need for multiple specialized jigs.

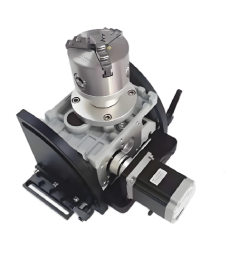

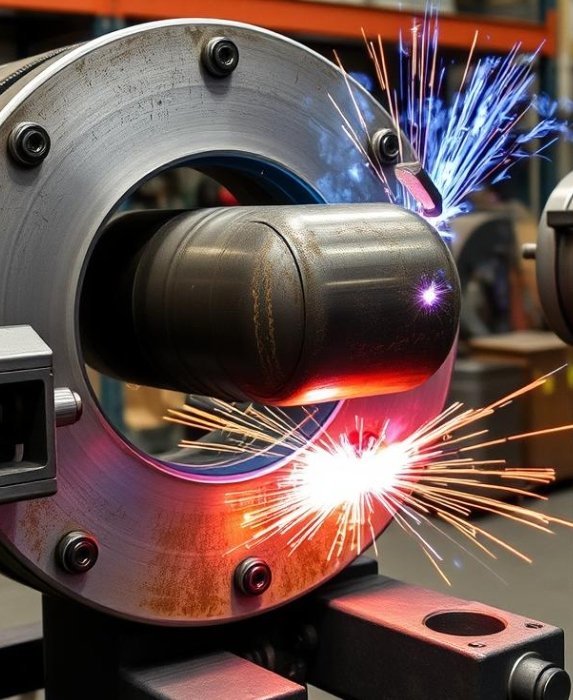

Rotating Welding Jigs

Allow the workpiece to be rotated during welding, enabling continuous work on cylindrical or circular components without repositioning the welder or the welding equipment.

Understanding the Difference

Jigs vs. Fixtures

While often used interchangeably, jigs and fixtures serve slightly different purposes in welding:

Welding Jigs

✅ Hold workpieces in position

✅ Guide the welding tool

✅ Allow movement of the tool while workpiece remains stationary

✅ Typically more complex in design

✅ Often used for repetitive production

Welding Fixtures

✅ Secure workpieces in place

✅ Don’t necessarily guide the tool

✅ Both tool and workpiece can move together

✅ Generally simpler in construction

✅ Often used for one-off projects

Materials for Welding Jigs

The material used to construct a welding jig significantly impacts its performance, durability, and suitability for specific applications.

Each material offers distinct advantages and limitations that should be considered when selecting or designing a jig.

Material Selection Considerations

For most general welding applications, mild steel offers the best balance of cost, durability, and functionality. However, specialized applications may benefit from alternative materials:

✅ High-precision production: Tool steel or cast iron provides superior stability and wear resistance

✅ Portable applications: Aluminum reduces weight while maintaining adequate strength

✅ High-heat environments: Ceramics or specialized heat-resistant alloys prevent warping

✅ Corrosive environments: Stainless steel or treated materials resist rust and degradation

Our team is available to provide expert guidance for your project.

Applications of Welding Jigs

Welding jigs find applications across numerous industries and project types.

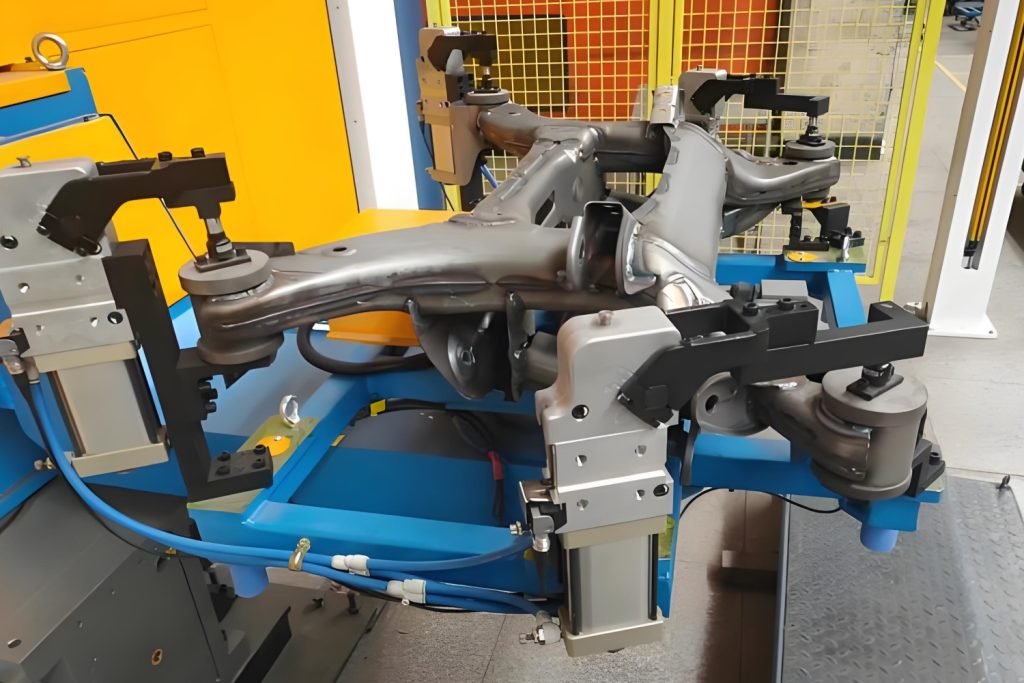

Automotive Manufacturing

The automotive industry relies heavily on welding jigs for consistent production of vehicle frames, chassis components, and body panels. These jigs ensure perfect alignment of critical safety components and help maintain tight tolerances required for modern vehicles.

✅ Frame and chassis assembly

✅ Suspension component fabrication

✅ Exhaust system manufacturing

✅ Body panel alignment and welding

Aerospace Applications

Aerospace manufacturing demands the highest levels of precision and quality control. Specialized welding jigs in this industry often incorporate advanced materials and digital positioning systems to achieve the extreme accuracy required for flight-critical components.

✅ Turbine and engine component fabrication

✅ Structural airframe assembly

✅ Landing gear component manufacturing

✅ Satellite and space vehicle constructiong

Construction and Infrastructure

Construction projects utilize welding jigs for fabricating structural components, railings, staircases, and other architectural elements. These jigs often need to accommodate large-scale components while maintaining precise alignment for structural integrity.

✅ Structural steel beam fabrication

✅ Railing and guardrail production

✅ Staircase and ladder manufacturing

✅ Bridge component assembly

Energy Sector

The energy sector requires welding jigs capable of handling large, heavy components with extreme precision. Pipeline construction, pressure vessel fabrication, and power generation equipment all rely on specialized welding jigs to ensure safety and reliability.

✅ Pipeline section fabrication

✅ Pressure vessel construction

✅ Wind turbine component manufacturing

✅ Power generation equipment assembly

Choose a Suitable Welding Jig

Selecting the right welding jig involves careful consideration of your specific project requirements, working environment, and budget constraints.

Volume Considerations

- One-off projects: Simple adjustable jigs or even temporary fixtures may be sufficient

- Small batch production: Modular or adjustable jigs offer good versatility

- High-volume production: Dedicated jigs provide maximum efficiency and consistency

Complexity Factors

- Simple geometries: Basic jigs with minimal adjustment features

- Moderate complexity: Adjustable jigs with multiple positioning options

- Complex components: 3-axis or specialized jigs with precise control

Material Compatibility

- Steel welding: Most standard jigs work well, with mild steel being a common choice

- Aluminum welding: Consider heat dissipation and potential for warping

- Mixed materials: Modular systems that can accommodate different thermal expansion rates

Space and Mobility Requirements

Your working environment plays a crucial role in jig selection:

❇️ Limited workspace: Compact or folding jigs that maximize available space

❇️ Multiple work locations: Portable jigs with lightweight construction

❇️ Dedicated workshop: Larger, more robust jigs with permanent installation

❇️ Shared equipment: Modular systems that can be quickly assembled and disassembled

Speak With Our Engineering Team

Discuss your specific application challenges with our fixture design specialists.

Ready to Improve Your Welding Precision?

Contact our team today for expert guidance on selecting, designing, or customizing the perfect welding jig solution for your specific needs.