Pneumatic Fixtures for Industrial Applications

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

Custom Pneumatic Fixtures

Engineered for Various Industrial Applications

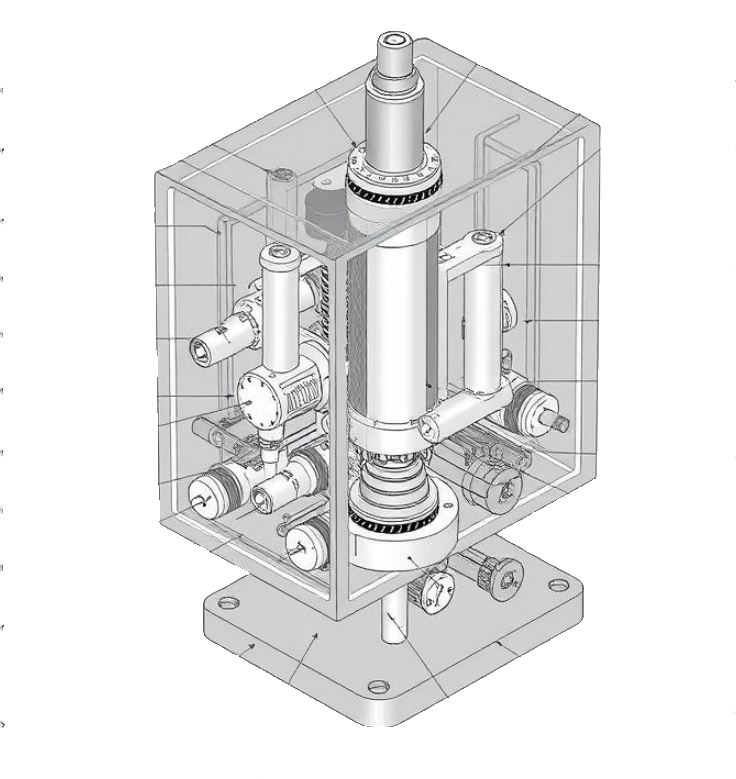

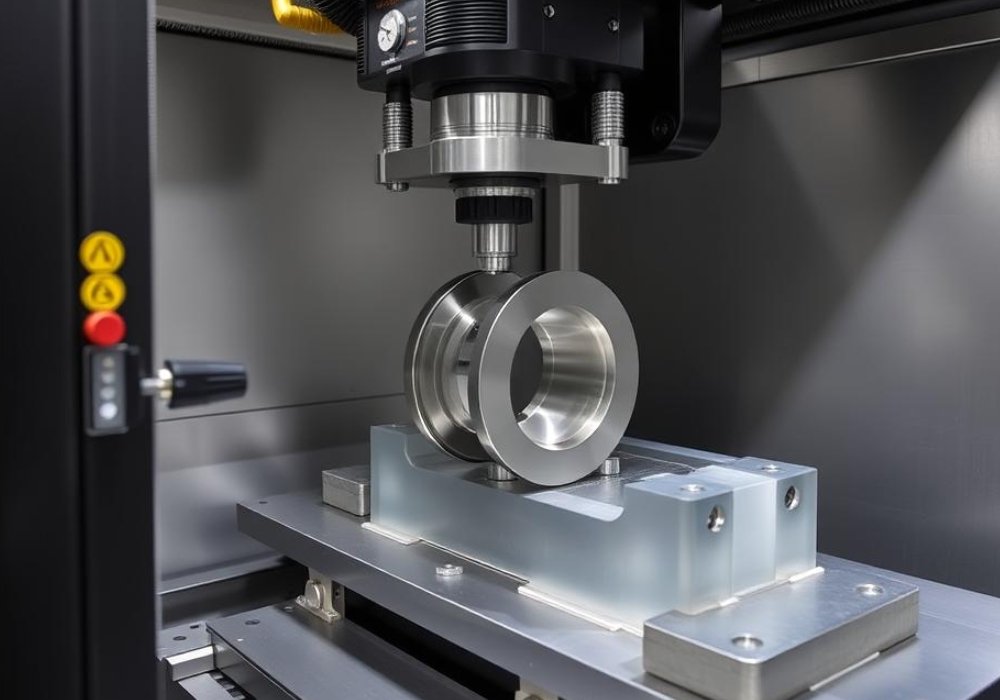

Pneumatic Fixture

A pneumatic fixture is a specialized workholding device that uses compressed air to generate clamping force for securing workpieces during manufacturing operations. These fixtures transform air pressure into mechanical force through precision-engineered cylinders and clamping mechanisms.

Unlike manual fixtures, pneumatic fixturing systems provide consistent, repeatable clamping pressure across multiple points simultaneously. This automation capability makes them ideal for high-volume production environments where efficiency and consistency are paramount.

Core Components

- Pneumatic cylinders that convert air pressure to linear force

- Clamping mechanisms (swing clamps, work supports, or linear clamps)

- Control valves for operation sequencing

- Base plate or structure for mounting components

- Air supply connections and distribution manifolds

Pneumatic Fixture Manufacturing Services

Fecision manufactures a comprehensive range of clamping fixtures to address diverse workholding requirements.

Each type offers specific advantages for different machining scenarios and workpiece geometries.

Precision Engineering

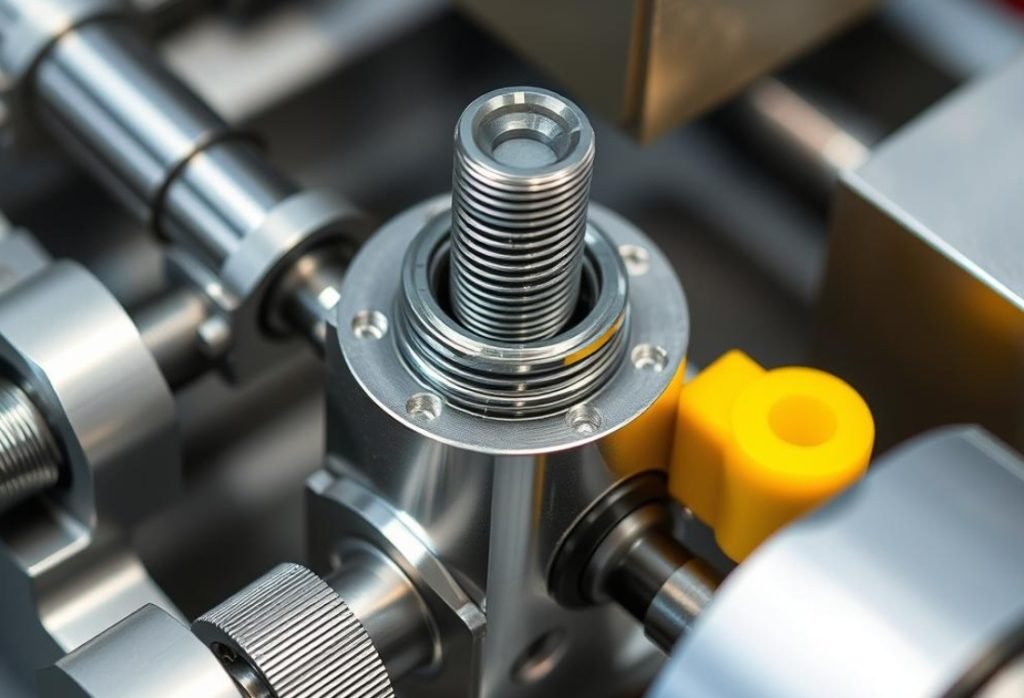

Our pneumatic fixtures are manufactured to exacting tolerances using high-grade materials. Each component is precision-machined to ensure perfect alignment and consistent performance over thousands of cycles.

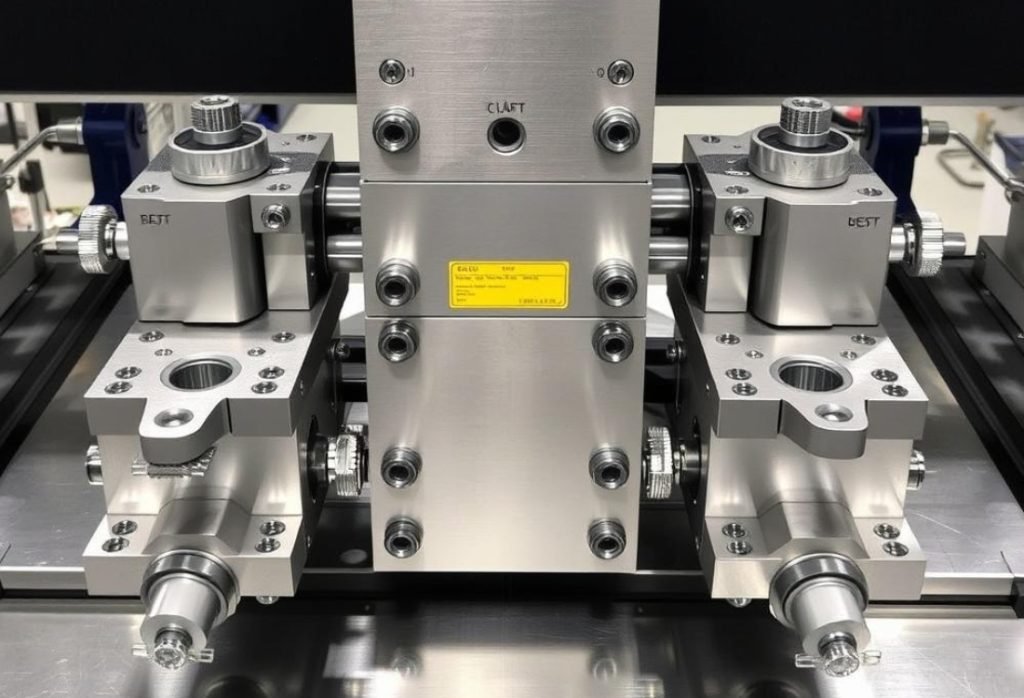

Modular Adaptability

Fecision fixtures feature modular designs that adapt to various workpiece geometries. Our quick-change components allow rapid reconfiguration for different production runs, minimizing downtime.

Advanced Automation

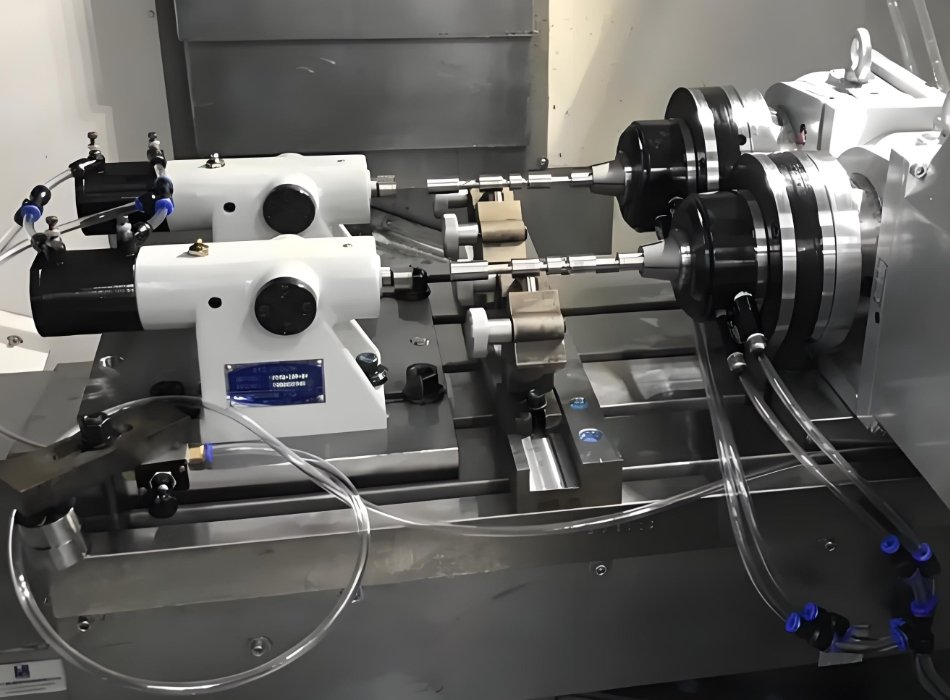

Our pneumatic fixtures integrate seamlessly with production automation systems. Optional digital pressure monitoring and position sensing provide real-time feedback for process control.

Pneumatic Fixtures for Superior Production

-Enhanced Operational Efficiency

Pneumatic fixtures dramatically reduce workpiece setup time compared to manual clamping methods. With the push of a button, operators can simultaneously engage multiple clamps, reducing cycle times by up to 70% and increasing throughput.

The consistent clamping force provided by pneumatic mechanisms also eliminates variations in operator technique, ensuring uniform quality across production runs regardless of who operates the equipment.

-Improved Quality and Consistency

Our pneumatic fixtures deliver precise, repeatable positioning for every workpiece. This consistency translates directly to improved part quality, reduced scrap rates, and fewer quality control issues in your production process.

The controlled application of clamping force prevents workpiece distortion while ensuring secure holding during machining operations. This balance is particularly valuable when working with thin-walled or delicate components.

Multiple clamps

simultaneous actuation

Automated systems

integration capability

Improved process

repeatability and quality

Safer operation

Lower pressure systems

Environmentally friendly

No hydraulic fluid disposal

Lighter weight

Easier to reconfigure

Applications of Pneumatic Fixtures

Welding Applications

Our pneumatic welding fixtures provide precise component alignment and secure holding during both manual and robotic welding processes. The fixtures maintain consistent positioning despite heat-induced expansion, ensuring weld quality.

Common applications include automotive frame assembly, structural steel fabrication, and precision sheet metal welding where dimensional accuracy is critical.

Machining Operations

Pneumatic fixtures excel in CNC machining environments where consistent workholding is essential for dimensional accuracy. Our fixtures provide rigid support that minimizes vibration while allowing full tool access.

Ideal for milling, drilling, and turning operations on components ranging from small precision parts to large structural elements requiring multi-point clamping.

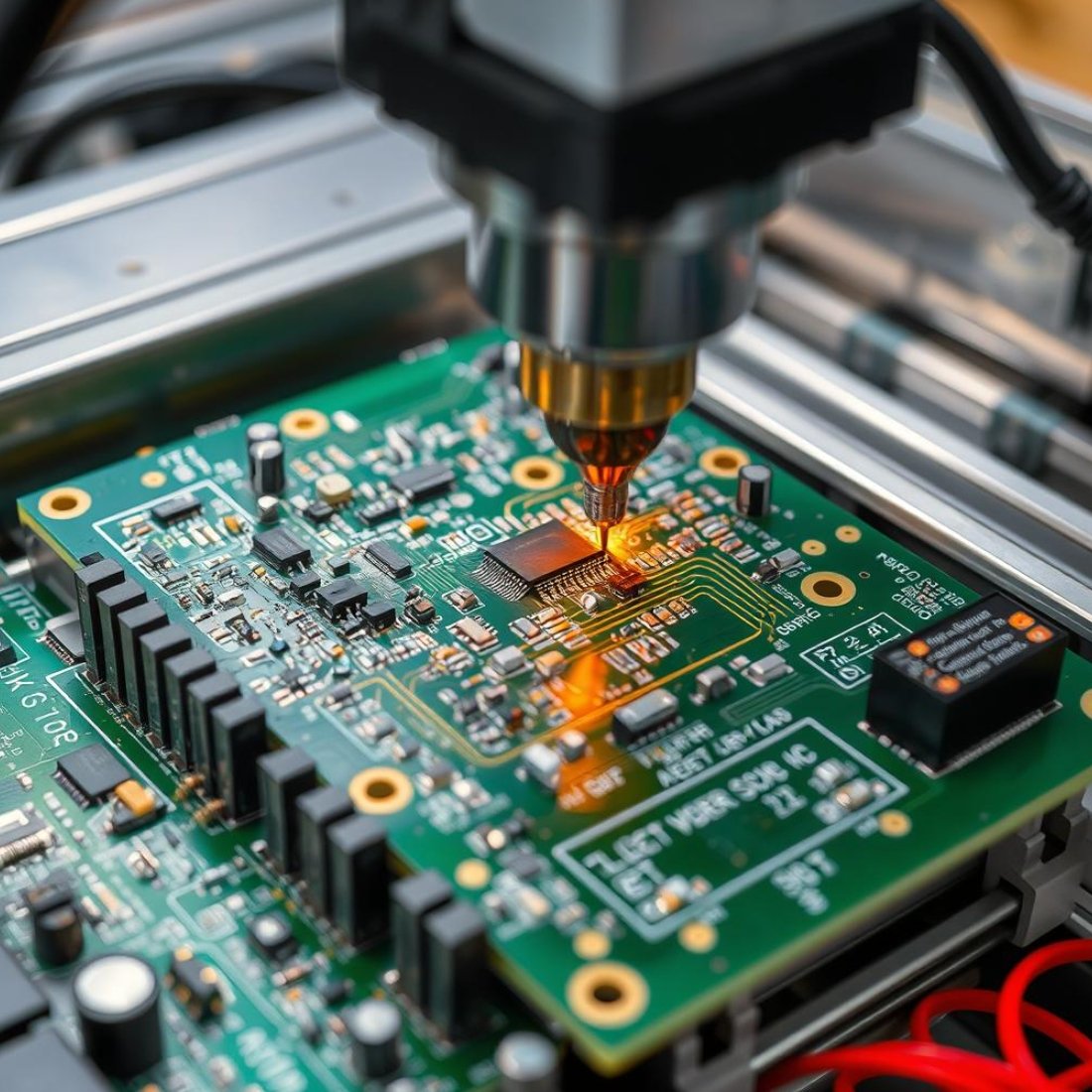

Assembly Processes

In assembly operations, our pneumatic fixtures ensure components are precisely positioned for joining processes. The fixtures integrate seamlessly with automated assembly systems for high-volume production.

Applications include electronics assembly, mechanical component assembly, and product testing where consistent positioning and gentle but secure holding are required.

Industry-Specific Applications

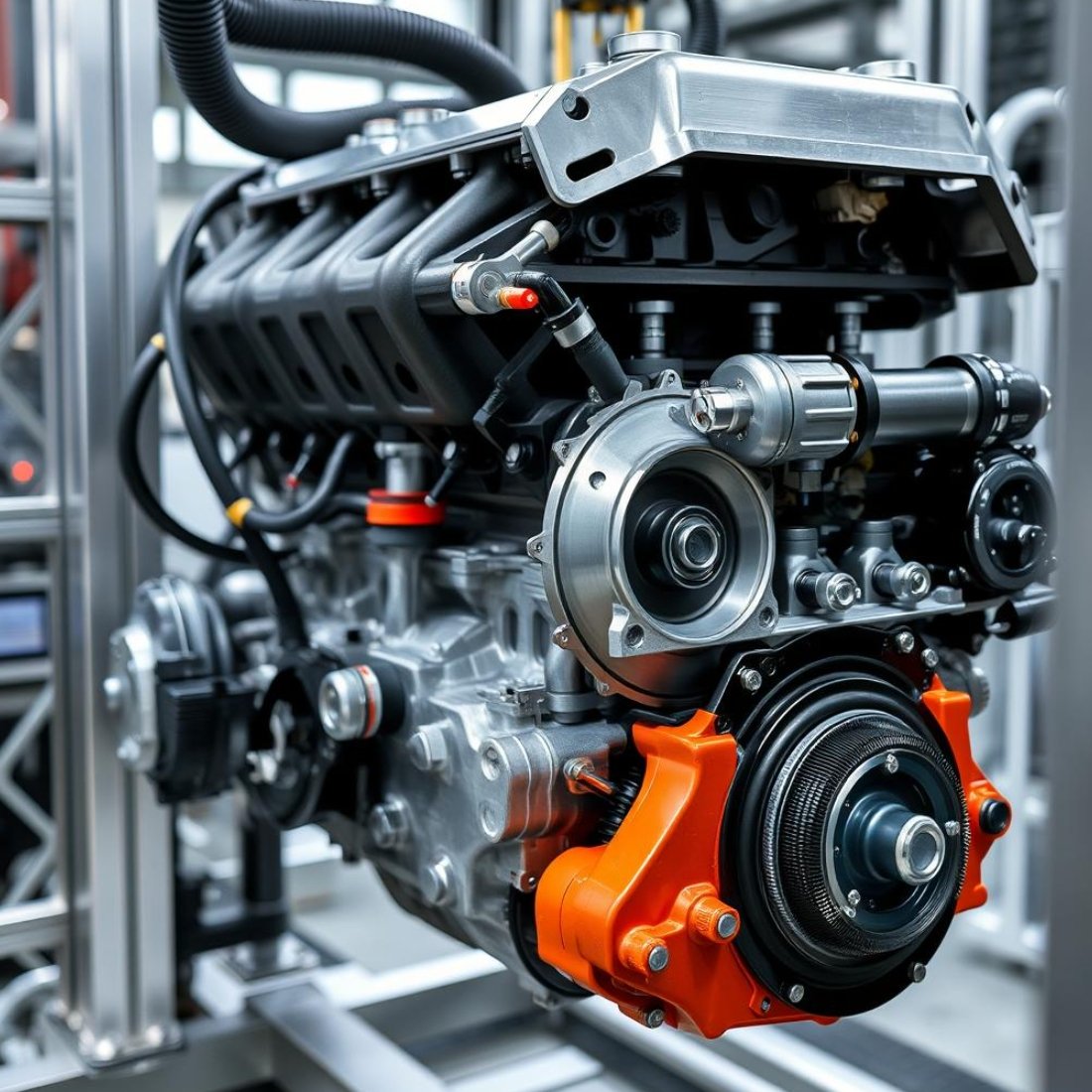

Automotive

Engine block machining

Transmission assembly

Body panel welding

Chassis component fabrication

Aerospace

Turbine component machining

Structural frame assembly

Landing gear component production

Interior panel fabrication

Medical

Surgical instrument production

Implant component machining

Medical device assembly

Testing fixture applications

Electronics

PCB assembly fixturing

Component testing

Housing assembly

Connector installation

Customized Pneumatic Fixtures

- Workpiece analysis for optimal clamping strategy

- Production volume and cycle time requirements

- Integration needs with existing equipment

- 3D CAD modeling of fixture concept

- Force analysis and structural validation

- Prototype fabrication of critical components

- Functional testing with sample workpieces

- Cycle time and repeatability verification

- Adjustments to optimize performance

- Final design approval

- Precision machining of fixture components

- Quality inspection at multiple stages

- Assembly by experienced technicians

- Pneumatic system integration and testing

- Final quality control verification

- Regular maintenance programs available

- Spare parts inventory management

- Technical support hotline

- Performance optimization services

- Fixture modification for new products

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Why Choose Fecision for Your Pneumatic Fixture Needs

With over 15 years of experience in precision workholding solutions, Fecision has established itself as a trusted partner for manufacturers seeking reliable, high-performance jigs and fixtures. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

Engineering Expertise

With over 15 years of specialized experience in pneumatic fixture design, our engineering team brings unparalleled expertise to every project. Our engineers average 12+ years in fixture design and hold advanced degrees in mechanical engineering and manufacturing technology.

We employ the latest design methodologies and simulation tools to validate fixture performance before manufacturing, ensuring your solution meets or exceeds expectations from day one.

Quality Commitment

Fecision is ISO 9001:2015 certified, with rigorous quality control processes at every stage of design and manufacturing. Our fixtures undergo comprehensive testing before delivery, including pressure cycling, dimensional verification, and functional validation.

We stand behind our products with a comprehensive warranty and responsive support team. Our pneumatic fixtures are designed for a service life of 1,000,000+ cycles under normal operating conditions.

Ready to start your custom fixture project?

Our engineering team is ready to discuss your specific requirements and develop a solution tailored to your manufacturing process.

Let’s get started now!