CNC Fixtures: Precision Workholding for Advanced Manufacturing

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

Custom Hydraulic Solutions

Engineered for precision and efficiency

Custom Manufacturing Expertise

CNC Fixtures in Machining

CNC fixtures are essential workholding devices that secure, position, and support workpieces during machining operations. By providing stability and precise positioning during machining processes. These specialized tools transform complex machining operations into repeatable, efficient procedures that maintain consistent quality standards.

Precision & Accuracy

Minimized operator fatigue and human error woth better utilization of machine capabilities

Consistency & Efficiency

Reduced setup time between operations and consistent part quality across production runs

Cost-Saving & Safety

Reduced scrap and material waste

Lower overall production costs

Improved workplace safety

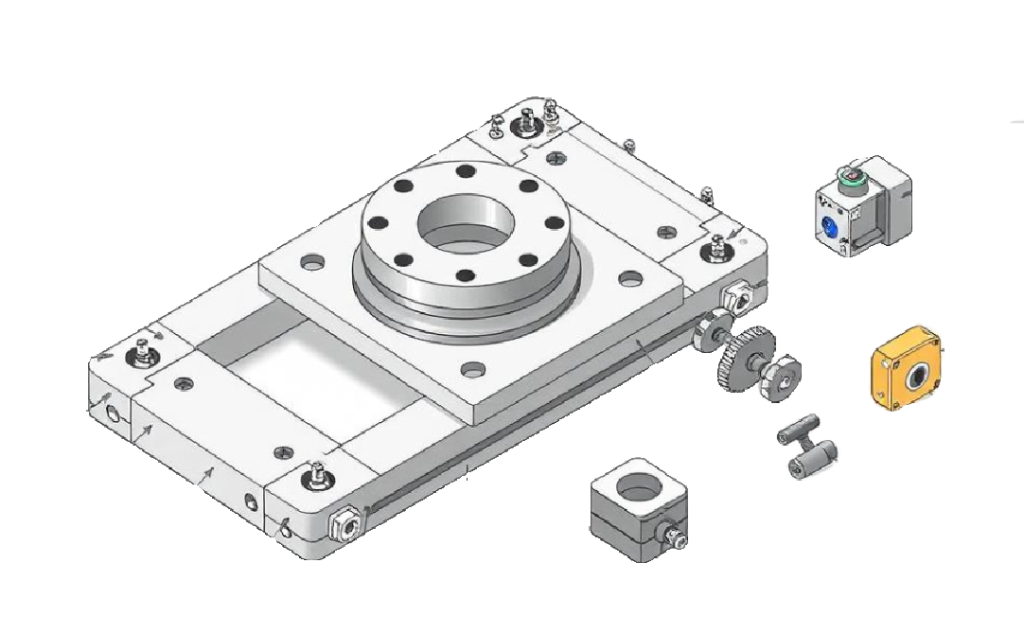

Our CNC Fixture Products

Different machining processes require specialized fixtures designed to accommodate their unique cutting methods and forces.

Understanding the specific requirements of each operation helps in selecting the appropriate fixture type.

Classification By Different Methods

Different machining processes require specialized fixtures designed to accommodate unique cutting methods and forces.

Milling Fixture

Designed to secure workpieces during material removal by rotating cutting tools. These fixtures must resist multi-directional cutting forces while providing tool clearance for complex geometries.

Turning Fixture

Used in CNC turning operations where the workpiece rotates against a stationary cutting tool. These fixtures must maintain perfect concentricity and balance during high-speed rotation.

Drilling Fixture

Specialized for operations that create or modify holes in workpieces. These fixtures provide precise positioning for drill bits while resisting axial cutting forces.

Grinding Fixture

Designed for precision surface finishing operations. These fixtures must maintain exact positioning while minimizing vibration for superior surface quality.

Boring Fixture

Specialized for enlarging and finishing existing holes with high precision. These fixtures ensure perfect alignment between the boring tool and workpiece.

Welding Fixture

Designed for stable workpiece holding during welding operations. These fixtures maintain precise alignment while reducing movement to ensure high-quality, distortion-free welds.

Assembly Fixture

Specialized for precise component alignment and joining in assembly. These fixtures ensure perfect positioning between parts to facilitate accurate, efficient integration.

Broaching Fixture

Designed for precise broaching operations to shape internal/external surfaces. These fixtures maintain exact workpiece positioning while minimizing movement for superior finish accuracy.

Tapping Fixture

Used in tapping operations where the tool cuts threads into holes. These fixtures must maintain perfect alignment and stability during high-precision thread formation.

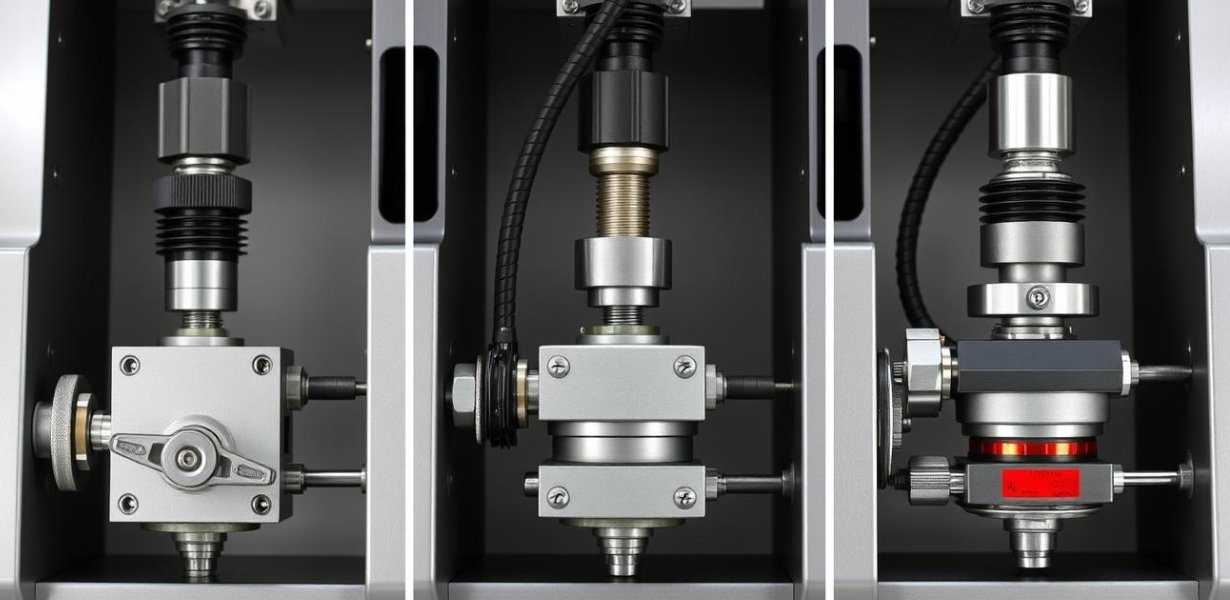

The clamping mechanism’s power source significantly impacts a fixture’s performance, setup time, and suitability for different applications.

Each power source offers distinct advantages for specific machining scenarios.

Fecision also manufature CNC fixtures combined with multiple power sources to leverage the advantages of each. For example, a fixture might use pneumatic clamps for quick positioning and hydraulic clamps for final securing, providing both speed and strength in a single system.

Contact our engineeruing team for custom solutions.

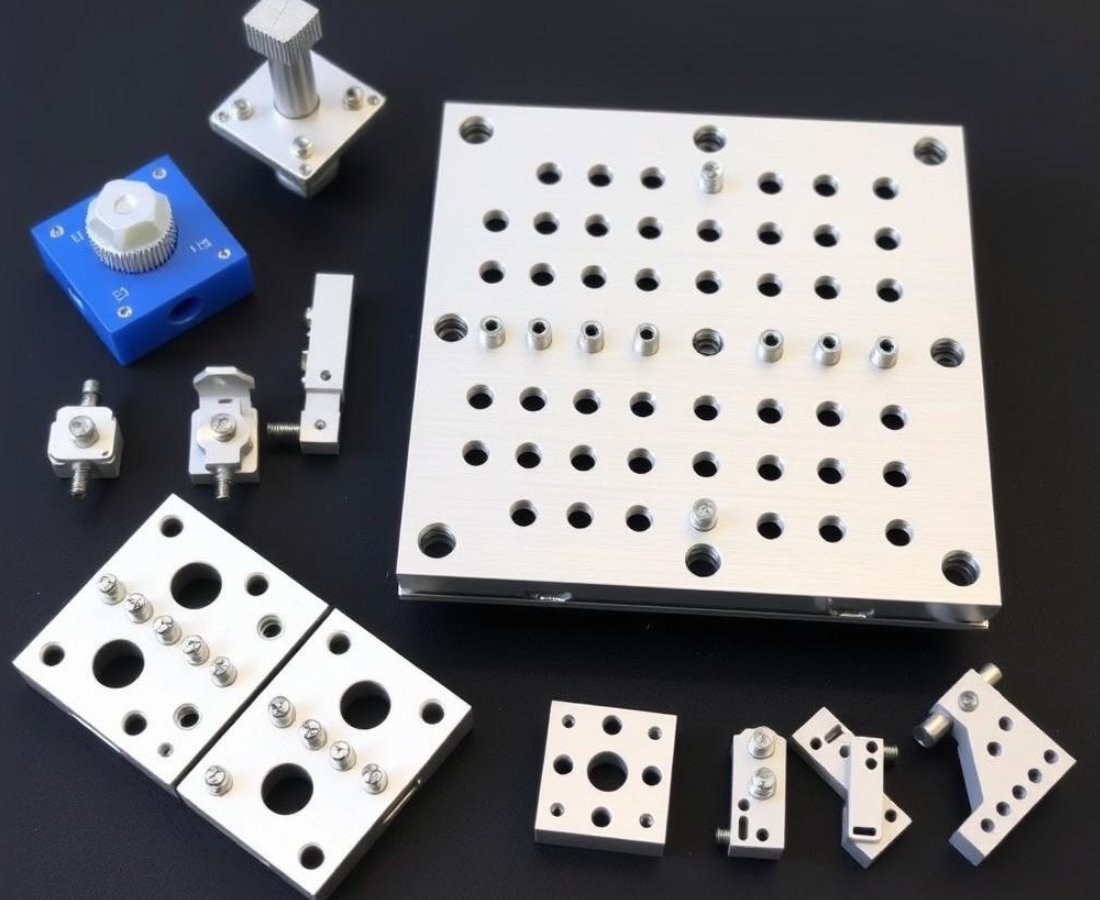

CNC fixtures can be categorized based on their adaptability and intended production volume.

This classification helps in selecting the most cost-effective fixture solution for specific manufacturing scenarios.

Dedicated Fixtures

Custom-designed for specific workpieces with no adaptability for other parts. Offer maximum efficiency and precision for high-volume production of identical components.

Modular Fixtures

Assembled from standardized, interchangeable components that can be reconfigured for different workpieces. Balance flexibility and precision for medium-volume production.

Universal Fixtures

General-purpose workholding devices that can be adjusted to accommodate a wide range of workpieces. Offer maximum flexibility for low-volume or prototype production.

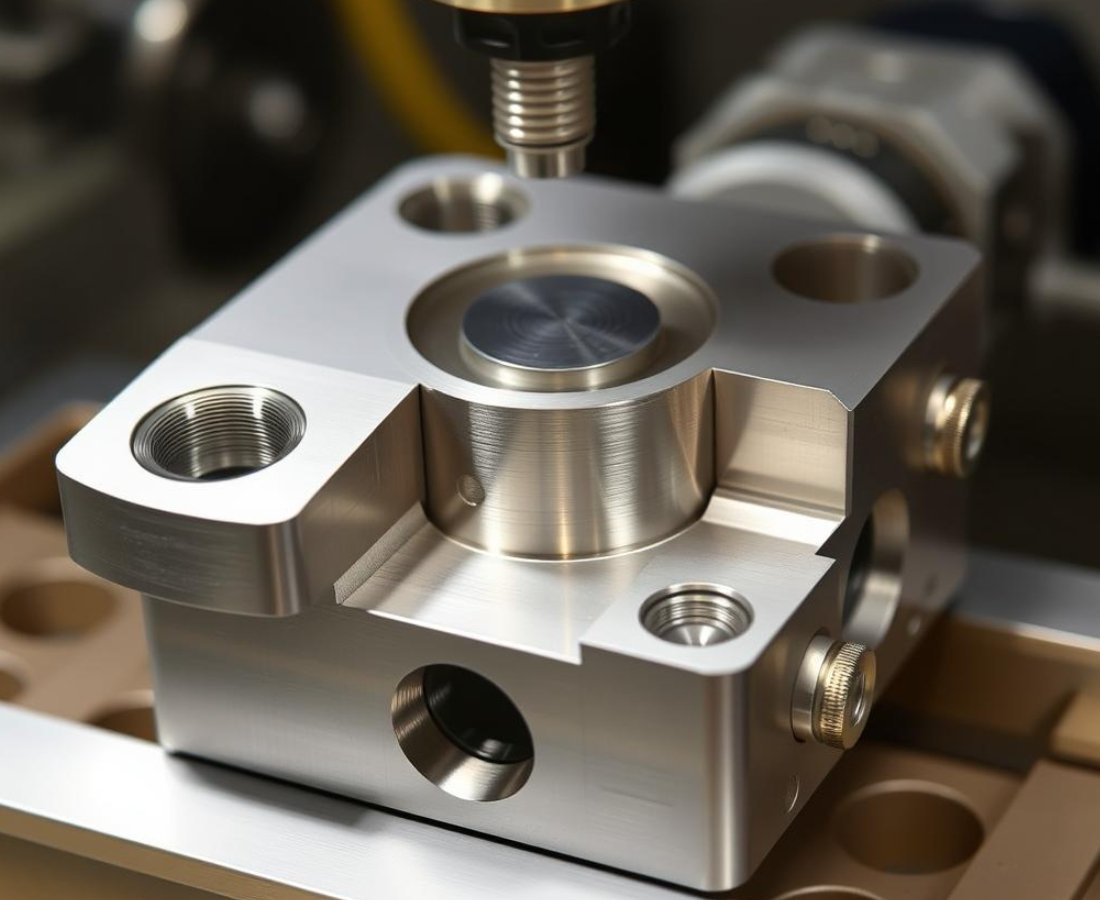

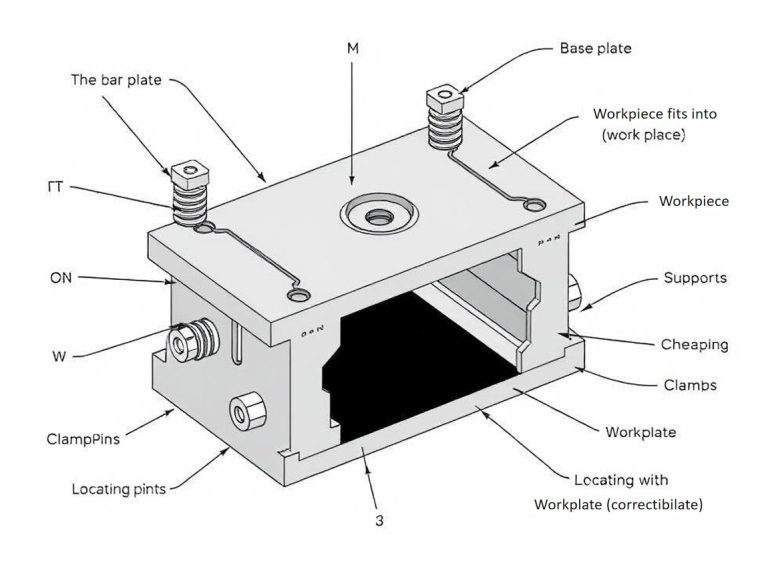

Components of CNC Fixtures

Understanding the essential components of CNC fixtures helps in evaluating fixture designs and communicating requirements effectively. Each element of the fixture serves a specific function in the overall workholding system.

The quality and precision of these key components directly impact the fixture's performance. High-quality materials, precise machining, and proper heat treatment ensure long-term reliability and accuracy in production environments.

Base Plate, Sub-plates, Riser Blocks, Angle Plates, T-slot Tables

Locating Pins, V-blocks, Rest Buttons, Edge Supports, Nesting Features

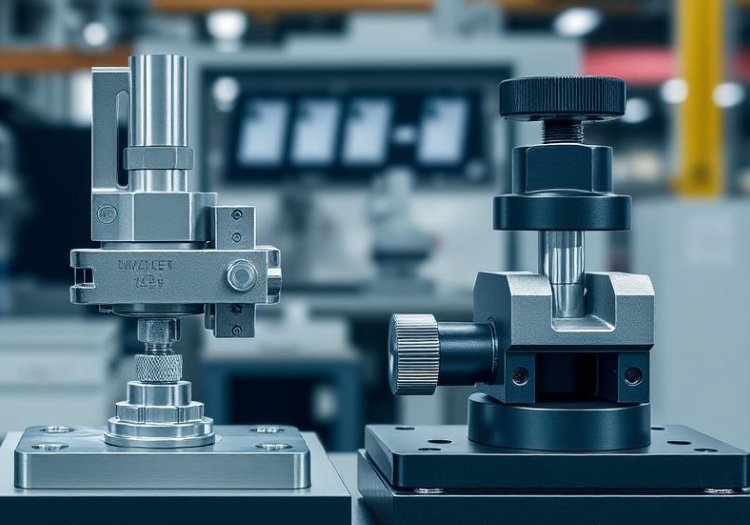

Strap Clamps, Toggle Clamps, Hydraulic Cylinders, Pneumatic Actuators, Cam Locks

Support Pillars, Adjustable Supports, Rest Padsm Spring-loaded Supports, Stabilizing Ribs

Bushings, Chip Shields, Quick-change Mechanisms, Alignment Features, Coolant Channels

T-slot Bolts, Socket Head Cap Screws, Dowel Pins, Quick-release Fasteners, Heel Blocks

CNC Fixture Work Principles

CNC fixtures function through a combination of positioning, clamping, and supporting mechanisms that work together to secure workpieces in the optimal orientation for machining. Understanding these core functions helps in selecting or designing the right fixture for your specific application.

Three Core Functions

The effectiveness of a CNC fixture depends on the proper balance of these three functions. When designed correctly, fixtures maintain workpiece stability while allowing unrestricted tool access to all required surfaces, resulting in precise, repeatable machining operations.

Positioning

Locating elements establish the workpiece's precise position relative to the machine tool. These components restrict movement in specific directions, ensuring the part maintains the correct orientation throughout machining.

Clamping

Clamping mechanisms apply force to hold the workpiece firmly against locators. These components prevent movement during cutting operations, maintaining stability even under significant machining forces.

Supporting

Support elements prevent workpiece deflection under cutting forces. These components maintain dimensional accuracy by providing additional contact points that minimize vibration and deformation during machining.

Which CNC Fixture Suits Better

Key Selection Criteria

Choosing the appropriate CNC fixture involves evaluating multiple factors related to your specific machining requirements. This systematic approach helps ensure optimal performance and cost-effectiveness.

Workpiece Characteristics

✅Material: Hardness, thermal properties, and machinability

✅Geometry: Size, shape, complexity, and critical features

✅Tolerances: Required precision and surface finish

✅Stability: Rigidity and potential for distortion

✅Weight: Handling requirements and fixture load capacity

Machining Requirements

✅Operations: Types of machining processes required

✅Cutting Forces: Magnitude and direction of machining forces

✅Tool Access: Required approach angles and clearances

✅Setup Time: Allowable fixture loading/unloading time

✅Machine Compatibility: Table size, T-slot configuration, etc.

Production Factors

✅Volume: Number of parts to be produced

✅Frequency: Production schedule and batch sizes

✅Variety: Number of different part designs

✅Future Changes: Likelihood of design modifications

✅Budget: Available investment for fixturing solutions

The optimal fixture solution often involves balancing multiple factors, including immediate production needs and long-term manufacturing strategy.

Consulting with our fixture design specialists can help you identify the most cost-effective approach for your specific requirements.

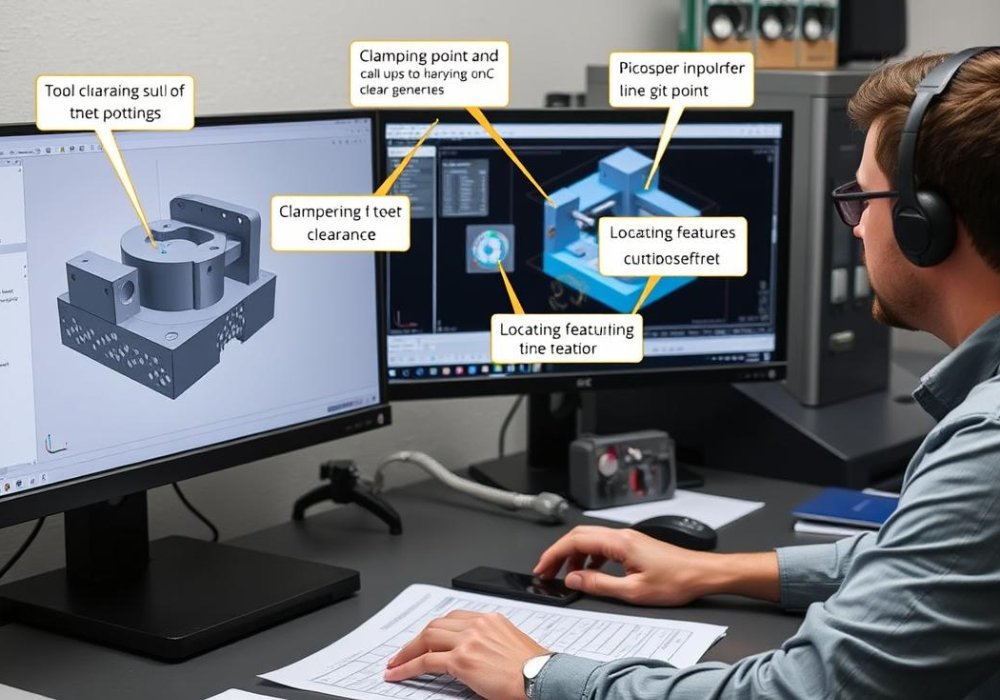

CNC Fixture Design Considerations

Effective CNC fixture design requires balancing multiple technical factors to create a solution that optimizes machining performance while remaining practical to manufacture and use.

Fundamental Design Principles

- 3-2-1 Principle: Properly constrain the workpiece in all six degrees of freedom

- Accessibility: Ensure tool access to all required machining surfaces

- Stability: Provide rigid support against cutting forces

- Repeatability: Enable consistent part positioning across production runs

- Efficiency: Minimize loading/unloading time and operator effort

- Safety: Eliminate pinch points and ensure secure workholding

Technical Considerations

- Material Selection: Choose appropriate materials for fixture components based on strength, wear resistance, and cost

- Thermal Effects: Account for thermal expansion during machining

- Vibration Damping: Design to minimize chatter and vibration

- Chip Evacuation: Provide paths for chip and coolant flow

- Tolerance Stacking: Minimize cumulative errors in fixture assembly

- Wear Compensation: Design for long-term accuracy maintenance

Practical Considerations

- Manufacturability: Design fixtures that can be produced with available resources

- Standardization: Utilize standard components where possible

- Modularity: Design for potential reuse of components

- Maintenance: Enable easy cleaning and component replacement

- Documentation: Create clear assembly and usage instructions

- Cost-effectiveness: Balance performance with production budget

Design Optimization Process

Effective fixture design is often an iterative process that balances theoretical principles with practical manufacturing considerations.

Involving machinists and operators in the design process can provide valuable insights that improve the fixture's usability and performance in production environments.

- Define Requirements: Clearly document workpiece specifications, machining operations, and production parameters

- Conceptual Design: Develop initial fixture concepts based on workholding principles and requirements

- 3D Modeling: Create detailed CAD models of the fixture design with the workpiece in position

- Engineering Analysis: Verify fixture rigidity, clamping forces, and tool clearances through simulation

- Design Refinement: Optimize the design based on analysis results and manufacturing feedback

- Prototype Testing: Validate the design with physical testing under actual machining conditions

- Documentation: Create comprehensive drawings, assembly instructions, and usage guidelines

Our Custom Fixture Services

- Comprehensive fixture design and engineering

- Precision manufacturing of fixture components

- Integration with existing production systems

- Fixture validation and performance testing

- Documentation and operator training

- Ongoing support and maintenance

Why Choose Fecision?

At Fecision, we specialize in designing and manufacturing custom CNC fixtures tailored to your specific machining requirements. Our engineering team combines decades of experience with advanced design tools to create fixture solutions that enhance precision, reduce setup time, and improve production efficiency.

- Specialized expertise in complex workholding solutions

- State-of-the-art design and manufacturing capabilities

- Commitment to quality and precision

- Competitive pricing and rapid turnaround

- Proven track record with demanding applications

- Comprehensive project management approach

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Need Custom CNC Fixtures for Your Project?

Contact Fecision today to discuss your custom CNC fixture requirements and discover how our solutions can improve your manufacturing efficiency.

Let’s Get Started Now!