Industrial Clamping Fixtures: Precision Workholding Solutions

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

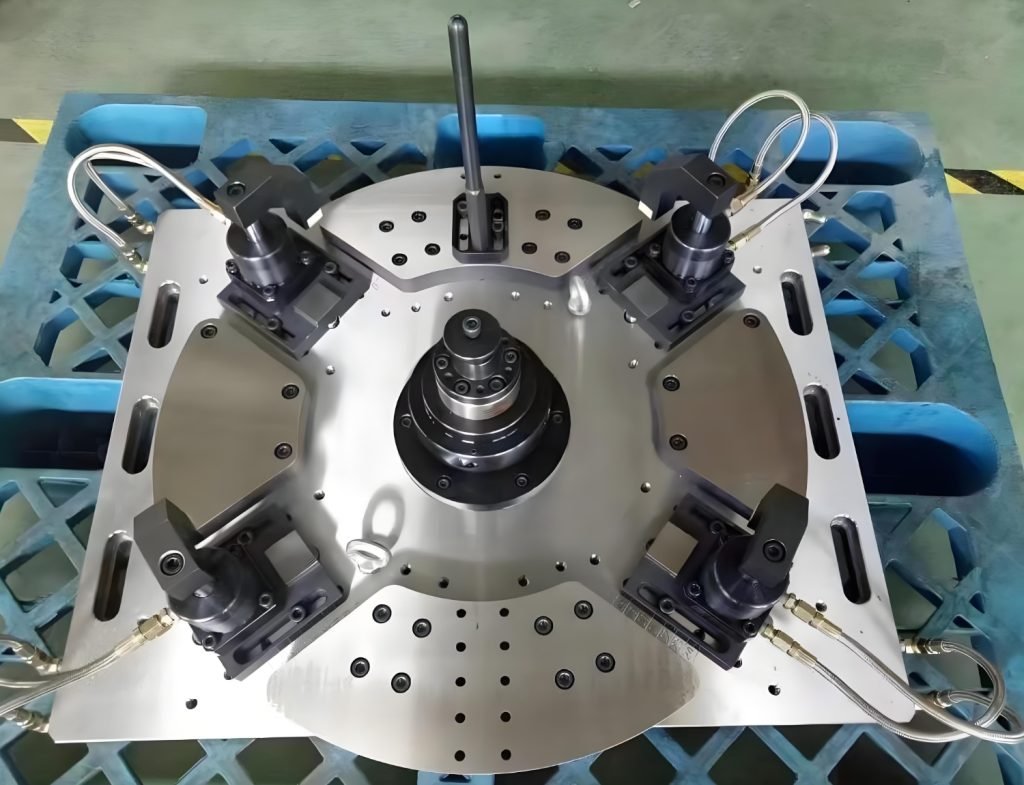

Custom Clamping Fixtures

Engineered for superior workholding performance

----Who We Are

Your Trusted Partner for Clamping Fixture Manufacturing

Fecision’s clamping fixtures are engineered to provide superior workholding performance across diverse manufacturing environments. Our fixtures combine innovative design with precision engineering to deliver solutions that enhance your production capabilities.

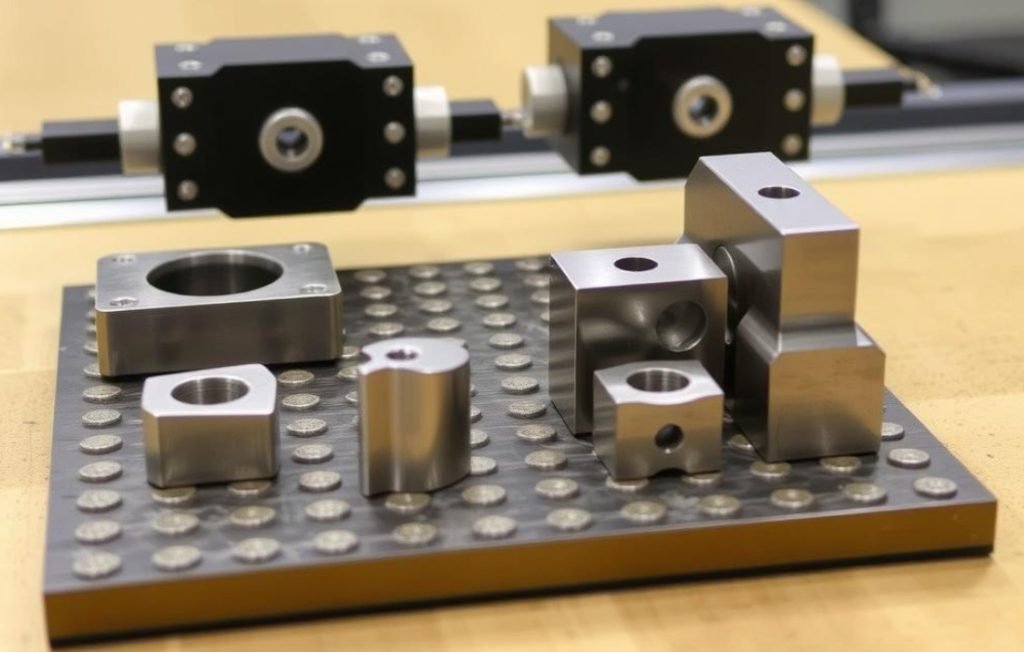

Precision Engineering

Manufactured to exacting standards with tolerances of ±0.0005", ensuring consistent part positioning and repeatable results across production runs.

Modular Design

Our modular clamping systems allow for quick reconfiguration to accommodate different workpieces, reducing setup time and increasing machine utilization.

Enhanced Stability

provide superior holding force to eliminate workpiece movement during high-speed cutting operations, allowing for more aggressive machining parameters.

Rapid Deployment

Designed for quick installation and adjustment, our clamping fixtures minimize downtime and maximize productivity in fast-paced manufacturing environments.

Fixture Clamp Types

Fecision manufactures a comprehensive range of clamping fixtures to address diverse workholding requirements.

Each type offers specific advantages for different machining scenarios and workpiece geometries.

Toggle Clamps

Our toggle fixture clamps provide rapid workpiece securing and releasing with mechanical advantage that multiplies clamping force.

- Quick-action operation

- Adjustable clamping pressure

- Horizontal and vertical configurations

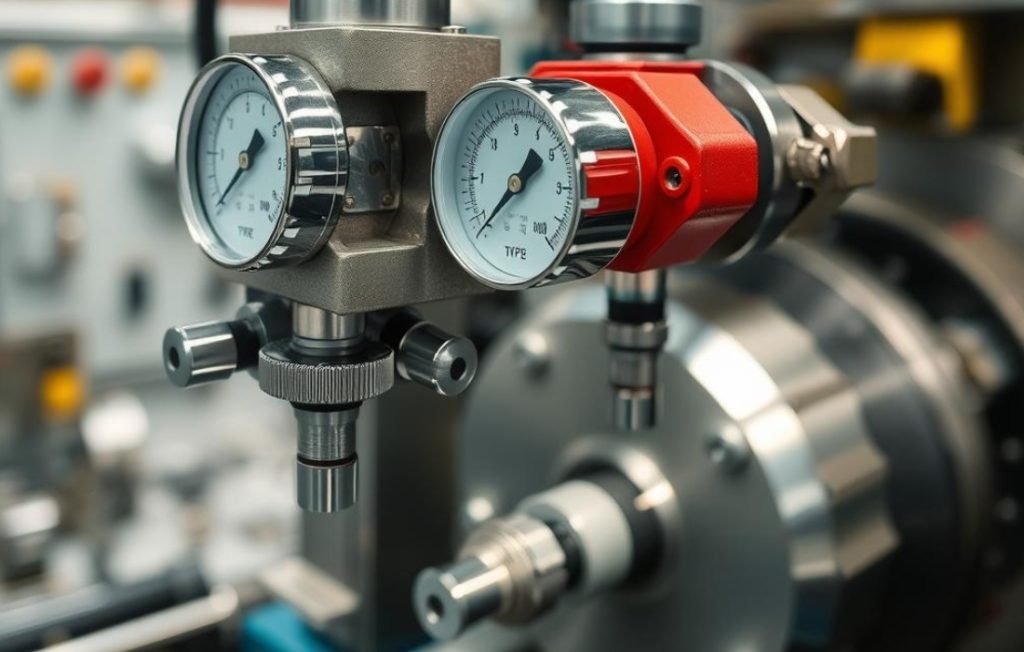

Hydraulic Clamps

Fecision’s hydraulic fixture clamps deliver consistent, powerful clamping force ideal for heavy-duty applications and automated systems.

- Consistent clamping pressure

- Remote operation capability

- Ideal for automation integration

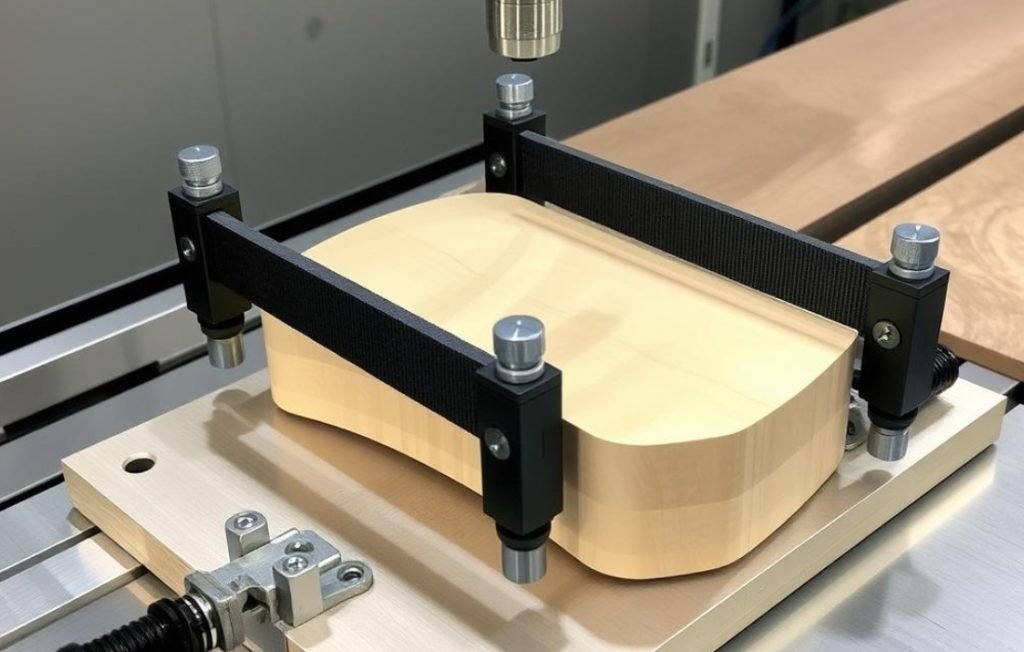

Strap Clamps

Our versatile strap fixture clamps adapt to irregular workpiece geometries while providing secure holding power for complex machining operations.

- Adaptable to irregular shapes

- Adjustable clamping height

- Minimal workpiece interference

CNC Fixture Clamps

Designed specifically for CNC machining centers, these fixture clamps offer precision positioning and secure workholding during high-speed operations.

- Low-profile design to avoid tool interference

- Hardened components for longevity

- Compatible with major CNC systems

Vacuum Clamps

Fecision’s vacuum clamping fixtures provide uniform holding force across the entire workpiece surface, ideal for thin or delicate materials.

- Distortion-free workholding

- Full surface access for machining

- Quick setup and release cycles

Magnetic Clamps

Our magnetic fixture clamps provide instant, powerful holding force for ferrous materials with complete access to five sides of the workpiece.

- Instant on/off operation

- No mechanical deformation of parts

- Ideal for batch processing

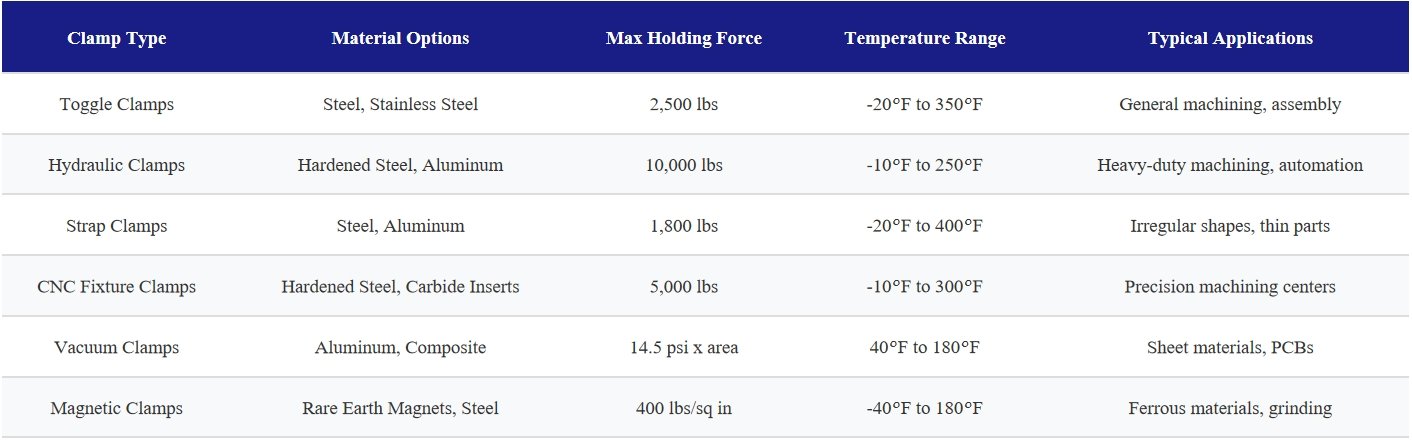

Technical Specifications

Fecision's clamping fixtures are manufactured to exacting standards to ensure optimal performance in demanding industrial environments.

Our engineering team carefully selects materials and designs to maximize durability, precision, and functionality.

Applications of Clamping Fixtures

Fecision's clamping fixtures are utilized across diverse industries where precision, reliability, and efficiency are paramount.

Our solutions are engineered to address specific challenges in various manufacturing environments.

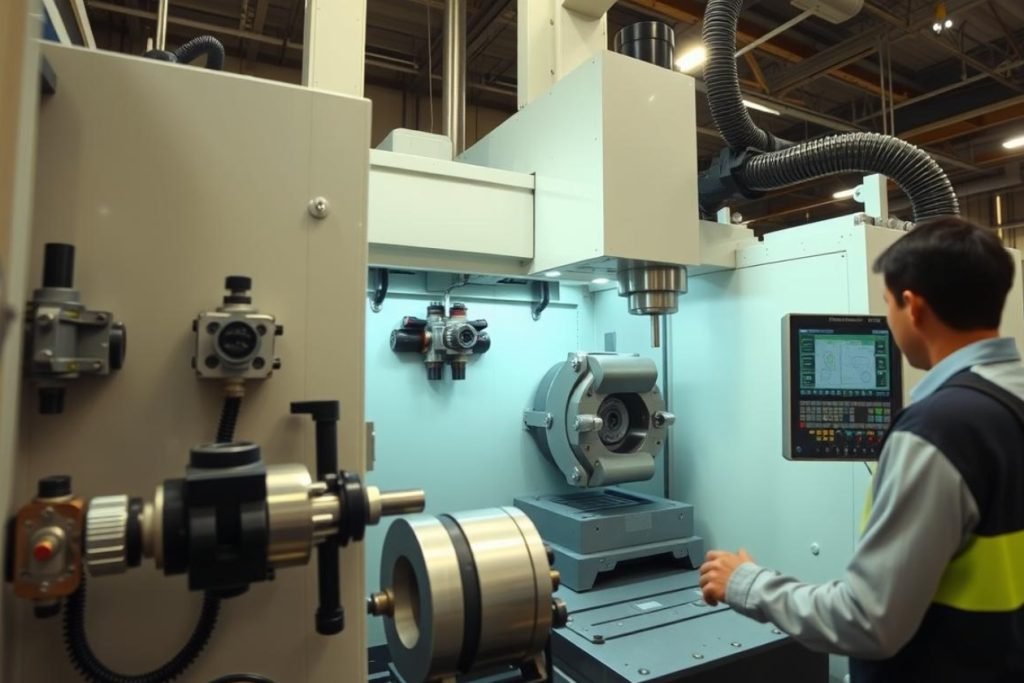

CNC Machining Centers

Our fixture clamps excel in CNC environments where precision and stability are critical for achieving tight tolerances and superior surface finishes.

- Multi-axis machining support

- Vibration dampening for high-speed operations

- Quick-change systems for reduced setup time

- Compatible with major CNC machine brands

Welding Applications

Fecision’s heat-resistant clamping fixtures maintain precise component alignment during welding processes, ensuring consistent quality.

- Heat-resistant materials and coatings

- Precision alignment features

- Ground connection integration

- Spatter-resistant design

Assembly Operations

Our fixture clamps streamline assembly processes by securely holding components in the optimal position for manual or automated assembly.

- Ergonomic designs for manual operations

- Integration with automated systems

- Quick-release mechanisms

- Modular configurations for line flexibility

Inspection and Quality Control

Precision is paramount in quality control processes. Fecision's inspection-grade clamping fixtures ensure consistent part positioning for accurate measurement and verification. Our fixtures are compatible with coordinate measuring machines (CMMs) and other metrology equipment, featuring non-marring contact surfaces to protect finished parts and repeatable positioning to within ±0.0002".

Speak With Our Engineering Team

Discuss your specific application challenges with our fixture design specialists.

Our Custom Design Process

Custom Clamping Solutions

Beyond our standard fixture clamp offerings, Fecision specializes in developing custom clamping solutions tailored to your unique manufacturing challenges. Our engineering team works closely with you to design and manufacture fixtures that optimize your specific production processes.

Requirement Analysis

We begin by thoroughly understanding your application, workpiece characteristics, and production goals.

Conceptual Design

Our engineers develop initial concepts, considering factors like access requirements, clamping forces, and material selection.

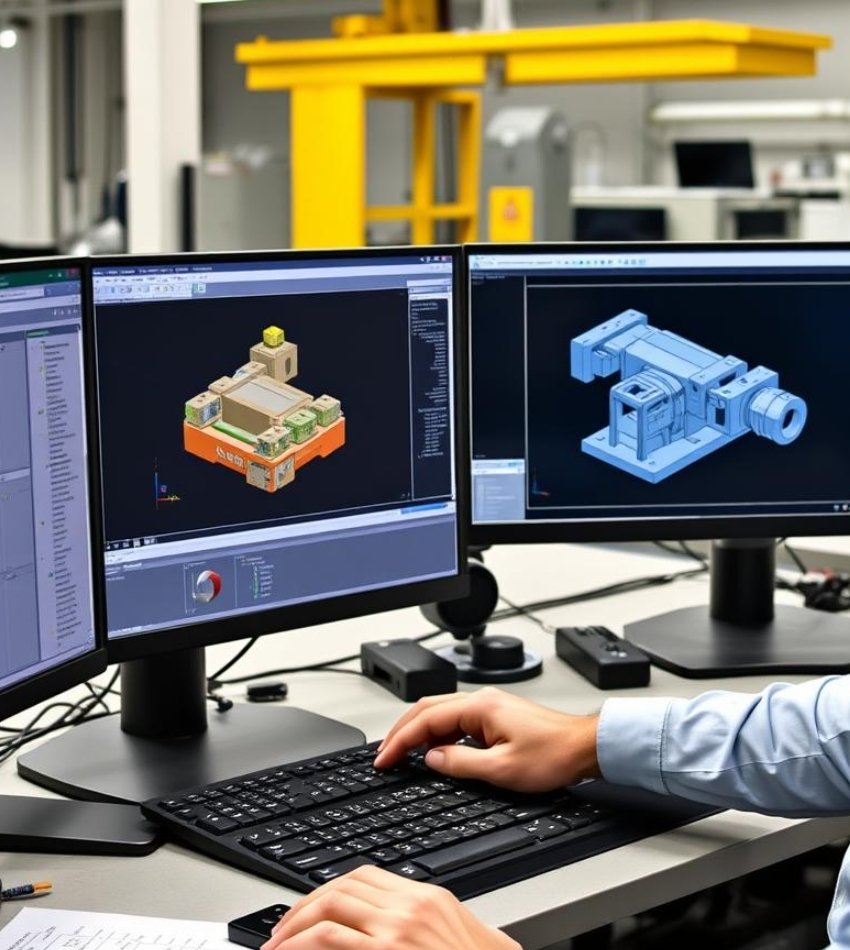

3D Modeling & Simulation

Advanced CAD/CAM software allows us to create detailed models and simulate performance before manufacturing.

Prototype Development

For complex applications, we can produce prototype fixtures for testing and validation.

Manufacturing & Quality Control

Our precision manufacturing capabilities ensure your custom fixture clamps meet exact specifications.

Clamping Fixture Maintenance & Best Practices

Proper maintenance of your clamping fixtures ensures optimal performance and extends service life. Follow these industry-proven best practices to maximize your investment in Fecision's workholding solutions.

Maintenance Recommendations

- Regular Inspection: Check for wear, damage, and proper operation before each use

- Proper Cleaning: Remove chips, coolant, and debris after each production run

- Lubrication Schedule: Apply recommended lubricants to moving parts according to usage frequency

- Torque Verification: Periodically check fastener torque settings to manufacturer specifications

- Component Replacement: Replace worn components before they impact performance or safety

Application Best Practices

- Proper Force Application: Use appropriate clamping force for the material and operation

- 3-2-1 Locating Principle: Implement proper workpiece location before clamping

- Minimize Distortion: Position clamps to reduce workpiece deflection

- Tool Clearance: Ensure adequate clearance between clamps and cutting tools

- Documentation: Maintain setup documentation for repeatable processes

Industries We Serve

Aerospace & Defense

Energy & Power Generation

General Machining

Automotive Manufacturing

Electronics Manufacturing

Precision Engineering

Medical Device Production

Tool & Die Making

Research & Development

Why Choose Fecision for Your Clamping Fixture Needs

With over two decades of experience in precision workholding solutions, Fecision has established itself as a trusted partner for manufacturers seeking reliable, high-performance clamping fixtures. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

Engineering Expertise

Our team of specialized engineers brings decades of combined experience in fixture design and manufacturing process optimization.

Quality Assurance

Every clamping fixture undergoes rigorous testing and inspection to ensure it meets our exacting standards and your specific requirements.

Ongoing Support

From initial consultation through implementation and beyond, our technical team provides comprehensive support for all your fixture clamp needs.

Frequently Asked Questions

When selecting the appropriate clamping fixtures for your application, consider these key factors: workpiece material and geometry, required holding force, machining operations to be performed, setup time requirements, production volume, and environmental conditions (temperature, coolant exposure, etc.). Fecision's engineering team can help evaluate these factors to recommend the optimal fixture solution.

Standard fixture clamps from our catalog typically ship within 3-5 business days. For custom clamping fixtures, lead times vary based on complexity, but generally range from 2-6 weeks. This includes design consultation, engineering, manufacturing, and quality verification. For urgent requirements, we offer expedited services—please contact our sales team to discuss your timeline needs.

Determining optimal clamping force involves calculating the forces generated during machining operations (cutting forces, vibration, etc.) and applying an appropriate safety factor. For most applications, the clamping force should be 3-5 times the maximum cutting force. Fecision's application engineers can help perform these calculations based on your specific machining parameters and workpiece characteristics.

Ready to Optimize Your Manufacturing Process?

Contact Fecision today to discuss your clamping fixture requirements.

Discover how our solutions can enhance your production efficiency.