Assembly Fixtures: Precision Engineering for Manufacturing Excellence

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

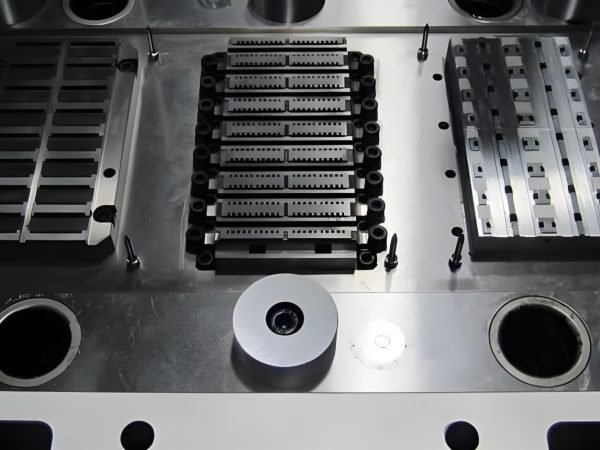

Custom Assembly Fixtures

Engineered for precision and efficiency

Assembly Fixtures: Precision Manufacturing Tools

Assembly fixtures are specialized workholding devices designed to securely position, align, and hold components during assembly operations. As essential tools in modern manufacturing, assembly fixtures ensure consistent quality, improved productivity, and enhanced precision across diverse industrial applications.

Our comprehensive range of custom assembly fixtures delivers the reliability and accuracy required for today's demanding production environments.

Our expertise in designing and manufacturing precision assembly fixtures spans multiple industries, from automotive and aerospace to electronics and medical devices. We specialize in creating custom assembly jigs that optimize your specific assembly processes while maintaining the highest standards of quality and repeatability.

Positional Accuracy

Repeatability

Flatness of Locating Surfaces

Perpendicularity of Locating Pins

Assembly Fixture Types and Classifications

Discover our comprehensive range of hydraulic fixtures designed for precision, durability, and efficiency in industrial applications.

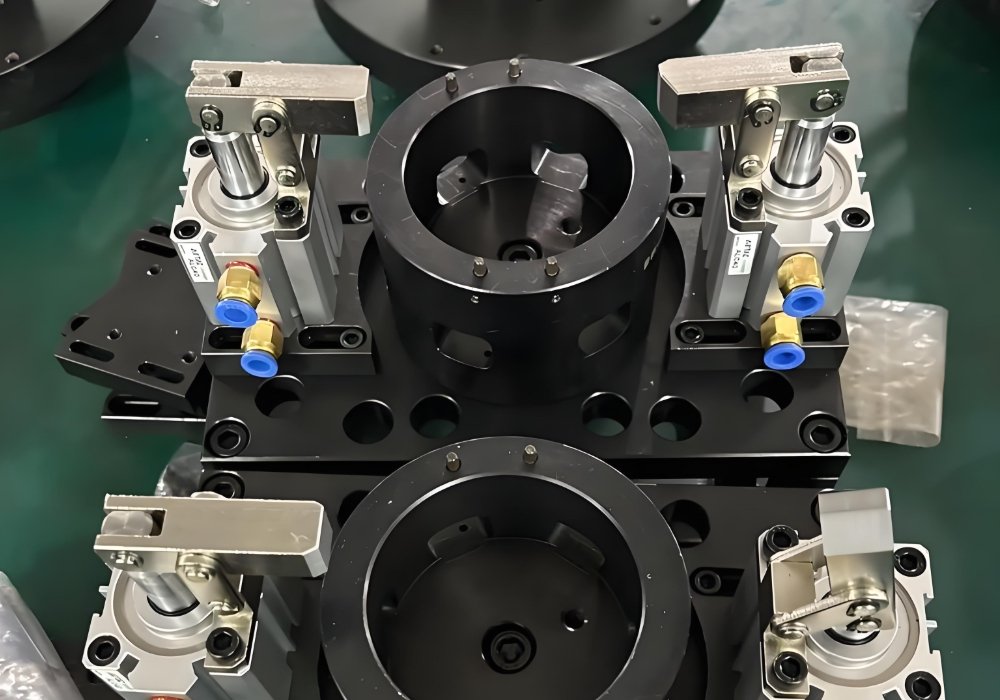

Pneumatic Assembly Fixture

- Automated clamping: Air-powered actuation for consistent clamping force

- Rapid cycle times: Fast opening and closing for high-volume production

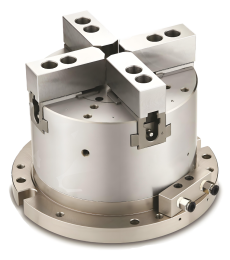

Hydraulic Assembly Fixture

- High clamping forces: Up to 50,000 lbs for heavy-duty applications

- Superior accuracy: Force control within ±1% of set pressure

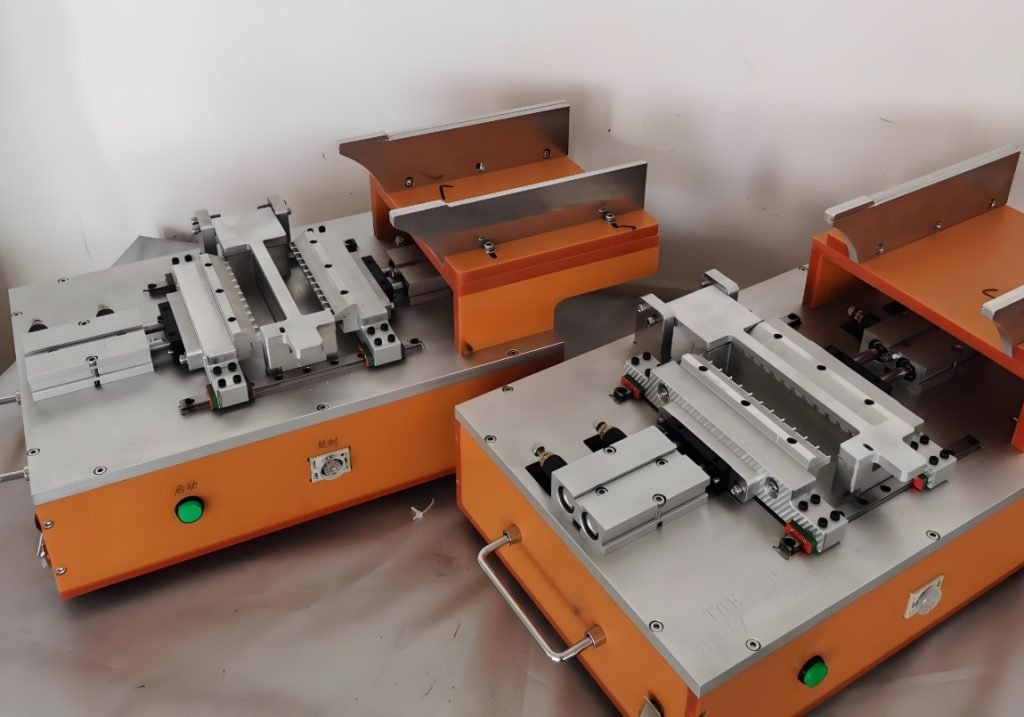

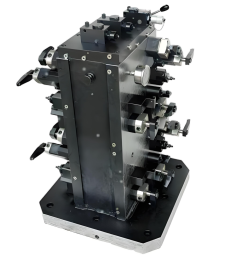

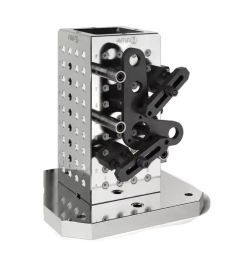

Modular Assembly Fixture

- Flexible configuration: Adjustable components for multiple product variants

- Quick changeover: Rapid reconfiguration for different assemblies

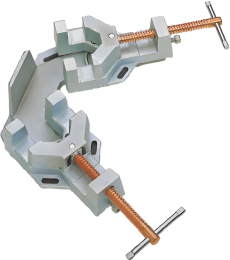

Welding Assembly Fixture

- Tack welding fixtures: Pre-positioning components for initial welding

- Robotic welding fixtures: Automated positioning for robotic welding systems

- Rotary welding fixtures: 360-degree access for complex weldments

Electronic Assembly Fixture

- ESD protection: Anti-static materials and grounding capabilities

- Precision locating: Micro-positioning for component placement

- Vibration isolation: Minimizing disturbance during delicate operations

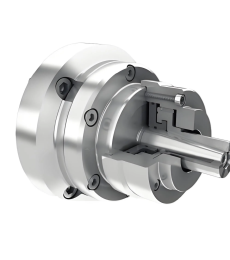

Automotive Assembly Fixture

- Engine assembly fixtures: Crankshaft, cylinder head, and block assemblies

- Body panel fixtures: Door, hood, and panel alignment systems

- Transmission fixtures: Gear train and housing assembly tools

Load Capacity and Forces

- Static load capacity: Up to 100,000 lbs depending on fixture design

- Dynamic load rating: Engineered for operational shock and vibration

- Clamping force: 50 lbs to 50,000 lbs across fixture types

- Safety factors: Minimum 4:1 safety factor for all load calculations

- Fatigue resistance: Designed for 10+ million operation cycles

Material Specifications

Assembly fixture construction utilizes:

- Steel alloys: 4140, 4340, and tool steels for high-strength applications

- Aluminum alloys: 6061-T6 and 7075-T6 for lightweight fixtures

- Stainless steel: 316 and 17-4 PH for corrosive environments

- Surface treatments: Hard anodizing, nitriding, and coating options

- Hardness ratings: 58-62 HRC for wear-resistant surfaces

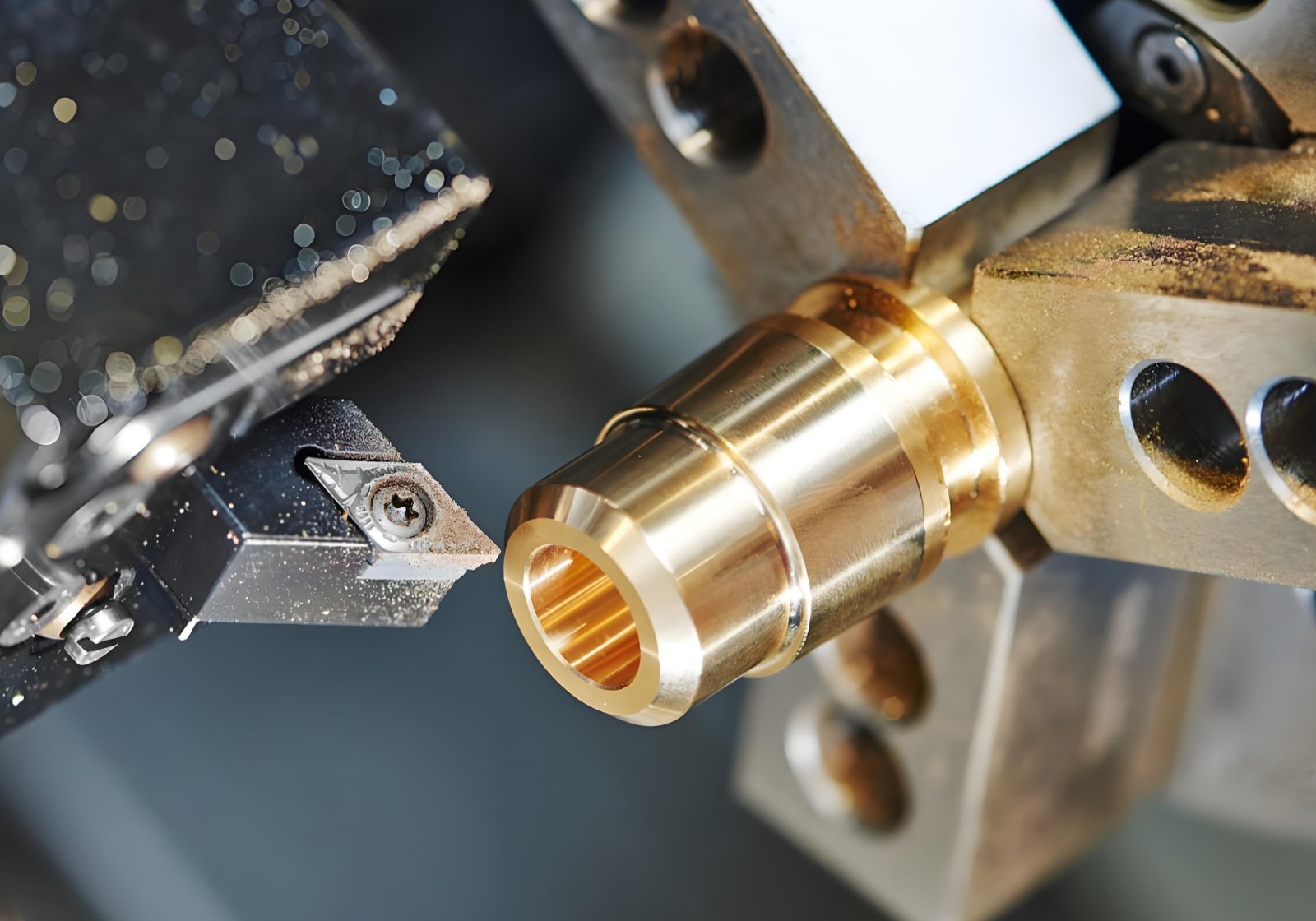

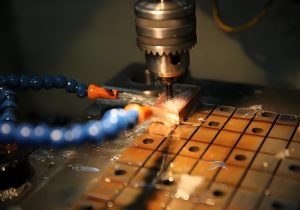

Manufacturing Capabilities

Precision manufacturing services include:

Industry Applications

- Aircraft structural assembly: Wing, fuselage, and empennage fixtures

- Engine component assembly: Turbine blade and case assembly tools

- Avionics integration: Precision fixtures for electronic assemblies

- Quality compliance: AS9100 and NADCAP certified processes

- Traceability: Complete documentation and material certification

- Powertrain assembly: Engine, transmission, and drivetrain fixtures

- Body-in-white: Structural welding and assembly fixtures

- Interior components: Dashboard, seat, and trim assembly tools

- Quality systems: IATF 16949 compliant manufacturing processes

- Lean manufacturing: Fixtures designed for efficient workflow

- Surgical instrument assembly: Precision tools for medical devices

- Implant manufacturing: Orthopedic and dental implant fixtures

- Diagnostic equipment: Assembly tools for medical instrumentation

- FDA compliance: Medical device manufacturing standards

- Sterile processing: Cleanable and sterilizable fixture designs

- Circuit board assembly: Component placement and soldering fixtures

- Device assembly: Smartphone, tablet, and computer assembly tools

- Connector installation: Precision alignment for electrical connections

- Testing fixtures: Functional test and quality verification tools

- Clean room operation: Contamination-controlled manufacturing

- Construction equipment: Large machinery assembly fixtures

- Mining equipment: Heavy-duty component assembly tools

- Marine applications: Shipbuilding and offshore equipment fixtures

- Power generation: Turbine and generator assembly systems

- Oil and gas: Pipeline and drilling equipment assembly tools

Professional Assembly Fixtures

We provide comprehensive assembly fixtures to production ensure precision and efficiency for your manufacturing needs.

Enhanced Quality Control

- Consistent positioning: Eliminates human error in component placement

- Tight tolerances: Maintains critical assembly dimensions

- Reduced defects: Minimizes rework and scrap rates

- Quality documentation: Traceable assembly processes

- Statistical process control: Data collection for quality monitoring

Improved Productivity

- Faster assembly times: Streamlined workflows and reduced handling

- Reduced setup time: Quick-change capabilities for multiple products

- Operator efficiency: Ergonomic designs reduce fatigue

- Automation compatibility: Integration with robotic systems

- Increased throughput: Higher production rates with consistent quality

Cost Reduction

- Lower labor costs: Reduced assembly time and skill requirements

- Minimized rework: Consistent quality reduces defects

- Extended tool life: Proper support reduces component wear

- Inventory reduction: Just-in-time assembly capabilities

- ROI optimization: Rapid payback through improved efficiency

Quality Assurance and Standards

- Consistent positioning: Eliminates human error in component placement

- Tight tolerances: Maintains critical assembly dimensions

- Reduced defects: Minimizes rework and scrap rates

- Quality documentation: Traceable assembly processes

- Statistical process control: Data collection for quality monitoring

Testing and Validation

- Dimensional inspection: CMM verification of all critical dimensions

- Load testing: Proof testing to 125% of rated capacity

- Cycle testing: Durability validation for expected service life

- Material certification: Mill test certificates for all materials

- Performance documentation: Complete test reports and certification

Why Choose Fecision

We are your trusted partner for high-quality assembly fixtures, offering expertise, precision, and reliability.

Industry Certifications

ISO 9001:2015, IATF 16949 certified for automotive applications, ensuring the highest quality standards.

Precision Engineering

Utilizing advanced 5-axis machining and German/Japanese equipment for micron-level precision.

Proven Expertise

20+ years of assembly fixture design and manufacturing experience from concept to production.

Competitive Pricing

Cost-effective solutions without compromising on quality or performance.

Custom Solutions

Custom Design

Application-specific design tailored to your exact requirements

Low to HighVolumes

Flexible manufacturing accommodating prototype to production volumes

Ongoing Support

Integration assistance and long-term partnership approach with ongoing support

Getting Started!

Submit your specifications for detailed proposal Engineering Consultation.

We have the expertise to deliver the optimal workholding solution for your manufacturing process.