Angle Plate Jig: Essential Precision Tool for Machining & Fixturing

From material selection to angle customization, we excel in custom manufacturing of angle plate jigs to meet your specific machining needs and enhance accuracy and efficiency for your unique applications.

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

Custom Angle Plate Jigs

Precision Workholding for Versatile Machining

Custom Manufacturing Expertise

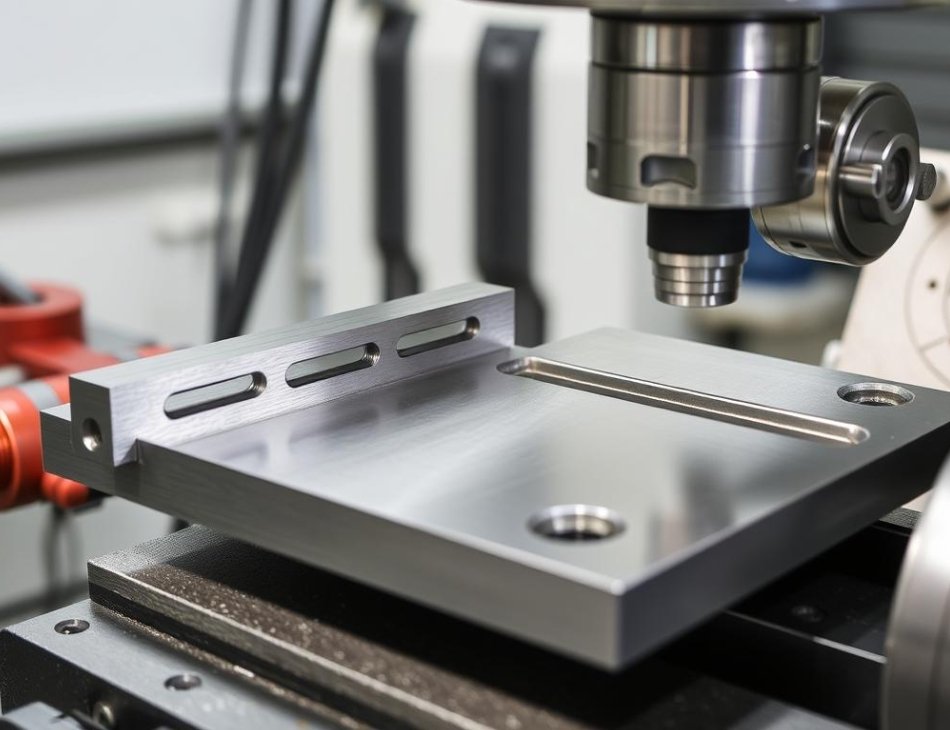

Angle Plate Jigs for Machining

An angle plate jig is a precision-engineered workholding device featuring two or more surfaces joined at specific angles (typically 90 degrees). Manufactured from high-tensile cast iron or hardened steel, these robust tools provide a stable platform for securing workpieces at precise angles during machining, welding, or inspection procedures.

The defining characteristic of an angle plate jig is its ground surfaces, which are machined to exacting tolerances to ensure squareness and parallelism. Most quality angle plates are ground to within ±0.0001" tolerance, making them indispensable for precision work. The surfaces typically feature machined slots or holes that allow for versatile workpiece mounting and fixturing options.

Differ from Simple Angle Brackets

Professional-grade angle plate jigs undergo stress-relieving processes during manufacturing to ensure they maintain their precision over years of use. The steel angle plate variants offer exceptional durability in demanding industrial environments, while specialized versions may incorporate features like adjustable angles or magnetic surfaces.

Uses of Angle Plate Jigs

The versatility of angle plate jigs makes them indispensable across numerous machining and inspection applications.

Their primary function is to hold workpieces at precise angles (most commonly 90°) relative to a machine table or measurement surface.

Machining Operations

✅Milling perpendicular surfaces

✅Drilling at precise angles

✅Grinding operations requiring 90° positioning

✅EDM (Electrical Discharge Machining) setups

✅Creating compound angles when used in pairs

Inspection & Layout

✅Checking squareness of machined parts

✅Setting up dial indicators for measurement

✅Creating reference planes for CMM inspection

✅Layout work requiring precise angular references

✅Fixture building and prototyping

Modular Fixture

✅Holding components at right angles during welding

✅Creating precise assembly fixtures

✅Checking assemblies for squareness

✅Positioning parts for brazing operations

✅Creating jigs for repetitive assembly tasks

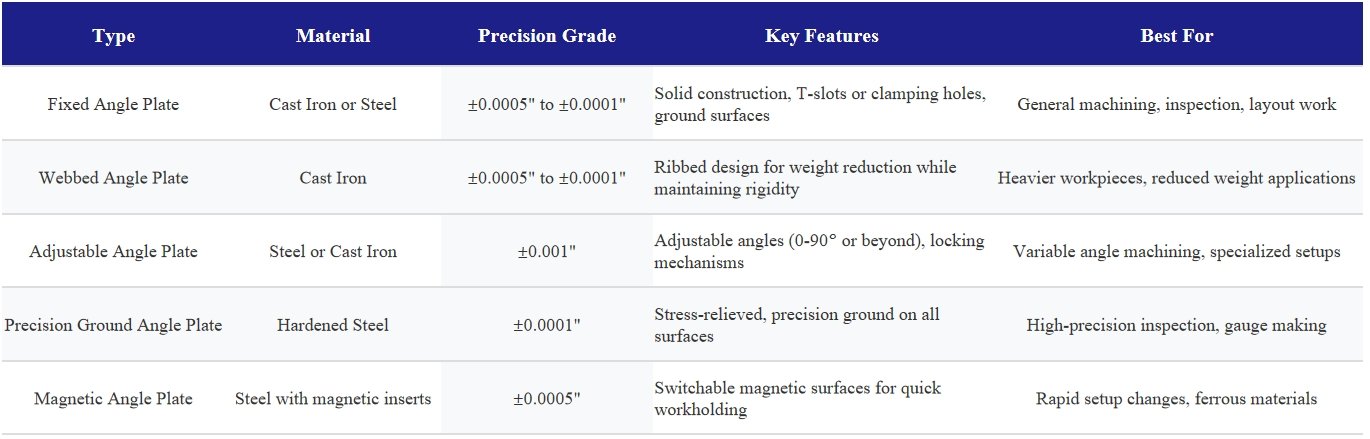

Types of Angle Plates

Angle plate jigs come in various configurations to suit different applications and precision requirements.

Understanding the differences between these types will help you select the most appropriate tool for your specific machining or inspection needs.

Fixed vs. Adjustable Angle Plates

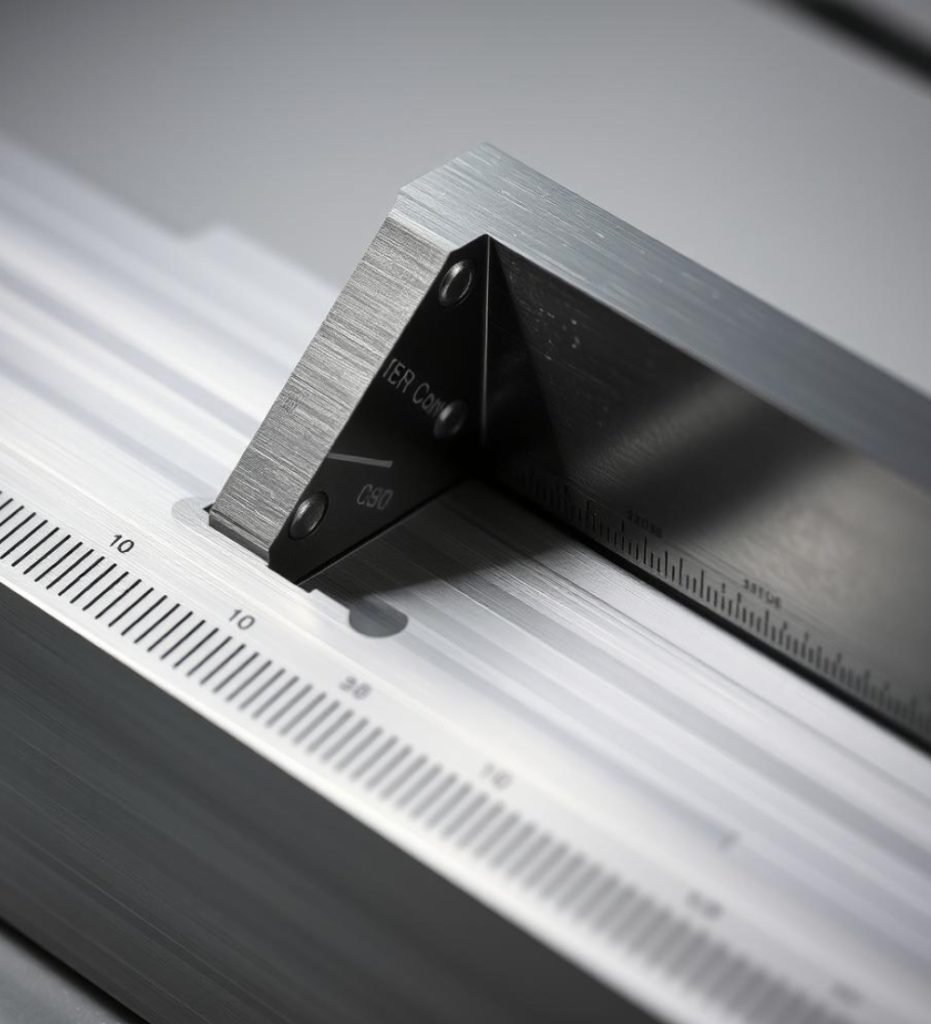

Fixed angle plates offer superior rigidity and precision, typically maintaining a perfect 90° angle between surfaces. They're the standard choice for most machining operations where right angles are required. The ground surfaces ensure parallelism and perpendicularity within tight tolerances.

Adjustable angle plate jigs sacrifice some rigidity for versatility, allowing the angle between surfaces to be modified. These are invaluable for specialized operations requiring compound angles or non-standard positioning. Most feature graduated scales for precise angle setting and robust locking mechanisms to maintain position during machining.

Speak With Our Engineering Team

Discuss your specific application challenges with our fig design specialists.

Understanding the Differences

Angle Plate Jig vs. Plate Jig

While they may sound similar, angle plate jigs and standard plate jigs serve distinctly different functions in the machining and fixturing world. Understanding these differences is crucial for selecting the right tool for your specific application.

Angle Plate Jig

- Features two or more surfaces at precise angles (typically 90°)

- Primarily used for holding workpieces perpendicular to the machine table

- Enables machining on multiple faces in a single setup

- Provides reference surfaces for squareness and perpendicularity

- Available in fixed or adjustable angle configurations

- Typically more robust and heavier construction

- Essential for operations requiring precise angular positioning

Plate Jig

- Features a single flat reference surface

- Used for holding workpieces parallel to the machine table

- Primarily enables machining on a single face at a time

- Provides reference surface for flatness and parallelism

- Generally simpler in design with fewer variables

- Often lighter and more portable

- Better suited for operations requiring only planar references

Can I use an angle plate jig for inspection purposes?

Yes, precision-ground angle plate jigs are frequently used in quality control and inspection departments. Their accurately machined 90° angle provides an excellent reference for checking the squareness of machined components. When used on a surface plate with dial indicators or height gauges, angle plates become versatile inspection tools for verifying geometric tolerances.

What material is best for a durable angle plate jig?

For most industrial applications, high-tensile cast iron that has been properly stress-relieved offers the best combination of stability, vibration damping, and value. For the highest precision requirements or harsh environments, hardened steel angle plates provide superior durability and long-term accuracy. The ground surfaces on quality angle plates are typically hardened to HRC 50-55 for wear resistance.

Application Considerations

When deciding between an angle plate jig and a standard plate jig, consider the geometry of your workpiece and the machining operations required. Angle plate jigs excel when you need to machine surfaces perpendicular to each other or when checking the squareness of components. Their rigid construction maintains precise angles even under heavy cutting forces.

Standard plate jigs are preferable when working primarily on a single surface or when the workpiece already provides the necessary angular references. They typically offer a larger working area and may be more suitable for larger workpieces where only planar references are needed.

Preventing Damage

Maintaining Your Angle Plate Jig

✅Proper maintenance ensures your angle plate jig maintains its precision over years of use. Store angle plates in a dry environment with a light coat of protective oil to prevent corrosion. Before each use, clean all surfaces thoroughly with a lint-free cloth and check for any nicks or damage that might affect accuracy.

✅Periodically verify the accuracy of your angle plate using precision measurement tools such as a dial indicator on a surface plate. For inspection-grade angle plates, consider professional recertification every few years, especially if used for quality control purposes.

Never use an angle plate jig as a hammer or striking tool. The precision ground surfaces can be easily damaged, affecting accuracy. When clamping workpieces, use proper torque and avoid over-tightening, which can induce stress and potentially distort the angle plate over time.

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Need Custom Angle Plate Jigs for Your Project?

Contact Fecision today to discuss your custom angle plate jig requirements and discover how our solutions can improve your manufacturing efficiency.

Let’s Get Started Now!