Did you know that lathes have been a cornerstone of manufacturing for centuries, shaping everything from wooden furniture to complex aerospace components? At its core, a lathe is a machine that rotates a workpiece around a fixed cutting tool, enabling precise turning, boring, and shaping operations.

This versatility makes the lathe an indispensable tool in various industries, including automotive, medical, and general manufacturing. As you explore the world of lathes, you’ll discover a range of machines, from manual engine lathes to advanced CNC systems, each designed to optimize machining efficiency and precision.

Understanding the different types of lathes and their applications is crucial for selecting the right machine for your specific needs, whether you’re a professional machinist or a hobbyist.

What is a Lathe Machine?

A lathe machine, also known as a turning machine, is used for various machining operations, including turning, facing, and boring. The workpiece is rotated against a cutting tool, allowing for the creation of symmetrical objects with precise dimensions. This basic principle of operation makes lathes indispensable in many manufacturing processes.

Key Components of a Lathe Machine

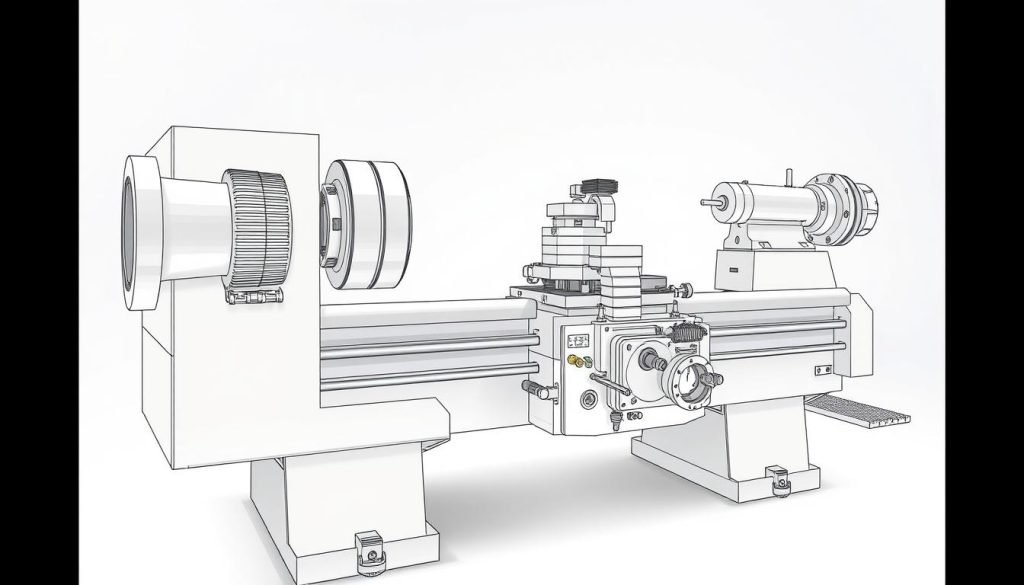

Understanding the key components of a lathe machine is crucial for effective machining operations. A lathe machine is a complex piece of equipment made up of several critical parts that work together to enable precise turning, cutting, and shaping of workpieces.

Headstock and Spindle Assembly

The headstock is a fundamental component that houses the main spindle, speed change mechanism, and change gears. It provides the rotational force necessary for turning operations, making it a critical element in the functioning of the lathe machine. The spindle assembly is responsible for holding and rotating the workpiece.

Bed, Carriage, and Tailstock

The bed serves as a robust base that connects to the headstock and allows the carriage and tailstock to move parallel to the spindle axis. The carriage, comprising the saddle and apron, facilitates the movement of the cutting tool along the workpiece. The tailstock, located opposite the headstock, provides additional support for the workpiece and can be used to mount drills or other tools.

Tool Post and Cutting Tools

The tool post is where the cutting tool is mounted, and it comes in various styles, including the American lantern style, traditional four-sided square style, and quick-change style. The choice of tool post and cutting tool depends on the specific machining operation and the type of workpiece being machined.

Feed and Lead Screws

Feed and lead screws play a crucial role in controlling the movement of the carriage, enabling precise threading operations and other machining tasks. The lead screw is particularly important for threading, as it allows for accurate control over the thread pitch.

By understanding how these components interact, you can optimize your lathe operations and achieve more accurate and efficient machining results. Proper maintenance of each part is essential for the overall performance and longevity of the lathe machine.

How Lathes Work: Basic Operations

As you explore the world of machining, understanding how lathes work is crucial for any enthusiast or professional. Lathes are versatile machines that perform a variety of operations, making them indispensable in manufacturing and machining processes.

The primary function of a lathe is to rotate a workpiece around a fixed axis, allowing various operations to be performed on it. This fundamental process enables the creation of symmetrical and precise parts.

The Turning Process Explained

Turning is the most common operation performed on a lathe. In this process, the workpiece rotates on its axis while a stationary cutting tool shapes its outside periphery. This results in the creation of cylindrical, conical, or other symmetrical forms. The turning process is crucial in machining as it helps in making various shaped and sized parts.

Common Lathe Operations

Beyond turning, lathes are capable of performing several other essential operations. Facing is another critical operation where the lathe creates a flat surface perpendicular to the workpiece’s axis of rotation. Drilling operations on a lathe involve creating holes along the central axis of the workpiece using the tailstock. Additionally, lathes can perform threading operations, which allow for the creation of both internal and external threads with precise pitch and diameter.

Other specialized operations include knurling, which creates patterned grips on cylindrical surfaces, and taper turning for creating conical shapes. Understanding these basic operations is fundamental to mastering more complex machining tasks and applying them in various manufacturing contexts.

Different Types of Lathes and Their Functions

The world of lathes is diverse, with several types designed to cater to specific machining needs and applications. As you explore the different types of lathes, you’ll find that each has its unique characteristics, advantages, and uses.

Engine Lathes

Engine lathes are the most common and versatile type of lathe. They’re widely used across different industries for a broad range of turning operations. Engine lathes can work with various materials and are essential for tasks ranging from simple cutting to complex shaping.

Turret Lathes

Turret lathes feature a rotating turret that can hold multiple cutting tools simultaneously. This design allows for quick tool changes and efficient production of multiple identical parts. Turret lathes are ideal for applications where precision and repeatability are crucial.

Bench Lathes

Bench lathes are multipurpose machines used for cutting a wide range of components. They’re particularly useful where space is limited, and precision is required. Bench lathes are smaller and lighter than industrial turning machines, making them suitable for smaller workpieces.

Tool Room Lathes

Tool room lathes are high-precision machines designed specifically for creating tools, dies, and other components that require exceptional accuracy. These lathes are built to deliver precise results and are often used in tool rooms and precision manufacturing facilities.

Understanding the different types of lathes and their functions can help you choose the right machine for your specific machining needs. Whether you’re working on general-purpose machining or specialized production work, there’s a lathe designed to meet your requirements.

Specialized Lathe Machines

Specialized lathe machines are engineered to handle particular machining challenges that standard lathes can’t efficiently address. These machines are designed for specific applications and materials, expanding the capabilities of lathe operations.

Vertical Turret Lathes

Vertical turret lathes feature a vertical spindle orientation, making them ideal for handling large, heavy workpieces that are difficult to mount on a horizontal lathe. This design is particularly useful in heavy industries for machining large components like turbine disks and flanges.

Gap Bed Lathes

Gap bed lathes are designed with a removable gap in the bed, allowing for the accommodation of larger diameter workpieces. This unique feature enables the lathe to handle workpieces that wouldn’t fit in a standard lathe, while maintaining the functionality of a conventional machine.

Speed Lathes

Speed lathes are characterized by their high-speed spindle and simpler design, primarily used for finishing and polishing operations. These lathes are optimized for rapid rotation, making them suitable for applications where high precision is not the primary concern.

Glass Working Lathes

Glass working lathes are specially designed for precision glassworking, used for shaping and forming glass pieces. These lathes differ significantly from metal-working lathes, with features tailored for the delicate manipulation of glass materials.

These specialized lathe machines demonstrate the diversity and adaptability of lathe technology, catering to a wide range of industries and applications. By understanding the unique features and capabilities of each type, you can better appreciate the role of lathes in modern manufacturing.

CNC Lathes: The Modern Revolution

CNC lathes represent a significant leap forward in machining technology, offering unprecedented precision and automation. You’re now entering a world where computer numerical control (CNC) technology has revolutionized lathe operations, bringing about a new era of precision and efficiency.

Features of CNC Lathes

CNC lathes are equipped with advanced features that make them highly versatile and efficient. They operate through computer numerical control, allowing for highly precise machining processes. These machines can execute complex machining sequences with minimal operator intervention, thanks to their programmable toolpaths.

The precision offered by CNC lathes is unmatched, making them ideal for producing parts with stringent and intricate requirements. Their ability to perform multi-axial operations further enhances their capability, allowing for the production of complex parts that would be challenging or impossible to achieve with manual machines.

CNC Swiss-Type Lathes

CNC Swiss-type lathes are a specialized form of CNC lathe designed for producing small, high-precision parts with exceptional surface finishes. The unique guide bushing system in these lathes supports the workpiece close to the cutting tool, reducing deflection and enabling the machining of long, slender parts with tight tolerances.

These machines are particularly useful for manufacturing parts that require high precision and intricate details, such as those used in medical devices, aerospace, and precision instruments.

As CNC lathe technology continues to evolve, you’ll see advancements in computing power, control systems, and integration with other manufacturing technologies. This evolution will further enhance the capabilities of CNC lathes, making them even more integral to modern manufacturing processes.

Manual Lathes vs. Automated Lathes

Understanding the differences between manual and automated lathes is essential for selecting the right tool for your machining needs. Both types of lathes have their place in modern manufacturing, offering unique advantages depending on the specific requirements of your projects.

Advantages of Manual Lathes

Manual lathes offer several benefits, including lower initial costs and greater flexibility for one-off or prototype parts. They require direct operator control, which can be advantageous for simple projects or when working with unique materials. Manual lathes are also excellent training tools, providing hands-on experience with fundamental machining principles.

Benefits of Automated Lathes

Automated lathes, including CNC machines, excel in repeatability and precision for complex parts. They can operate continuously with minimal human intervention, reducing operator fatigue and maximizing productivity. Automated lathes are ideal for large production runs and complex parts that require multiple operations, ensuring consistent quality across all units.

When to Choose Each Type

The choice between manual and automated lathes depends on several factors, including production volume, part complexity, required precision, and available budget. For simple, one-off parts or prototyping, manual lathes may be the better choice. However, for high-volume production or complex parts requiring precision, automated lathes are generally more efficient. Many machine shops maintain both types to leverage their unique advantages for different projects.

Optimizing Lathe Machining Efficiency

Improving lathe machining efficiency involves understanding the intricacies of the machining process and applying best practices. By optimizing various aspects of lathe operations, you can significantly enhance productivity, part quality, and tool life.

Tool Selection and Maintenance

Choosing the right cutting tools for specific materials and operations is crucial. Different cutting tools, such as carbide for high-speed and HSS for general operation, should be used for lathe operations. Regular maintenance is essential to ensure that tools remain sharp, which is vital for clean cutting, reduced cycle time, and freedom from defects.

Proper Workpiece Positioning

Correct positioning of the workpiece relative to the cutting tool is critical in turning machine operations to produce quality parts. Ensuring that the workpiece is well secured to the lathe chuck by tightening the clamping lever is the first step. Proper setup prevents vibration, improves surface finish, and ensures dimensional accuracy.

Optimal Cutting Parameters

Through the proper choice of cutting speed and feed rate, the material removal rate, as well as the wear rate of the tool, can be well balanced. Determining optimal cutting parameters, including speed, feed rate, and depth of cut for different materials and operations, is essential for efficient machining.

Coolant and Lubrication Practices

Adequate coolant and lubricant are crucial to the effectiveness and durability of lathe operations. They play a critical role in extending tool life, improving surface finish, and facilitating chip evacuation during machining operations. Proper coolant and lubrication practices are vital for maintaining high-quality standards.

By implementing these strategies, you can optimize lathe machining efficiency, leading to improved productivity and part quality. Regular maintenance and proper setup are key to achieving high accuracy and precision in your machining operations.

Common Problems in Lathe Operations

Common challenges in lathe operations can lead to poor surface finish and dimensional inaccuracies. When working with lathes, it’s essential to be aware of these potential issues to maintain the quality of your workpiece and ensure efficient machining operations.

Vibration and Chatter Issues

Vibration and chatter are significant problems that can occur during lathe operations, often resulting from improper tool or workpiece setup, inadequate machine rigidity, or inappropriate cutting parameters. These issues can lead to a poor surface finish and affect the dimensional accuracy of your workpiece.

Tool Wear and Breakage

Tool wear and breakage are frequent challenges in lathe machining, often caused by incorrect cutting speeds, inadequate cooling, or using the wrong tool material for the workpiece. Regular tool maintenance and proper selection of cutting parameters can help minimize these issues.

Workpiece Deformation

Workpiece deformation can occur due to excessive cutting forces, improper clamping, or thermal expansion during the machining process. This is particularly problematic with thin-walled or long workpieces. Techniques such as proper clamping methods and controlled cutting parameters can help mitigate this issue.

By understanding these common problems and implementing preventive measures, you can significantly improve the efficiency and quality of your lathe operations.

Troubleshooting and Solutions for Lathe Machines

Effective troubleshooting of lathe machines involves understanding common issues and their solutions. To maintain optimal performance, it’s crucial to address problems promptly and effectively.

Alignment and Calibration Techniques

Proper alignment and calibration of lathe machines are essential for accurate machining. This includes checking and adjusting the headstock-tailstock alignment, ensuring the ways are level, and verifying that the cross-slide moves perpendicular to the spindle axis. Regular calibration helps prevent issues such as inconsistent dimensions and poor surface finish.

Resolving Common Operational Issues

Common operational issues with lathe machines include inconsistent dimensions, poor surface finish, and unusual noises or vibrations. These problems can often be resolved by checking for worn bearings, loose gibs, or damaged gears. Identifying the root cause of the issue is crucial for applying the correct solution.

Preventive Maintenance Practices

Preventive maintenance is key to extending the life of your lathe machine and preventing unexpected breakdowns. This includes regular cleaning and lubrication of all moving parts, checking and adjusting gibs for proper tightness, and inspecting belts, gears, and electrical components for signs of wear or damage. By implementing a regular maintenance schedule, you can ensure your lathe machine continues to operate efficiently.

By following these troubleshooting and maintenance practices, you can optimize the performance of your lathe machine and ensure it continues to produce high-quality parts.

How to Choose the Right Lathe for Your Needs

With numerous types of lathes available, determining the most suitable one for your specific needs requires careful consideration. Choosing the right lathe involves assessing your requirements, budget, and workspace constraints.

Assessing Your Requirements

To select the ideal lathe, you need to analyze the types of parts you’ll be making, the materials you’ll be working with, and the precision levels you need to achieve. Consider the size and complexity of the parts, as well as your production volume. This will help you decide between manual and CNC lathes.

Budget Considerations

Budget considerations extend beyond the initial purchase price to include ongoing costs such as tooling, maintenance, power consumption, and potential training needs. Evaluate the total cost of ownership to ensure you’re getting the best value for your investment.

Space and Power Constraints

Space and power constraints are crucial practical factors. Lathes vary significantly in their footprint and electrical requirements. Larger lathes may require three-phase power, and adequate space must be available for safe operation and material handling.

By carefully evaluating these factors, you can choose a lathe that meets your needs and enhances your machining capabilities.

Applications of Different Lathe Types Across Industries

You can find lathes being utilized in a wide range of industries, from high-precision manufacturing to hobbyist projects. The versatility of lathes makes them essential tools across various sectors.

Aerospace and Automotive Applications

In the aerospace industry, lathes are used to manufacture critical components such as turbine shafts, hydraulic fittings, and landing gear components. The automotive industry relies heavily on lathes for producing engine components, transmission parts, and brake system components. These industries require high-precision lathes that can meet stringent quality standards.

Medical and Precision Instrument Manufacturing

Medical device manufacturing requires high-precision lathes for creating surgical instruments, implantable devices, and diagnostic equipment components. Precision instrument manufacturers use specialized lathes to produce components for scientific instruments, measuring devices, and optical equipment. The precision and accuracy of these lathes are crucial for the production of complex medical and scientific instruments.

General Manufacturing and Hobbyist Uses

General manufacturing applications include the production of fasteners, shafts, pulleys, and countless other components used in various products. Hobbyists and small workshops use lathes for woodturning, creating custom parts for projects, and small-scale production of specialized components. The accessibility of lathe technology across different skill levels makes it a valuable tool for both industrial and personal use.

Alternative Technologies to Lathes

Beyond the lathe, other machining technologies offer unique capabilities that can enhance your manufacturing processes. While lathes excel at creating cylindrical parts, other machines and techniques can handle more complex geometries or different manufacturing needs.

Milling Machines

Milling machines are a primary alternative to lathes, particularly for producing parts with flat surfaces, slots, and complex shapes. Modern CNC milling centers with live tooling can even perform some turning operations, blurring the lines between milling and lathe work.

3D Printing for Prototyping

3D printing offers a fundamentally different approach to part creation through additive manufacturing. This technology is particularly useful for rapid prototyping and creating complex geometries that would be challenging or impossible to machine conventionally.

Wire EDM and Other Cutting Technologies

Wire EDM (Electrical Discharge Machining) and other specialized cutting technologies provide precision cutting capabilities for conductive materials and complex shapes. These technologies can produce features that are difficult to achieve with traditional turning operations on a lathe.

By understanding these alternative technologies, you can create a more versatile manufacturing environment, leveraging the unique strengths of each technology to produce a wide range of parts efficiently.

Conclusion

With the knowledge of different lathe types and their applications, you can now make informed decisions for your machining projects. Lathes remain one of the most versatile and essential machine tools in manufacturing, evolving from traditional engine lathes to advanced CNC systems. By understanding the various types of lathes available and how to optimize their operation, manufacturers and hobbyists alike can achieve the best possible results in their turning operations.

The diverse world of lathes offers various solutions for different machining needs, with engine lathes being the most widely used due to their versatility. Optimizing lathe operations through proper tool selection, workpiece positioning, and maintenance practices is crucial for achieving high accuracy and efficiency. Whether you’re equipping a professional machine shop or pursuing machining as a hobby, this comprehensive guide should help you select the right lathe for your specific needs.