Advanced Solutions for Electronics & Semiconductor Manufacturing

The electronics and semiconductor industry continues to evolve at an unprecedented pace, driven by increasing demands for miniaturization, performance, and reliability.

As technologies like AI, 5G, and quantum computing advance, manufacturers require precision components and tooling solutions that can meet increasingly stringent specifications while maintaining cost-effectiveness and production efficiency.

- Dust-free workshop capability

- Ultra-high cleanliness processing environment (ISO Class 5)

- Quality management system per ISO 9001:2015/13485:2016/14001:2015

- DFM and product validation

- Real-time Process Tracking System

- One-stop service for manufacturing, finishing and logistics

Why Choose FECISION for Electronics Manufacturing

Electronics & Semiconductor Manufacturing Expertise

At FECISION, we understand the critical challenges facing electronics and semiconductor manufacturers. Our state-of-the-art facilities and advanced manufacturing capabilities enable us to deliver high-precision molds, tooling, and components that meet the exacting standards of the electronics and semiconductor industry.

From integrated circuits to complex electronic assemblies, we provide comprehensive manufacturing solutions for the entire electronics supply chain.

Our Electronics & Semiconductor Manufacturing Capabilities Include:

Semiconductor Mold Manufacturing

Electronic Component Tooling

PCB Manufacturing Components

Lead Frame Progressive Die Tools

Advanced Materials for Electronics Applications

The electronics and semiconductor industry demands materials that meet strict electrical, thermal, and mechanical requirements. Our components utilize:

√ High-Performance Metals

Precision-machined copper, aluminum, and specialized alloys for electronic applications

√ Semiconductor-Grade Plastics

High-purity, ESD-safe polymers for sensitive electronic components

√ Thermally Conductive Materials

Specialized materials for heat dissipation in electronic assemblies

√ Low-Ionic Content Compounds

Materials with high electrical stability for semiconductor applications

√ CTE-Matched Materials

Precisely engineered materials to match thermal expansion coefficients of semiconductor substrates

Ultra-Clean Manufacturing Environment

Electronics and semiconductor components require exceptional cleanliness standards. Our manufacturing facilities include:

√ ISO Class 5 Cleanroom

Ultra-high cleanliness environment for critical semiconductor component manufacturing

√ Advanced Contamination Control

Comprehensive protocols to eliminate particulate and ionic contamination

√ ESD Protection Systems

Complete electrostatic discharge protection throughout the manufacturing process

√ Precision Climate Control

Tightly controlled temperature and humidity for optimal manufacturing conditions

√ Automated Material Handling

Minimized human contact to reduce contamination risks

Electronics & Semiconductor Manufacturing Process

1. Design Collaboration

- Working with electronics engineers to optimize designs for manufacturability

2. Material Selection

- Choosing optimal materials based on electrical, thermal, and mechanical requirements

3. Prototyping

- Rapid production of prototype components for testing and validation

4. Tooling Development

- Creating precision tooling for production manufacturing

5. Process Validation

- Comprehensive process validation including statistical process control

6. Production Manufacturing

- Implementing efficient production processes with rigorous quality controls

7. Assembly Integration

- Supporting seamless integration into final electronic assemblies

8. Documentation

- Complete documentation package including material certifications and inspection reports

Robotics Manufacturing from Prototype to Production

Fecision offers a highly efficient and simplified supply chain solution. Whether you’re in the stage of creating prototypes, moving on to test units, initiating mass-production, or dealing with subsequent phases, Fecision has got you covered.

Prototype

- For the purpose of validating your materials and designs, get prototypes that come as close as feasible to your final design.

Prototype

DVT

Production

EVT

PVT

- Comprehensive functionality testing on the prototype

- Identify any flaws or areas for improvement in the design

Applications in Electronics & Semiconductor Industry

Our precision manufacturing capabilities serve diverse aerospace applications:

Integrated Circuits

- Semiconductor packaging molds

- IC encapsulation tooling

- Lead frame components

- Die attach components

- Wire bonding fixtures

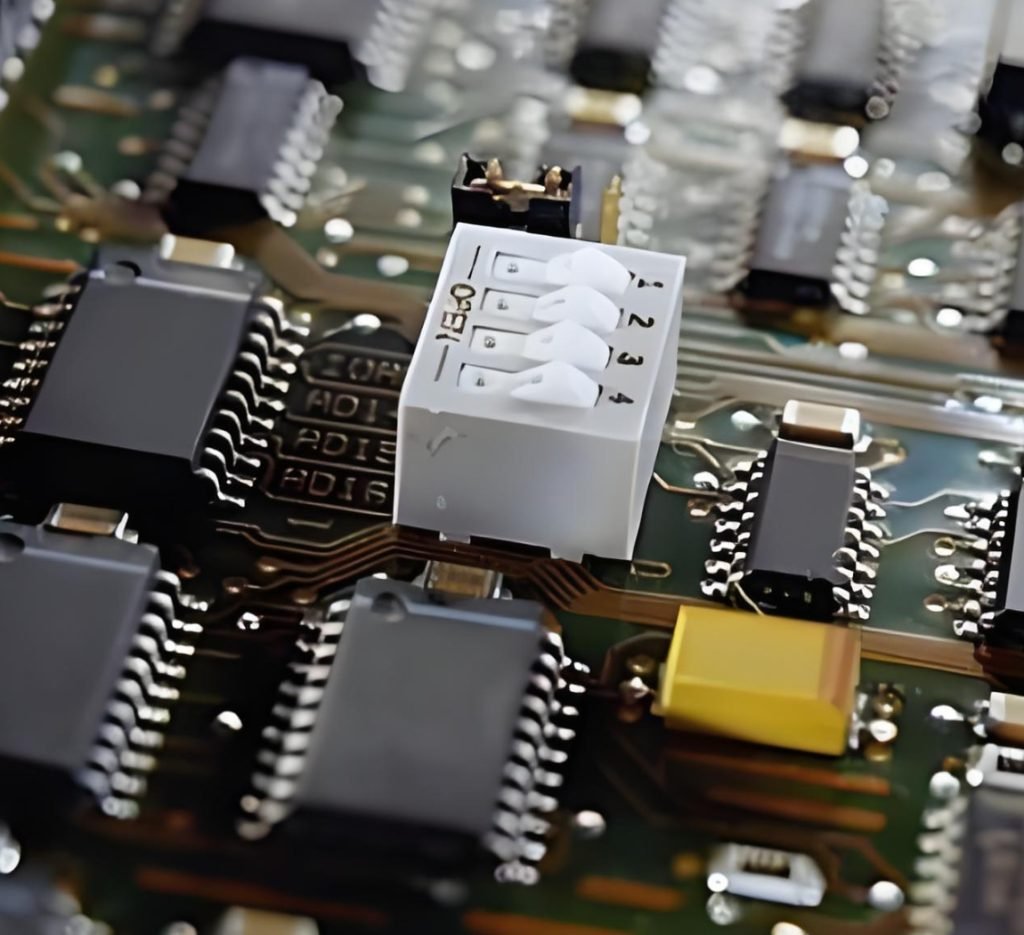

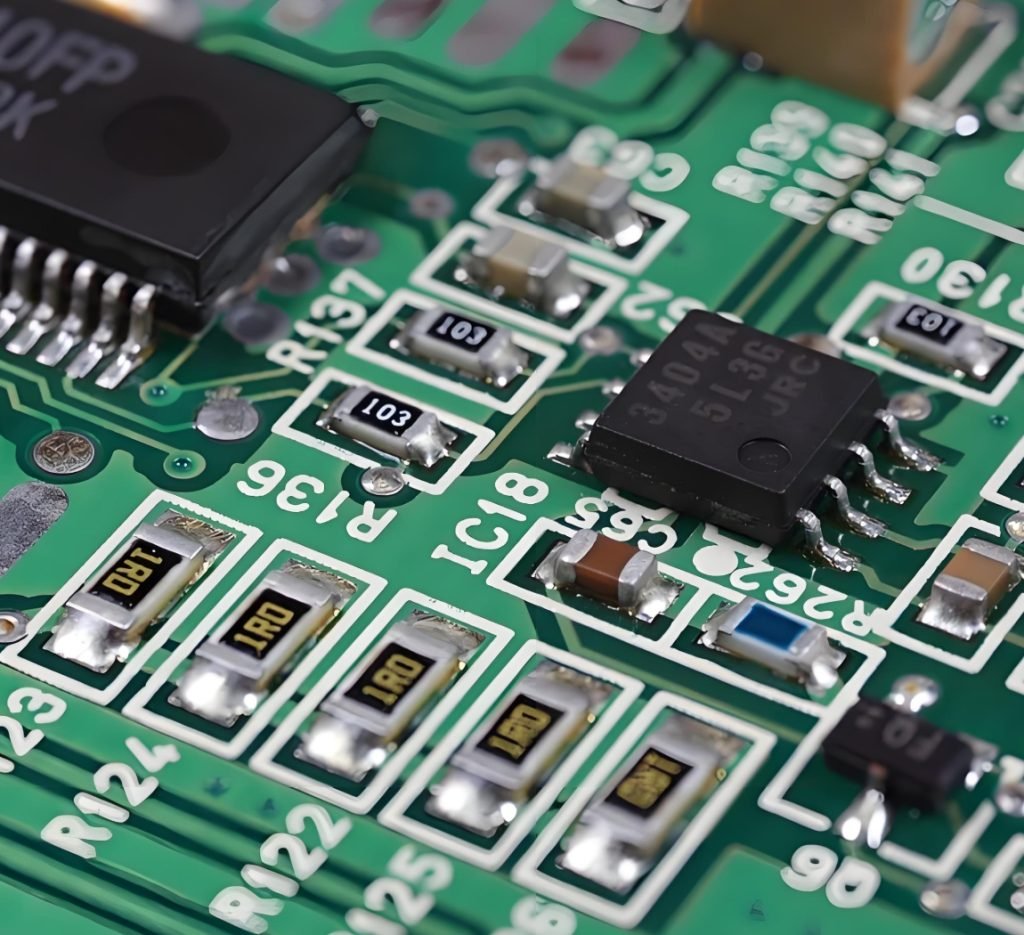

Printed Circuit Boards

- PCB manufacturing fixtures

- Surface mount technology (SMT) components

- PCB testing equipment parts

- High-density interconnect (HDI) tooling

- Flexible circuit manufacturing components

Consumer Electronics

- Smartphone component molds

- Wearable device parts

- Tablet and laptop housing components

- Audio equipment precision parts

- Camera and optical device components

Telecommunications

- 5G infrastructure components

- Network equipment parts

- Antenna system components

- Signal processing hardware

- Fiber optic connection components

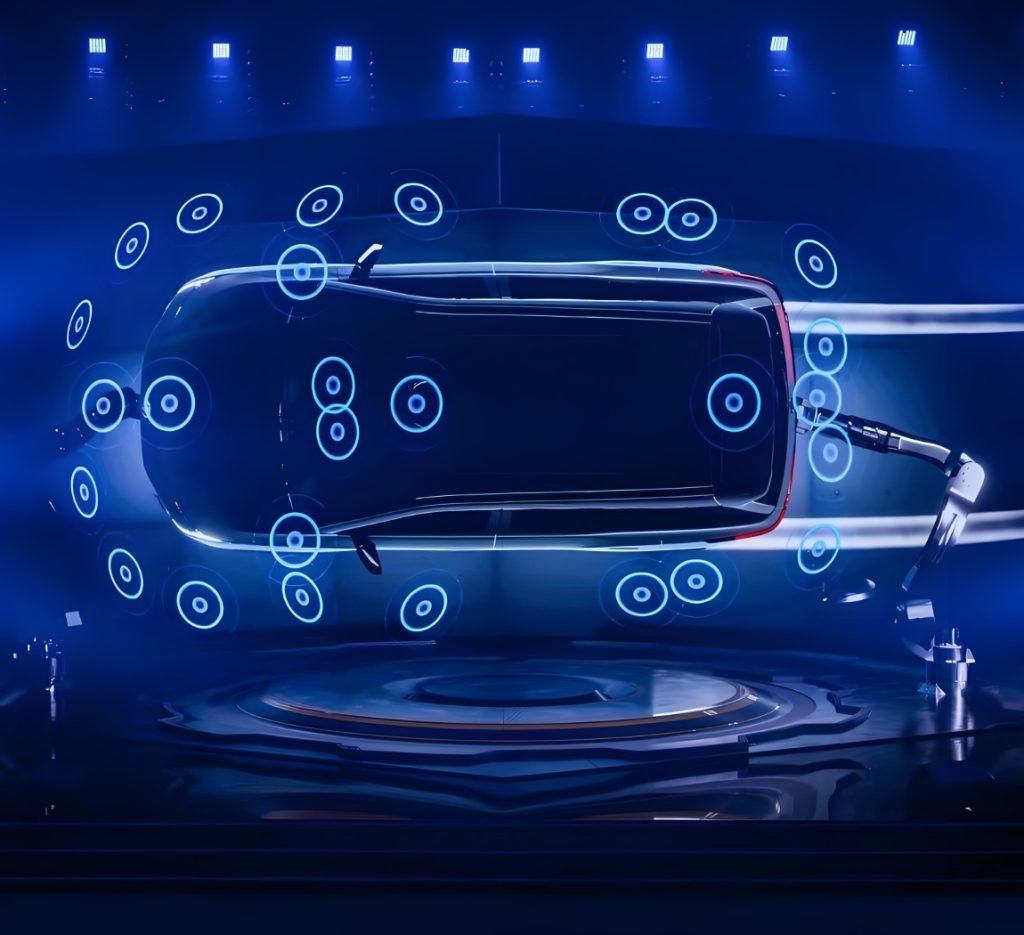

Automotive Electronics

- Electronic control unit (ECU) components

- Advanced driver assistance system (ADAS) parts

- Infotainment system components

- Electric vehicle control systems

- Automotive sensor components

Advanced Metrology

State-of-the-art measurement systems for nanometer-level precision

Automated Inspection Systems

100% inspection capabilities for critical electronic components

Electrical Testing

Comprehensive testing for electrical performance and stability

Quality Assurance for Electronics Manufacturing

Quality is paramount in robotics manufacturing.

Environmental Stress Testing

Validation under extreme temperature, humidity, and mechanical stress

Material Composition Analysis

Verification of material purity and composition

Dimensional Stability Monitoring

Long-term monitoring of critical dimensions under various conditions

Customized Electronics & Semi-Conductor Parts

Common

Application

With the capability of dust-free workshop and certification of SEMI (Semiconductor Equipment and Materials International) standards and ISO Class 5 clean room, Fecision has multiple solutions for Electronics & Semi-conductor part production, aiming to provide qualified products with precision and exellent function.

- Vacuum Chuck

- Vacuum Chamber Flange

- Silicon Wafer Transfer Robot Arm

- Turbomolecular Pump Blade

- Plastic Mold Insert

- Substrate Fixture

- Lead Frame Stamping Mold

- Molecular Pump Impeller

- Anti-static Gears

- Heat Exchanger Fins

Automotive Manufacturing Case Studies

Advanced Semiconductor Packaging

We developed precision molds for a next-generation semiconductor packaging application, achieving sub-micron tolerances while reducing cycle time by 25% compared to conventional methods.

5G Communication Components

Our team manufactured critical components for 5G communication infrastructure, delivering parts with exceptional RF performance characteristics and reliability under extreme environmental conditions.

Automotive Electronics Assembly

FECISION produced high-precision components for an automotive electronic control unit, utilizing advanced materials and manufacturing processes to ensure reliability in harsh automotive environments.

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.