It is a modern manufacturing method mostly used in manufacturing line industries. It’s the process behind making many of the plastic products we touch every day, from toys to car parts. The ejector system is one crucial piece of this puzzle. But what is the ejector system, and what is its primary significance in injection molding?

In this post, you will find everything you need to know about the ejector system, including its role in the injection molding process, key components, working principles, and tips to optimize it for better performance. If you are a new engineer in manufacturing or attempting to elevate your production process, be sure the ejector system used in injection molding will aid in producing repeatable quality and output..

What is Injection Molding?

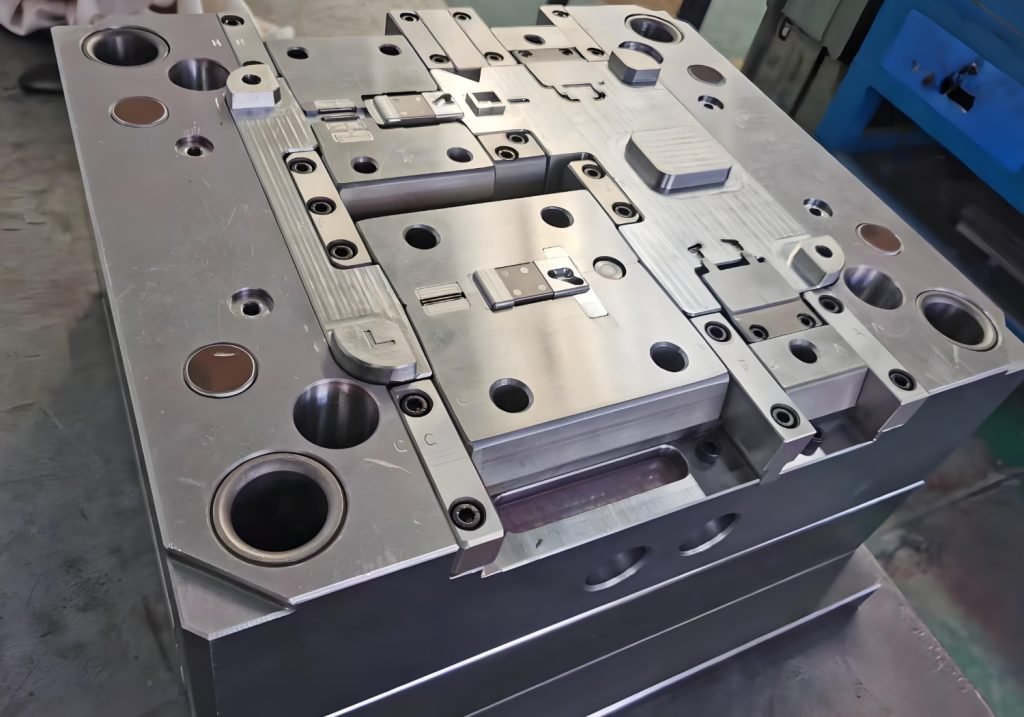

Before we go into ejector systems discussion, we first need to understand what injection molding is. Injection molding is a process of making plastic products. Here’s how it works:

- Plastic is softened with heat until it melts and flows.

- This melted plastic is subsequently injected into a mold, which is considered a hollow shape for the plastic to fit into.

- The mold opens when the plastic cools and hardens.

- Remove the final product (a plastic toy, for example)

Doesn’t that sound simple? However, removing the plastic part from the mold can be a challenge. That’s where the ejector system steps in.

What is an Ejector System?

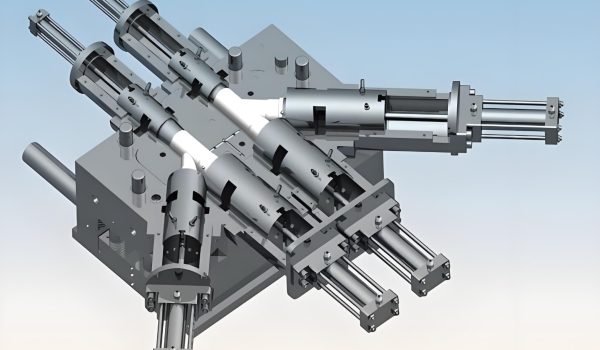

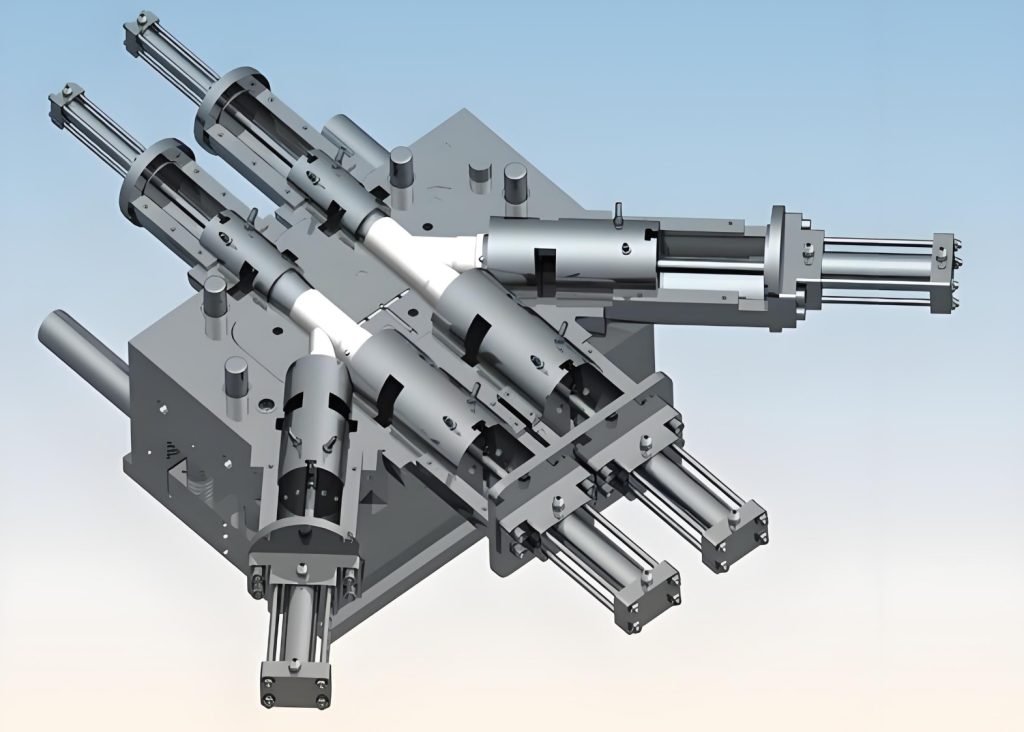

The ejector mechanism consists of components positioned in the injection mold. Upon completion, it removes the completed plastic part from the mold.

It’s as if you were baking a cake in a cake mold. When the cake is ready, gently push or tap the mold to get it out. You can’t just tap the mold in injection molding. We need an integral method to push the plastic component out safely.

Why is the Ejector System Important?

The ejector system is crucial in injection molds because the success of the process relies heavily on this component. Most importantly, it ejects the molded plastic without causing damage, necessary for the product’s high quality and consistency. It also aids in maintaining speed and continuity in production, pushing out each component as soon as it is formed and cool. This velocity is critical in industries needing large volumes of parts in short time periods.

The ejector system also allows the reuse of mold repeatedly without manual interference, which benefits time and labor cost savings.

It guarantees that each part makes it to the same size, shape, and quality. If the system did not exist, they would remove the parts by hand, which is a slow process that increases the likelihood of defects and damage. In short, it’s integral to keeping your injection molding running fast and accurate.

Main Components of an Ejector System

Let’s break down the important pieces of an ejector system:

Ejector Pins

Ejector pins are small metal rods that help push the plastic part out of the mold. They progress when the mold opens. Injection molds are designed in a variety of shapes and sizes.

Ejector Plate

The ejector pins are held in place by the ejector plate. It swings inward to push the pins outward so the mold can close again.

Return Pins or Springs

These allow the ejector pins to return to their original position after they push the part out.

Guide Pins

Guide pins keep everything in the ejector system going in the right direction without any play.

How Does the Ejector System Work?

Here’s a look at the ejector system step by step:

- The plastic gets injected into the mold, forming the shape.

- The plastic cools and hardens.

- The mold opens.

- The ejector plate heads into the forward position.

- The ejector pins push out the solid plastic part.

- The ejector plate and pins are pushed back by the return pins or springs.

- The mold closes, ready for the next round.

It all happens incredibly quickly—sometimes in seconds flat!

Types of Ejection Methods

Molded parts can be ejected out in a few different ways. The product shape/size and the design of the mold determine the technique. Below are the types most commonly seen:

Pin Ejection

This is the (by far) most used method. Ejector pins force the part out directly.

Sleeve Ejection

For round or tubular parts. A hollow sleeve pushes the piece out.

Blade Ejection

Used for flat or thin parts. A thin metal blade pushes the part.

Air Ejection

Air is injected into the mold to push the part out carefully.

Common Problems in Ejector Systems

Ejector systems are simple, but problems can occur. Here are some common issues:

Ejector Marks

Sometimes, the pins leave tiny marks on the plastic part. This can happen if the pressure is too high or you have not inserted the pins correctly.

Sticking Parts

If the part becomes stuck and doesn’t pop right out, it can delay production. Poor Mold Design or Weak Ejector System

Pin Breakage

They can snap if the pins are too thin or the pressure is too high. This can be averted with regular maintenance.

How to Optimize the Ejector System

In order to ensure perfect functionality of the ejector system, some best practices should be followed. Use the correct number of ejector pins first, as too little could cause part stick while too much could cause markings. In addition, these pins have to be placed in suitably balanced positions for a uniform ejection to prevent distortions of the part. You should select the proper ejection method , which will vary based on the shape and complexity of your part — pin, sleeve, blade, air, or stripper plate.

Routine maintenance is a big one as well. Regularly cleaning the mold and checking the condition of the ejector pins can prevent buildup and mechanical malfunctions. Finally, always work with high-quality material when creating ejector elements.

High-end materials in our product construction decrease the likelihood of breakage and wear out your tools, meaning the longer-lasting, better-performing tools. These tips will help keep your ejector system functioning efficiently, consistently, and safely, use after use.

Factors to Consider When Designing an Ejector System

The best ejector system to use will need to be engineered into the design. Some important factors affecting cycle time are the product size and shape, the material being shaped, and the complexity of the mold design. The geometric orientation of the parts is such that the forces created should be balanced to avoid distortion, and the ejector pins should not cause the same.

You must also match the number of pins to the part geometry to prevent bending or sticking. Furthermore, cooling time and mold opening speed should be coordinated with ejection timing for smooth removal. Choosing the correct method of ejection, whether pin, air, or stripper plate, is another critical step that impacts part quality and overall throughput.

Safety Considerations During Ejection

Safety is essential while working with injection molding machines while doing an injection for the ejection process. If these tools are not adequately enclosed by the mold or synchronized with the operation of the mold, they could pose serious hazards in the workplace. Operators should ensure that all safety interlocks are established and operational.

Routine ejector system maintenance prevents surprises and avoids injuries or damage to parts. So, too, it is repeatedly verifying pressure and speed on ejection to avoid forceful movements that could damage the product or machinery. Safety first allows manufacturers to keep their people safe and achieve constant, high-quality results.

Importance of Maintenance for Long-Term Efficiency

A well-conducted maintenance of the ejector system guarantees high efficiency, cost-effectiveness, and product consistency. Frequent inspections can identify early signs of wear, misalignment, or damage that could lead to defective products or system failure. Parts of the machine, such as pins and plates, need to be cleaned and lubricated to ensure that the system runs smoothly while preventing mold contamination.

Without attention, minor problems in the ejector system can rapidly turn into larger downtimes and increased maintenance expenses. Use of proper maintenance must be documented and strictly followed to avoid untimely breakdown and improve the service life of both ejector components and complete injection mold. Proactive care ensures the safe and efficient operation of your production lines.

Learn More About High-Quality Injection Molds at Fengchi

Fengchi is focused on the best solutions in the field of plastic manufacturing. Injection molding is your core competency, but we can help you end-to-end with CNC machining, mold tooling, prototype development, and production optimization.

Whether you are looking for design advice, need to scale up your production, or need long-term tooling solutions, our skilled team is with you. Working with you, we apply precision engineering with cutting-edge technology to create molds that not only perform but also last longer and drive down costs with time. With custom solutions designed to fit your unique needs, learn how Fengchi can help you deliver your project.

Final Thoughts

The ejector system is essentially the unsung hero of injection molding. It may not be visible on the finished product, but it helps ensure every piece comes out clean, quickly, and perfectly.

If you are new to plastic manufacturing or interested in how plastic items are produced, the following information about injection molds and the ejector system will give you better insight into the inner workings.