Did you know that nearly 80% of manufacturing failures are attributed to the improper selection of materials? One crucial property that can make or break your material choice is its ability to deform without breaking.

This property, known as ductility, is vital in applications where materials are subjected to bending, stretching, or other forms of deformation.

Understanding ductility and its implications on material performance is essential for manufacturers and engineers. It directly impacts the durability and reliability of the final product.

As you consider materials for your next manufacturing project, understanding the role of ductility can help you make more informed decisions, potentially saving you from costly failures.

Understanding Ductility in Materials

When selecting materials for various applications, understanding their ductility is crucial for ensuring the longevity and performance of the final product. Ductility refers to a material’s ability to deform under tensile stress without failing. This property is critical in many engineering and construction applications where materials are subjected to various types of loading.

Definition and Basic Concepts

Ductility is defined as a measure of a material’s ability to undergo significant plastic deformation before rupturing. This deformation is permanent and occurs when a material is subjected to tensile stress beyond its elastic limit. Initially, materials deform elastically when stress is applied; however, once the stress exceeds the material’s elastic limit, plastic deformation occurs. Understanding this transition from elastic to plastic deformation is vital for predicting how materials will behave under different loading conditions.

Ductility vs. Elasticity

While both ductility and elasticity describe how materials respond to stress, they are distinct properties. Elasticity refers to a material’s ability to return to its original shape after the stress is removed, provided the stress does not exceed the material’s elastic limit. In contrast, ductility measures how much a material can deform plastically without breaking. A material can be highly elastic but have low ductility, or vice versa. For instance, some materials can stretch significantly (high ductility) but not return to their original shape after the load is removed (low elasticity).

Understanding the difference between these properties is essential for selecting the right materials for specific applications. For example, in applications where materials are subjected to repeated loading and unloading, elasticity is crucial. However, in situations where materials are subjected to significant deformation without failing, ductility is more relevant.

The Importance of Ductility in Manufacturing

Ductility plays a crucial role in manufacturing, affecting both material processing and product performance. It is a vital property that determines a material’s ability to withstand stress and deformation without failing.

Role in Material Processing

Ductility is essential for certain manufacturing operations, such as cold working, where materials are shaped without heating. Materials with high ductility can be formed into various shapes without breaking, making them ideal for processes like bending, drawing, and forging.

- Ductile materials can be easily shaped and formed.

- High ductility reduces the risk of material failure during processing.

- Ductility allows for more complex product designs.

Impact on Product Performance

The ductility of a material directly impacts the performance and reliability of the final product. Ductile materials can absorb energy and withstand unexpected overloads and impact forces, reducing the risk of catastrophic failures.

- Ductile materials provide visual warning signs before failure.

- Ductility enhances a product’s resistance to fatigue and crack propagation.

- Products made from ductile materials are generally safer and more reliable.

Common Ductile Materials for Manufacturing

When it comes to manufacturing, selecting materials with the right level of ductility is crucial for product performance and durability. Ductility, the ability of a material to deform without breaking, is a key property that influences how materials behave under stress. Manufacturers often choose materials based on their ductility to ensure they can be formed into the desired shape without failing.

Highly Ductile Metals

Highly ductile metals are preferred in applications where significant deformation is required without fracture. Metals like copper and certain aluminum alloys exhibit high ductility, making them suitable for applications such as wiring and complex forming processes. These metals can be stretched and shaped extensively, offering versatility in manufacturing.

Moderately Ductile Materials

Moderately ductile materials strike a balance between formability and strength, making them suitable for a wide range of applications. Steel alloys, for instance, offer varying levels of ductility based on their carbon content and alloying elements. Lower carbon content generally increases ductility, while higher carbon content enhances strength but reduces ductility. Aluminum alloys and certain copper alloys also fall into this category, providing a good balance between ductility and other mechanical properties.

Moderately ductile materials are commonly used in automotive, construction, and consumer products. For example, steel with moderate ductility is used in car body panels, offering a balance between formability and crashworthiness. Aluminum alloys are used in aircraft and automotive components, where moderate ductility is sufficient for the application while providing the benefits of being lightweight.

Factors Affecting Ductility

Ductility is a complex property influenced by multiple factors, including temperature, chemical composition, and microstructure. Understanding these factors is crucial for optimizing material performance in various applications.

Temperature Effects

Temperature significantly affects a material’s ductility. As temperature increases, many materials become more ductile, while others may become brittle. For instance, some metals exhibit increased ductility at elevated temperatures due to enhanced atomic mobility, allowing for greater plastic deformation before failure.

Chemical Composition

The chemical composition of a material plays a vital role in determining its ductility. Alloying elements can either enhance or reduce ductility, depending on their interaction with the base material. For example, certain alloying elements can strengthen grain boundaries, improving ductility, while others may form brittle phases that reduce it.

Grain Size and Crystal Structure

Grain size and crystal structure are fundamental to a material’s ductility. Typically, smaller grain sizes lead to increased tensile strength and ductility due to grain boundary hardening. The crystal structure, whether face-centered cubic (FCC), body-centered cubic (BCC), or hexagonal close-packed (HCP), also fundamentally determines ductility potential. FCC metals like copper and aluminum generally exhibit higher ductility than BCC or HCP metals due to their crystal structure.

The grain size effect on ductility is attributed to the increased grain boundary area, which acts as a barrier to dislocation movement. Refining grain size can significantly enhance ductility; for instance, reducing ferrite grain size from 40 microns to 1.3 microns can eliminate the ductile-to-brittle transition temperature (DBTT) in ferritic steel, preventing brittle fracture.

You can modify grain structure and enhance ductility through processing techniques like annealing, cold working, and grain refinement. Understanding the relationship between crystal defects, dislocations, and plastic deformation is key to optimizing material ductility.

Ductility vs. Brittleness: Material Behavior Under Stress

When materials are subjected to stress, their behavior can be broadly categorized into two types: ductile and brittle. Understanding the differences between these behaviors is crucial for selecting the right materials for various applications.

Characteristics of Ductile Failure

Ductile failure is characterized by significant plastic deformation before fracture. Materials that exhibit ductile behavior can absorb a considerable amount of energy before failing, often providing warning signs such as necking or deformation.

- Significant plastic deformation

- Warning signs before failure

- Energy absorption

Characteristics of Brittle Failure

In contrast, brittle failure occurs with minimal plastic deformation, leading to sudden and catastrophic failure. Brittle materials fracture rapidly, often without warning, and typically have flat fracture surfaces.

- Minimal plastic deformation

- Rapid crack propagation

- Flat fracture surfaces

The behavior of a material under stress, whether ductile or brittle, depends on its cohesive characteristics, temperature, and other factors. For instance, inorganic materials like ceramics and semiconductors are generally brittle due to their strong ionic or covalent bonds, which restrict atomic movement.

Understanding these characteristics is essential for material selection and design, especially in applications subject to impact or variable loading. By recognizing the differences between ductile and brittle behaviors, you can make informed decisions to ensure the safety and performance of your materials.

Measuring Ductility in Materials

To ensure the optimal performance of materials, it’s essential to understand the methods of measuring ductility. Ductility is a critical property that determines how a material behaves under stress, particularly its ability to deform without breaking.

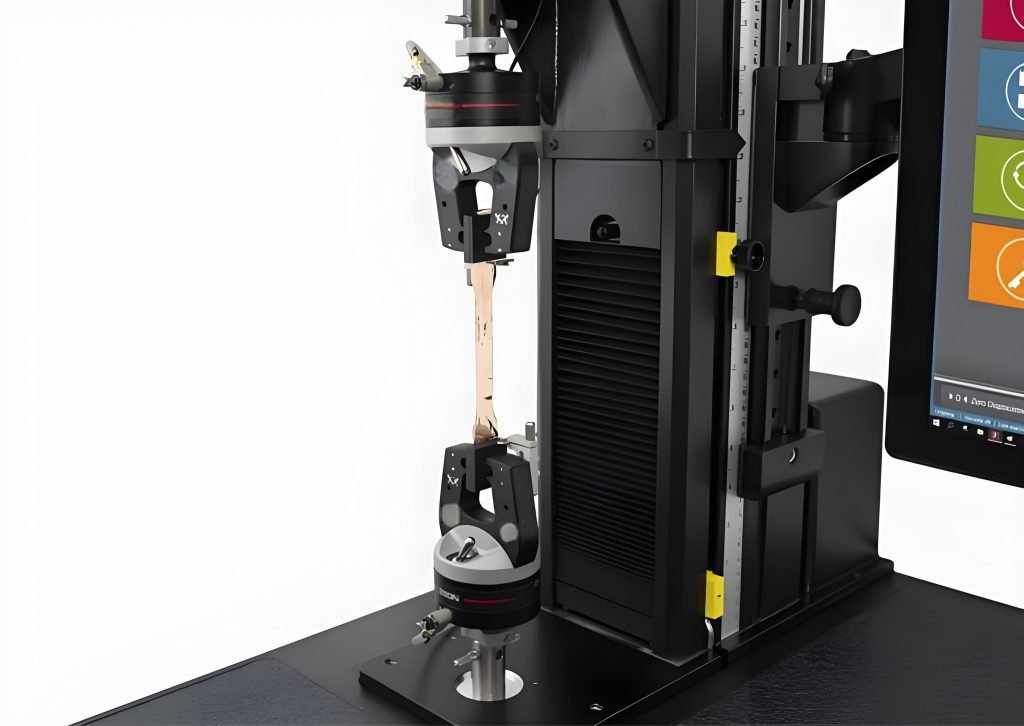

Tensile Testing Methods

Tensile testing is the most common method used to measure ductility. During a tensile test, a sample is subjected to increasing tension until it fractures. The test measures various parameters, including elongation and reduction in area, which are crucial for determining ductility.

Interpreting Ductility Test Results

Interpreting the results of a ductility test involves understanding the significance of percent elongation and reduction in area measurements. According to Shigley’s Mechanical Engineering Design, a ‘significant’ ductility is denoted by about 5.0 percent elongation. It’s also important to consider how sample dimensions affect the test results, as ductility measurements can be influenced by the sample’s geometry.

When interpreting test results, you’ll need to account for both uniform elongation before necking and post-necking elongation. This understanding helps in comparing ductility across different materials and testing standards, enabling you to make informed material selections.

Conclusion: Making Informed Material Choices Based on Ductility

In the world of manufacturing, ductility is a key factor that influences the performance and reliability of materials. When choosing materials, considering ductility is vital to ensure they can withstand various stresses and loads without failing.

By understanding how to balance ductility with other material properties, you can make informed decisions for your manufacturing applications. This involves evaluating trade-offs between high ductility materials and those with higher strength or cost-effectiveness, and prioritizing ductility based on application requirements.

Ultimately, considering ductility as a critical property will help you implement a more systematic approach to material selection, preventing manufacturing problems and product failures.

FAQ

What is the difference between ductility and malleability?

Ductility refers to a material’s ability to deform under tensile stress, while malleability is its ability to deform under compressive stress. Both properties allow materials to change shape without fracturing, but they are measured and applied differently in various manufacturing processes.

How does temperature affect the ductility of a material?

Temperature significantly impacts a material’s ductility. Generally, as temperature increases, the ductility of a material also increases, making it more capable of plastic deformation. Conversely, at lower temperatures, materials tend to become more brittle.

What role does grain size play in determining a material’s ductility?

The grain size of a material can influence its ductility. Typically, materials with finer grain sizes exhibit higher ductility due to the increased grain boundary area, which can help to absorb and distribute stress more effectively.

How is ductility measured in materials?

Ductility is commonly measured through tensile testing, where a sample is subjected to increasing tensile stress until it fractures. The elongation and reduction in area at the point of fracture are used as indicators of the material’s ductility.

Can a material be both strong and ductile?

Yes, certain materials can exhibit both high strength and good ductility. The balance between these properties is crucial for many applications, as high strength is often required for load-bearing purposes, while ductility is necessary for absorbing impact and resisting fracture.

How does chemical composition affect a material’s ductility?

The chemical composition of a material plays a significant role in determining its ductility. Certain elements can enhance or detract from a material’s ability to deform plastically. For instance, some alloying elements can improve ductility by modifying the material’s microstructure.