In the world of CNC machining, the right cutting fluids can make all the difference in achieving high-quality results. Did you know that the improper use of cutting fluids can lead to reduced tool life, poor surface finish, and decreased manufacturing efficiency?

Industry leaders in Aerospace, Energy, Medical, and Military manufacturing trust SterlingCool cutting fluids for their CNC machining needs, achieving the same quality results at a significantly lower cost. As you explore the world of CNC machining, understanding the functions and selection criteria for cutting fluids is crucial for optimizing your processes.

This comprehensive guide will walk you through the various types of fluids used in CNC machining, their specific functions, and how to choose the optimal fluid for different materials and operations, ultimately improving your manufacturing efficiency and tool longevity.

Understanding Cutting Fluids in CNC Machining

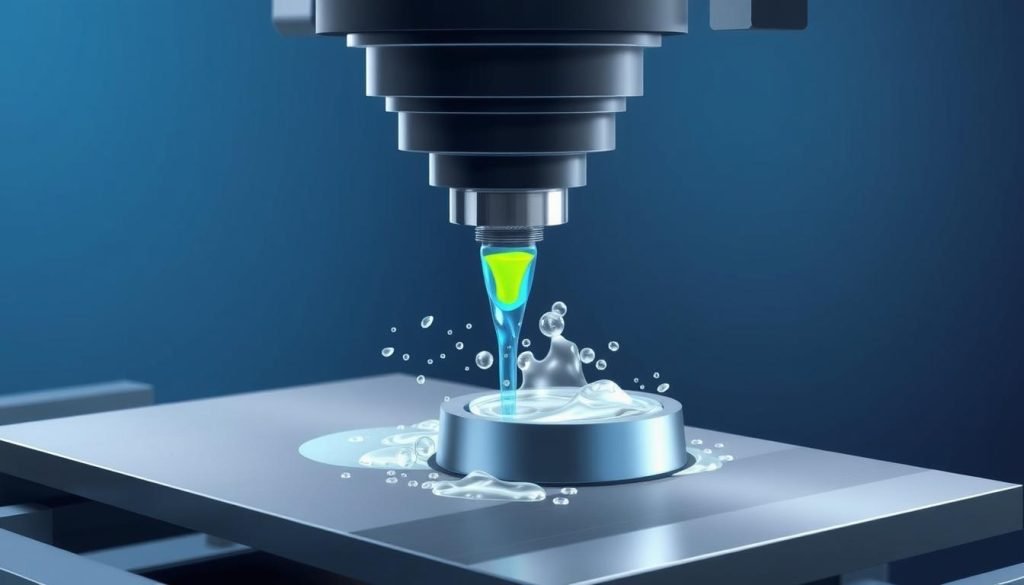

CNC machining relies heavily on cutting fluids to achieve efficient results. Cutting fluids are specialized liquids designed to improve machining processes.

Definition and Importance

Cutting fluids are crucial for reducing friction and heat at the cutting zone. They have become essential in modern manufacturing.

Evolution in Modern Manufacturing

Over decades, cutting fluids have evolved from simple oils to sophisticated formulations. Our team of chemists, with over 70 years of combined experience, can tailor cutting fluids to your needs, including making “direct SDS crossovers” for less money.

- Cutting fluids improve machining processes by reducing friction and heat.

- These fluids have evolved significantly over decades of manufacturing experience.

- Modern cutting fluids address multiple challenges: heat dissipation, lubrication, chip evacuation, and corrosion prevention.

- Proper fluid selection is crucial with the advancement of high-speed machining.

- Understanding cutting fluids helps machinists optimize processes, reduce costs, and improve part quality.

- The evolution of cutting fluids parallels developments in CNC technology.

Key Functions of Cutting Fluids

The effectiveness of CNC machining operations heavily relies on the functions of cutting fluids. These fluids are multifaceted, serving to enhance the machining process in several critical ways.

Cooling Properties

Cutting fluids provide essential cooling, preventing thermal damage to the workpiece and maintaining dimensional accuracy by dissipating heat generated during machining.

Lubrication Benefits

Effective lubrication reduces friction between the cutting tool and workpiece, minimizing energy consumption and significantly extending tool life through superior lubrication properties.

Chip Removal and Corrosion Protection

Cutting fluids also facilitate chip removal and offer corrosion protection, preventing oxidation on both machine components and freshly machined surfaces, thus maintaining part quality.

Basic Classifications of Cutting Fluids

Understanding the basic classifications of cutting fluids is essential for effective machining. You need to know the different types to select the right one for your CNC machining operations.

Straight Oils

Straight oils are undiluted petroleum or vegetable-based products providing excellent lubrication but limited cooling capacity, ideal for low-speed, high-pressure applications.

Soluble Oils and Emulsions

Soluble oils combine mineral oils with emulsifiers, creating emulsions that balance cooling and lubrication properties for general-purpose machining. These water-soluble emulsions typically contain 3-10% oil concentrate in water.

Synthetic and Semi-Synthetic Fluids

Synthetic fluids contain no petroleum oils, are completely water-soluble, and provide superior cooling, cleanliness, and stability. Semi-synthetic fluids represent a hybrid approach, balancing the benefits of both synthetic and conventional fluids.

Selecting Cutting Fluids Based on Workpiece Material

To achieve optimal results, it’s essential to select cutting fluids that are compatible with your workpiece material. The right cutting fluid can significantly impact tool life, surface quality, and overall machining efficiency.

Aluminum and Non-Ferrous Alloys

For aluminum and non-ferrous alloys, you should use cutting fluids that prevent built-up edge formation and staining, ensuring excellent surface finish quality. Avoid fluids with high sulfur content, as they can cause discoloration.

Ferrous Materials and Cast Iron

Ferrous materials and cast iron require cutting fluids with higher lubricity and extreme pressure additives to combat their abrasive nature. Proper fluid filtration is also crucial to prevent tool wear.

Exotic and Difficult-to-Machine Materials

Exotic materials like titanium and Inconel demand specialized cutting fluids that can withstand extreme heat generation while providing superior lubrication, ensuring tool performance and part quality.

Matching Cutting Fluids to Machining Operations

To achieve optimal results in CNC machining, it’s essential to match the cutting fluid to the specific operation. The right cutting fluid can enhance tool performance, reduce wear, and improve surface finish.

Milling and Turning Applications

Milling and turning operations benefit from cutting fluids that balance cooling and lubrication. Higher-speed operations require enhanced cooling capabilities.

Drilling and Tapping Requirements

Drilling and tapping operations need cutting fluids with superior penetration and extreme pressure additives. Tapping benefits from fluids with enhanced lubricity to reduce torque and prevent tap breakage.

Grinding and Finishing Operations

Grinding operations require cutting fluids with excellent cooling properties and good flushing ability. Finishing operations demand cutting fluids that leave minimal residue and provide a superior surface finish.

By selecting the appropriate cutting fluid for each machining operation, you can optimize tool performance, improve surface finish, and extend tool life. For instance, a soluble fluid range based on advanced biodegradable ester technology can maintain high surface finish and dimensional accuracy, making it suitable for a wide range of ferrous alloys cutting processes.

Optimizing Cutting Fluid Performance

To get the most out of your cutting fluids, optimizing their performance is crucial. Proper management of cutting fluids can significantly impact the quality and efficiency of your machining operations.

Concentration Management

Maintaining the optimal concentration of cutting fluids is critical. Too low concentrations can reduce lubricity and corrosion protection, while too high concentrations can waste product and cause residue issues. Regular refractometer readings help maintain the proper concentration levels, typically between 5-10% for most water-soluble fluids.

Monitoring and Testing Procedures

Regular monitoring of pH levels, microbial contamination, and tramp oil is essential. Acidic conditions can accelerate corrosion, while excessive alkalinity may cause skin irritation. Bacterial and fungal contamination can degrade fluid quality, and tramp oil can impair performance. Implementing a comprehensive monitoring program ensures consistent cutting fluid performance and extends its useful life.

Maintenance and Disposal Considerations

Proper maintenance and disposal of cutting fluids are crucial for optimizing their performance and ensuring environmental compliance. Effective management involves several key practices that help extend fluid life and minimize environmental impact.

Extending Fluid Life

To extend the life of your cutting fluids, implement proper filtration systems to remove particulates and tramp oils. Regular sump cleaning is also essential to prevent the buildup of sludge and biofilms. Additionally, using splash guards and covers can minimize contamination and fluid loss.

- Proper filtration systems remove particulates and tramp oils, significantly extending useful life and maintaining consistent corrosion protection.

- Regular sump cleaning prevents buildup of sludge and biofilms that harbor bacteria and compromise fluid performance.

- Implementing splash guards and covers minimizes contamination and fluid loss through evaporation.

- Many facilities implement fluid recycling programs that can extend fluid life by 2-3 times.

Environmental and Regulatory Compliance

Modern cutting fluids are formulated with environmental considerations in mind, but still require proper disposal in accordance with local regulations. Understanding and complying with regulatory requirements for handling, storage, and disposal is essential for avoiding fines and ensuring workplace safety.

- Modern cutting fluids are designed to be environmentally friendly, but proper disposal is still necessary.

- Compliance with regulatory requirements is crucial for avoiding fines and ensuring workplace safety.

- Documentation of fluid maintenance activities and disposal practices is increasingly important for regulatory compliance.

Conclusion

Ultimately, understanding cutting fluids is key to enhancing tool life and part quality in CNC machining. Selecting the right cutting fluid impacts machining efficiency, and factors like workpiece material and desired surface finish are crucial.

Proper maintenance and monitoring ensure consistent performance and extended fluid life, protecting your investment in premium oils. The evolution of cutting fluid technology continues to advance, offering improved lubrication properties and environmental compatibility.

Partnering with experienced suppliers like SterlingCool, trusted by industry leaders, can provide valuable insights. By choosing the right cutting fluid and maintaining it properly, you can optimize your machining processes.