Did you know that nearly 70% of manufactured parts require some form of countersinking to ensure a flush finish? Countersink holes play a vital role in modern engineering and manufacturing, providing both functional and aesthetic benefits.

These conical holes allow the head of a screw to sit flush or below the surface, giving products a professional and polished look. As an engineer, manufacturer, or designer, understanding countersink technology is essential for creating high-quality products.

This comprehensive guide will explore the fundamentals of countersink holes, their applications, and best practices for implementation in your manufacturing processes, helping you to create products with clean, professional finishes.

Understanding Countersink Holes in Engineering

To grasp the concept of countersink holes, it’s essential to understand the role of countersinks in engineering. Countersinks are tools used to create a conical hole for flathead screws, allowing them to sit flush with the surface of the material.

What is a Countersink Hole?

A countersink hole is a conical recess created at the opening of a drilled hole, specifically designed to accommodate the angled underside of flathead screws or other fasteners. The distinctive V-shaped profile of a countersink hole enables the fastener head to sit flush with or slightly below the surface of the material, creating a smooth, uninterrupted surface.

Countersink holes are characterized by their angle, diameter, and depth. The diameter of the countersink hole must match the diameter of the screw head, while the depth determines how far below the surface the screw head will sit. Unlike regular holes, countersink holes have two key measurements: the through-hole diameter for the screw shaft and the countersink diameter for the screw head.

Types of Countersink Holes

In engineering, countersink holes are not a one-size-fits-all solution; they come in different types to suit specific needs. The type of countersink used depends on the application, the type of screw or fastener, and the desired finish.

Flathead Countersink

The flathead countersink is one of the most common types, used to accommodate flathead screws. This countersink creates a conical recess that allows the screw head to sit flush with the surface of the material. Flathead countersinks are widely used in construction, furniture making, and other applications where a flush surface is required.

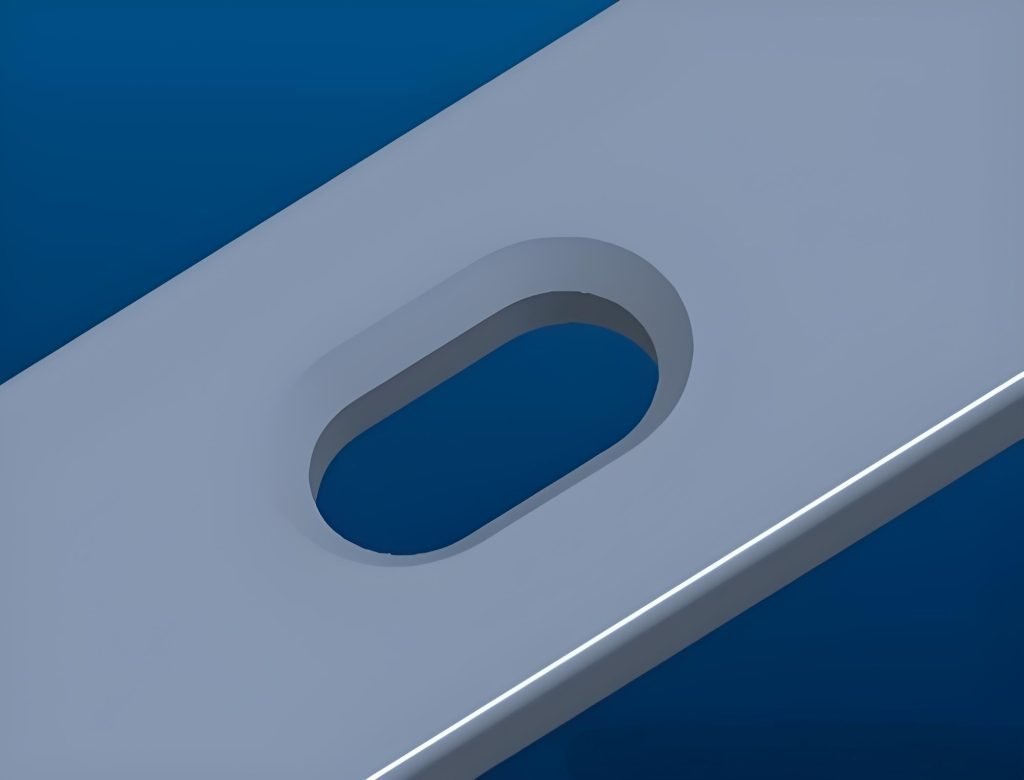

Oval-Head Countersink

Oval-head countersinks are used for oval-head screws and provide a countersink with a slightly rounded edge. This type is beneficial when a high degree of surface finish is required, as it provides a smooth transition between the screw head and the material surface. Oval-head countersinks are often used in applications where aesthetics are important.

Round-Head Countersink

Round-head countersinks are less common but serve specific purposes, particularly with round-head screws. Unlike traditional countersinks, round-head countersinks create a spherical or partially spherical depression. This type is useful when a prominent, aesthetically pleasing screw head is desired. Round-head countersinks are often used in historical reproductions, period furniture, and applications where frequent removal of fasteners is necessary, as they provide better grip for tools.

Some of the key benefits of round-head countersinks include their ability to provide a secure and aesthetically pleasing connection when mounting hardware with flat, non-countersunk screw holes. While they do not offer a flush surface, they are advantageous in certain design applications.

When to Use Countersink Holes

In engineering, countersink holes play a vital role in ensuring the structural integrity and aesthetic appeal of a project. The decision to use countersink holes depends on various factors, including the type of material, the design requirements, and the intended application.

Component Alignment Applications

You need countersink holes for component alignment in assembly applications. Countersink holes help in aligning parts correctly, ensuring that the assembly is properly fitted together. This is particularly important in applications where precision is crucial.

Aesthetic Considerations

Countersink holes are also used to improve the aesthetic appeal of a product. By allowing the screw head to sit flush with the surface, countersink holes provide a smooth finish, enhancing the overall appearance of the product. This is especially relevant in consumer products where appearance matters.

Safety Requirements

In some applications, countersink holes are necessary to meet safety requirements. For instance, in environments where protruding screw heads could pose a hazard, countersink holes help to eliminate this risk by recessing the screw head below the surface.

Structural Integrity Benefits

Countersink holes significantly contribute to the structural integrity of a material or assembly. By distributing the load of the screw head across a wider area, countersink holes reduce the risk of material damage, such as splitting or cracking. This is particularly beneficial in materials like wood or certain plastics that are prone to damage under concentrated pressure. For example, in wooden furniture, countersink screws help to evenly distribute stress at joints, preventing the wood from splitting and ensuring greater durability. Moreover, in vibration-prone environments, countersunk fasteners are less likely to work loose over time, maintaining the structural integrity of the assembly.

By understanding when to use countersink holes, you can improve the quality, safety, and performance of your projects. Whether it’s for component alignment, aesthetic considerations, safety requirements, or structural integrity benefits, countersink holes play a crucial role in achieving the desired outcomes in various engineering applications.

How to Make a Countersink Hole

To achieve professional-grade countersink holes, you’ll need to understand the process and the tools involved. Creating a countersink hole is a task that requires precision and the right equipment.

Required Tools and Materials

To start, you’ll need a few essential tools and materials. These include a drill press or a hand drill, a countersink bit, and the material you’re working with. The countersink bit is specifically designed to create the conical hole that allows the screw head to sit flush with the surface.

The choice of drill bit and countersink angle depends on the type of screw you’re using. For metric screws, a 90° countersink angle is standard, while for imperial or standard screws, an 82° angle is typically used.

| Screw Type | Countersink Angle | Drill Bit Size |

|---|---|---|

| Metric | 90° | Matches screw head diameter |

| Imperial/Standard | 82° | Matches screw head diameter |

Step-by-Step Process

The process of making a countersink hole involves several key steps. First, mark the location of the hole accurately. Then, drill a pilot hole if necessary, followed by the countersink hole using the appropriate bit.

It’s crucial to control the depth of the countersink to ensure the screw head sits flush with the surface. Using a depth stop or making test holes in scrap material can help achieve the correct depth.

Tips for Precision Countersinking

To achieve precise countersink holes, start with accurate measurements and markings. Double-check your dimensions before drilling to ensure precise hole placement and alignment.

Using the correct countersink angle for your fastener type is also crucial. For consistent results across multiple holes, consider creating a simple jig or using a drill press with depth stop settings.

When working with harder materials, start with a smaller pilot hole and gradually increase to the final size to reduce stress on both the material and the tool.

Countersunk Hole Size Chart and Specifications

Countersunk hole specifications are vital for ensuring the proper fit and function of fasteners in various applications. You need to understand these specifications to achieve precision in engineering and manufacturing.

Metric Countersink Specifications

Metric countersink specifications are used globally and are essential for manufacturing processes that require precision. The standard countersink angle for metric fasteners is typically 90°. The depth of the countersink is calculated based on the major hole diameter and the countersink angle.

For instance, when working with metric screws, the countersink diameter must be matched to the screw size to ensure a flush fit. Common metric screw sizes range from M2 to M20, with corresponding countersink diameters that must be precisely calculated.

Imperial Countersink Specifications

Imperial countersink specifications differ from metric specifications, using an 82° countersink angle for imperial fasteners. The depth of the countersink hole is inversely related to the sinking angle when the major diameter remains constant.

When working with imperial specifications, it’s crucial to convert all measurements to inches to avoid errors. Common imperial screw sizes range from #2 (0.086″ diameter) to 1″ and larger, requiring corresponding countersink diameters for proper fastener seating.

Countersink vs. Counterbore Holes

Countersink and counterbore holes serve distinct purposes in engineering and manufacturing. While both are used to accommodate fasteners, they differ significantly in design and application. Understanding these differences is crucial for selecting the right type of hole for your specific needs.

Key Differences in Design

The primary difference between countersink and counterbore holes lies in their geometry. Countersink holes are conical, allowing flathead screws to sit flush with or below the surface. In contrast, counterbore holes are cylindrical, providing a recessed pocket for socket head cap screws or other fasteners with flat bottoms. This fundamental design difference dictates their respective applications. For instance, countersink holes are ideal for compact designs where space is limited, such as in smartphones.

When to Choose Each Type

Your choice between countersink and counterbore holes depends on the specific requirements of your project. Opt for countersink holes when working with flathead screws and when a flush finish is necessary for aesthetic or functional reasons. On the other hand, choose counterbore holes when using socket head cap screws or when your design prioritizes strong attachment over space-saving considerations. For example, counterbore holes are often used in heavy machinery where high torque is involved. Ultimately, the decision hinges on the type of fastener, material properties, and whether your application prioritizes aesthetics, space efficiency, or maximum holding strength.

Conclusion

To achieve precision in countersinking, proper tool selection, careful measurement, and attention to detail are crucial. For professional manufacturing needs, services like CNC machining, injection molding, and precision fabrication can create perfect countersink holes to exact specifications. To get started with your next project, consider reaching out for an instant quote from manufacturing specialists who understand the intricacies of precision hole creation.

By mastering countersink technology, you can enhance both the form and function of your products, whether you’re designing consumer electronics, furniture, automotive components, or industrial machinery. Let our team of manufacturing specialists help you perfect your design, including those tricky countersink holes, and get an instant quote today.

FAQ

How do I choose the correct drill bit for countersinking?

To choose the correct drill bit, you need to consider the type of material you’re working with and the size of the screw or fastener. A drill bit with a countersink attachment or a specialized countersink drill bit is ideal for creating a countersink hole.

What is the difference between a countersink and a counterbore hole?

A countersink hole is designed to allow the head of a screw to sit flush with the surface, while a counterbore hole is a larger diameter hole that allows the head of a screw or bolt to be recessed below the surface.

Can I use a countersink hole with any type of screw or fastener?

No, you should choose a screw or fastener that is designed for countersinking, such as a flathead screw. Using the wrong type of screw or fastener can result in a poor fit or damage to the surrounding material.

How do I ensure precision when creating a countersink hole?

To ensure precision, use a drill press or a CNC machining center, and carefully align the drill bit with the center of the hole. You can also use a countersink jig or fixture to help guide the drill bit.

What are some common applications for countersink holes?

Countersink holes are commonly used in various industries, including aerospace, automotive, and construction, where a smooth surface finish is required or where the screw head needs to be recessed for safety or aesthetic reasons.

Can I create a countersink hole in different materials, such as metal or plastic?

Yes, you can create a countersink hole in various materials, including metal, plastic, and wood. However, the type of drill bit and technique used may vary depending on the material.