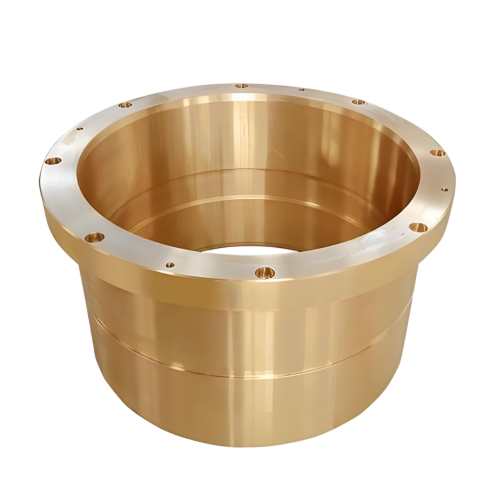

Copper Machining Services

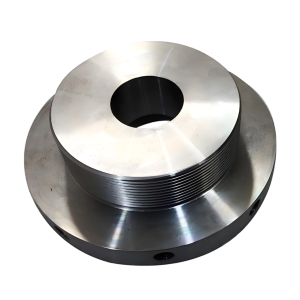

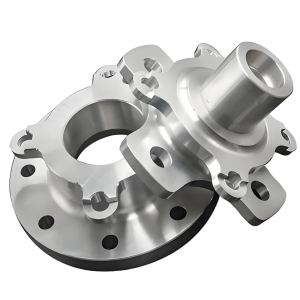

Copper CNC machining delivers precise, high-quality components by leveraging advanced milling, turning, and drilling processes. Known for excellent electrical and thermal conductivity, copper parts are widely used in electronics, aerospace, automotive, and medical industries. This service ensures tight tolerances, superior finishes, and reliable performance for complex applications.

Various Options

Functionality

Cost-effectiveness

| Specification | Capability |

| Tolerance | ±0.005mm (±0.0002″) |

| Surface Finish | Up to Ra 0.4μm |

| Minimum Wall Thickness | 0.5mm (0.02″) |

| Maximum Part Dimensions | 600mm × 400mm × 300mm |

| Minimum Feature Size | 0.2mm (0.008″) |

| Thread Sizes | M1.6 to M36 |

| Certifications | ISO 9001:2015, AS9100D |

Understanding Copper in CNC Machining

Copper stands out in the manufacturing world due to its exceptional electrical and thermal conductivity, making it invaluable for numerous applications. However, these same properties present unique challenges during the CNC machining process.

Key Properties of Copper

- Excellent electrical conductivity (second only to silver)

- Superior thermal conductivity for heat dissipation

- High ductility and malleability

- Natural antimicrobial properties

- Good corrosion resistance in various environments

- Recyclable without loss of properties

Speak With Our Engineering Team

Discuss your specific application needs with our CNC machining specialists.

Machining Challenges with Copper

While copper offers exceptional properties, it presents several machining challenges that require specialized expertise:

High Ductility

Copper's softness can cause it to deform rather than cut cleanly, requiring precise feed rates and sharp tooling.

Heat Management

Copper's high thermal conductivity spreads heat quickly, affecting dimensional accuracy and tool life during machining.

Built-up Edge

Copper particles can adhere to cutting tools, creating a built-up edge that affects surface finish and dimensional accuracy.

At Fecision, we've developed specialized techniques to overcome these challenges, ensuring precision results with every copper component we manufacture.

Advantages and Limitations of Copper CNC Machining

Understanding the benefits and challenges of working with copper helps in making informed decisions for your manufacturing projects.

Advantages of Copper Machining

- Exceptional electrical and thermal conductivity

- Excellent corrosion resistance in most environments

- High ductility allows for complex shapes

- Natural antimicrobial properties

- Good machinability with proper techniques

- Recyclable and environmentally sustainable

Limitations of Copper Machining

- Higher material cost compared to aluminum or steel

- Softness can lead to deformation during machining

- Requires specialized tooling and techniques

- Potential for work hardening during machining

- Susceptible to oxidation without proper finishing

- Lower strength-to-weight ratio than steel

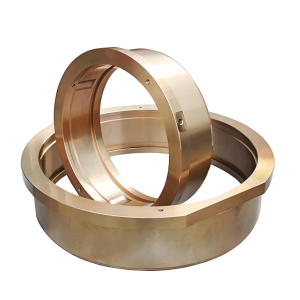

Subtypes of Copper for CNC Machining

Selecting the right copper alloy is crucial for achieving optimal performance in your application.

Each grade offers specific properties that make it suitable for different uses.

C101

(OFE, T2)

- High-purity oxygen-free copper (minimum copper content: 99.99%) with ultra-low oxygen (≤0.003%) and impurity levels.

- Ideal for applications requiring high reliability and minimal signal loss.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

220-240

69-83

90–100 (at 10⁸ cycles)

35-45

45-55

8.96

300 (continuous)

600 (intermittent)

C102

(OF, T1)

- High-purity oxygen-free copper (minimum copper content: 99.95%) with slightly higher oxygen (≤0.005%) than C101.

- Suitable for most high-conductivity applications where ultra-purity is not mandatory.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

210–230

65-80

85–95 (at 10⁸ cycles)

30-40

40-50

8.96

280 (continuous)

580 (intermittent)

C103

(OFE, TU2)

- Oxygen-free copper grade (minimum copper content: 99.95%) optimized for maximum electrical conductivity (≥101% IACS).

- Offer good ductility, compatible with cold working (e.g., drawing, bending).

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

215-235

68-82

88–98 (at 10⁸ cycles)

32-42

42-52

8.96

290 (continuous)

590 (intermittent)

C110

(ETP, T2)

- The most widely used copper grade (minimum copper content: 99.90%) and belongs to the electrolytic tough pitch (ETP) family.

- Offer excellent ductility, machinability, and affordability; versatile for general-purpose applications.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

200-220

60-75

80–90 (at 10⁸ cycles)

28-38

35-45

8.94

250 (continuous)

550 (intermittent)

C122

(DHP, TP2)

- A phosphorus-deoxidized copper (minimum copper content: 99.90%) with phosphorus added (0.015 – 0.040%) to remove oxygen, eliminating hydrogen embrittlement risks.

- Often used in welded or brazed assemblies.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

220-240

70-85

90–100 (at 10⁸ cycles)

35-45

30-40

8.93

260 (continuous)

560 (intermittent)

Copper CNC Machining Surface Finishing Options

The right surface finish enhances both the functionality and aesthetics of your copper components.

Fecision offers a comprehensive range of finishing options to meet your specific requirements.

Mechanical Finishes

- Polishing: Creates a mirror-like reflective surface

- Brushing: Produces a directional, satin appearance

- Bead Blasting: Creates a uniform matte finish

- Tumbling: Smooths edges and creates a consistent surface

Protective Coatings

- Clear Coating: Prevents oxidation while preserving appearance

- Nickel Plating: Enhances hardness and wear resistance

- Gold Plating: Improves conductivity and corrosion resistance

- Silver Plating: Maximizes electrical conductivity

Chemical Treatments

- Passivation: Improves corrosion resistance

- Patination: Creates decorative colored finishes

- Electropolishing: Smooths microscopic surface irregularities

- Anodizing: Creates a durable oxide layer (for certain alloys)

Our finishing experts can recommend the optimal surface treatment based on your component's functional requirements, environmental exposure, and aesthetic preferences.

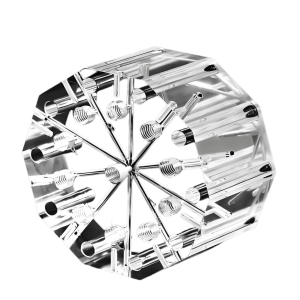

Copper CNC Machining Application

Industries We Serve

Copper's unique combination of electrical conductivity, thermal properties, and corrosion resistance makes it invaluable across numerous industries. Fecision produces precision copper components for a wide range of applications.

Medical

Electrical components for devices

Thermal management in equipment

MRI/imaging system components

Aerospace

Electrical distribution parts

Heat exchanger components

Waveguides for communication

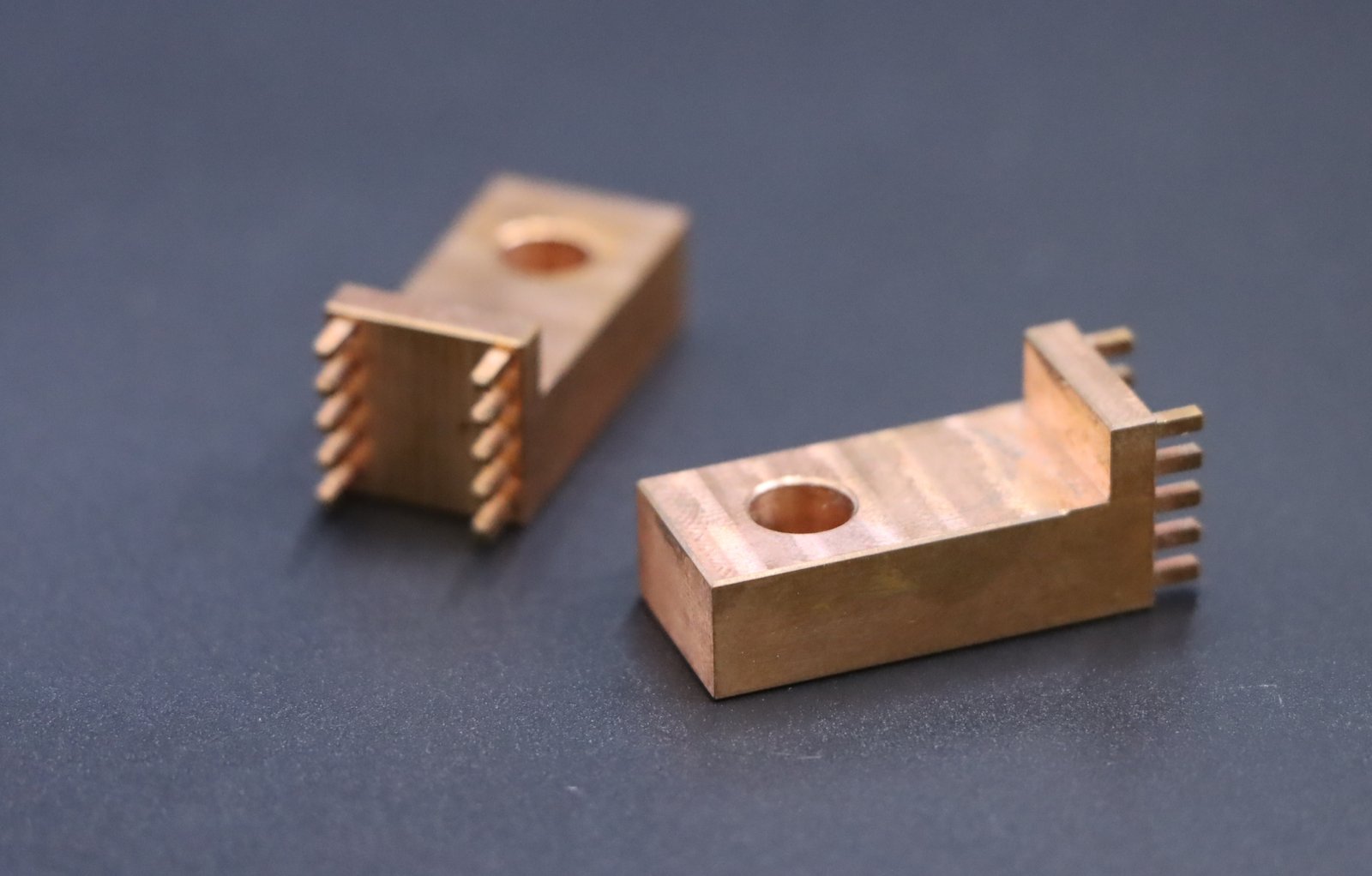

Electronics

Electrical connectors and terminals

EMI/RFI shielding components

Busbars and power distribution

Industrial

Injection molding nozzles

Induction heating components

Fluid handling systems

Copper Machining FAQs

Prefer to speak with an expert directly?

Our technical team is available to discuss your copper CNC machining requirements and provide immediate assistance.

Why Choose Fecision for Your Copper CNC Machining Needs

The right surface finish enhances both the functionality and aesthetics of your copper components.

Fecision offers a comprehensive range of finishing options to meet your specific requirements.

Ready to Experience Superior Copper CNC Machining?

Contact Fecision today to discuss your project requirements and discover how our expertise can bring your designs to life.