Electrical Discharge Machining (EDM) is a precise manufacturing process used to create complex shapes in hard materials. With over 90% of EDM operations relying on high-quality electrodes, the choice of electrode material is crucial for achieving optimal results.

Understanding the properties and performance characteristics of different copper alloy electrodes is essential for optimizing EDM operations. This comprehensive guide will explore the world of copper alloy EDM electrodes and their critical role in electrical discharge machining processes.

Understanding Electrical Discharge Machining (EDM)

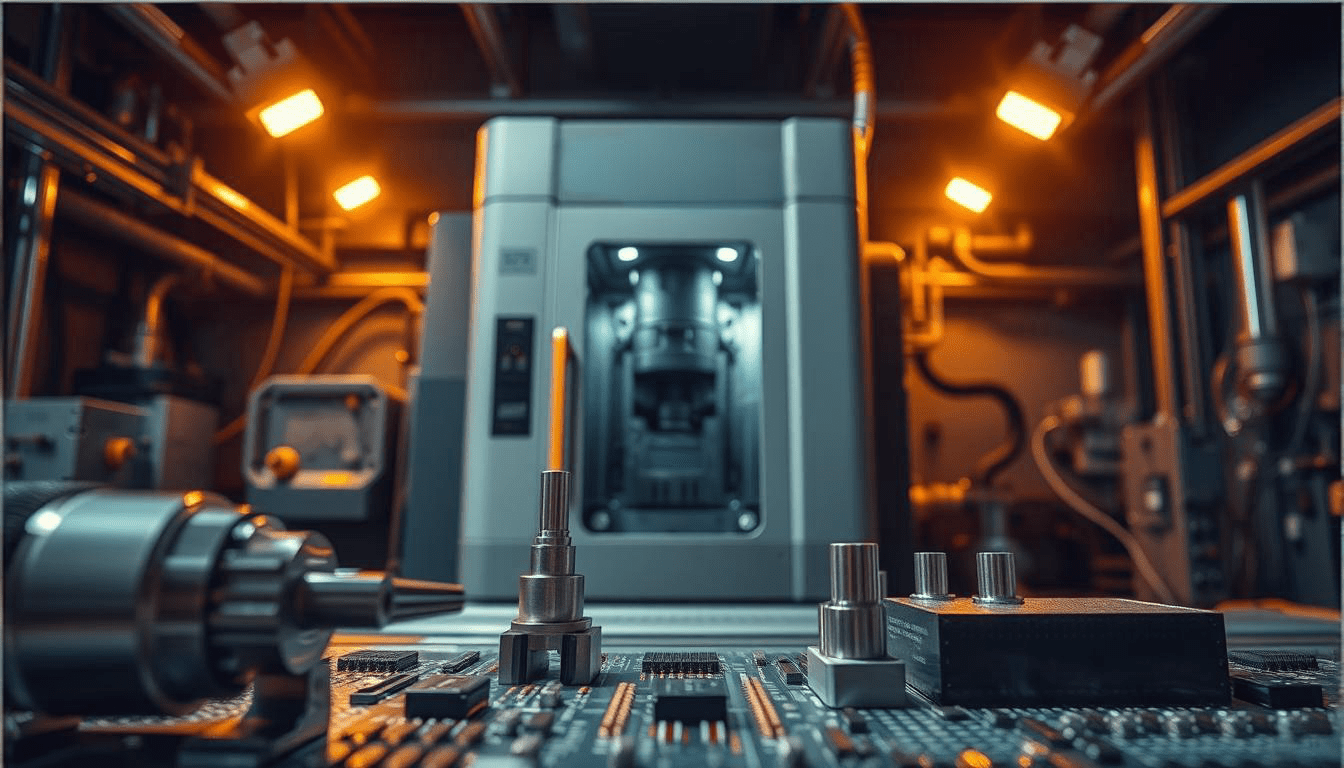

EDM is a precise machining method used to remove material from a workpiece through controlled electrical discharges. This process is particularly useful for creating complex shapes and geometries in hard materials.

The EDM Process and How It Works

The EDM process involves the generation of electrical discharges between an electrode and a workpiece, submerged in a dielectric fluid. These discharges erode the workpiece, allowing for precise material removal. The electrode, typically made of copper or graphite, is carefully controlled to achieve the desired shape.

Key Components of EDM Systems

EDM systems consist of several critical components that work together to achieve precise machining. These include a machine tool with a work table, an electrode, a dielectric delivery system, a power supply unit, and a control system. The dielectric fluid, usually oil or deionized water, plays a crucial role in insulating until breakdown voltage is reached, cooling the workpiece and electrode, and flushing away eroded particles.

Understanding these components is essential for optimizing EDM performance and achieving high-quality results. The power supply unit generates and regulates electrical pulses, while the control system manages operational parameters for different materials and geometries.

Copper Alloy EDM Electrodes: An Overview

Copper alloy EDM electrodes have revolutionized the manufacturing industry with their precision and durability. These electrodes are essential tools in Electrical Discharge Machining (EDM), a process used to machine complex and intricate parts.

What Makes Copper Alloys Ideal for EDM

Copper alloys are particularly well-suited for EDM due to their excellent electrical and thermal conductivity. This property allows for efficient machining and helps maintain the electrode’s integrity during the EDM process. The durability of copper alloys ensures long-lasting performance, making them a cost-effective choice for both high-volume production and custom machining applications.

Common Applications in Modern Manufacturing

Copper alloy EDM electrodes are used across various high-tech industries that require complex and accurate components. You can find these electrodes in use in the aerospace industry for producing turbine components and intricate structural elements. The automotive sector relies on them for creating injection mold cavities and precision engine components. Additionally, the electronics industry utilizes copper alloy EDM electrodes for manufacturing semiconductor components and microelectronic parts where precision is paramount.

Other significant applications include medical device manufacturing, tool and die making, and the production of luxury items like jewelry and watches, where intricate details and superior surface finish are critical.

Types of Copper Alloy EDM Electrodes

Copper alloy EDM electrodes are not one-size-fits-all; they come in different varieties. You can choose from several types, each with its unique characteristics and applications.

Pure Copper Electrodes

Pure copper electrodes offer excellent electrical conductivity, making them efficient for EDM operations. They are suitable for a wide range of applications.

Brass EDM Electrodes

Brass EDM electrodes are another popular choice, known for their good machinability and reasonable electrical conductivity. They are often used in specific EDM applications.

Tellurium Copper Electrodes

Tellurium copper electrodes contain about 0.5% tellurium, enhancing machinability while maintaining excellent electrical conductivity. They are ideal for complex shapes and fine details.

- Improved machinability due to tellurium addition.

- Maintains approximately 95% of pure copper’s electrical conductivity.

- Suitable for both roughing and finishing operations.

Copper Tungsten EDM Electrodes

For applications requiring extreme precision and minimal wear, copper tungsten EDM electrodes are the preferred choice. These electrodes offer high wear resistance and efficient debris removal, maintaining consistent performance in high-volume production environments.

Properties and Performance Characteristics

Copper tungsten EDM electrodes boast exceptional properties, including high wear resistance and thermal stability. This ensures precision in micro-drilling and fine-detail machining without distortion, making them ideal for demanding applications.

Specialized Applications

Copper tungsten EDM electrodes excel in various specialized applications, including micro-machining, producing high-precision injection mold components, and creating intricate passages in aerospace components. They’re also valuable in semiconductor manufacturing and medical device production, where precision and surface quality are critical.

- Micro-machining applications creating tiny features below 0.1mm.

- Producing high-precision injection mold components with complex geometries.

- Aerospace industry applications for creating cooling holes and intricate passages.

- Semiconductor and electronics manufacturing for microscopic features.

- Medical device manufacturing for surgical instruments and implantable devices.

Advantages of Copper Alloy EDM Electrodes

Copper alloy EDM electrodes offer numerous benefits in electrical discharge machining. You can expect improved performance and efficiency in your EDM operations.

Superior Electrical and Thermal Conductivity

Copper alloy EDM electrodes provide excellent electrical and thermal conductivity, enhancing the efficiency of the EDM process. This results in faster machining times and reduced energy consumption.

Precision and Surface Finish Capabilities

These electrodes enable you to achieve high precision and excellent surface finishes. The predictability of their wear characteristics allows for accurate compensation during electrode design, ensuring precise final dimensions.

Durability and Wear Resistance

Copper alloy EDM electrodes are known for their durability and wear resistance. Different copper alloys offer varying levels of wear resistance, with copper tungsten composites providing exceptional durability. Their resistance to thermal deformation and oxidation ensures consistent performance and extended tool life.

Copper Alloy vs. Graphite Electrodes: Making the Right Choice

The choice between copper alloy and graphite electrodes can significantly impact the efficiency and quality of your EDM operations. Understanding the differences between these two materials is crucial for achieving optimal results.

Performance Comparison

Copper alloy electrodes offer superior electrical and thermal conductivity, making them ideal for complex geometries and fine details. Graphite electrodes, on the other hand, are more resistant to wear and tear, and are often preferred for machining steel and iron.

Cost Considerations

The cost of copper alloy and graphite electrodes varies significantly. Copper alloy electrodes are generally more expensive, but they offer longer lifespan and better surface finish. Graphite electrodes are cheaper upfront but may require more frequent replacement.

Application-Specific Selection Criteria

When choosing between copper alloy and graphite electrodes, consider factors such as workpiece material, detail requirements, electrode size, and surface finish requirements. Your specific application needs will dictate the most suitable electrode material.

Choosing the Right Copper Alloy Electrode for Your EDM Machine

To achieve the best results with your EDM machine, choosing the right copper alloy electrode is essential. Consider your EDM machine’s specifications, workpiece material, and production requirements. We offer expert customer CNC machining service to help you manufacture the ideal electrode.