CNC Laser Cutting Services for Your Needs

- IATF 16949 (Automotive)

- AS9100 Rev D (Aerospace)

Start your project now

ISO 9001: 2015 Certified Processes

In-Process Inspection with CMM (Coordinate Measuring Machine)

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

No Minimum Order Quantities

High-Speed Sheet Metal Laser Cutting

Technical Advantages

Narrow Kerf

0.1-0.3mm width for material conservation

Non-Mechanical Force

Zero tool wear for delicate parts

Smart Automation

Integrated vision systems for error-proofing

CNC Laser Cutting Technical Specs

| Specs | Tolerance |

| Fiber Laser Power | 2kW-12kW |

| Cutting Thickness | 0.5-25mm (stainless steel) |

| Positioning accuracy | ±0.03mm (ISO 2768-Fine) |

| Max Sheet Size | 1500x3000mm |

| Tolerance | ±0.1mm |

| Speed (mm/min) | 20,000 (thin sheets) |

| Max Cutting Speed | 40m/min (1mm SS304) |

| Minimum Hole Diameter | Ø0.8mm (stainless steel) |

CNC Laser Cutting Materials

Steel

Different types of steel, such as carbon steel and alloy steel, have varying levels of hardness and wear-resistance.

Properties:

- Good strength and toughnes

- Tool steels known for high hardness and ability to retain shape under high-stress conditions

Applications:

- Automotive: car body parts, engine components, chassis parts

- Construction: building frames, bridges, structural elements

- Machinery: gears, shafts, machine tool parts

Aluminum

Common grades include 6061, 7075, and 2024. They are favored for their ease of machining but require proper cleaning and protection post-processing due to oxidation.

Properties:

- Lightweight

- Easy to machine

- Relatively high thermal conductivity

- Corrosion resistance

Applications:

- Aerospace: aircraft frames, wings, engine parts

- Electronics: heat sinks, enclosures

- Transportation: bicycle frames, boat hulls, some automotive parts

Copper

Copper alloys, like brass and bronze, combine the conductivity of copper with improved mechanical properties.

Properties:

- Excellent electrical and thermal conductivity

- Strength and corrosion resistance

Applications:

- Electronics: wires, cables, electrical connectors

- Heat exchange industry: heat exchangers, radiators

- Decorative arts: sculptures, jewelry

Acrylic (PMMA)

Properties:

- High transparency

- Good optical clarity

- Excellent weather resistance

- Relatively easy to machine.

Applications:

- Signage industry: display signs, lightboxes

- Furniture industry: decorative elements, tabletops

- Lighting industry: diffusers, lenses

Polycarbonate (PC)

Properties:

- High impact resistance

- Good heat resistanc

- Transparency and Lightweight

- Good electrical insulation properties

Applications:

- Automotive: headlight lenses, dashboards, interior trim

- Electronics: protective covers, housings

- Construction: skylights, safety glazing

Carbon Fiber Reinforced Polymer (CFRP)

Engineering plastics (e.g., ABS, POM, PC, PMMA) offer a balance of lightweight, cost-effectiveness, and ease of machining, although they may lack the heat resistance and strength of metals.

Properties:

- Extremely high strength-to-weight ratio

- Can be tailored to have specific mechanical properties

- High strength

- Low weight

Applications:

- Aerospace: aircraft wings, fuselages, other structural components

- Automotive: body panels, interior parts, suspension components

- Sports equipment: tennis rackets, golf clubs, bicycle frames

Glass Fiber Reinforced Polymer (GFRP)

Engineering plastics (e.g., ABS, POM, PC, PMMA) offer a balance of lightweight, cost-effectiveness, and ease of machining, although they may lack the heat resistance and strength of metals.

Properties:

- Extremely high strength-to-weight ratio

- Can be tailored to have specific mechanical properties

- More cost-effective

- Good corrosion resistance

Applications:

- Aerospace: aircraft wings, fuselages, other structural components

- Automotive: body panels, interior parts, suspension components

- Sports equipment: tennis rackets, golf clubs, bicycle frames

CNC Laser Cutting Surface Finishing

Powder Coating

Durable, corrosion-resistant finish with customizable colors/textures.

Anodizing

Enhances corrosion resistance, improves surface hardness, and offers aesthetic color options.

Passivation

Removes free iron contaminants and enhances stainless steel’s corrosion resistance.

Electroplating

Deposits a thin layer of metal (such as nickel, chrome, or zinc) on the surface of the drilled part.

Why Fecision for CNC Machining?

Advanced Technology

Traditional machining methods may not be able to deal with complex geometries and high-precision parts. Our multi-axis machines, ranging from 3-axis to 5-axis CNC machines, enable us to perform intricate cuts, angles, and curves.

Experienced Engineering Team

Our engineering team has decades of experience in CNC machining and design optimization. At Fecision, we specialize in Design for Manufacturability (DFM) and leverage advanced CAD/CAM software to ensure smooth integration between design and machining processes.

Versatility Across Materials

Fecision offers a broad spectrum of material options to match the needs of your specific application. Meanwhile, we provide guidance on material selection based on part performance requirements such as strength, corrosion resistance, or wear resistance, ensuring optimal results.

Quality Assurance

Our products are trusted by high-profile customers from industries across global, meeting strict and complete quality standard. Access to ISO 9001: 2015 quality certification and our manufacturing partners certified to ISO 13485: 2016, ISO 14001: 2015, and IATF 16949: 2016.

Fast Turnaround Times

Fecision recognizes the critical need for timely delivery. Most machines of our partner manufactuers run 7*24 hours with integrated process. Through streamlined workflows and optimized production processes, we ensure fast lead times while maintaining the highest standards of quality.

Commitment to Sustainability

Fecision is committed to minimizing waste and reducing our environmental impact. We prioritize sustainable practices such as material recycling, energy-efficient operations, and waste reduction in our machining processes.

Start CNC Machining

Submit Technical Files

Export your design to a CNC-compatible CAD file format. For CNC machining, we advise STEP format as it’s more standardized and can be used across platforms. It would be better if you can provide a technical drawing, especially when your design contain threads, specified tolerances or need a different finishing.

DFM & Quotation

We will provide a DFM (Design for Manufacturability) report to detect any potential design issues before production begins. Please be aware that further discussions may be needed during the process.

Start Manufacturing

Upon your confirmation to the design, our team will begin CNC machining, which will then be sent for inspection and assembly.

Delivery

Your custom-designed workpieces undergoes thorough inspection, will be carefully packaged, and delivered to you.

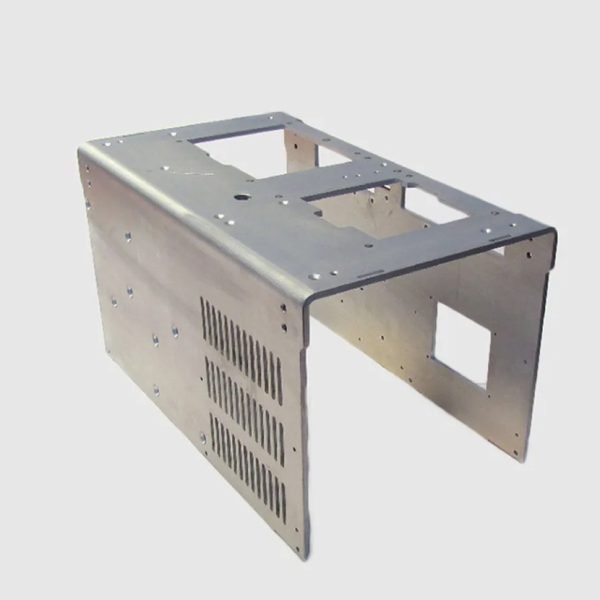

Recent Projects

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.

CNC Laser Cutting FAQs

0.05mm shim stock with ±0.01mm tolerance.

Our pulsed cutting mode reduces HAZ to <0.1mm.

Yes, using green wavelength lasers (515nm) with anti-backlash systems.

DXF, DWG, STEP, and AI files with layer standardization.

Real-time monitoring with OPC-UA protocol and SPC data tracking.