Selecting the appropriate cutting direction is essential when working on a milling project. Everything depends on how your tool moves against the material. Variations in vibration, tool wear, surface finish, and chip formation will be apparent. Because of this, knowing the difference between climb milling and conventional milling can help you increase productivity and prevent expensive errors.

Both methods are demonstrated in this guide. You’ll know how they operate, what their advantages are, and which one best suits your configuration. Let’s begin.

What Is Climb Milling?

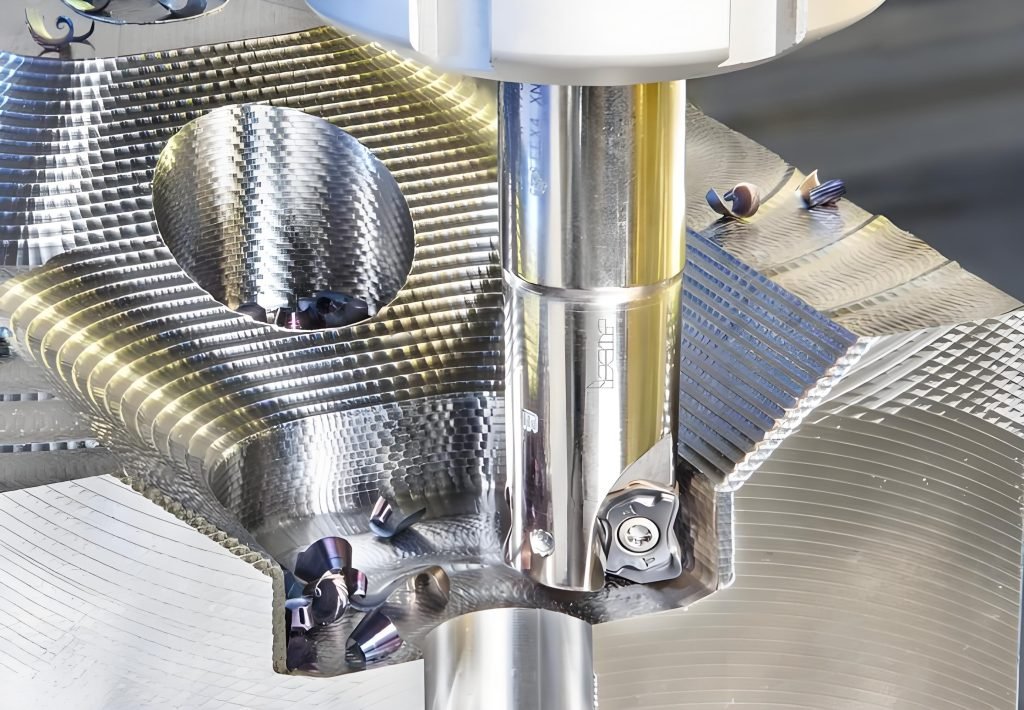

Your cutter moves in the same direction as the workpiece feed when you use climb milling. The tool seems to “pull” into the cut. Under the correct circumstances, this approach functions flawlessly. Let’s examine how cutting works and when climb milling is the best choice.

Understanding The Cutting Direction

· The cutter rotates with the feed direction when climb milling.

· As the cut continues, the chip becomes thinner after beginning thick.

Cleaner chips, less rubbing, and smoother engagement are the outcomes of this. However, any backlash may result in jumping or tool dig-in because the tool pulls the material. For reliable results, you’ll need a robust setup free from backlash.

When It Works Best

In controlled settings such as CNC machining, climb milling excels. When to use it:

- Use in CNC: with precision backlash compensation.

- Good for soft materials, such as aluminum and plastic, where you want a clean finish.

- Requires a rigid setup: If your setup is loose or worn out, avoid climb milling.

Advantages Of Climb Milling

Climb milling offers noticeable performance advantages if your machine is sturdy and free of backlash. Let’s now examine its main benefits.

Clean Finish & Chip Control

- Chips are not thrown over the cutter, but behind it. It maintains the cutting path tidy.

- With a smooth exit from the material, the tool produces less burr.

- With minimal re-cutting of chips, the surface appears more polished.

There will be less cleanup required after machining. When aesthetics and tolerance are important, this is essential.

Tool Life And Power Use

Climb milling lessens the impact of rubbing between the material and the tool. It leads to:

- Lower heat and friction, which extends tool life

- Less power draw, making the process more energy-efficient.

What Is Conventional Milling?

The cutter spins in the opposite direction of the feed movement in traditional milling. This older, more conventional approach is still in use today. Many machinists prefer it in certain setups because the conventional milling direction offers more predictable control on older machines. Let’s now examine where and how this approach works best.

Understanding The Feed Direction

- The cutter rotates opposite to the feed motion.

- Chips start thin and become thicker during the cut.

This results in tearing at the end and rubbing at the beginning. The tool may dull more quickly because it slides before cutting. On some setups, though, it offers superior control.

When It’s A Better Choice

Conventional milling is occasionally the more sensible or safe choice. When to use it:

- Working with rough surfaces or scale layers

- Using older machines or ones with observable backlash.

- Performing manual labor, where accuracy is more important than completion.

In certain situations, this approach is more predictable because it won’t “pull in” the tool like climb milling does.

Advantages Of Conventional Milling

Conventional milling has good advantages if you’re cleaning up a rough surface or your setup isn’t completely rigid. That’s what it provides.

Safe On Loose Machines

- The table and ways are pushed against by conventional milling.

- It lessens the possibility of backlash-induced tool grabbing. It is safer for worn parts or older, less rigid machines.

- With manual feeds or semi-auto cycles, you’ll feel more in control.

Great For Surface Cleanup

When scaling, rust, or coatings are being removed:

- At the beginning of the pass, the cutter skims lightly.

- It facilitates breaking the surface without gouging or jumping.

Conventional milling is the best option if your initial cut is only intended to reveal a clean layer.

Climb Vs Conventional Milling

To assist you in making the best decision, let’s compare the two approaches directly.

Key Performance Differences

| Feature | Climb Milling | Conventional Milling |

| Cutter Rotation | With feed direction | Against the feed direction |

| Chip Thickness | Thick to thin | Thin to thick |

| Finish Quality | Smoother, cleaner | Rougher, more burr |

| Tool Wear | Lower with a rigid setup | Higher due to rubbing |

| Setup Needs | Rigid, backlash-free | Flexible, works on loose setups |

| Machine Compatibility | Best on CNC or modern machines | Works on older/manual machines |

Which One Should You Use?

Your goal, material, and machine all matter. You must assess your precise configuration.

Choosing Based On Your Setup

- Machine Type: Utilize servo-driven and CNC climb milling. Use manual or worn-out mills only.

- Material Type: Soft, ductile materials work well with climb milling. Use the traditional method for surfaces that are hardened or rough.

- Skill Level: Climb is ideal if you have experience making precise cuts. Beginners frequently favor conventional because it is more forgiving.

Although there isn’t a single solution that works for everyone, you can gain more control by tailoring the approach to your machine and project.

Why Milling Direction Affects Your Outcome

Cutting direction has a direct impact on cycle time and final part quality; it’s not just about technique.

- Chip Evacuation: Chips are thrown away during climb milling, making room for the tool. They are left in the cut by convention.

- Vibration: If the machine is stable, the climb cuts more smoothly, which lowers vibration. It increases chatter on sluggish machines.

- Cycle Time: Climb milling typically completes more quickly because it produces cleaner cuts and fewer passes.

Making the correct choice lowers tool wear, increases productivity, and decreases errors. It is a minor detail that has a significant effect.

Conclusion:

Both traditional milling and climb milling have their uses in machining. Now you’ve seen how their behavior, chip formation, and direction alter your outcomes. When you have a precise and robust setup, use climb milling. For older machines, use conventional milling for control and safety. You can make better decisions and get better results if you are aware of the differences.

Fecision provides trustworthy solutions that are customized to meet your needs if you’re searching for high-precision CNC milling services. Our team consistently produces clean results, whether it’s for production runs or complex parts. To maximize your next project, contact us right now.