Have you ever wondered how manufacturers ensure the safety and functionality of their products? One crucial process involves modifying the edges of a workpiece to eliminate sharp edges. This technique, known as creating a chamfer, is vital in various engineering applications.

For instance, the diagonal corners of smartphones are designed to prevent injury, illustrating the importance of chamfering in everyday life. By understanding the purpose and techniques of chamfer creation, you can appreciate its role in enhancing product durability and aesthetics. As we explore the world of chamfering, you’ll discover its significance in deburring and improving the overall quality of engineered products.

What is Chamfering and Why is it Important?

The process of chamfering is essential in engineering, serving purposes beyond mere aesthetics. Chamfering involves creating angled or beveled edges on workpieces, typically at a 45-degree angle, though this can vary based on application requirements.

Definition and Basic Concepts of Chamfering

Chamfering is defined as the process of cutting or machining a workpiece to create a specific angle or bevel on its edge. This technique is distinct from other edge treatment processes like deburring, beveling, and rounding, each serving different purposes and applied based on the specific needs of the component or assembly.

Key Functions and Benefits of Chamfering

Chamfering yields numerous advantages, enhancing both product quality and functionality. By eliminating sharp edges and burrs, it significantly reduces the risk of injuries during handling and use.

Enhanced Safety and Handling

Parts with chamfered edges are safer to handle, as the removal of sharp edges minimizes the risk of cuts and other injuries. This is particularly crucial in environments where components are frequently handled or where safety is a paramount concern.

Improved Assembly and Installation

Chamfered edges facilitate smoother assembly and installation processes. By guiding parts together more smoothly, chamfering reduces the risk of cross-threading or improper alignment, thus improving the overall efficiency of the assembly process.

Increased Component Durability

By reducing stress concentration at edges, chamfering improves the fatigue strength of components. This prevents crack propagation and extends the fatigue life of parts under cyclic loading, thereby increasing component durability.

Overall, chamfering is a vital process in engineering that not only enhances the aesthetic appeal of components but also significantly improves their functionality, safety, and durability. By understanding the purpose and benefits of chamfering, engineers can better design and manufacture components that meet the required standards of quality and performance.

Different Types of Chamfering in Engineering

To appreciate the nuances of chamfering, it’s essential to explore the different types used in modern engineering.

C-Chamfer: The 45-Degree Standard

C-Chamfering is a prevalent technique where edges are sliced at a precise 45° angle. This method is often referred to when discussing “chamfering.” Practical directives like “C1” indicate the removal of a 1mm width from the edge, making it a straightforward and effective approach for many applications.

R-Chamfer: Creating Curved Edges

R-Chamfering involves curving corners, making it an effective method for mitigating the risk of injuries. By creating smoother edges, R-Chamfering not only enhances safety but also reduces stress concentration more effectively than angular chamfers.

Thread Chamfering: Precision Edge Treatment

Thread chamfering is a meticulous process that delicately trims corners to an imperceptible degree. It serves a unique purpose, ideal in cases where neither C-Chamfering nor R-Chamfering is required. Instead, the focus remains on eliminating burrs to facilitate thread engagement and prevent cross-threading.

Understanding the differences between these chamfering types is crucial for selecting the most appropriate method for specific engineering applications. Factors such as load requirements, assembly needs, and aesthetic considerations play a significant role in this decision-making process.

Common Chamfering Techniques

Chamfering techniques and tools play a vital role in modern manufacturing, enabling the creation of precise and consistent chamfers on various workpiece geometries. The choice of technique and tool depends on the specific application, material, and desired outcome.

There are several common chamfering methods used in engineering, including turning, milling, and back chamfering. Each method has its advantages and is suited to specific applications.

Turning Techniques for Chamfering

Turning involves using internal or external diameter tools to create precise chamfers on cylindrical parts and holes. The cutting parameters and tool positioning are critical in achieving accurate results.

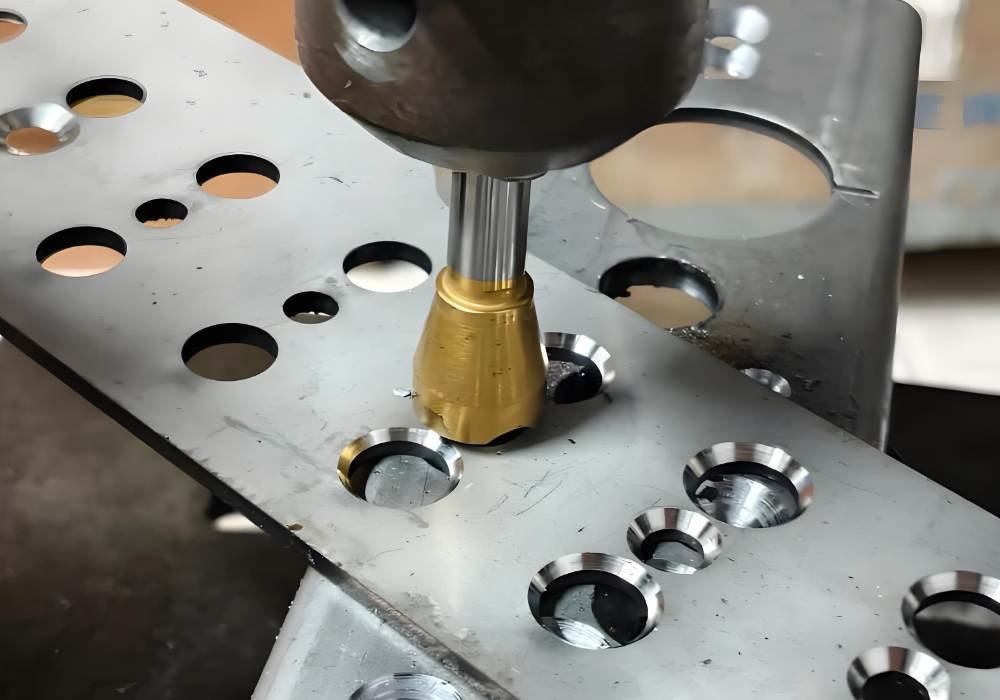

Milling Approaches for Effective Chamfering

Milling uses dedicated chamfer cutters or solid head replaceable chamfer tools to efficiently create consistent chamfers on various workpiece geometries. The choice of cutter or tool depends on the material and desired chamfer size.

Back Chamfering Processes

Back chamfering is a specialized technique used to create chamfers on the far side of holes or other features that are not directly accessible with conventional tools. This process requires specific tools and techniques.

Overcoming Challenges in Chamfering Processes

One of the primary challenges in chamfering is managing chatter, particularly when working with 45-degree C-chamfers. To minimize chatter, manufacturers can employ several strategies, including proper tool selection, enhancing tool rigidity, and optimizing rotation speed. Effective chip management is also crucial to prevent tool damage and workpiece impairment.

Chamfering applications span various industries, including automotive, aerospace, and medical device manufacturing. Each industry has its unique requirements and best practices. By understanding these needs and leveraging advanced chamfering techniques, manufacturers can improve efficiency, quality, and overall productivity. As chamfering technology continues to evolve, we can expect to see advancements in tool design, machining processes, and inspection systems.

FAQ

How do I select the right chamfering technique for my project?

To select the right chamfering technique, consider the material, part geometry, and desired finish. You should also evaluate the efficiency and cost-effectiveness of the process. For instance, back chamfering is used for parts with complex geometries or hard-to-reach areas.

What are the benefits of precision chamfering?

Precision chamfering offers several benefits, including improved part quality, reduced assembly time, and enhanced safety. By removing sharp edges, precision chamfering also reduces the risk of injury during handling and assembly.

Can chamfering be performed on various materials?

Yes, chamfering can be performed on a wide range of materials, including steel, aluminum, and titanium. The choice of tool and technique may vary depending on the material properties and desired finish.