Nylon Application in Rail Transit Industry: PA66 Injection Molding Difficulties Addressed

Project Background

The rapid evolution of the global rail transit industry has spurred an increasing demand for advanced materials, particularly nylon materials, within railway fastener systems.

High-speed railways, for instance, utilize an average of 8 tons of nylon materials per kilometer, while urban rail transit systems, including subways, light rails, and trams, consume 4-5 tons per kilometer. These critical components, such as insulators and gauge blocks, are integral to ensuring the safety, stability, and longevity of railway infrastructure.

Key Technical Challenges in Nylon Molding

The application of nylon materials in railway fastener systems presents several significant technical difficulties that require specialized expertise to address.

Shrinkage Holes in Thick-Walled Parts

High-Speed Rail

Low-Temperature Impact Cracking Resistance

-50°C, Alpine Regions

Insulation Resistance Failure After Boiling

Urban Rail – Like South China

Evolution of Technical Requirements

The development of the rail transit industry has driven changes in material performance requirements.

Excellent low-temperature impact resistance at -50°C

(no cracking after multiple heavy impacts)

No visible holes (hole diameter < 0.5 mm), resistivity ≥ 10⁸ Ω

Meet basic railway standards

Fecision's Solution

Advanced Injection Molding Expertise

Leveraging deep material science knowledge and advanced precision injection molding capabilities, we developed tailored solutions to address each technical difficulty, ensuring the production of robust and reliable nylon railway components.

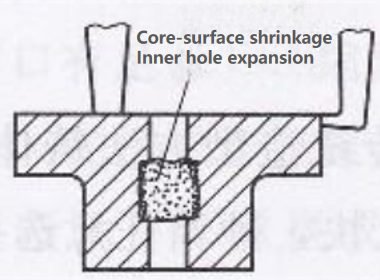

Solution for Thick-Walled Shrinkage Holes

Root Causes

▲ Insufficient thermal stability → excessive small-molecule gas generation

▲ Uneven cooling → outer solidification before inner shrinkage

Engineering Solutions

High-efficiency thermal stabilizing additives

Heat-resistant processing additives to reduce gas formation

Increased molecular chain entanglement

Extended holding pressure and holding time

Optimized cooling water channels for uniform heat dissipation

No shrinkage holes after improvement

Solution for Low-Temperature Impact Cracking Resistance

Achieve an optimal balance between toughness and low-temperature impact strength.

To enhance the low-temperature performance of nylon components, Fecision focused on material formulation and process refinement.

“Similar to the application of railway fastening systems in the cold regions of Northeast China, highly cold-resistant rail clips are needed to cope with extreme weather conditions.” our customer pointed out, “Impact cracking and flexural deformation at -50°C are the key problems.”

Optimization strategy for solving the pain points of our customer:

- Fine-tuning resin viscosity

- Selecting appropriate glass fiber type

- Balancing toughening agent type and content

Solution for Enhanced Insulation Resistance

Application: Insulated gauge blocks in humid urban rail environments

Pain Points: Volume resistivity drops significantly after boiling

Key Evaluation Metric: Volume resistivity after boiling

Optimization Approach:

- Reducing water absorption rate of nylon resin

- Optimizing glass fiber selection

- Balancing toughening agents

Performance Requirements for Raw Materials of Insulated Gauge Block

| Item | Unit | Requirements |

| Density | g/cm³ | 1.33~1.42 |

| Melting Point | °C | 255~270 |

| Tensile Strength | MPa | ≥150 |

| Flexural Strength | MPa | ≥200 |

| Unnotched Impact Strength | kJ/m² | ≥80 |

| Volume Resistivity | Ω·cm | ≥1×10¹⁴ (Dry Condition) ≥1×10¹¹ (Wet Condition) |

| Glass Fiber Content | 33%-35% |

Results and Impact

High-Reliability Railway Components

Through Fecision's expertise in nylon injection molding and problem-solving, the railway fastener system components achieved superior performance, meeting and exceeding stringent industry standards. The successful implementation of these solutions resulted in:

- Elimination of Shrinkage Defects: Consistently producing thick-walled nylon parts free from shrinkage holes, ensuring structural integrity and dimensional accuracy.

- Uncompromised Low-Temperature Performance: Delivering components capable of withstanding extreme cold without cracking or deformation, crucial for alpine railway operations.

- Robust Insulation in Humidity: Providing insulated parts that maintain high electrical resistance even after exposure to high-humidity and boiling conditions, enhancing safety and reliability in urban rail transit.

- Enhanced Product Lifespan: Contributing to the overall durability and extended service life of railway infrastructure materials.

Fecision-Your Partner for Advanced Railway Plastic Solutions

Our Manufacturing Capability

With extensive experience in nylon injection molding for railway applications, we deliver:

- Advanced material formulation support

- Precision mold design for thick-walled parts

- Process optimization for shrinkage, insulation, and impact resistance

- Consistent quality for both high-speed rail and urban transit systems

Your Success Story Could Be Next!

Want results like these for your own production?

Reach out — let’s talk about what we can achieve together.