If you’re working with polycarbonate, you might be wondering—can it be laser cut? It seems like a great option, right? A strong, impact-resistant material that’s used in everything from machine guards to eyewear.

But here’s the catch: polycarbonate doesn’t react well to laser cutting.

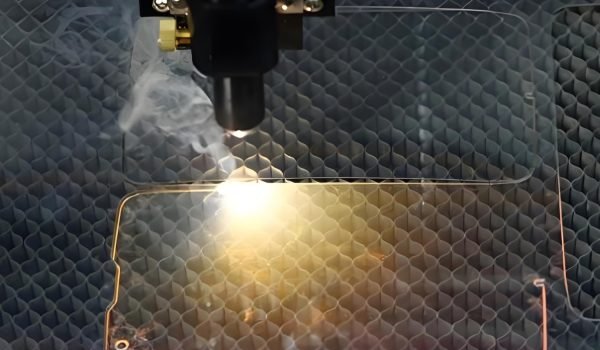

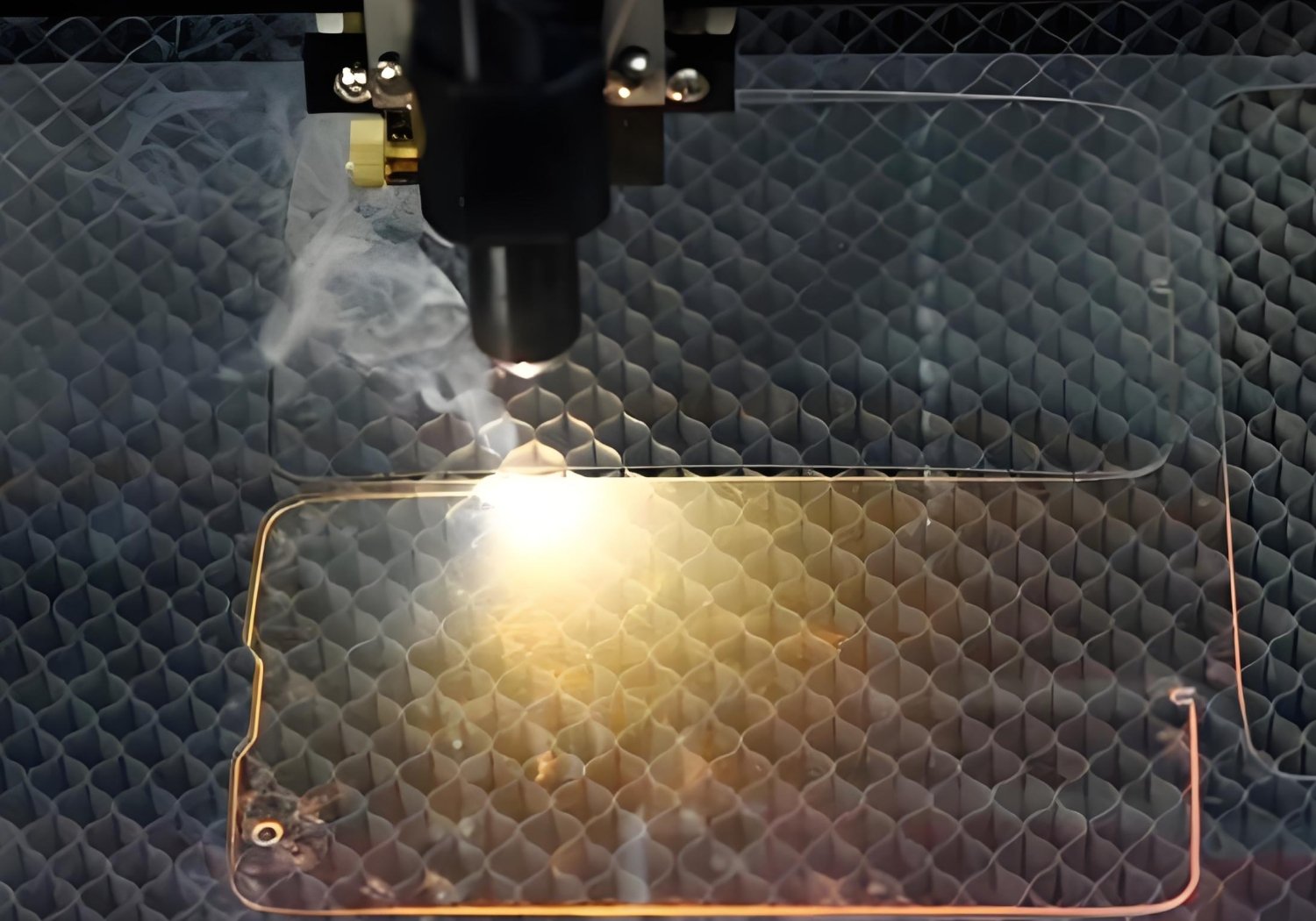

Instead of giving you clean, smooth edges like acrylic, polycarbonate tends to burn, discolor, and release toxic fumes when exposed to a laser. So, is there any way to make laser-cut polycarbonate work? Are there better alternatives? Let’s dive in and find out!

Can Someone Laser Cut Polycarbonate?

Technically, yes, you can laser-cut polycarbonate, but it’s not recommended due to poor results and safety concerns. Unlike materials such as acrylic, which vaporizes cleanly under a laser, polycarbonate tends to burn, melt, and produce toxic fumes. Why? Because polycarbonate’s reaction to heat makes it unsafe and ineffective for CNC laser cutting.

According to guidelines and experts, polycarbonate is not ideal for laser processing. Some laser machine manufacturers also confirm that polycarbonate’s reaction to high heat makes it unsuitable for laser cutting beyond very thin sheets (less than 1mm).

Why Laser Cutting Polycarbonate Is Not Recommended

While laser cutting is a popular method for working with plastics, polycarbonate does not respond well to the process. Unlike acrylic, which cuts cleanly with a laser, polycarbonate tends to burn, melt, and produce harmful fumes. Let’s take a closer look at these reasons:

1. Poor Cutting Quality

Polycarbonate doesn’t evaporate cleanly when exposed to a laser. Instead, it melts and burns, leading to:

- Charred and discolored edges (turning brown or yellow).

- Sticky, rough, and melted surfaces instead of sharp, smooth cuts.

- Micro-cracks and structural weakness make parts more likely to break.

2. Toxic Fumes and Health Hazards

One of the biggest concerns with laser cutting polycarbonate is the release of toxic gases. When burned, polycarbonate emits:

- Carbon Monoxide (CO): A poisonous gas that can be lethal in enclosed spaces.

- Bisphenol A (BPA): An endocrine disruptor that poses health risks when inhaled.

Safety Warning: Without proper industrial-grade ventilation, cutting polycarbonate can contaminate the air and create serious health risks.

3. Unpredictable Melting Behavior

Contrary to materials like acrylic, which cleanly evaporates under a laser, polycarbonate has a high heat absorption rate, causing it to melt rather than cut. This then leads to:

- Uncontrolled warping and deformation.

- Sticky residue can damage the laser cutter’s lens and mirrors.

- Inconsistent cuts, making precision nearly impossible.

How Laser Cutting Can Be Used for Polycarbonate

Even though laser-cut polycarbonate is not recommended, there are a few situations where it can work under controlled conditions. Below are some key factors that improve the chances of success:

1. Limited Success with Very Thin Polycarbonate Sheets (<1mm)

Polycarbonate less than 1mm thick may be laser-cut with some degree of success. Thinner sheets absorb less heat, and reduce the risk of excessive melting and burning.

Fiber lasers have been shown to cut thin polycarbonate more effectively than higher-powered lasers (e.g., 100W CO₂ lasers), which usually struggle. One important thing to remember is that the cutting speeds must be very high to avoid overheating, as slower speeds cause the material to warp.

2. Special Low-Power Laser Settings to Reduce Melting

Using low-power settings on a CO₂ laser can help reduce excessive heat buildup when cutting polycarbonate. Lower wattage (e.g., 10W to 40W) works better for fine cuts than higher-wattage lasers.

Increasing the laser speed and reducing dwell time prevents overheating. Moreover, using multiple light passes instead of a single deep cut can minimize melting.

Best Practice: Instead of trying to cut in one strong pass, set the laser to make multiple fast, shallow passes to help limit heat damage.

3. Using Air Assist and Cooling Techniques to Minimize Burning

Air assist is a key technique for improving laser-cutting results for polycarbonate. By using a high-pressure air assist system, you can blow away heat and debris, reducing burn marks and scorching.

Nitrogen or compressed air instead of oxygen is recommended to shield polycarbonate from catching fire. Water-cooled laser beds can also prevent material warping and melting.

Alternatives for Cutting Polycarbonate

Using alternative methods is often the best way to cut polycarbonate. Here are some methods widely used for polycarbonate sheets without the associated risk.

1. CNC Cutting or Routing (Cleaner and Safer)

CNC routers are one of the best tools for cutting polycarbonate because they offer high precision and smooth edges without heat-related damage. Here’s why:

- Uses high-speed rotating tools that cut cleanly without melting.

- Works for thin and thick sheets with excellent accuracy.

- Reduces burning and discoloration compared to laser cutting.

If this is something you’re looking for, use sharp carbide or single-flute end mills for best results. Also, moderate spindle speeds (15,000–20,000 RPM) should be applied to avoid excessive heat.

2. Score-and-Snap Method (For Thin Sheets)

For polycarbonate sheets under 3mm thick, the score-and-snap method is a simple and effective cut method without specialized tools. For this approach:

- Use a utility knife or scoring tool to make several deep passes along the cut line.

- Align the scored line with the edge of a table or a straight surface.

- Apply even pressure to snap the sheet cleanly along the line.

This method is best for thin polycarbonate sheets, DIY, and small projects.

3. Sawing Methods (Table Saw, Jigsaw, Bandsaw)

Sawing is one of the most practical cutting methods for thicker polycarbonate sheets. Different types of saws can be used based on the precision and shape of the cut needed. For instance:

- Table Saw: Best for straight, clean cuts on thick sheets. It uses fine-toothed blades (e.g., carbide-tipped blade with 80+ teeth) to prevent chipping.

- Jigsaw: This one is great for curved or irregular cuts. It utilizes a fine-tooth blade for plastic to prevent melting or cracking.

- Bandsaw: Ideal for detailed or intricate cuts on thicker polycarbonate sheets. The machine works on medium-speed settings to maintain control and accuracy.

Make the Right Choice for Cutting Polycarbonate

Laser cutting polycarbonate is not a good idea because it melts, burns, and releases harmful fumes. Use safer methods like CNC cutting, sawing, or the score-and-snap method for the best results.

If you need clean and precise cuts, CNC routers or table saws work best. For quick, simple cuts, the score-and-snap method is an easy option. In the end, remember to always use the right tools to avoid damage and achieve smooth edges.

The right cutting method saves time, improves quality, and keeps you safe. Choose wisely!