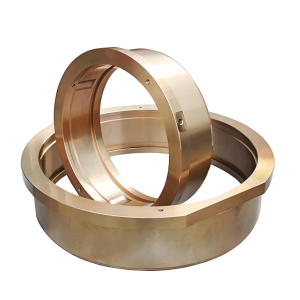

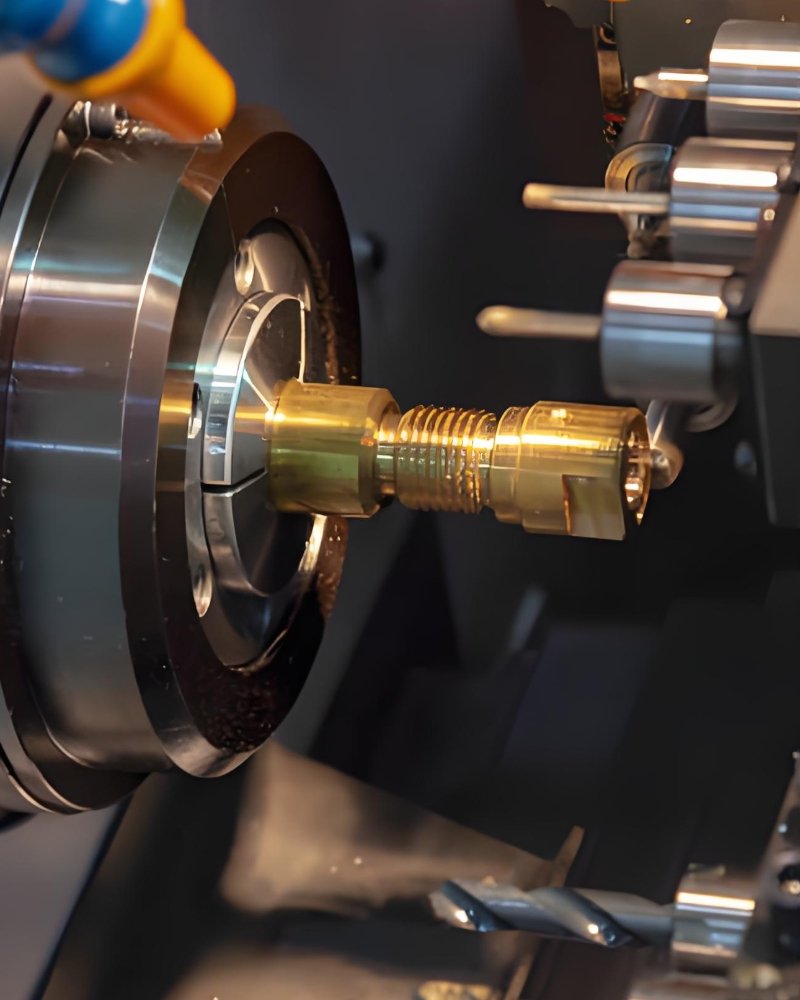

Brass Machining Services

Brass CNC machining provides precise, efficient manufacturing of components using advanced milling, turning, and drilling techniques. With excellent machinability, corrosion resistance, and aesthetic appeal, brass parts are ideal for electronics, plumbing, automotive, and decorative applications, delivering tight tolerances, smooth finishes, and reliable performance for both prototypes and production runs.

Various Options

Functionality

Cost-effectiveness

| Specification | Capabilities |

| Machine Types | 3-axis to 5-axis CNC capabilities |

| Tolerance Capabilities | ±0.001″ (0.025mm) |

| Hole Tolerances: | ±0.02 mm achievable with reaming or precision boring |

| Maximum Part Dimensions | Up to 24″ x 24″ x 12″ |

| Surface Finish | Typically Ra 1.6 – 3.2 μm (can be polished to < Ra 0.8 μm) |

| Production Volume | From prototypes to 100,000+ units |

| Lead Times | Standard 2-3 weeks, expedited options available |

Understanding Brass in CNC Machining

Brass is a versatile copper-zinc alloy that offers exceptional properties for CNC machining applications. Its unique combination of characteristics makes it an ideal choice for a wide range of components across multiple industries.

Key Properties of Brass

- Excellent Machinability: Allows for high cutting speeds, extended tool life, and precise detail work

- Corrosion Resistance: Provides durability in various environments without additional protective coatings

- Electrical Conductivity: Ideal for electrical components and connectors

- Thermal Conductivity: Excellent for heat exchange applications and thermal management

- Ductility: Enables complex shapes and thin-walled sections without cracking

- Aesthetic Appeal: Attractive golden finish suitable for decorative applications

Speak With Our Engineering Team

Discuss your specific application needs with our CNC machining specialists.

Strengths and Limitations of Brass CNC Machining

Advantages of Copper Machining

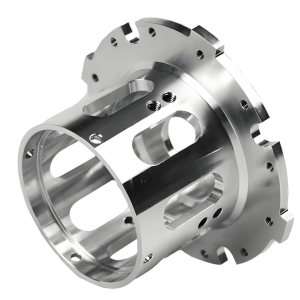

- Superior machinability allows for complex geometries and fine details

- Excellent corrosion resistance, particularly in marine environments

- Good electrical and thermal conductivity for specialized applications

- Cost-effective compared to many other metals for machining

- Attractive appearance with natural golden finish

- Self-lubricating properties extend tool life and improve surface finish

- Environmentally friendly and fully recyclable material

Limitations of Copper Machining

- Lower strength compared to steel or titanium

- Not suitable for high-temperature applications (above 200°C)

- Some grades contain lead, limiting use in certain applications

- May develop stress corrosion in specific environments

- Higher weight compared to aluminum alloys

- Susceptibility to dezincification in certain conditions

Subtypes of Brass for CNC Machining

At Fecision, we work with a variety of brass grades to meet your specific application requirements. Each grade offers unique properties that make it suitable for particular uses.

Our engineering team can help you select the optimal brass alloy for your project.

Brass C36000

(HPb63-3)

- A free-cutting leaded brass with excellent machinability (one of the most machinable brasses) due to 2.5–3.7% lead content.

- It’s high lead content improves chip breaking during machining, making it ideal for high-volume screw machining.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

310-345

124-152

140–160 (10⁸ cycles)

65-80

30-35

8.5

120 (continuous)

Brass C28000

(H59)

- A high-zinc brass (zinc ~40%, copper 57–61%) with high strength but lower ductility compared to other brasses.

- It offers good machinability and affordability, though corrosion resistance is moderate.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

345-380

140-165

120-140 (at 10⁸ cycles)

80-95

12-25

8.45

100 (continuous)

Brass C27200

(H65)

- A medium-zinc brass (zinc ~35%, copper 63–66%) with an excellent balance of strength, ductility, and formability.

- It exhibits good cold workability (e.g., drawing, bending) and weldability, with better corrosion resistance than high-zinc brasses.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

300-330

103-124

110-130 (at 10⁸ cycles)

60-75

40-50

8.5

150 (continuous)

Brass C27400

(H62)

- A widely used general-purpose brass (zinc ~38%, copper 60–63%) valued for its high strength, good machinability, and low cost.

- It performs well in both hot and cold working processes but has slightly lower ductility than C27200.

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

320-350

110-138

115-135 (at 10⁸ cycles)

70-85

30-40

8.45

120 (continuous)

Brass C26000

(H68)

- A low-zinc brass (zinc ~32%, copper 66–68%) with good corrosion resistance in atmospheric and freshwater environments but lower strength than higher-zinc brasses.

- Exceptional ductility and cold formability; ideal for deep drawing and complex shaping

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

290-320

90-110

105-125 (at 10⁸ cycles)

55-70

45-55

8.55

150 (continuous)

Surface Finishing Options for Brass CNC Machined Parts

Fecision offers a variety of surface finishing options to enhance the appearance, durability, and performance of your brass CNC machined components.

Our finishing capabilities ensure your parts meet both functional and aesthetic requirements.

Standard Finishes

- As-Machined: Natural finish directly from the CNC process

- Bead Blasting: Uniform matte finish that reduces reflectivity

- Polishing: Smooth, reflective surface for decorative applications

- Brushing: Directional satin finish with fine linear pattern

Protective Coatings

- Nickel Plating: Enhances hardness and corrosion resistance

- Chrome Plating: Provides exceptional wear resistance and appearance

- Clear Coating: Preserves natural brass appearance while preventing tarnishing

- Powder Coating: Available in various colors with excellent durability

Brass CNC Machining Application

Industries We Serve

Brass CNC machined components are utilized across numerous industries due to their unique combination of properties. At Fecision, we produce precision brass parts for a wide range of applications where reliability, conductivity, and corrosion resistance are essential.

Plumbing & Fluid Systems

Valves and valve bodies

Pipe fittings and connectors

Pump components

Sprinkler system parts

Water meter components

Electrical & Electronics

Electrical connectors

Terminal blocks

Switch components

Heat sinks

EMI/RFI shielding components

Automotive & Transportation

Transmission components

Sensor housings

Hydraulic fittings

Fuel system components

vDecorative trim elements

Marine Industry

Propeller components

Navigation equipment parts

Underwater hardware

Corrosion-resistant fittings

Boat hardware and accessories

Industrial Equipment

Gears and bearings

Pneumatic system components

Instrumentation parts

Wear plates and bushings

Safety equipment components

Architectural & Decorative

Door and cabinet hardware

Lighting fixtures

Decorative elements

Furniture components

Signage and plaques

Brass Machining FAQs

Prefer to speak with an expert directly?

Our technical team is available to discuss your brass CNC machining requirements and provide immediate assistance.

Ready to Get Started?

Contact us today to discuss your brass CNC machining requirements.

Discover how Fecision can help bring your designs to life with precision and quality.